Application of Gas Welding in Solar Power Installation Projects

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gas Welding in Solar Power: Background and Objectives

Gas welding has been a cornerstone in metal fabrication for over a century, and its application in solar power installation projects represents a significant intersection of traditional techniques and modern renewable energy technologies. The evolution of gas welding in this context can be traced back to the early days of solar power adoption, when the need for robust and cost-effective joining methods became apparent in the construction of solar panel support structures and mounting systems.

The primary objective of utilizing gas welding in solar power installations is to create strong, durable connections between metal components that can withstand the harsh environmental conditions often associated with solar array locations. These conditions may include extreme temperatures, high winds, and corrosive atmospheres, all of which place significant stress on the structural integrity of solar installations.

As the solar energy sector has grown exponentially over the past few decades, the demands placed on welding technologies have similarly increased. Gas welding, with its versatility and relatively low equipment costs, has emerged as a viable option for both large-scale solar farms and smaller residential installations. The technique's ability to join a variety of metals, including steel and aluminum, which are commonly used in solar panel frames and support structures, has contributed to its widespread adoption in the industry.

The technological trajectory of gas welding in solar power applications has been marked by continuous improvements in welding equipment, consumables, and methodologies. These advancements have aimed to enhance weld quality, increase efficiency, and reduce the environmental impact of the welding process. For instance, the development of more efficient gas mixtures and precision control systems has led to cleaner, stronger welds with less material waste.

Looking ahead, the goals for gas welding in solar power installations are multifaceted. There is a push towards further automation to improve consistency and reduce labor costs, especially in large-scale projects. Additionally, research is being conducted to develop new filler materials that can better withstand the specific stresses encountered in solar installations, such as thermal cycling and UV radiation exposure.

Another critical objective is the optimization of welding processes to minimize the carbon footprint of solar power installation. This aligns with the overarching goal of renewable energy to reduce greenhouse gas emissions. Efforts are being made to increase the energy efficiency of gas welding equipment and to explore the use of renewable gases in the welding process.

The primary objective of utilizing gas welding in solar power installations is to create strong, durable connections between metal components that can withstand the harsh environmental conditions often associated with solar array locations. These conditions may include extreme temperatures, high winds, and corrosive atmospheres, all of which place significant stress on the structural integrity of solar installations.

As the solar energy sector has grown exponentially over the past few decades, the demands placed on welding technologies have similarly increased. Gas welding, with its versatility and relatively low equipment costs, has emerged as a viable option for both large-scale solar farms and smaller residential installations. The technique's ability to join a variety of metals, including steel and aluminum, which are commonly used in solar panel frames and support structures, has contributed to its widespread adoption in the industry.

The technological trajectory of gas welding in solar power applications has been marked by continuous improvements in welding equipment, consumables, and methodologies. These advancements have aimed to enhance weld quality, increase efficiency, and reduce the environmental impact of the welding process. For instance, the development of more efficient gas mixtures and precision control systems has led to cleaner, stronger welds with less material waste.

Looking ahead, the goals for gas welding in solar power installations are multifaceted. There is a push towards further automation to improve consistency and reduce labor costs, especially in large-scale projects. Additionally, research is being conducted to develop new filler materials that can better withstand the specific stresses encountered in solar installations, such as thermal cycling and UV radiation exposure.

Another critical objective is the optimization of welding processes to minimize the carbon footprint of solar power installation. This aligns with the overarching goal of renewable energy to reduce greenhouse gas emissions. Efforts are being made to increase the energy efficiency of gas welding equipment and to explore the use of renewable gases in the welding process.

Market Analysis for Solar Power Installation

The solar power installation market has experienced significant growth in recent years, driven by increasing global demand for renewable energy sources and the declining costs of solar technology. This market segment is closely tied to the broader solar energy industry, which has seen a compound annual growth rate (CAGR) of over 20% in the past decade. The market for solar power installations encompasses both residential and commercial sectors, with utility-scale projects representing a substantial portion of the overall market value.

In terms of regional distribution, Asia-Pacific leads the market, with China and India being major contributors to the growth. North America and Europe follow closely, with the United States and Germany being key players in their respective regions. Emerging markets in Latin America and Africa are also showing promising growth potential, albeit from a smaller base.

The market dynamics are influenced by several factors, including government policies and incentives, technological advancements, and environmental concerns. Many countries have implemented favorable policies such as feed-in tariffs, tax credits, and renewable portfolio standards to promote solar energy adoption. These initiatives have significantly boosted market growth and are expected to continue driving demand in the coming years.

Technological improvements in solar panel efficiency and energy storage solutions have made solar power installations more attractive to consumers and businesses alike. The integration of smart grid technologies and the development of more efficient inverters have further enhanced the appeal of solar power systems. Additionally, the increasing focus on sustainability and corporate social responsibility has led many businesses to invest in solar installations as part of their environmental strategies.

The competitive landscape of the solar power installation market is diverse, with a mix of large multinational corporations and smaller local installers. Key players in the market include companies involved in manufacturing solar panels, inverters, and other components, as well as those specializing in system design, installation, and maintenance. The market has seen a trend towards vertical integration, with some manufacturers expanding into installation services to capture more value along the supply chain.

Looking ahead, the solar power installation market is projected to continue its growth trajectory. Factors such as the increasing electrification of transportation, the push for energy independence, and the growing awareness of climate change are expected to drive further demand for solar installations. However, challenges such as grid integration, intermittency issues, and the need for more efficient energy storage solutions will need to be addressed to fully realize the potential of solar power in the global energy mix.

In terms of regional distribution, Asia-Pacific leads the market, with China and India being major contributors to the growth. North America and Europe follow closely, with the United States and Germany being key players in their respective regions. Emerging markets in Latin America and Africa are also showing promising growth potential, albeit from a smaller base.

The market dynamics are influenced by several factors, including government policies and incentives, technological advancements, and environmental concerns. Many countries have implemented favorable policies such as feed-in tariffs, tax credits, and renewable portfolio standards to promote solar energy adoption. These initiatives have significantly boosted market growth and are expected to continue driving demand in the coming years.

Technological improvements in solar panel efficiency and energy storage solutions have made solar power installations more attractive to consumers and businesses alike. The integration of smart grid technologies and the development of more efficient inverters have further enhanced the appeal of solar power systems. Additionally, the increasing focus on sustainability and corporate social responsibility has led many businesses to invest in solar installations as part of their environmental strategies.

The competitive landscape of the solar power installation market is diverse, with a mix of large multinational corporations and smaller local installers. Key players in the market include companies involved in manufacturing solar panels, inverters, and other components, as well as those specializing in system design, installation, and maintenance. The market has seen a trend towards vertical integration, with some manufacturers expanding into installation services to capture more value along the supply chain.

Looking ahead, the solar power installation market is projected to continue its growth trajectory. Factors such as the increasing electrification of transportation, the push for energy independence, and the growing awareness of climate change are expected to drive further demand for solar installations. However, challenges such as grid integration, intermittency issues, and the need for more efficient energy storage solutions will need to be addressed to fully realize the potential of solar power in the global energy mix.

Current Challenges in Solar Panel Welding

Gas welding in solar power installation projects faces several significant challenges that impact efficiency, quality, and overall project success. One of the primary issues is the precision required for welding solar panel frames and support structures. The thin materials used in solar panels demand exceptional accuracy to prevent warping or damage during the welding process. This level of precision is often difficult to achieve consistently with gas welding techniques, especially in outdoor installation environments where conditions can be variable.

Another challenge is the potential for contamination during the welding process. Solar panels are highly sensitive components, and any impurities introduced during welding can significantly affect their performance. Gas welding, which involves the use of filler materials and flux, carries a higher risk of introducing contaminants compared to other welding methods. This necessitates stringent quality control measures and may increase production time and costs.

The portability of gas welding equipment, while generally considered an advantage, can also present challenges in large-scale solar installations. Transporting and managing gas cylinders across vast solar fields can be logistically complex and potentially hazardous. Additionally, the open flame used in gas welding poses fire risks, especially in dry environments where many solar installations are located.

Temperature control is another critical issue in solar panel welding. The heat-sensitive nature of photovoltaic cells requires precise temperature management during the welding process. Gas welding's heat input can be more difficult to control compared to other welding methods, potentially leading to thermal stress and damage to the solar cells or surrounding materials.

Productivity and efficiency concerns also arise with gas welding in solar installations. The process is generally slower compared to more modern welding techniques, which can impact project timelines and labor costs. This becomes particularly significant in large-scale solar farms where thousands of welds may be required.

Environmental considerations add another layer of complexity. The emissions from gas welding, while not as significant as some industrial processes, still contribute to the carbon footprint of solar installations. This presents a paradox where the construction of clean energy systems relies on processes that are not entirely environmentally friendly.

Lastly, the skill level required for high-quality gas welding in solar applications is considerable. The shortage of skilled welders, particularly those experienced in the specific requirements of solar panel installation, can lead to quality issues or project delays. Training and maintaining a workforce capable of meeting the exacting standards of solar panel welding remains an ongoing challenge in the industry.

Another challenge is the potential for contamination during the welding process. Solar panels are highly sensitive components, and any impurities introduced during welding can significantly affect their performance. Gas welding, which involves the use of filler materials and flux, carries a higher risk of introducing contaminants compared to other welding methods. This necessitates stringent quality control measures and may increase production time and costs.

The portability of gas welding equipment, while generally considered an advantage, can also present challenges in large-scale solar installations. Transporting and managing gas cylinders across vast solar fields can be logistically complex and potentially hazardous. Additionally, the open flame used in gas welding poses fire risks, especially in dry environments where many solar installations are located.

Temperature control is another critical issue in solar panel welding. The heat-sensitive nature of photovoltaic cells requires precise temperature management during the welding process. Gas welding's heat input can be more difficult to control compared to other welding methods, potentially leading to thermal stress and damage to the solar cells or surrounding materials.

Productivity and efficiency concerns also arise with gas welding in solar installations. The process is generally slower compared to more modern welding techniques, which can impact project timelines and labor costs. This becomes particularly significant in large-scale solar farms where thousands of welds may be required.

Environmental considerations add another layer of complexity. The emissions from gas welding, while not as significant as some industrial processes, still contribute to the carbon footprint of solar installations. This presents a paradox where the construction of clean energy systems relies on processes that are not entirely environmentally friendly.

Lastly, the skill level required for high-quality gas welding in solar applications is considerable. The shortage of skilled welders, particularly those experienced in the specific requirements of solar panel installation, can lead to quality issues or project delays. Training and maintaining a workforce capable of meeting the exacting standards of solar panel welding remains an ongoing challenge in the industry.

Gas Welding Solutions for Solar Panel Installation

01 Gas welding equipment and techniques

This category covers various aspects of gas welding equipment and techniques, including torch designs, gas mixing systems, and welding process improvements. Innovations in this area aim to enhance welding efficiency, precision, and safety for operators.- Welding equipment and techniques: Gas welding involves specialized equipment and techniques for joining metals using heat generated by combustion of gases. This includes torches, regulators, and various gas mixtures to achieve optimal welding results for different materials and applications.

- Gas mixture control and optimization: Precise control and optimization of gas mixtures are crucial in gas welding. This involves regulating the flow and composition of fuel gases and oxygen to achieve the desired flame characteristics and temperature for specific welding tasks.

- Safety measures and equipment: Gas welding requires stringent safety measures due to the use of flammable gases and high temperatures. This includes specialized safety equipment, proper ventilation, and protocols to prevent accidents and ensure worker protection during welding operations.

- Automated gas welding systems: Development of automated gas welding systems to improve efficiency, consistency, and precision in welding processes. These systems may incorporate robotics, sensors, and computer control to optimize welding parameters and reduce human error.

- Specialized gas welding applications: Gas welding techniques adapted for specific applications or materials, such as thin sheet metal, pipes, or exotic alloys. This includes modifications to equipment, gas mixtures, or welding techniques to address unique challenges in various industries.

02 Welding gas composition and control

This point focuses on the development of specialized gas mixtures and control systems for gas welding applications. It includes innovations in gas composition, flow regulation, and pressure control to optimize welding performance and quality across different materials and conditions.Expand Specific Solutions03 Automated and robotic gas welding systems

This category encompasses advancements in automated and robotic gas welding systems. It includes innovations in control algorithms, sensor technologies, and integration with other manufacturing processes to improve welding precision, consistency, and productivity in industrial applications.Expand Specific Solutions04 Safety features and protective equipment

This point addresses safety innovations in gas welding, including improved personal protective equipment, fume extraction systems, and safety interlocks. These advancements aim to reduce the risks associated with gas welding operations and enhance worker protection.Expand Specific Solutions05 Specialized gas welding applications

This category covers innovations in gas welding techniques for specific applications or materials. It includes advancements in welding thin materials, joining dissimilar metals, and gas welding in challenging environments or industries with unique requirements.Expand Specific Solutions

Key Players in Solar Power and Welding Equipment

The gas welding market in solar power installation projects is in a growth phase, driven by increasing adoption of solar energy worldwide. The market size is expanding, with a projected CAGR of 6-8% over the next five years. Technologically, gas welding is mature but continues to evolve with innovations in equipment and processes. Key players like Illinois Tool Works, Lincoln Global, and Panasonic are investing in R&D to improve efficiency and reduce costs. Emerging companies such as Zhejiang Aiko Solar and Guangdong Aiko Solar are also making strides in developing specialized welding solutions for solar applications, intensifying competition in this niche market.

Illinois Tool Works Inc.

Technical Solution: Illinois Tool Works (ITW) has developed advanced gas welding solutions specifically tailored for solar power installation projects. Their technology focuses on precision and efficiency, utilizing a proprietary mixture of gases that optimizes heat distribution and minimizes distortion in solar panel frames and mounting structures. ITW's gas welding equipment incorporates digital controls for precise flame adjustment, ensuring consistent weld quality across various materials used in solar installations[1]. The company has also introduced portable gas welding units designed for on-site use, featuring lightweight components and quick-connect fittings to enhance mobility and reduce setup time in field installations[3].

Strengths: Precision welding for delicate solar components, portable solutions for field work, and digital control systems for consistency. Weaknesses: Potential higher initial equipment costs and the need for specialized training for operators.

Lincoln Global, Inc.

Technical Solution: Lincoln Global has pioneered a gas welding system specifically designed for solar power installation projects, focusing on versatility and durability. Their technology incorporates a multi-gas compatibility feature, allowing welders to switch between different gas mixtures to optimize performance for various materials used in solar panel frames and support structures. Lincoln's gas welding torches are equipped with advanced cooling systems, enabling longer operational periods without overheating, which is crucial for large-scale solar installations[2]. The company has also developed specialized filler materials that enhance the corrosion resistance of welds exposed to harsh outdoor environments, a critical factor in ensuring the longevity of solar power installations[4].

Strengths: Multi-gas compatibility for versatile applications, advanced cooling systems for extended use, and specialized filler materials for enhanced durability. Weaknesses: Potentially higher gas consumption compared to other welding methods and the need for careful gas management in remote installation sites.

Innovations in Gas Welding for Solar Applications

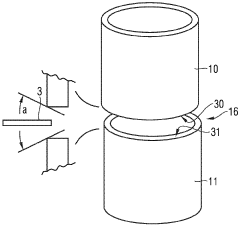

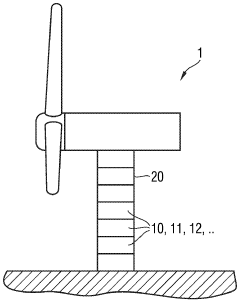

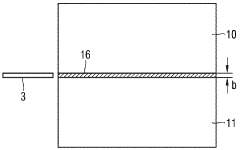

Method for connecting a plurality of cylindrical elements of the tower of a wind power plant

PatentWO2012041677A1

Innovation

- The method employs a mechanized metal shielding gas (MSG) narrow-gap welding process with a circumferential weld seam and automatic electrode repositioning, allowing for faster, high-quality connections with a horizontal weld seam, enabling the connection of vertically stacked tubular elements on-site.

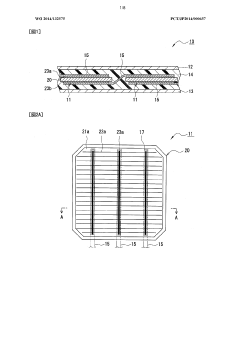

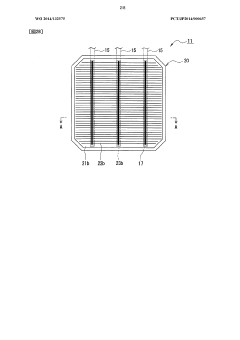

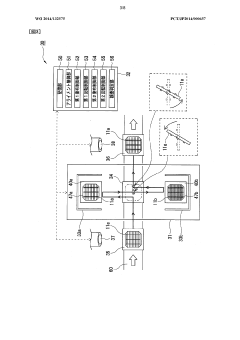

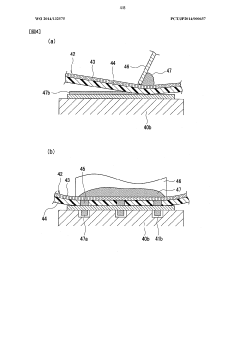

Solar cell module production method, and solar cell module adhesive application system

PatentWO2014132575A1

Innovation

- A method using a resin adhesive applied to both surfaces of solar cells, with a coating system that includes a coating device, reversing device, and control device to apply adhesive on the light-receiving and back surfaces, ensuring proper alignment and inspection to optimize adhesive application and prevent fillet formation.

Environmental Impact of Gas Welding in Solar Projects

Gas welding, while an effective technique in solar power installation projects, carries significant environmental implications that warrant careful consideration. The process involves the combustion of gases, typically acetylene or propane, which releases various pollutants into the atmosphere. These emissions include carbon dioxide, carbon monoxide, nitrogen oxides, and particulate matter, all of which contribute to air pollution and climate change.

The release of greenhouse gases during gas welding operations directly impacts local air quality and contributes to the global carbon footprint. This is particularly concerning in the context of solar power projects, which aim to reduce reliance on fossil fuels and mitigate environmental damage. The irony of using a carbon-intensive process to install clean energy systems is not lost on environmental advocates and industry experts.

Furthermore, the production and transportation of welding gases also have environmental consequences. The extraction, processing, and distribution of these gases involve energy-intensive processes that further add to the overall environmental impact of gas welding in solar projects. This upstream impact is often overlooked but is crucial when assessing the full lifecycle environmental footprint of solar installations.

Noise pollution is another environmental concern associated with gas welding in solar projects. The high-decibel levels produced during welding operations can disrupt local ecosystems, particularly in rural or previously undeveloped areas where many large-scale solar installations are located. This noise can affect wildlife behavior, breeding patterns, and overall biodiversity in the surrounding habitat.

Waste generation is an additional environmental issue to consider. Gas welding produces slag, a byproduct that requires proper disposal. Improper management of welding waste can lead to soil contamination and potential groundwater pollution, especially if hazardous materials are present in the welding consumables.

Despite these environmental challenges, it's important to note that the long-term benefits of solar power installations generally outweigh the short-term environmental costs of construction methods like gas welding. However, the industry is increasingly exploring alternative welding techniques and more environmentally friendly installation methods to minimize the ecological impact of solar project construction.

The release of greenhouse gases during gas welding operations directly impacts local air quality and contributes to the global carbon footprint. This is particularly concerning in the context of solar power projects, which aim to reduce reliance on fossil fuels and mitigate environmental damage. The irony of using a carbon-intensive process to install clean energy systems is not lost on environmental advocates and industry experts.

Furthermore, the production and transportation of welding gases also have environmental consequences. The extraction, processing, and distribution of these gases involve energy-intensive processes that further add to the overall environmental impact of gas welding in solar projects. This upstream impact is often overlooked but is crucial when assessing the full lifecycle environmental footprint of solar installations.

Noise pollution is another environmental concern associated with gas welding in solar projects. The high-decibel levels produced during welding operations can disrupt local ecosystems, particularly in rural or previously undeveloped areas where many large-scale solar installations are located. This noise can affect wildlife behavior, breeding patterns, and overall biodiversity in the surrounding habitat.

Waste generation is an additional environmental issue to consider. Gas welding produces slag, a byproduct that requires proper disposal. Improper management of welding waste can lead to soil contamination and potential groundwater pollution, especially if hazardous materials are present in the welding consumables.

Despite these environmental challenges, it's important to note that the long-term benefits of solar power installations generally outweigh the short-term environmental costs of construction methods like gas welding. However, the industry is increasingly exploring alternative welding techniques and more environmentally friendly installation methods to minimize the ecological impact of solar project construction.

Safety Regulations for Gas Welding in Solar Installations

Safety regulations for gas welding in solar installations are crucial to ensure the protection of workers, equipment, and the environment. These regulations typically cover various aspects of the welding process, including equipment handling, personal protective gear, and workplace safety measures.

One of the primary safety concerns in gas welding for solar installations is the proper storage and handling of compressed gas cylinders. Regulations often mandate that cylinders must be secured in an upright position, stored in well-ventilated areas, and kept away from heat sources. Additionally, specific guidelines are in place for transporting cylinders to and from job sites, emphasizing the need for proper restraints and protective valve caps.

Personal protective equipment (PPE) is another critical component of safety regulations. Workers engaged in gas welding activities are required to wear appropriate eye protection, such as welding goggles or face shields with the correct shade of filter lens. Heat-resistant gloves, flame-resistant clothing, and safety boots are also mandatory to protect against burns and other potential injuries.

Workplace safety measures are equally important in gas welding regulations. These include maintaining a clutter-free work area, ensuring proper ventilation to disperse welding fumes, and implementing fire prevention strategies. Fire extinguishers must be readily available, and welding operations should be conducted at a safe distance from flammable materials.

Regulations also address the importance of proper training and certification for workers involved in gas welding. This includes knowledge of equipment operation, understanding of potential hazards, and familiarity with emergency procedures. Regular safety briefings and updates on best practices are often required to maintain a high level of safety awareness among workers.

Specific to solar power installations, safety regulations may include additional considerations related to working at heights, as many solar panels are installed on rooftops. This can involve the use of fall protection systems, proper scaffolding, and guidelines for safely maneuvering on sloped surfaces.

Environmental safety is another aspect covered by regulations, particularly in the context of solar installations. This includes proper disposal of welding waste, minimizing emissions, and protecting surrounding vegetation or wildlife habitats from potential harm caused by welding activities.

Regular equipment inspection and maintenance are typically mandated by safety regulations to ensure that all welding tools and accessories are in good working condition. This includes checking for gas leaks, verifying the integrity of hoses and connections, and ensuring that safety devices such as flashback arrestors are properly installed and functioning.

One of the primary safety concerns in gas welding for solar installations is the proper storage and handling of compressed gas cylinders. Regulations often mandate that cylinders must be secured in an upright position, stored in well-ventilated areas, and kept away from heat sources. Additionally, specific guidelines are in place for transporting cylinders to and from job sites, emphasizing the need for proper restraints and protective valve caps.

Personal protective equipment (PPE) is another critical component of safety regulations. Workers engaged in gas welding activities are required to wear appropriate eye protection, such as welding goggles or face shields with the correct shade of filter lens. Heat-resistant gloves, flame-resistant clothing, and safety boots are also mandatory to protect against burns and other potential injuries.

Workplace safety measures are equally important in gas welding regulations. These include maintaining a clutter-free work area, ensuring proper ventilation to disperse welding fumes, and implementing fire prevention strategies. Fire extinguishers must be readily available, and welding operations should be conducted at a safe distance from flammable materials.

Regulations also address the importance of proper training and certification for workers involved in gas welding. This includes knowledge of equipment operation, understanding of potential hazards, and familiarity with emergency procedures. Regular safety briefings and updates on best practices are often required to maintain a high level of safety awareness among workers.

Specific to solar power installations, safety regulations may include additional considerations related to working at heights, as many solar panels are installed on rooftops. This can involve the use of fall protection systems, proper scaffolding, and guidelines for safely maneuvering on sloped surfaces.

Environmental safety is another aspect covered by regulations, particularly in the context of solar installations. This includes proper disposal of welding waste, minimizing emissions, and protecting surrounding vegetation or wildlife habitats from potential harm caused by welding activities.

Regular equipment inspection and maintenance are typically mandated by safety regulations to ensure that all welding tools and accessories are in good working condition. This includes checking for gas leaks, verifying the integrity of hoses and connections, and ensuring that safety devices such as flashback arrestors are properly installed and functioning.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!