Atomic Force Microscopy Vs Ion Beam Milling: Application Insights

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM and IBM Technology Background and Objectives

Atomic Force Microscopy (AFM) and Ion Beam Milling (IBM) represent two pivotal technologies in the field of nanoscale material characterization and modification. Since their inception in the 1980s, these technologies have evolved significantly, transforming our capabilities in nanoscience and nanotechnology. AFM, developed by Gerd Binnig, Calvin Quate, and Christoph Gerber in 1986, emerged as a revolutionary imaging technique capable of achieving atomic-level resolution by measuring forces between a sharp probe and sample surface. Concurrently, IBM technology evolved from early focused ion beam systems to sophisticated nanofabrication tools.

The technological trajectory of these complementary techniques has been marked by continuous refinement in precision, resolution, and application versatility. AFM has progressed from basic contact mode operations to advanced multimodal capabilities including tapping mode, non-contact mode, and specialized techniques like Kelvin probe force microscopy and piezoresponse force microscopy. Similarly, IBM has advanced from rudimentary material removal processes to highly controlled nanofabrication with sub-10 nm precision.

Current market trends indicate a growing convergence between characterization and modification capabilities, with integrated systems that combine AFM's imaging prowess with IBM's material manipulation abilities. This integration represents a significant technological frontier, enabling in-situ observation of nanoscale modifications and expanding application possibilities across semiconductor, materials science, and biological research domains.

The primary technical objective of this investigation is to comprehensively compare AFM and IBM technologies, evaluating their respective strengths, limitations, and complementary aspects across various application domains. Specifically, we aim to identify optimal deployment scenarios for each technology based on specific industry requirements, material characteristics, and desired outcomes.

Secondary objectives include mapping the technological evolution pathways for both AFM and IBM, identifying key innovation milestones, and forecasting future development trajectories. This includes assessing emerging hybrid approaches that leverage the strengths of both technologies while mitigating their individual limitations.

Additionally, this analysis seeks to quantify performance metrics including resolution limits, throughput capabilities, operational constraints, and cost-effectiveness across different application scenarios. By establishing these benchmarks, we can provide actionable insights for technology selection and implementation strategies across research and industrial contexts.

The ultimate goal is to develop a strategic framework for technology selection and implementation that optimizes outcomes for specific applications while considering factors such as capital investment, operational expertise requirements, and long-term scalability. This framework will serve as a valuable resource for research institutions and industrial entities navigating the complex landscape of nanoscale characterization and modification technologies.

The technological trajectory of these complementary techniques has been marked by continuous refinement in precision, resolution, and application versatility. AFM has progressed from basic contact mode operations to advanced multimodal capabilities including tapping mode, non-contact mode, and specialized techniques like Kelvin probe force microscopy and piezoresponse force microscopy. Similarly, IBM has advanced from rudimentary material removal processes to highly controlled nanofabrication with sub-10 nm precision.

Current market trends indicate a growing convergence between characterization and modification capabilities, with integrated systems that combine AFM's imaging prowess with IBM's material manipulation abilities. This integration represents a significant technological frontier, enabling in-situ observation of nanoscale modifications and expanding application possibilities across semiconductor, materials science, and biological research domains.

The primary technical objective of this investigation is to comprehensively compare AFM and IBM technologies, evaluating their respective strengths, limitations, and complementary aspects across various application domains. Specifically, we aim to identify optimal deployment scenarios for each technology based on specific industry requirements, material characteristics, and desired outcomes.

Secondary objectives include mapping the technological evolution pathways for both AFM and IBM, identifying key innovation milestones, and forecasting future development trajectories. This includes assessing emerging hybrid approaches that leverage the strengths of both technologies while mitigating their individual limitations.

Additionally, this analysis seeks to quantify performance metrics including resolution limits, throughput capabilities, operational constraints, and cost-effectiveness across different application scenarios. By establishing these benchmarks, we can provide actionable insights for technology selection and implementation strategies across research and industrial contexts.

The ultimate goal is to develop a strategic framework for technology selection and implementation that optimizes outcomes for specific applications while considering factors such as capital investment, operational expertise requirements, and long-term scalability. This framework will serve as a valuable resource for research institutions and industrial entities navigating the complex landscape of nanoscale characterization and modification technologies.

Market Applications and Demand Analysis

The market for advanced microscopy and material processing technologies has witnessed significant growth in recent years, driven by increasing demands across multiple industries. Atomic Force Microscopy (AFM) and Ion Beam Milling (IBM) represent two distinct yet complementary technologies that serve critical functions in materials science, semiconductor manufacturing, and nanotechnology research.

The global microscopy market, which includes AFM technology, was valued at approximately $7.2 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2030. Within this broader market, AFM holds a substantial share due to its non-destructive imaging capabilities and atomic-level resolution. The primary demand drivers for AFM include semiconductor research and development, biological sciences, and materials characterization.

Ion Beam Milling equipment, part of the broader focused ion beam market, was valued at $1.1 billion in 2022 with projected growth rates exceeding 8% annually. The technology finds its strongest demand in semiconductor device fabrication, where precise material removal and cross-sectioning capabilities are essential for failure analysis and process development.

Geographically, North America and Asia-Pacific represent the largest markets for both technologies. Asia-Pacific, particularly countries like China, Japan, and South Korea, demonstrates the fastest growth rate due to expanding semiconductor manufacturing facilities and increased R&D investments in nanotechnology.

Application-specific demand analysis reveals distinct market segments for each technology. AFM sees highest utilization in academic and research institutions (38%), semiconductor industry (27%), life sciences (18%), and materials science (17%). IBM technology is predominantly deployed in semiconductor manufacturing (52%), followed by data storage device fabrication (21%), optical component manufacturing (15%), and research institutions (12%).

End-user surveys indicate different purchasing considerations for these technologies. AFM customers prioritize resolution capabilities, software integration, and non-destructive analysis features. In contrast, IBM customers focus on precision control, throughput rates, and compatibility with existing fabrication processes.

The competitive landscape shows increasing demand for integrated systems that combine both technologies, allowing for comprehensive sample preparation, analysis, and modification within a single workflow. This convergence trend is expected to accelerate, with market forecasts suggesting that integrated AFM-IBM systems could capture 15% of the total market share by 2028.

The global microscopy market, which includes AFM technology, was valued at approximately $7.2 billion in 2022 and is projected to grow at a CAGR of 7.8% through 2030. Within this broader market, AFM holds a substantial share due to its non-destructive imaging capabilities and atomic-level resolution. The primary demand drivers for AFM include semiconductor research and development, biological sciences, and materials characterization.

Ion Beam Milling equipment, part of the broader focused ion beam market, was valued at $1.1 billion in 2022 with projected growth rates exceeding 8% annually. The technology finds its strongest demand in semiconductor device fabrication, where precise material removal and cross-sectioning capabilities are essential for failure analysis and process development.

Geographically, North America and Asia-Pacific represent the largest markets for both technologies. Asia-Pacific, particularly countries like China, Japan, and South Korea, demonstrates the fastest growth rate due to expanding semiconductor manufacturing facilities and increased R&D investments in nanotechnology.

Application-specific demand analysis reveals distinct market segments for each technology. AFM sees highest utilization in academic and research institutions (38%), semiconductor industry (27%), life sciences (18%), and materials science (17%). IBM technology is predominantly deployed in semiconductor manufacturing (52%), followed by data storage device fabrication (21%), optical component manufacturing (15%), and research institutions (12%).

End-user surveys indicate different purchasing considerations for these technologies. AFM customers prioritize resolution capabilities, software integration, and non-destructive analysis features. In contrast, IBM customers focus on precision control, throughput rates, and compatibility with existing fabrication processes.

The competitive landscape shows increasing demand for integrated systems that combine both technologies, allowing for comprehensive sample preparation, analysis, and modification within a single workflow. This convergence trend is expected to accelerate, with market forecasts suggesting that integrated AFM-IBM systems could capture 15% of the total market share by 2028.

Current Technological Status and Challenges

Atomic Force Microscopy (AFM) and Ion Beam Milling (IBM) represent two distinct yet complementary advanced characterization and fabrication technologies that have evolved significantly over the past three decades. Currently, AFM technology has reached a high level of sophistication, with commercial systems offering sub-nanometer resolution in various operational modes including contact, tapping, and non-contact. Modern AFM systems incorporate advanced features such as high-speed scanning capabilities (>10 frames/second), multifrequency modes, and integration with complementary techniques like Raman spectroscopy and infrared analysis.

The global AFM market is dominated by established manufacturers including Bruker, Oxford Instruments, and Park Systems, with recent innovations focusing on automation, improved probe designs, and enhanced data processing algorithms. Despite these advancements, AFM continues to face challenges including tip wear during extended scanning, limited imaging speed for certain applications, and difficulties in characterizing samples with extreme topographical variations.

Ion Beam Milling technology has similarly progressed substantially, with current systems offering beam spot sizes down to 2.5 nm and precise control over milling parameters. The technology has diversified into several variants including Focused Ion Beam (FIB), Reactive Ion Beam Etching (RIBE), and Broad Ion Beam (BIB) systems, each optimized for specific applications. Recent developments include multi-beam systems for increased throughput and hybrid platforms that combine ion milling with other analytical techniques.

The geographical distribution of these technologies shows concentration in advanced manufacturing hubs across North America, Europe, and East Asia, with emerging adoption in developing economies. Research institutions and semiconductor manufacturers represent the primary users, though applications continue to expand into new sectors.

A significant technical challenge for both technologies lies in their integration into high-volume manufacturing environments. AFM's relatively slow throughput limits its application in production-line quality control, while ion beam milling faces challenges in scaling to larger substrate sizes while maintaining precision. Additionally, both technologies require highly skilled operators, presenting a human resource constraint for widespread industrial adoption.

Environmental considerations also present challenges, particularly for ion beam milling which often utilizes gases like xenon or gallium that have supply chain vulnerabilities. The high vacuum requirements for both technologies contribute to their operational complexity and maintenance costs. Recent research has focused on developing more environmentally friendly processes and reducing energy consumption.

Cross-platform compatibility represents another challenge, as data formats and control systems often lack standardization across different manufacturers, complicating the integration of these technologies into comprehensive analytical workflows. Industry efforts toward open standards and interoperability protocols are ongoing but remain in early stages of development.

The global AFM market is dominated by established manufacturers including Bruker, Oxford Instruments, and Park Systems, with recent innovations focusing on automation, improved probe designs, and enhanced data processing algorithms. Despite these advancements, AFM continues to face challenges including tip wear during extended scanning, limited imaging speed for certain applications, and difficulties in characterizing samples with extreme topographical variations.

Ion Beam Milling technology has similarly progressed substantially, with current systems offering beam spot sizes down to 2.5 nm and precise control over milling parameters. The technology has diversified into several variants including Focused Ion Beam (FIB), Reactive Ion Beam Etching (RIBE), and Broad Ion Beam (BIB) systems, each optimized for specific applications. Recent developments include multi-beam systems for increased throughput and hybrid platforms that combine ion milling with other analytical techniques.

The geographical distribution of these technologies shows concentration in advanced manufacturing hubs across North America, Europe, and East Asia, with emerging adoption in developing economies. Research institutions and semiconductor manufacturers represent the primary users, though applications continue to expand into new sectors.

A significant technical challenge for both technologies lies in their integration into high-volume manufacturing environments. AFM's relatively slow throughput limits its application in production-line quality control, while ion beam milling faces challenges in scaling to larger substrate sizes while maintaining precision. Additionally, both technologies require highly skilled operators, presenting a human resource constraint for widespread industrial adoption.

Environmental considerations also present challenges, particularly for ion beam milling which often utilizes gases like xenon or gallium that have supply chain vulnerabilities. The high vacuum requirements for both technologies contribute to their operational complexity and maintenance costs. Recent research has focused on developing more environmentally friendly processes and reducing energy consumption.

Cross-platform compatibility represents another challenge, as data formats and control systems often lack standardization across different manufacturers, complicating the integration of these technologies into comprehensive analytical workflows. Industry efforts toward open standards and interoperability protocols are ongoing but remain in early stages of development.

Comparative Analysis of AFM and IBM Solutions

01 Combined AFM and ion beam milling for sample preparation

Integration of atomic force microscopy (AFM) with ion beam milling techniques for precise sample preparation and analysis. This combination allows for controlled material removal at the nanoscale while simultaneously enabling high-resolution imaging and characterization of the modified surface. The approach is particularly valuable for preparing cross-sections, creating nanostructures, and analyzing subsurface features with minimal damage to the surrounding material.- Combined AFM and ion beam milling for sample preparation and analysis: Integration of atomic force microscopy (AFM) with ion beam milling techniques enables precise sample preparation and high-resolution surface analysis. This combination allows for controlled material removal at the nanoscale while simultaneously imaging the resulting surface features. The approach is particularly valuable for preparing cross-sections, creating nanostructures, and analyzing subsurface features in materials science and semiconductor applications.

- AFM probe modification using ion beam techniques: Ion beam milling can be used to modify and customize atomic force microscopy probes for specialized applications. This includes sharpening probe tips, creating specific tip geometries, or functionalizing tips with particular materials. Modified probes enable enhanced resolution, improved durability, and application-specific capabilities for measuring mechanical, electrical, or magnetic properties at the nanoscale.

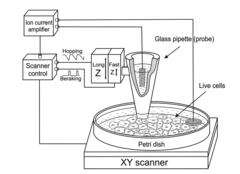

- In-situ AFM characterization during ion beam processing: Systems that integrate real-time atomic force microscopy imaging during ion beam milling processes allow for in-situ monitoring and characterization of surface modifications. This capability enables precise endpoint detection, process control, and immediate feedback on structural changes during nanofabrication. The approach is valuable for developing advanced nanomanufacturing techniques and studying dynamic surface phenomena.

- Multi-modal microscopy combining AFM with focused ion beam systems: Integrated instruments that combine atomic force microscopy with focused ion beam capabilities provide complementary analytical information about sample surfaces. These multi-modal systems enable correlative microscopy approaches where the same region can be characterized by different techniques without sample transfer. Applications include failure analysis in semiconductor devices, materials characterization, and nanoscale prototyping.

- Specialized sample holders and positioning systems for AFM and ion beam applications: Advanced sample manipulation systems facilitate precise positioning and alignment of specimens for sequential or simultaneous atomic force microscopy and ion beam processing. These specialized sample holders maintain positional accuracy, minimize drift, and enable reproducible targeting of specific sample regions. Such systems are critical for nanofabrication workflows and high-precision analytical procedures in research and industrial settings.

02 In-situ AFM characterization during ion beam processing

Systems and methods for real-time atomic force microscopy characterization during ion beam milling processes. This approach enables direct observation of surface modifications as they occur, allowing for precise control over milling depth, feature dimensions, and surface quality. The in-situ monitoring capabilities help optimize processing parameters and ensure accurate fabrication of nanoscale structures while minimizing artifacts and damage.Expand Specific Solutions03 AFM probe modification using ion beam techniques

Methods for modifying and customizing atomic force microscopy probes using focused ion beam milling. These techniques allow for precise shaping of AFM tips to create specialized geometries for specific applications, such as high-aspect-ratio probes for deep trench imaging or functionalized tips for chemical sensing. Ion beam processing can also be used to repair damaged probes or create novel tip structures with enhanced durability and resolution capabilities.Expand Specific Solutions04 3D nanofabrication combining AFM and ion beam technologies

Advanced nanofabrication approaches that leverage both atomic force microscopy and ion beam milling for creating three-dimensional nanostructures. This combination enables precise material removal guided by AFM imaging and manipulation capabilities, allowing for the creation of complex 3D features with nanometer precision. Applications include fabrication of nanoelectronic devices, photonic structures, and specialized research samples for materials science investigations.Expand Specific Solutions05 Correlative microscopy integrating AFM with ion beam techniques

Methodologies and systems for correlative microscopy that integrate atomic force microscopy with ion beam technologies and other analytical techniques. This multi-modal approach provides complementary information about sample properties by combining the high-resolution topographical data from AFM with compositional and structural information obtained through ion beam analysis. The correlation of these different data types enables comprehensive characterization of complex materials and devices across multiple length scales.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Atomic Force Microscopy (AFM) and Ion Beam Milling (IBM) technology landscape is currently in a mature growth phase, with an estimated global market size exceeding $2 billion. Key industry players demonstrate varying levels of technical specialization, with FEI Co., Hitachi High-Tech, and Carl Zeiss Microscopy dominating the high-end research equipment segment. Companies like Oxford Instruments Asylum Research and Bruker Nano have established strong positions in AFM technology, while TechInsights and Primenano focus on specialized applications. Academic institutions including Tianjin University, Zhejiang University, and CNRS contribute significant research advancements. The competitive landscape is characterized by increasing integration of complementary technologies, with companies like Agilent Technologies and Shimadzu developing hybrid systems that combine AFM precision with IBM's material modification capabilities.

Carl Zeiss Microscopy GmbH

Technical Solution: Carl Zeiss has developed the Crossbeam series that integrates focused ion beam milling with high-resolution imaging capabilities. Their approach emphasizes workflow automation between surface characterization and subsurface analysis. The company's ZEISS Atlas 5 software platform enables correlative microscopy by allowing researchers to identify regions of interest using AFM and then precisely target those areas for ion beam milling. Their proprietary ion column design achieves beam stability below 1nm for ultra-precise milling operations. Zeiss has also pioneered cryo-FIB techniques that preserve biological samples during both AFM imaging and subsequent ion beam processing. Their latest systems incorporate machine learning algorithms that optimize milling parameters based on material properties detected during initial AFM scans, significantly reducing sample damage and improving throughput.

Strengths: Exceptional beam stability for high-precision milling; advanced software for correlative workflows; specialized solutions for biological samples. Weaknesses: Higher initial investment compared to competitors; steeper learning curve for utilizing full system capabilities; limited compatibility with third-party AFM probes.

Oxford Instruments Asylum Research, Inc.

Technical Solution: Oxford Instruments Asylum Research has developed the Cypher AFM platform with capabilities specifically designed to complement ion beam milling processes. Their blueDrive photothermal excitation technology enables ultra-stable AFM imaging with minimal drift, providing precise targeting information for subsequent ion beam operations. Their approach focuses on high-resolution characterization of surface properties before selective material removal via ion beam techniques. Asylum Research's GetReal automated probe calibration ensures quantitative force measurements across different samples, allowing researchers to establish correlations between surface mechanical properties and subsurface structures revealed by ion beam milling. Their MFP-3D AFM systems can be equipped with specialized holders that maintain sample registration between AFM and FIB instruments, facilitating accurate before-and-after comparisons. The company has also developed proprietary algorithms for reconstructing 3D subsurface features by combining AFM topography with ion beam cross-sectional data.

Strengths: Exceptional AFM stability and resolution; quantitative mechanical property mapping; sophisticated 3D reconstruction capabilities. Weaknesses: Lacks integrated ion beam capabilities; requires additional equipment for complete workflow; more complex sample transfer procedures between instruments.

Key Technical Innovations and Patents

Scanning ion conductance microscopy using surface roughness for probe movement

PatentActiveUS20160274146A1

Innovation

- A method involving adaptive scanning where the SICM probe cycles in height above the surface at discrete points, estimating surface roughness to determine the spacing and number of measurements, allowing for localized resolution adjustment, thereby reducing scanning time and avoiding collisions, using a combination of piezo actuators for precise control and simultaneous fluorescence mapping.

Probe for magnetic force microscopy and method of preparing such a probe

PatentWO2003087859A1

Innovation

- Depositing magnetic material on the AFM tip followed by focused ion beam milling, allowing for one-sided milling while the tip is still part of a wafer, which simplifies and economizes the process, and enables higher aspect ratios and improved probe geometry.

Cost-Benefit Analysis and ROI Considerations

When evaluating the implementation of Atomic Force Microscopy (AFM) versus Ion Beam Milling (IBM) technologies, organizations must conduct thorough cost-benefit analyses to determine the most economically viable solution for their specific applications. The initial capital expenditure for AFM systems typically ranges from $100,000 to $500,000, while IBM systems generally command higher prices between $500,000 and $2 million, depending on specifications and capabilities.

Operational costs present significant differentials between these technologies. AFM systems consume minimal power and require relatively inexpensive consumables such as probe tips ($20-100 each), with typical annual maintenance costs of $5,000-15,000. Conversely, IBM systems demand substantial power consumption, specialized gases, and ion sources that can cost $10,000-30,000 per replacement, with annual maintenance expenses potentially reaching $50,000-100,000.

The return on investment timeline varies considerably between these technologies. AFM systems typically achieve ROI within 2-4 years in research environments and 1-3 years in industrial applications due to their versatility and lower operational costs. IBM systems, despite higher initial and operational costs, may deliver ROI within 3-5 years in semiconductor manufacturing and advanced materials processing where their precision capabilities directly impact product quality and yield rates.

Productivity metrics reveal that while AFM offers greater sample throughput for surface characterization (processing 10-20 samples daily), IBM excels in precision manufacturing applications where quality improvements translate to substantial downstream value. For semiconductor manufacturers, IBM systems can reduce defect rates by 15-30%, potentially saving millions in yield improvements.

Application-specific ROI calculations demonstrate that for research institutions primarily focused on surface characterization, AFM typically delivers 25-40% higher ROI than IBM. However, in semiconductor fabrication facilities, IBM's precision capabilities can generate 30-50% higher ROI through improved device performance and reduced failure rates.

Long-term financial planning must account for technology obsolescence factors. AFM systems typically maintain operational relevance for 7-10 years with incremental upgrades, while IBM systems may require more substantial reinvestment after 5-8 years due to rapid advances in ion source technology and control systems. Organizations should incorporate these lifecycle considerations into their financial models when calculating the true cost of ownership and expected returns.

Operational costs present significant differentials between these technologies. AFM systems consume minimal power and require relatively inexpensive consumables such as probe tips ($20-100 each), with typical annual maintenance costs of $5,000-15,000. Conversely, IBM systems demand substantial power consumption, specialized gases, and ion sources that can cost $10,000-30,000 per replacement, with annual maintenance expenses potentially reaching $50,000-100,000.

The return on investment timeline varies considerably between these technologies. AFM systems typically achieve ROI within 2-4 years in research environments and 1-3 years in industrial applications due to their versatility and lower operational costs. IBM systems, despite higher initial and operational costs, may deliver ROI within 3-5 years in semiconductor manufacturing and advanced materials processing where their precision capabilities directly impact product quality and yield rates.

Productivity metrics reveal that while AFM offers greater sample throughput for surface characterization (processing 10-20 samples daily), IBM excels in precision manufacturing applications where quality improvements translate to substantial downstream value. For semiconductor manufacturers, IBM systems can reduce defect rates by 15-30%, potentially saving millions in yield improvements.

Application-specific ROI calculations demonstrate that for research institutions primarily focused on surface characterization, AFM typically delivers 25-40% higher ROI than IBM. However, in semiconductor fabrication facilities, IBM's precision capabilities can generate 30-50% higher ROI through improved device performance and reduced failure rates.

Long-term financial planning must account for technology obsolescence factors. AFM systems typically maintain operational relevance for 7-10 years with incremental upgrades, while IBM systems may require more substantial reinvestment after 5-8 years due to rapid advances in ion source technology and control systems. Organizations should incorporate these lifecycle considerations into their financial models when calculating the true cost of ownership and expected returns.

Environmental Impact and Safety Regulations

Both Atomic Force Microscopy (AFM) and Ion Beam Milling (IBM) technologies present distinct environmental challenges and safety considerations that necessitate comprehensive regulatory frameworks. AFM operations generally pose minimal environmental risks due to their non-destructive nature and absence of hazardous materials in standard applications. However, certain specialized AFM techniques utilizing functionalized tips may incorporate chemicals requiring proper handling and disposal protocols in accordance with laboratory safety standards.

In contrast, Ion Beam Milling presents more significant environmental concerns. The process typically employs inert gases like argon or reactive gases such as oxygen, which must be properly contained and monitored. More critically, IBM generates potentially hazardous waste materials, including sputtered target materials and contaminated components that may contain heavy metals or toxic compounds depending on the processed substrates. These waste streams require specialized disposal procedures compliant with hazardous waste regulations.

Workplace safety regulations for AFM primarily focus on electrical safety, laser protection (for certain AFM variants), and ergonomic considerations for operators. The relatively low-risk profile of AFM has resulted in less stringent regulatory oversight compared to more hazardous analytical techniques. Nevertheless, facilities must still adhere to general laboratory safety protocols and equipment-specific guidelines provided by manufacturers.

IBM operations face considerably more rigorous safety requirements due to multiple hazard sources. High-voltage systems (typically 1-30 kV) necessitate comprehensive electrical safety measures and operator training. Vacuum systems present potential implosion risks requiring regular maintenance and inspection. Additionally, radiation shielding may be necessary for certain high-energy ion beam configurations, with corresponding monitoring protocols and exposure limitations for personnel.

Regulatory frameworks governing these technologies vary globally but generally include occupational health and safety regulations, environmental protection standards, and specific technical standards for equipment operation. In the United States, OSHA regulations address workplace safety aspects, while EPA guidelines govern waste disposal. The European Union implements the REACH regulation for chemical management and the Waste Electrical and Electronic Equipment (WEEE) Directive for equipment disposal.

Recent regulatory trends indicate increasing scrutiny of nanomaterial waste management, potentially affecting both technologies as they frequently involve nanoscale materials. Additionally, energy efficiency requirements are becoming more stringent, prompting manufacturers to develop more environmentally sustainable instrumentation with reduced power consumption and improved waste heat management.

In contrast, Ion Beam Milling presents more significant environmental concerns. The process typically employs inert gases like argon or reactive gases such as oxygen, which must be properly contained and monitored. More critically, IBM generates potentially hazardous waste materials, including sputtered target materials and contaminated components that may contain heavy metals or toxic compounds depending on the processed substrates. These waste streams require specialized disposal procedures compliant with hazardous waste regulations.

Workplace safety regulations for AFM primarily focus on electrical safety, laser protection (for certain AFM variants), and ergonomic considerations for operators. The relatively low-risk profile of AFM has resulted in less stringent regulatory oversight compared to more hazardous analytical techniques. Nevertheless, facilities must still adhere to general laboratory safety protocols and equipment-specific guidelines provided by manufacturers.

IBM operations face considerably more rigorous safety requirements due to multiple hazard sources. High-voltage systems (typically 1-30 kV) necessitate comprehensive electrical safety measures and operator training. Vacuum systems present potential implosion risks requiring regular maintenance and inspection. Additionally, radiation shielding may be necessary for certain high-energy ion beam configurations, with corresponding monitoring protocols and exposure limitations for personnel.

Regulatory frameworks governing these technologies vary globally but generally include occupational health and safety regulations, environmental protection standards, and specific technical standards for equipment operation. In the United States, OSHA regulations address workplace safety aspects, while EPA guidelines govern waste disposal. The European Union implements the REACH regulation for chemical management and the Waste Electrical and Electronic Equipment (WEEE) Directive for equipment disposal.

Recent regulatory trends indicate increasing scrutiny of nanomaterial waste management, potentially affecting both technologies as they frequently involve nanoscale materials. Additionally, energy efficiency requirements are becoming more stringent, prompting manufacturers to develop more environmentally sustainable instrumentation with reduced power consumption and improved waste heat management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!