Improve Atomic Force Microscopy Stability For Long-Duration Scans

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Stability Evolution and Research Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Gerd Binnig, Calvin Quate, and Christoph Gerber. Initially designed as an extension of Scanning Tunneling Microscopy (STM), AFM has transformed from a basic imaging tool into a sophisticated instrument capable of nanoscale manipulation and characterization across multiple scientific disciplines. The evolution of AFM stability represents one of the most critical development paths in microscopy technology over the past three decades.

Early AFM systems in the late 1980s and early 1990s suffered from significant stability limitations, with drift rates often exceeding 1 nm/minute, making long-duration scans virtually impossible. The primary stability challenges included thermal drift, mechanical vibrations, and piezoelectric creep, which collectively compromised measurement accuracy and reproducibility. By the early 2000s, improved feedback systems and environmental controls reduced drift to approximately 100-200 pm/minute, enabling more extended observation periods but still limiting many applications requiring prolonged imaging.

The technological trajectory has been driven by increasing demands from semiconductor manufacturing, biological research, and materials science, where atomic-level precision over extended periods is essential. Current state-of-the-art systems have achieved drift rates below 50 pm/minute under optimal conditions, representing a 20-fold improvement compared to early instruments. This progress has been achieved through innovations in mechanical design, advanced materials for probe construction, and sophisticated digital signal processing algorithms.

Despite these advances, significant challenges remain in achieving the sub-10 pm/minute stability required for next-generation applications such as real-time monitoring of biological processes and in-situ characterization of dynamic material transformations. The fundamental limitations stem from the inherent susceptibility of AFM to environmental perturbations, including temperature fluctuations, acoustic noise, and electromagnetic interference.

The primary research objectives for improving AFM stability for long-duration scans include developing active drift compensation systems that can predict and counteract thermal and mechanical drift in real-time. Additionally, research aims to create novel probe materials with minimal thermal expansion coefficients and enhanced mechanical stability. Integration of machine learning algorithms for adaptive feedback control represents another promising direction, potentially enabling the system to anticipate and correct for environmental disturbances before they affect measurement quality.

Achieving these objectives would enable transformative applications across multiple fields, including continuous monitoring of protein folding dynamics, real-time observation of catalytic reactions at the atomic scale, and non-destructive quality control in semiconductor manufacturing. The ultimate goal is to develop AFM systems capable of maintaining atomic-resolution imaging stability over periods exceeding 24 hours, which would represent a paradigm shift in nanoscale characterization capabilities.

Early AFM systems in the late 1980s and early 1990s suffered from significant stability limitations, with drift rates often exceeding 1 nm/minute, making long-duration scans virtually impossible. The primary stability challenges included thermal drift, mechanical vibrations, and piezoelectric creep, which collectively compromised measurement accuracy and reproducibility. By the early 2000s, improved feedback systems and environmental controls reduced drift to approximately 100-200 pm/minute, enabling more extended observation periods but still limiting many applications requiring prolonged imaging.

The technological trajectory has been driven by increasing demands from semiconductor manufacturing, biological research, and materials science, where atomic-level precision over extended periods is essential. Current state-of-the-art systems have achieved drift rates below 50 pm/minute under optimal conditions, representing a 20-fold improvement compared to early instruments. This progress has been achieved through innovations in mechanical design, advanced materials for probe construction, and sophisticated digital signal processing algorithms.

Despite these advances, significant challenges remain in achieving the sub-10 pm/minute stability required for next-generation applications such as real-time monitoring of biological processes and in-situ characterization of dynamic material transformations. The fundamental limitations stem from the inherent susceptibility of AFM to environmental perturbations, including temperature fluctuations, acoustic noise, and electromagnetic interference.

The primary research objectives for improving AFM stability for long-duration scans include developing active drift compensation systems that can predict and counteract thermal and mechanical drift in real-time. Additionally, research aims to create novel probe materials with minimal thermal expansion coefficients and enhanced mechanical stability. Integration of machine learning algorithms for adaptive feedback control represents another promising direction, potentially enabling the system to anticipate and correct for environmental disturbances before they affect measurement quality.

Achieving these objectives would enable transformative applications across multiple fields, including continuous monitoring of protein folding dynamics, real-time observation of catalytic reactions at the atomic scale, and non-destructive quality control in semiconductor manufacturing. The ultimate goal is to develop AFM systems capable of maintaining atomic-resolution imaging stability over periods exceeding 24 hours, which would represent a paradigm shift in nanoscale characterization capabilities.

Market Demand for High-Precision Long-Duration AFM Scanning

The global market for Atomic Force Microscopy (AFM) has been experiencing steady growth, driven primarily by increasing demand for high-precision imaging and measurement capabilities across multiple industries. The market for advanced AFM systems with enhanced stability for long-duration scans is particularly robust, with an estimated annual growth rate of 6-7% over the past five years. This growth trajectory is expected to continue as research institutions, semiconductor manufacturers, and life science companies seek more reliable and precise imaging solutions.

In the semiconductor industry, the continuous miniaturization of electronic components has created an urgent need for AFM systems capable of maintaining stability during extended scanning periods. As chip manufacturers push toward 3nm and smaller process nodes, the ability to conduct consistent, drift-free measurements over several hours becomes critical for quality control and process optimization. Industry reports indicate that semiconductor fabrication facilities are willing to invest significantly in AFM systems that can reduce measurement errors caused by thermal drift and mechanical instability.

The life sciences sector represents another major market driver, with researchers requiring stable long-duration AFM scanning to observe biological processes at the nanoscale. The ability to monitor cellular dynamics, protein interactions, and drug delivery mechanisms in real-time necessitates AFM systems that can maintain focus and precision over extended periods, often exceeding 24 hours. Research institutions and pharmaceutical companies have expressed growing interest in AFM technologies that minimize disruptions during these critical observations.

Materials science research has similarly contributed to market demand, as the development of novel materials requires comprehensive characterization at the atomic level. Long-duration stability is essential for mapping large sample areas with consistent resolution and for monitoring dynamic processes such as corrosion, crystallization, and phase transitions. Survey data from materials research laboratories indicates that stability during extended scanning ranks among the top three priorities when selecting new AFM equipment.

The industrial quality control segment has emerged as a rapidly expanding market for stable AFM systems. Manufacturing companies, particularly in precision engineering and advanced materials production, increasingly incorporate AFM into their quality assurance protocols. These applications demand systems that can operate reliably for extended periods in production-adjacent environments, often with minimal operator intervention.

Geographically, North America and Europe currently represent the largest markets for high-stability AFM systems, though the Asia-Pacific region is showing the fastest growth rate, driven by expanding semiconductor manufacturing and research activities in China, South Korea, and Taiwan. Market analysis suggests that research institutions account for approximately 40% of the demand, followed by semiconductor manufacturers (30%), life science companies (20%), and other industrial applications (10%).

In the semiconductor industry, the continuous miniaturization of electronic components has created an urgent need for AFM systems capable of maintaining stability during extended scanning periods. As chip manufacturers push toward 3nm and smaller process nodes, the ability to conduct consistent, drift-free measurements over several hours becomes critical for quality control and process optimization. Industry reports indicate that semiconductor fabrication facilities are willing to invest significantly in AFM systems that can reduce measurement errors caused by thermal drift and mechanical instability.

The life sciences sector represents another major market driver, with researchers requiring stable long-duration AFM scanning to observe biological processes at the nanoscale. The ability to monitor cellular dynamics, protein interactions, and drug delivery mechanisms in real-time necessitates AFM systems that can maintain focus and precision over extended periods, often exceeding 24 hours. Research institutions and pharmaceutical companies have expressed growing interest in AFM technologies that minimize disruptions during these critical observations.

Materials science research has similarly contributed to market demand, as the development of novel materials requires comprehensive characterization at the atomic level. Long-duration stability is essential for mapping large sample areas with consistent resolution and for monitoring dynamic processes such as corrosion, crystallization, and phase transitions. Survey data from materials research laboratories indicates that stability during extended scanning ranks among the top three priorities when selecting new AFM equipment.

The industrial quality control segment has emerged as a rapidly expanding market for stable AFM systems. Manufacturing companies, particularly in precision engineering and advanced materials production, increasingly incorporate AFM into their quality assurance protocols. These applications demand systems that can operate reliably for extended periods in production-adjacent environments, often with minimal operator intervention.

Geographically, North America and Europe currently represent the largest markets for high-stability AFM systems, though the Asia-Pacific region is showing the fastest growth rate, driven by expanding semiconductor manufacturing and research activities in China, South Korea, and Taiwan. Market analysis suggests that research institutions account for approximately 40% of the demand, followed by semiconductor manufacturers (30%), life science companies (20%), and other industrial applications (10%).

Current AFM Stability Limitations and Technical Barriers

Despite significant advancements in Atomic Force Microscopy (AFM) technology, several critical limitations continue to impede stable long-duration scanning capabilities. Thermal drift remains one of the most persistent challenges, causing dimensional distortions in images acquired over extended periods. This thermal instability stems from differential expansion and contraction of AFM components due to ambient temperature fluctuations, even at variations as small as 0.1°C, resulting in lateral drift rates typically ranging from 0.1 to 10 nm/minute.

Mechanical vibrations constitute another major barrier to stability, with sources ranging from building vibrations (1-20 Hz) to acoustic noise (20-20,000 Hz). Even with advanced vibration isolation systems, residual vibrations can significantly impact nanoscale measurements during long scans, particularly in high-resolution imaging modes where sub-nanometer precision is required.

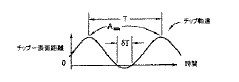

Piezoelectric creep presents a time-dependent stability challenge, manifesting as continued scanner movement after the application of a voltage step. This non-linear behavior typically follows a logarithmic time dependence, with displacement continuing for hours after initial positioning. For long-duration experiments, this can result in positional errors of 1-5% of the commanded movement over the first hour of scanning.

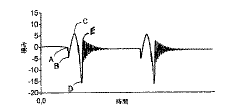

Electronic noise from control systems and detection electronics introduces another layer of instability. While modern instruments have reduced noise floors to sub-angstrom levels, cumulative effects during extended operations can degrade image quality and measurement accuracy, particularly when attempting to resolve atomic-scale features.

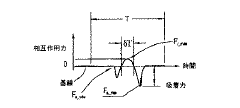

Tip-sample interactions evolve dynamically during prolonged scanning sessions, with tip wear and contamination progressively altering imaging conditions. Studies indicate that silicon tips can experience wear rates of approximately 0.01-0.1 nm³ per scan line under typical imaging conditions, significantly impacting measurement consistency during multi-hour experiments.

Environmental factors beyond temperature also play crucial roles in stability limitations. Humidity fluctuations affect capillary forces between tip and sample, while atmospheric pressure variations can influence the resonant behavior of cantilevers. These environmental dependencies are particularly problematic in non-environmentally controlled laboratories.

Current commercial AFM systems typically specify drift rates of 1-2 nm/minute under optimal conditions, which remains insufficient for many advanced applications requiring atomic precision over hours. The combined effect of these limitations creates a technical ceiling that particularly impacts research areas requiring both high spatial resolution and temporal stability, such as biological processes monitoring, slow crystallization studies, and long-term materials degradation analysis.

Mechanical vibrations constitute another major barrier to stability, with sources ranging from building vibrations (1-20 Hz) to acoustic noise (20-20,000 Hz). Even with advanced vibration isolation systems, residual vibrations can significantly impact nanoscale measurements during long scans, particularly in high-resolution imaging modes where sub-nanometer precision is required.

Piezoelectric creep presents a time-dependent stability challenge, manifesting as continued scanner movement after the application of a voltage step. This non-linear behavior typically follows a logarithmic time dependence, with displacement continuing for hours after initial positioning. For long-duration experiments, this can result in positional errors of 1-5% of the commanded movement over the first hour of scanning.

Electronic noise from control systems and detection electronics introduces another layer of instability. While modern instruments have reduced noise floors to sub-angstrom levels, cumulative effects during extended operations can degrade image quality and measurement accuracy, particularly when attempting to resolve atomic-scale features.

Tip-sample interactions evolve dynamically during prolonged scanning sessions, with tip wear and contamination progressively altering imaging conditions. Studies indicate that silicon tips can experience wear rates of approximately 0.01-0.1 nm³ per scan line under typical imaging conditions, significantly impacting measurement consistency during multi-hour experiments.

Environmental factors beyond temperature also play crucial roles in stability limitations. Humidity fluctuations affect capillary forces between tip and sample, while atmospheric pressure variations can influence the resonant behavior of cantilevers. These environmental dependencies are particularly problematic in non-environmentally controlled laboratories.

Current commercial AFM systems typically specify drift rates of 1-2 nm/minute under optimal conditions, which remains insufficient for many advanced applications requiring atomic precision over hours. The combined effect of these limitations creates a technical ceiling that particularly impacts research areas requiring both high spatial resolution and temporal stability, such as biological processes monitoring, slow crystallization studies, and long-term materials degradation analysis.

Current Drift Compensation and Vibration Isolation Solutions

01 Vibration isolation and damping systems

Various vibration isolation and damping systems are employed to enhance the stability of atomic force microscopy (AFM) measurements. These systems minimize environmental vibrations that can interfere with the precise measurements required in AFM. Solutions include active vibration isolation platforms, passive damping materials, and specialized mounting systems that effectively reduce noise and improve measurement accuracy. These technologies are critical for high-resolution imaging and force measurements at the nanoscale.- Vibration isolation and damping systems: Vibration isolation and damping systems are critical for maintaining stability in atomic force microscopy (AFM). These systems minimize environmental vibrations that can interfere with measurements at the nanoscale level. Various approaches include active vibration isolation platforms, passive damping mechanisms, and specialized mounting systems that reduce the transmission of mechanical noise to the microscope. These solutions significantly improve measurement accuracy and resolution by ensuring a stable imaging environment.

- Thermal stability control mechanisms: Thermal stability is essential for high-precision AFM measurements. Temperature fluctuations can cause thermal drift in the microscope components, leading to image distortion and measurement errors. Advanced thermal control mechanisms include temperature-regulated enclosures, thermally stable materials for critical components, and compensation algorithms that correct for thermal drift during operation. These technologies maintain consistent temperature conditions and minimize thermal expansion effects during imaging sessions.

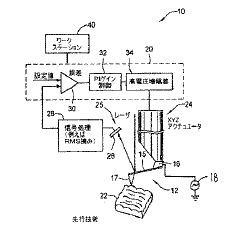

- Feedback control systems for probe positioning: Sophisticated feedback control systems are implemented to maintain stable probe-sample interactions during AFM operation. These systems continuously monitor and adjust the probe position relative to the sample surface, compensating for drift and ensuring consistent imaging force. Advanced algorithms process signals from the cantilever deflection sensors in real-time, making rapid adjustments to maintain optimal scanning conditions. This approach significantly enhances image quality and measurement reliability, particularly during long-duration scans.

- Mechanical design improvements for stability: Innovative mechanical designs significantly enhance AFM stability. These include rigid structural frameworks that minimize flexing, specialized materials with low thermal expansion coefficients, and optimized geometric configurations that increase natural resonance frequencies. Some designs incorporate integrated damping elements and improved cantilever holders that reduce mechanical noise. These mechanical improvements provide a stable platform for the sensitive components of the microscope, reducing drift and improving measurement repeatability.

- Environmental control and isolation chambers: Environmental control systems create optimal conditions for AFM operation by isolating the microscope from external disturbances. These systems include acoustic isolation chambers, electromagnetic shielding, humidity control, and pressure regulation. Some advanced setups incorporate complete environmental enclosures that maintain stable atmospheric conditions and prevent contamination. By controlling these environmental factors, measurement stability is significantly improved, enabling higher resolution imaging and more precise force measurements.

02 Thermal stability control mechanisms

Thermal drift is a significant challenge in atomic force microscopy that affects measurement stability. Various thermal stability control mechanisms have been developed to address this issue, including temperature-controlled enclosures, thermally compensated components, and drift correction algorithms. These solutions minimize thermal expansion effects on the microscope components and sample, ensuring consistent and reliable measurements over extended periods, particularly important for time-dependent studies and high-precision measurements.Expand Specific Solutions03 Feedback control systems for probe positioning

Advanced feedback control systems are essential for maintaining stable probe-sample interactions in atomic force microscopy. These systems continuously monitor and adjust the probe position relative to the sample surface, compensating for drift and ensuring consistent imaging force. Implementations include PID controllers, adaptive feedback algorithms, and high-speed digital signal processing that enable precise control of the probe-sample distance. These technologies are crucial for obtaining high-quality images and accurate force measurements across various sample types and environmental conditions.Expand Specific Solutions04 Environmental control chambers

Environmental control chambers provide stable conditions for atomic force microscopy by regulating factors such as humidity, temperature, and atmospheric composition. These chambers shield the microscope from external disturbances while allowing controlled experimental conditions. Some designs incorporate gas flow systems, humidity regulators, and temperature stabilization mechanisms to maintain consistent measurement environments. Environmental control is particularly important for biological samples, reactive materials, and experiments requiring specific atmospheric conditions to ensure reproducible and reliable measurements.Expand Specific Solutions05 Probe and cantilever design optimization

The design and optimization of probes and cantilevers significantly impact the stability of atomic force microscopy measurements. Innovations include specialized cantilever geometries, material compositions with improved mechanical properties, and tip designs that enhance measurement stability. These optimizations focus on reducing thermal drift, improving mechanical resonance characteristics, and enhancing tip-sample interaction stability. Advanced manufacturing techniques enable the production of cantilevers with precise dimensions and mechanical properties tailored for specific applications, resulting in more stable and reliable AFM measurements.Expand Specific Solutions

Leading Manufacturers and Research Institutions in AFM Technology

The Atomic Force Microscopy (AFM) stability for long-duration scans market is currently in a growth phase, with increasing demand for high-precision imaging across research and industrial applications. The market size is expanding steadily, driven by semiconductor, materials science, and nanotechnology sectors. Leading players include established instrument manufacturers like Bruker Nano, Oxford Instruments Asylum Research, and Hitachi, alongside emerging specialized companies such as Infinitesima and Nearfield Instruments. Academic institutions (Beihang University, Zhejiang University) and research organizations (CNRS, KRISS) are advancing technical innovations to address thermal drift, vibration isolation, and feedback control challenges. The competitive landscape shows a mix of commercial solutions and research breakthroughs, with recent developments focusing on automated drift compensation, advanced piezoelectric materials, and AI-enhanced stability control systems.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced PeakForce Tapping technology that significantly improves AFM stability during long-duration scans. Their system incorporates active vibration isolation platforms and temperature-controlled environments to minimize thermal drift. The FastScan technology enables high-speed imaging while maintaining stability through sophisticated feedback algorithms that continuously adjust tip-sample interactions. Their proprietary drift compensation algorithms automatically correct for XYZ drift in real-time, allowing for extended imaging periods of up to 72 hours with nanometer-level precision. Additionally, Bruker's ScanAsyst technology automatically optimizes scanning parameters throughout long experiments, adapting to changing sample conditions and environmental factors to maintain consistent imaging quality.

Strengths: Industry-leading vibration isolation systems and thermal drift compensation algorithms provide exceptional stability. Automated parameter optimization reduces operator intervention. Weaknesses: Premium pricing makes systems less accessible to smaller research institutions. Complex systems require significant training for optimal operation.

Infinitesima Ltd.

Technical Solution: Infinitesima has developed the revolutionary Rapid Probe Microscopy (RPM) technology that fundamentally reimagines AFM stability for long-duration scans. Unlike conventional AFMs that struggle with drift during extended imaging, RPM employs a video-rate scanning approach that captures complete images in milliseconds rather than minutes. This high-speed acquisition effectively "freezes" drift effects within each frame, while sophisticated image registration algorithms align sequential frames to compensate for longer-term drift. Their proprietary probe technology maintains consistent tip-sample interaction forces through active monitoring and feedback systems operating at over 100kHz. The Navigator platform incorporates reference structures on the sample stage that provide absolute positioning capability, allowing the system to automatically recalibrate position during extended experiments. This approach enables stability for scans lasting over 24 hours with drift rates below 0.1nm/minute, even in challenging industrial environments with variable temperature and vibration conditions.

Strengths: Revolutionary high-speed imaging effectively eliminates short-term drift concerns. Reference-based absolute positioning enables unprecedented long-term stability. Weaknesses: Relatively new technology with less established user base. Limited compatibility with some traditional AFM measurement modes.

Critical Patents and Innovations in AFM Stability Control

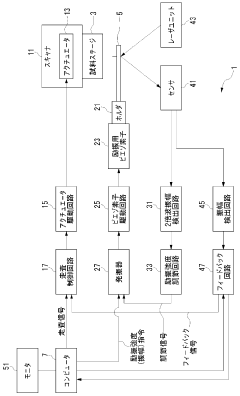

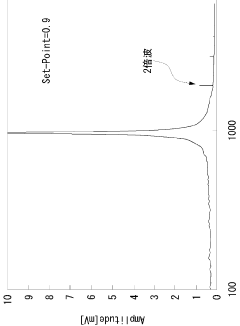

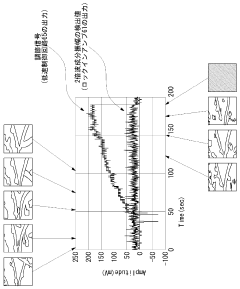

Scanning probe microscope

PatentWO2007072621A1

Innovation

- The implementation of a scanning probe microscope that includes an excitation unit capable of adjusting the excitation strength based on detected integer multiple component amplitudes, specifically using a second harmonic amplitude detection circuit to maintain constant contact strength and amplitude, thereby compensating for changes in excitation efficiency.

Scanning probe microscope and method of operating the same

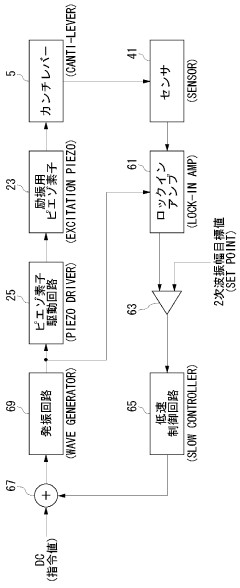

PatentActiveJP2018036272A

Innovation

- The implementation of Peak Force Tapping (PFT) Mode, which uses instantaneous interaction force control to minimize parasitic coupling and automate feedback adjustments, allowing for high-resolution imaging with minimal user intervention and reduced tip-sample forces.

Environmental Control Systems for Optimized AFM Performance

Environmental control systems represent a critical component in achieving optimal Atomic Force Microscopy (AFM) performance, particularly for long-duration scans where stability is paramount. These systems are designed to mitigate environmental factors that can introduce noise, drift, and measurement artifacts, thereby enhancing the reliability and reproducibility of AFM data.

Temperature fluctuations pose one of the most significant challenges to AFM stability, causing thermal expansion or contraction of both the sample and instrument components. Advanced environmental control systems employ precision temperature regulation with stability ranges of ±0.01°C to ±0.1°C, utilizing multi-stage feedback mechanisms and thermal isolation chambers. These systems often incorporate pre-equilibration periods to ensure thermal stability before initiating critical measurements.

Vibration isolation represents another crucial aspect of environmental control for AFM. High-resolution AFM measurements require vibration levels below 0.1 nm, necessitating sophisticated isolation strategies. Modern systems combine passive damping elements with active cancellation technologies that detect and counteract environmental vibrations in real-time, creating a stable measurement environment even in challenging settings.

Humidity control has emerged as an essential parameter for long-duration AFM scans, particularly for biological samples or hygroscopic materials. Fluctuations in relative humidity can alter sample properties and induce drift in the measurement system. State-of-the-art environmental chambers maintain humidity levels within ±1% using desiccant-based or refrigeration-based dehumidification systems coupled with precision humidifiers and vapor generators.

Acoustic isolation further enhances AFM performance by minimizing sound wave interference. Specialized acoustic enclosures with sound-absorbing materials can reduce ambient noise by 20-30 dB, preventing acoustic vibrations from coupling into the measurement system. Some advanced systems incorporate active noise cancellation technologies similar to those found in premium headphones.

Electromagnetic interference (EMI) shielding completes the environmental control ecosystem for AFM. Faraday cage designs with proper grounding schemes can attenuate external electromagnetic fields by 60-80 dB across a wide frequency spectrum. This protection is particularly important for electrical measurements and force spectroscopy applications where small currents and forces must be detected with high precision.

Integration of these environmental control systems with automated monitoring and compensation algorithms enables unprecedented stability for long-duration AFM scans. Modern systems can maintain sub-nanometer stability over periods exceeding 24 hours, opening new possibilities for time-lapse studies of dynamic processes at the nanoscale.

Temperature fluctuations pose one of the most significant challenges to AFM stability, causing thermal expansion or contraction of both the sample and instrument components. Advanced environmental control systems employ precision temperature regulation with stability ranges of ±0.01°C to ±0.1°C, utilizing multi-stage feedback mechanisms and thermal isolation chambers. These systems often incorporate pre-equilibration periods to ensure thermal stability before initiating critical measurements.

Vibration isolation represents another crucial aspect of environmental control for AFM. High-resolution AFM measurements require vibration levels below 0.1 nm, necessitating sophisticated isolation strategies. Modern systems combine passive damping elements with active cancellation technologies that detect and counteract environmental vibrations in real-time, creating a stable measurement environment even in challenging settings.

Humidity control has emerged as an essential parameter for long-duration AFM scans, particularly for biological samples or hygroscopic materials. Fluctuations in relative humidity can alter sample properties and induce drift in the measurement system. State-of-the-art environmental chambers maintain humidity levels within ±1% using desiccant-based or refrigeration-based dehumidification systems coupled with precision humidifiers and vapor generators.

Acoustic isolation further enhances AFM performance by minimizing sound wave interference. Specialized acoustic enclosures with sound-absorbing materials can reduce ambient noise by 20-30 dB, preventing acoustic vibrations from coupling into the measurement system. Some advanced systems incorporate active noise cancellation technologies similar to those found in premium headphones.

Electromagnetic interference (EMI) shielding completes the environmental control ecosystem for AFM. Faraday cage designs with proper grounding schemes can attenuate external electromagnetic fields by 60-80 dB across a wide frequency spectrum. This protection is particularly important for electrical measurements and force spectroscopy applications where small currents and forces must be detected with high precision.

Integration of these environmental control systems with automated monitoring and compensation algorithms enables unprecedented stability for long-duration AFM scans. Modern systems can maintain sub-nanometer stability over periods exceeding 24 hours, opening new possibilities for time-lapse studies of dynamic processes at the nanoscale.

Materials Science Implications of Enhanced AFM Stability

Enhanced stability in Atomic Force Microscopy (AFM) for long-duration scans represents a significant advancement with profound implications for materials science research. The ability to maintain consistent imaging quality over extended periods enables researchers to observe dynamic processes at the nanoscale with unprecedented clarity and reliability.

Materials scientists can now conduct in-situ experiments to monitor material transformations, such as crystallization processes, phase transitions, and chemical reactions, which typically occur over hours or even days. This capability provides direct visualization of mechanisms that were previously only inferred through indirect measurements or theoretical models.

The improved stability facilitates more accurate characterization of mechanical properties through nanoindentation and force spectroscopy measurements. When combined with long-duration capabilities, researchers can now track how material properties evolve over time under various environmental conditions, including temperature fluctuations, humidity changes, and exposure to reactive species.

For soft materials and biological samples, enhanced AFM stability reduces artifacts caused by tip-sample interactions, allowing for non-destructive imaging of delicate structures. This advancement is particularly valuable for studying polymers, hydrogels, and biomaterials where structural integrity must be maintained throughout the measurement process.

In thin film research, stable long-duration scanning enables the investigation of growth mechanisms, defect formation, and surface diffusion phenomena with temporal resolution previously unattainable. These insights are crucial for developing next-generation electronic materials, protective coatings, and functional interfaces.

The materials development pipeline benefits significantly from enhanced AFM stability through more reliable quality control procedures. Manufacturers can now implement more thorough surface analysis protocols to detect defects, impurities, and structural irregularities that might compromise product performance or longevity.

For energy materials research, stable AFM enables the real-time monitoring of electrode-electrolyte interfaces, catalyst degradation mechanisms, and ion transport processes. These observations are essential for designing more efficient batteries, fuel cells, and photovoltaic devices with improved durability and performance characteristics.

Additionally, the enhanced stability allows for more accurate correlation between nanoscale structure and macroscopic properties, bridging the gap between fundamental materials science and practical engineering applications. This multi-scale understanding accelerates the development of materials with tailored properties for specific technological needs.

Materials scientists can now conduct in-situ experiments to monitor material transformations, such as crystallization processes, phase transitions, and chemical reactions, which typically occur over hours or even days. This capability provides direct visualization of mechanisms that were previously only inferred through indirect measurements or theoretical models.

The improved stability facilitates more accurate characterization of mechanical properties through nanoindentation and force spectroscopy measurements. When combined with long-duration capabilities, researchers can now track how material properties evolve over time under various environmental conditions, including temperature fluctuations, humidity changes, and exposure to reactive species.

For soft materials and biological samples, enhanced AFM stability reduces artifacts caused by tip-sample interactions, allowing for non-destructive imaging of delicate structures. This advancement is particularly valuable for studying polymers, hydrogels, and biomaterials where structural integrity must be maintained throughout the measurement process.

In thin film research, stable long-duration scanning enables the investigation of growth mechanisms, defect formation, and surface diffusion phenomena with temporal resolution previously unattainable. These insights are crucial for developing next-generation electronic materials, protective coatings, and functional interfaces.

The materials development pipeline benefits significantly from enhanced AFM stability through more reliable quality control procedures. Manufacturers can now implement more thorough surface analysis protocols to detect defects, impurities, and structural irregularities that might compromise product performance or longevity.

For energy materials research, stable AFM enables the real-time monitoring of electrode-electrolyte interfaces, catalyst degradation mechanisms, and ion transport processes. These observations are essential for designing more efficient batteries, fuel cells, and photovoltaic devices with improved durability and performance characteristics.

Additionally, the enhanced stability allows for more accurate correlation between nanoscale structure and macroscopic properties, bridging the gap between fundamental materials science and practical engineering applications. This multi-scale understanding accelerates the development of materials with tailored properties for specific technological needs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!