How To Calibrate Atomic Force Microscopy Laser Alignment — Precision Steps

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Laser Alignment Background and Objectives

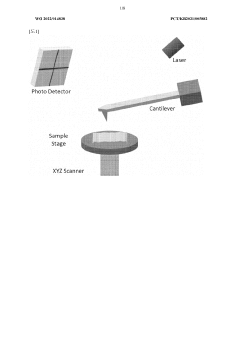

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Gerd Binnig, Calvin Quate, and Christoph Gerber. This revolutionary scanning probe microscopy technique has transformed our ability to visualize and manipulate matter at the nanoscale, offering unprecedented resolution down to the atomic level. The laser alignment system represents one of the most critical components in AFM operation, serving as the primary mechanism for detecting cantilever deflections that ultimately translate into topographical data.

The evolution of AFM laser alignment technology has progressed from simple optical lever systems to sophisticated laser detection arrangements that can simultaneously track multiple degrees of freedom. Early AFM systems utilized basic laser diodes with manual alignment procedures that were time-consuming and operator-dependent. Modern systems have incorporated automated alignment features, position-sensitive photodetectors (PSDs), and advanced optical components that significantly enhance measurement precision and reproducibility.

Current technological trends in AFM laser alignment focus on increasing stability, reducing drift, minimizing noise, and simplifying the calibration process. Innovations include temperature-compensated optical paths, fiber-coupled laser sources, and digital signal processing algorithms that can correct for alignment imperfections in real-time. These advancements aim to address the persistent challenges of thermal drift, mechanical vibrations, and optical interference that can compromise measurement accuracy.

The primary objective of AFM laser alignment calibration is to establish an optimal optical path from the laser source to the cantilever and then to the photodetector, ensuring maximum sensitivity and signal-to-noise ratio. Proper alignment directly impacts force measurement accuracy, topographical resolution, and overall instrument performance. A well-calibrated system should maintain stable alignment over extended periods, even under varying environmental conditions.

Secondary objectives include minimizing laser-induced heating of the cantilever, reducing optical interference artifacts, and ensuring compatibility with various cantilever geometries and coating materials. Additionally, modern calibration procedures aim to be user-friendly, reproducible, and less dependent on operator expertise, facilitating broader adoption of AFM technology across scientific disciplines.

The significance of precise laser alignment extends beyond basic topographical imaging to advanced AFM applications such as force spectroscopy, nanomechanical mapping, and high-speed imaging. As researchers push the boundaries of AFM capabilities—exploring phenomena at ever-smaller scales and faster time resolutions—the demands on laser alignment precision continue to increase, driving innovation in calibration methodologies and hardware designs.

Understanding the historical context, current state, and future trajectory of AFM laser alignment technology provides essential groundwork for developing improved calibration protocols that can enhance measurement reliability and expand the application scope of this powerful microscopy technique.

The evolution of AFM laser alignment technology has progressed from simple optical lever systems to sophisticated laser detection arrangements that can simultaneously track multiple degrees of freedom. Early AFM systems utilized basic laser diodes with manual alignment procedures that were time-consuming and operator-dependent. Modern systems have incorporated automated alignment features, position-sensitive photodetectors (PSDs), and advanced optical components that significantly enhance measurement precision and reproducibility.

Current technological trends in AFM laser alignment focus on increasing stability, reducing drift, minimizing noise, and simplifying the calibration process. Innovations include temperature-compensated optical paths, fiber-coupled laser sources, and digital signal processing algorithms that can correct for alignment imperfections in real-time. These advancements aim to address the persistent challenges of thermal drift, mechanical vibrations, and optical interference that can compromise measurement accuracy.

The primary objective of AFM laser alignment calibration is to establish an optimal optical path from the laser source to the cantilever and then to the photodetector, ensuring maximum sensitivity and signal-to-noise ratio. Proper alignment directly impacts force measurement accuracy, topographical resolution, and overall instrument performance. A well-calibrated system should maintain stable alignment over extended periods, even under varying environmental conditions.

Secondary objectives include minimizing laser-induced heating of the cantilever, reducing optical interference artifacts, and ensuring compatibility with various cantilever geometries and coating materials. Additionally, modern calibration procedures aim to be user-friendly, reproducible, and less dependent on operator expertise, facilitating broader adoption of AFM technology across scientific disciplines.

The significance of precise laser alignment extends beyond basic topographical imaging to advanced AFM applications such as force spectroscopy, nanomechanical mapping, and high-speed imaging. As researchers push the boundaries of AFM capabilities—exploring phenomena at ever-smaller scales and faster time resolutions—the demands on laser alignment precision continue to increase, driving innovation in calibration methodologies and hardware designs.

Understanding the historical context, current state, and future trajectory of AFM laser alignment technology provides essential groundwork for developing improved calibration protocols that can enhance measurement reliability and expand the application scope of this powerful microscopy technique.

Market Demand for Precision AFM Calibration

The global market for Atomic Force Microscopy (AFM) calibration solutions has been experiencing robust growth, driven primarily by increasing demand for nanoscale research and manufacturing precision across multiple industries. Current market valuations place the AFM instrumentation sector at approximately $500 million annually, with calibration tools and services representing about 15% of this market.

Research institutions and academic laboratories continue to be the largest consumers of AFM calibration solutions, accounting for nearly 40% of the market share. This segment's demand is primarily fueled by the need for reproducible experimental results and the growing complexity of nanoscale research projects requiring higher precision measurements.

The semiconductor industry represents the fastest-growing segment for AFM calibration solutions, with a compound annual growth rate of 8.7% over the past five years. As semiconductor manufacturers push toward smaller node sizes, the precision requirements for AFM measurements have increased dramatically, necessitating more sophisticated laser alignment calibration procedures.

Materials science and nanotechnology sectors collectively account for approximately 25% of the market demand. These industries require highly accurate AFM measurements for quality control, materials characterization, and development of novel nanomaterials, where even minor calibration errors can lead to significant research setbacks or manufacturing defects.

Healthcare and life sciences applications are emerging as significant growth drivers, particularly in pharmaceutical research and biomedical engineering. The need for precise characterization of biomolecules, drug delivery systems, and cellular structures has created new demand for specialized AFM calibration protocols that maintain accuracy in diverse biological environments.

Market analysis indicates a growing preference for automated calibration solutions that reduce human error and increase reproducibility. Systems offering computer-guided laser alignment procedures command premium pricing, with customers willing to pay 30-40% more for solutions that provide documented calibration accuracy improvements.

Regional market distribution shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (27%). However, the Asia-Pacific region demonstrates the highest growth rate, driven by expanding semiconductor manufacturing and increasing R&D investments in China, South Korea, and Taiwan.

Customer surveys reveal that precision and reproducibility rank as the top priorities when selecting AFM calibration solutions, followed by ease of use and integration capabilities with existing systems. Time efficiency in the calibration process has emerged as an increasingly important factor, with laboratories seeking to minimize downtime associated with instrument calibration.

Research institutions and academic laboratories continue to be the largest consumers of AFM calibration solutions, accounting for nearly 40% of the market share. This segment's demand is primarily fueled by the need for reproducible experimental results and the growing complexity of nanoscale research projects requiring higher precision measurements.

The semiconductor industry represents the fastest-growing segment for AFM calibration solutions, with a compound annual growth rate of 8.7% over the past five years. As semiconductor manufacturers push toward smaller node sizes, the precision requirements for AFM measurements have increased dramatically, necessitating more sophisticated laser alignment calibration procedures.

Materials science and nanotechnology sectors collectively account for approximately 25% of the market demand. These industries require highly accurate AFM measurements for quality control, materials characterization, and development of novel nanomaterials, where even minor calibration errors can lead to significant research setbacks or manufacturing defects.

Healthcare and life sciences applications are emerging as significant growth drivers, particularly in pharmaceutical research and biomedical engineering. The need for precise characterization of biomolecules, drug delivery systems, and cellular structures has created new demand for specialized AFM calibration protocols that maintain accuracy in diverse biological environments.

Market analysis indicates a growing preference for automated calibration solutions that reduce human error and increase reproducibility. Systems offering computer-guided laser alignment procedures command premium pricing, with customers willing to pay 30-40% more for solutions that provide documented calibration accuracy improvements.

Regional market distribution shows North America leading with 38% market share, followed by Europe (29%) and Asia-Pacific (27%). However, the Asia-Pacific region demonstrates the highest growth rate, driven by expanding semiconductor manufacturing and increasing R&D investments in China, South Korea, and Taiwan.

Customer surveys reveal that precision and reproducibility rank as the top priorities when selecting AFM calibration solutions, followed by ease of use and integration capabilities with existing systems. Time efficiency in the calibration process has emerged as an increasingly important factor, with laboratories seeking to minimize downtime associated with instrument calibration.

Current Challenges in AFM Laser Alignment

Despite significant advancements in Atomic Force Microscopy (AFM) technology, laser alignment remains one of the most challenging aspects of AFM operation and calibration. The primary difficulty stems from the nanoscale precision required for optimal performance, where even sub-micron misalignments can significantly compromise measurement accuracy and resolution. Current AFM systems typically utilize a laser beam reflected off the cantilever onto a position-sensitive photodetector (PSPD), making proper alignment critical for accurate force measurements.

A major challenge in laser alignment is the inherent mechanical drift that occurs during operation. Environmental factors such as temperature fluctuations, humidity changes, and mechanical vibrations can cause gradual misalignment of the laser beam relative to the cantilever and detector. This drift introduces measurement errors that compound over time, particularly problematic for long-duration experiments or when comparing measurements taken at different times.

The miniaturization of cantilevers for improved sensitivity has paradoxically made alignment more difficult. Smaller cantilevers provide better force sensitivity but present a reduced target area for laser positioning. Modern cantilevers with dimensions in the tens of micrometers require extremely precise alignment systems, often pushing the limits of manual adjustment capabilities.

Optical interference effects represent another significant challenge. Multiple reflections between the sample surface and cantilever can create interference patterns that affect the laser signal. These interference effects are particularly problematic when working with highly reflective samples or in liquid environments where refractive index changes complicate the optical path.

The diversity of cantilever types and coatings further complicates standardization of alignment procedures. Different cantilever geometries, materials, and surface treatments exhibit varying optical properties that affect laser reflection. This necessitates customized alignment protocols for different experimental setups, increasing complexity and reducing reproducibility across different instruments or laboratories.

Automation attempts have been partially successful but remain imperfect. Current automated alignment systems can perform basic positioning but often lack the adaptability to handle unusual cantilever geometries or experimental conditions. The final fine-tuning typically still requires human intervention, introducing operator-dependent variability into the process.

For measurements in non-standard environments, such as high-temperature conditions or corrosive atmospheres, maintaining stable laser alignment becomes exceptionally challenging. Protective housings or windows introduced to shield optical components can introduce additional optical aberrations that must be compensated for in the alignment process.

The lack of universally accepted quantitative metrics for optimal alignment quality represents a fundamental challenge in the field. While signal-to-noise ratio provides some guidance, determining when alignment is truly "optimal" remains somewhat subjective and experience-dependent, hampering efforts to develop fully automated or standardized alignment protocols.

A major challenge in laser alignment is the inherent mechanical drift that occurs during operation. Environmental factors such as temperature fluctuations, humidity changes, and mechanical vibrations can cause gradual misalignment of the laser beam relative to the cantilever and detector. This drift introduces measurement errors that compound over time, particularly problematic for long-duration experiments or when comparing measurements taken at different times.

The miniaturization of cantilevers for improved sensitivity has paradoxically made alignment more difficult. Smaller cantilevers provide better force sensitivity but present a reduced target area for laser positioning. Modern cantilevers with dimensions in the tens of micrometers require extremely precise alignment systems, often pushing the limits of manual adjustment capabilities.

Optical interference effects represent another significant challenge. Multiple reflections between the sample surface and cantilever can create interference patterns that affect the laser signal. These interference effects are particularly problematic when working with highly reflective samples or in liquid environments where refractive index changes complicate the optical path.

The diversity of cantilever types and coatings further complicates standardization of alignment procedures. Different cantilever geometries, materials, and surface treatments exhibit varying optical properties that affect laser reflection. This necessitates customized alignment protocols for different experimental setups, increasing complexity and reducing reproducibility across different instruments or laboratories.

Automation attempts have been partially successful but remain imperfect. Current automated alignment systems can perform basic positioning but often lack the adaptability to handle unusual cantilever geometries or experimental conditions. The final fine-tuning typically still requires human intervention, introducing operator-dependent variability into the process.

For measurements in non-standard environments, such as high-temperature conditions or corrosive atmospheres, maintaining stable laser alignment becomes exceptionally challenging. Protective housings or windows introduced to shield optical components can introduce additional optical aberrations that must be compensated for in the alignment process.

The lack of universally accepted quantitative metrics for optimal alignment quality represents a fundamental challenge in the field. While signal-to-noise ratio provides some guidance, determining when alignment is truly "optimal" remains somewhat subjective and experience-dependent, hampering efforts to develop fully automated or standardized alignment protocols.

State-of-the-Art Laser Alignment Methodologies

01 Laser alignment systems for AFM cantilever detection

Atomic Force Microscopy requires precise laser alignment on the cantilever to accurately detect deflection. These systems include optical components that focus and position the laser beam onto the cantilever tip, with mechanisms for adjusting the laser spot position. Advanced systems incorporate automated alignment features that optimize the positioning of the laser on the cantilever to maximize signal quality and measurement accuracy.- Laser alignment systems for AFM cantilever detection: Atomic Force Microscopy requires precise laser alignment on the cantilever to accurately detect deflection. These systems include optical components that focus the laser beam onto the cantilever and position detection mechanisms that capture the reflected beam. Advanced alignment systems incorporate automated positioning controls, feedback mechanisms, and calibration procedures to ensure optimal laser spot positioning on the cantilever, which is critical for measurement accuracy and resolution.

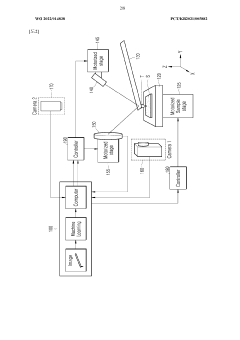

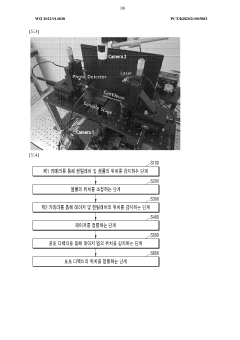

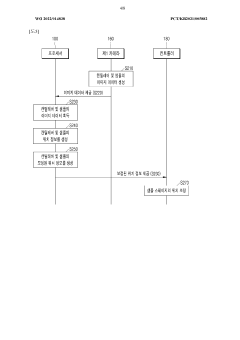

- Automated alignment and calibration methods: Automated methods for laser alignment in AFM systems utilize algorithms and motorized components to optimize the laser position without manual intervention. These methods employ image processing techniques to identify the cantilever position, followed by precision movement of either the laser source or the cantilever to achieve optimal alignment. Calibration procedures verify alignment quality through signal strength measurements and can include self-correction mechanisms that maintain alignment during operation, reducing drift and improving measurement consistency.

- Optical path design for improved laser reflection: Specialized optical path designs enhance laser reflection quality in AFM systems. These designs incorporate precision mirrors, beam splitters, and focusing lenses arranged to maximize signal-to-noise ratio. Some systems use multiple reflection points or differential detection methods to increase sensitivity. Advanced optical configurations can compensate for cantilever tilt and surface irregularities, ensuring consistent reflection capture even during complex scanning operations or when examining challenging sample topographies.

- Integration of laser alignment with scanning mechanisms: Integrated systems coordinate laser alignment with the AFM scanning mechanisms to maintain optimal detection during operation. These designs synchronize the laser tracking with cantilever movement across samples, ensuring continuous alignment throughout the scanning process. Some systems incorporate real-time adjustment capabilities that respond to changes in cantilever position or orientation during measurement. This integration improves data quality by maintaining consistent detection sensitivity across the entire scan area and reduces artifacts caused by alignment variations.

- Compact and portable AFM laser alignment solutions: Compact laser alignment solutions address space constraints and portability requirements for modern AFM systems. These designs miniaturize optical components while maintaining alignment precision through innovative arrangements of mirrors, lenses, and detectors. Some portable systems incorporate integrated alignment verification mechanisms that ensure proper setup in field applications. Miniaturized designs may use specialized micro-optical components or MEMS-based solutions to achieve the necessary alignment precision in reduced form factors, making high-resolution AFM more accessible for in-situ applications.

02 Feedback mechanisms for laser position optimization

Feedback control systems are implemented in AFM setups to continuously monitor and adjust laser alignment. These mechanisms use photodetectors to measure the reflected laser signal strength and position, then automatically make micro-adjustments to maintain optimal alignment during scanning operations. This helps compensate for thermal drift, mechanical vibrations, and other factors that could disrupt the laser-cantilever alignment during extended measurements.Expand Specific Solutions03 Multi-beam and array-based laser alignment techniques

Advanced AFM systems utilize multiple laser beams or laser arrays to enhance measurement capabilities. These configurations allow for simultaneous monitoring of multiple cantilevers or different points on a single cantilever, enabling more complex measurements and improved data collection. The alignment systems for these multi-beam setups include specialized optics and positioning mechanisms to coordinate multiple laser paths and their respective detection systems.Expand Specific Solutions04 Optical path design for improved laser alignment stability

Specialized optical path designs enhance the stability and precision of laser alignment in AFM systems. These designs incorporate elements such as beam splitters, mirrors, lenses, and waveguides arranged to minimize beam distortion and maximize alignment stability. Some systems include vibration isolation components and temperature-controlled environments to further enhance the stability of the laser path during measurements.Expand Specific Solutions05 Calibration and alignment verification methods

Systematic procedures and tools are developed for calibrating and verifying laser alignment in AFM systems. These methods include reference standards, alignment markers, and software algorithms that analyze the quality of the laser spot on the cantilever. Calibration protocols ensure that the laser-cantilever-detector system is properly aligned before measurements, with some systems incorporating periodic verification checks during operation to maintain measurement accuracy.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The atomic force microscopy (AFM) laser alignment calibration market is in a growth phase, characterized by increasing demand for high-precision microscopy across research and industrial applications. The global AFM market is projected to expand significantly, driven by nanotechnology advancements and materials science research. Technologically, the field shows moderate maturity with ongoing innovations in automation and precision. Leading players include established microscopy specialists like Leica Microsystems and Oxford Instruments Asylum Research, who offer sophisticated calibration solutions, alongside diversified technology corporations such as Canon and Olympus that leverage their optical expertise. Research institutions like CNRS and Harvard College contribute significantly to technical advancements, while emerging players from Asia, particularly Chinese institutions, are increasingly gaining market share through cost-effective innovations.

Leica Microsystems CMS GmbH

Technical Solution: Leica Microsystems has developed an integrated optical-mechanical approach to AFM laser alignment calibration that leverages their expertise in precision optics. Their system utilizes a combination of motorized optical components and specialized alignment algorithms to achieve optimal laser positioning on the cantilever. The calibration process begins with a pre-alignment phase using their proprietary "OptiView" technology, which provides a high-resolution optical view of both the cantilever and laser spot position. This is followed by a fine-tuning phase where the system makes incremental adjustments to the laser position while monitoring the photodetector signal in real-time. Leica's approach incorporates a unique dual-feedback mechanism that simultaneously optimizes both the laser spot position and the photodetector alignment, ensuring maximum sensitivity and signal-to-noise ratio. Their calibration software includes an automated alignment verification routine that compares the achieved alignment against theoretical optimal values and provides quantitative feedback on alignment quality. Additionally, Leica has implemented environmental stabilization features that minimize thermal drift effects on alignment stability, including active temperature compensation and vibration isolation systems integrated directly into their AFM platforms[2]. The company also offers specialized calibration standards with known geometries that allow users to verify alignment accuracy through reference measurements.

Strengths: Exceptional optical integration provides superior visualization of the alignment process, making it more accessible to new users. Their comprehensive approach addresses both laser and detector alignment simultaneously. Weaknesses: The sophisticated optical systems add significant cost to their instruments, and the alignment process requires more time compared to fully automated solutions.

Oxford Instruments Asylum Research, Inc.

Technical Solution: Oxford Instruments Asylum Research has developed comprehensive laser alignment calibration protocols for atomic force microscopy (AFM) that ensure optimal performance and measurement accuracy. Their approach involves a multi-step calibration process that begins with coarse alignment using visible alignment aids, followed by fine adjustment through real-time signal monitoring. The company's AFM systems incorporate specialized alignment tools that provide immediate feedback on laser position relative to the cantilever, allowing for precise adjustments to maximize the sum signal while balancing left-right and top-bottom photodetector quadrants. Their proprietary software includes diagnostic utilities that guide users through the alignment process with visual indicators and automated optimization routines. Additionally, they've implemented temperature compensation algorithms that maintain alignment stability during environmental fluctuations, reducing drift-related measurement errors[1]. Their systems also feature reference calibration standards that enable users to verify alignment accuracy against known parameters.

Strengths: Highly integrated hardware-software solution that simplifies the calibration process for users of varying expertise levels. Their systems provide real-time feedback during alignment, reducing the time required for optimization. Weaknesses: Their proprietary calibration approach may create vendor lock-in, and the sophisticated alignment systems add cost to their instruments compared to more basic AFM systems.

Critical Patents and Literature on AFM Calibration

Atomic-force microscope using artificial intelligence object recognition technology and method for operating same

PatentWO2022014838A1

Innovation

- An atomic force microscope equipped with artificial intelligence object recognition technology, including cameras and a processor, automatically aligns the cantilever, sample, laser, and photo detector positions using machine learning programs to ensure precise and accurate adjustments.

Caliber, method for manufacturing a caliber, and method for calibrating an atomic force microscope

PatentWO2025172655A1

Innovation

- A caliber for AFMs is developed with symmetrical, isotropic mechanical properties and identical friction coefficients, featuring grooves with equal and symmetrical angles, allowing for a simpler and more precise calibration process by reducing the number of unknowns to two, and enabling accurate determination of the conversion factor using a system of two equations.

Metrology Standards and Certification Requirements

In the field of Atomic Force Microscopy (AFM), adherence to established metrology standards and certification requirements is crucial for ensuring measurement accuracy and reliability. The International Organization for Standardization (ISO) has developed specific standards for AFM calibration, including ISO 11775 and ISO 11039, which provide guidelines for laser alignment procedures and verification methods. These standards establish the acceptable tolerance ranges for laser positioning and define the minimum requirements for calibration frequency.

National metrology institutes such as NIST (USA), PTB (Germany), and NPL (UK) have established traceability chains for AFM measurements, requiring regular calibration against certified reference materials. For laser alignment specifically, these institutions recommend calibration intervals ranging from 3 to 6 months, depending on usage intensity and environmental conditions. The certification process typically involves documenting the calibration procedure, recording pre and post-alignment parameters, and verifying system performance against known standards.

Laboratory accreditation programs like ISO/IEC 17025 impose additional requirements on facilities utilizing AFM technology. These include maintaining detailed calibration records, implementing quality management systems, and ensuring staff competency in calibration procedures. For research facilities and manufacturing environments, compliance with these standards is increasingly becoming a prerequisite for publication acceptance and product certification.

The American Society for Testing and Materials (ASTM) has published the E2382 standard, which specifically addresses AFM probe calibration and includes sections on laser alignment verification. This standard recommends using certified reference gratings with known dimensions to validate alignment accuracy and provides acceptance criteria for alignment quality. Compliance with this standard is particularly important in semiconductor manufacturing and materials characterization applications.

Regulatory bodies in pharmaceutical and medical device industries have adopted Good Manufacturing Practice (GMP) guidelines that incorporate AFM calibration requirements. These guidelines mandate documented evidence of regular laser alignment procedures and system performance verification. For AFM systems used in quality control applications, FDA regulations in 21 CFR Part 11 require electronic records of all calibration activities, including laser alignment procedures.

The emergence of Industry 4.0 has introduced new standards for automated calibration and remote monitoring of AFM systems. These standards emphasize real-time verification of laser alignment parameters and integration with laboratory information management systems (LIMS). Certification under these newer standards requires demonstration of system capability to maintain alignment within specified tolerances during extended operation periods and ability to automatically detect and correct alignment drift.

National metrology institutes such as NIST (USA), PTB (Germany), and NPL (UK) have established traceability chains for AFM measurements, requiring regular calibration against certified reference materials. For laser alignment specifically, these institutions recommend calibration intervals ranging from 3 to 6 months, depending on usage intensity and environmental conditions. The certification process typically involves documenting the calibration procedure, recording pre and post-alignment parameters, and verifying system performance against known standards.

Laboratory accreditation programs like ISO/IEC 17025 impose additional requirements on facilities utilizing AFM technology. These include maintaining detailed calibration records, implementing quality management systems, and ensuring staff competency in calibration procedures. For research facilities and manufacturing environments, compliance with these standards is increasingly becoming a prerequisite for publication acceptance and product certification.

The American Society for Testing and Materials (ASTM) has published the E2382 standard, which specifically addresses AFM probe calibration and includes sections on laser alignment verification. This standard recommends using certified reference gratings with known dimensions to validate alignment accuracy and provides acceptance criteria for alignment quality. Compliance with this standard is particularly important in semiconductor manufacturing and materials characterization applications.

Regulatory bodies in pharmaceutical and medical device industries have adopted Good Manufacturing Practice (GMP) guidelines that incorporate AFM calibration requirements. These guidelines mandate documented evidence of regular laser alignment procedures and system performance verification. For AFM systems used in quality control applications, FDA regulations in 21 CFR Part 11 require electronic records of all calibration activities, including laser alignment procedures.

The emergence of Industry 4.0 has introduced new standards for automated calibration and remote monitoring of AFM systems. These standards emphasize real-time verification of laser alignment parameters and integration with laboratory information management systems (LIMS). Certification under these newer standards requires demonstration of system capability to maintain alignment within specified tolerances during extended operation periods and ability to automatically detect and correct alignment drift.

Environmental Factors Affecting AFM Calibration Stability

Environmental factors play a crucial role in the stability and accuracy of Atomic Force Microscopy (AFM) laser alignment calibration. Temperature fluctuations represent one of the most significant environmental challenges, as they can cause thermal expansion or contraction of various AFM components. Even minor temperature changes of 1-2°C can lead to measurable drift in the laser alignment, potentially compromising measurement precision. This thermal sensitivity is particularly pronounced in high-resolution imaging applications where sub-nanometer accuracy is required.

Vibration interference constitutes another major environmental factor affecting AFM calibration stability. External vibrations from building HVAC systems, nearby equipment, or even foot traffic can introduce noise into the measurements and disrupt the laser alignment. Modern AFM systems typically incorporate vibration isolation platforms, but these may prove insufficient in particularly challenging environments, necessitating additional isolation measures or specialized laboratory design considerations.

Humidity variations can significantly impact AFM performance through multiple mechanisms. Changes in relative humidity can alter the mechanical properties of certain samples, particularly biological specimens, affecting the tip-sample interaction. Additionally, humidity fluctuations may cause dimensional changes in system components and contribute to drift in the laser alignment over time. Many advanced AFM facilities maintain strict humidity control (typically 40-60% RH) to mitigate these effects.

Airflow patterns within the laboratory environment merit careful consideration during AFM calibration procedures. Direct airflow across the instrument can induce thermal gradients and mechanical disturbances that destabilize the laser alignment. Proper positioning of the AFM away from air conditioning vents, doors, and windows is essential for maintaining calibration stability. Some research facilities employ specialized enclosures or dedicated rooms with controlled airflow patterns to minimize these disruptions.

Acoustic noise represents a frequently overlooked environmental factor that can compromise AFM calibration stability. Sound waves can induce mechanical vibrations in the AFM components, particularly affecting the cantilever and laser alignment system. Laboratory design should incorporate acoustic dampening materials, and sensitive measurements may require scheduling during periods of minimal activity to reduce ambient noise levels.

Electromagnetic interference (EMI) from nearby electronic equipment, power lines, or wireless communication devices can disrupt the electronic components of the AFM system, including the laser detection mechanism. Proper grounding, shielding, and strategic placement of the AFM away from significant EMI sources are essential practices for maintaining calibration stability in challenging electromagnetic environments.

Vibration interference constitutes another major environmental factor affecting AFM calibration stability. External vibrations from building HVAC systems, nearby equipment, or even foot traffic can introduce noise into the measurements and disrupt the laser alignment. Modern AFM systems typically incorporate vibration isolation platforms, but these may prove insufficient in particularly challenging environments, necessitating additional isolation measures or specialized laboratory design considerations.

Humidity variations can significantly impact AFM performance through multiple mechanisms. Changes in relative humidity can alter the mechanical properties of certain samples, particularly biological specimens, affecting the tip-sample interaction. Additionally, humidity fluctuations may cause dimensional changes in system components and contribute to drift in the laser alignment over time. Many advanced AFM facilities maintain strict humidity control (typically 40-60% RH) to mitigate these effects.

Airflow patterns within the laboratory environment merit careful consideration during AFM calibration procedures. Direct airflow across the instrument can induce thermal gradients and mechanical disturbances that destabilize the laser alignment. Proper positioning of the AFM away from air conditioning vents, doors, and windows is essential for maintaining calibration stability. Some research facilities employ specialized enclosures or dedicated rooms with controlled airflow patterns to minimize these disruptions.

Acoustic noise represents a frequently overlooked environmental factor that can compromise AFM calibration stability. Sound waves can induce mechanical vibrations in the AFM components, particularly affecting the cantilever and laser alignment system. Laboratory design should incorporate acoustic dampening materials, and sensitive measurements may require scheduling during periods of minimal activity to reduce ambient noise levels.

Electromagnetic interference (EMI) from nearby electronic equipment, power lines, or wireless communication devices can disrupt the electronic components of the AFM system, including the laser detection mechanism. Proper grounding, shielding, and strategic placement of the AFM away from significant EMI sources are essential practices for maintaining calibration stability in challenging electromagnetic environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!