How To Achieve Consistent Results In Atomic Force Microscopy — Guidelines

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Technology Background and Objectives

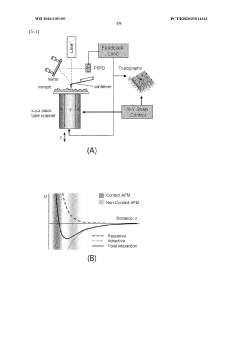

Atomic Force Microscopy (AFM) emerged in the mid-1980s as a revolutionary imaging technique capable of visualizing surfaces at the nanoscale. Developed by Gerd Binnig, Calvin Quate, and Christoph Gerber in 1986, AFM evolved from Scanning Tunneling Microscopy (STM) but offered the significant advantage of imaging non-conductive samples. Over the past three decades, AFM technology has undergone substantial refinements in probe design, feedback systems, and operational modes, transforming from a specialized research tool into an essential analytical instrument across multiple scientific disciplines.

The technological evolution of AFM has been characterized by continuous improvements in resolution, scanning speed, and environmental adaptability. Early AFM systems operated primarily in contact mode with limited resolution and sample damage concerns. Modern systems incorporate advanced operational modes including tapping mode, non-contact mode, and specialized techniques such as Kelvin Probe Force Microscopy (KPFM) and Magnetic Force Microscopy (MFM), enabling multi-parameter surface characterization beyond mere topography.

Recent technological trends in AFM development focus on automation, reproducibility, and quantitative measurement capabilities. High-speed AFM systems now allow for real-time observation of dynamic processes at the molecular level. Additionally, integration with complementary techniques such as Raman spectroscopy and infrared spectroscopy has expanded the analytical capabilities of AFM platforms, providing correlated chemical and mechanical information at nanoscale spatial resolution.

Despite these advancements, achieving consistent and reproducible results remains a significant challenge in AFM applications. Variations in probe characteristics, environmental conditions, sample preparation methods, and operator expertise contribute to measurement inconsistencies that limit quantitative analysis and inter-laboratory comparability. These challenges are particularly pronounced in emerging applications such as biological imaging, nanomechanical characterization, and industrial quality control.

The primary objective of current AFM technology development is to establish standardized protocols and methodologies that ensure measurement reliability and reproducibility across different instruments and operators. This includes the development of calibration standards, automated parameter optimization algorithms, and robust data processing techniques that minimize subjective interpretation. Additionally, there is a growing emphasis on enhancing user accessibility through simplified interfaces and intelligent feedback systems that adapt to varying sample characteristics.

Future technological goals include further improvements in spatial resolution beyond current limitations, increased scanning speeds without compromising measurement quality, and enhanced capabilities for in-situ and in-operando measurements under diverse environmental conditions. The integration of machine learning algorithms for automated feature recognition and anomaly detection represents another frontier in AFM technology development, potentially revolutionizing data interpretation and analysis workflows.

The technological evolution of AFM has been characterized by continuous improvements in resolution, scanning speed, and environmental adaptability. Early AFM systems operated primarily in contact mode with limited resolution and sample damage concerns. Modern systems incorporate advanced operational modes including tapping mode, non-contact mode, and specialized techniques such as Kelvin Probe Force Microscopy (KPFM) and Magnetic Force Microscopy (MFM), enabling multi-parameter surface characterization beyond mere topography.

Recent technological trends in AFM development focus on automation, reproducibility, and quantitative measurement capabilities. High-speed AFM systems now allow for real-time observation of dynamic processes at the molecular level. Additionally, integration with complementary techniques such as Raman spectroscopy and infrared spectroscopy has expanded the analytical capabilities of AFM platforms, providing correlated chemical and mechanical information at nanoscale spatial resolution.

Despite these advancements, achieving consistent and reproducible results remains a significant challenge in AFM applications. Variations in probe characteristics, environmental conditions, sample preparation methods, and operator expertise contribute to measurement inconsistencies that limit quantitative analysis and inter-laboratory comparability. These challenges are particularly pronounced in emerging applications such as biological imaging, nanomechanical characterization, and industrial quality control.

The primary objective of current AFM technology development is to establish standardized protocols and methodologies that ensure measurement reliability and reproducibility across different instruments and operators. This includes the development of calibration standards, automated parameter optimization algorithms, and robust data processing techniques that minimize subjective interpretation. Additionally, there is a growing emphasis on enhancing user accessibility through simplified interfaces and intelligent feedback systems that adapt to varying sample characteristics.

Future technological goals include further improvements in spatial resolution beyond current limitations, increased scanning speeds without compromising measurement quality, and enhanced capabilities for in-situ and in-operando measurements under diverse environmental conditions. The integration of machine learning algorithms for automated feature recognition and anomaly detection represents another frontier in AFM technology development, potentially revolutionizing data interpretation and analysis workflows.

Market Applications and Demand Analysis

The Atomic Force Microscopy (AFM) market has experienced significant growth over the past decade, driven by increasing demand for high-resolution imaging and characterization techniques across multiple industries. The global AFM market was valued at approximately 570 million USD in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030, reflecting the expanding applications and technological advancements in this field.

The semiconductor and electronics industry represents the largest market segment for AFM technology, accounting for nearly 35% of the total market share. This dominance stems from the critical need for nanoscale surface characterization in semiconductor manufacturing, where consistent AFM results directly impact quality control processes and yield optimization. As semiconductor devices continue to shrink in size, the demand for reliable AFM techniques with consistent results becomes increasingly crucial.

Life sciences and pharmaceutical research constitute the second-largest application segment, with growing adoption rates for studying biological samples, drug delivery systems, and biomaterials. The ability to achieve consistent AFM results in varying environmental conditions is particularly valuable for researchers working with sensitive biological specimens. Market analysis indicates that pharmaceutical companies are increasingly investing in advanced AFM systems that offer reproducible results for drug development and quality assurance.

Materials science applications represent another significant market segment, where AFM is extensively used for surface characterization, mechanical property measurements, and failure analysis. Industries such as aerospace, automotive, and energy storage rely on consistent AFM results to validate material performance and ensure product reliability. The growing focus on advanced materials development, including composites and nanomaterials, has further expanded the demand for reliable AFM techniques.

Academic and research institutions continue to be major consumers of AFM technology, driving innovation and expanding application boundaries. The educational sector's demand for user-friendly AFM systems that deliver consistent results regardless of operator expertise has led to the development of automated calibration systems and standardized protocols.

Regional market analysis reveals that North America and Europe currently dominate the AFM market, accounting for approximately 60% of global revenue. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding semiconductor manufacturing capabilities, increasing R&D investments, and growing adoption of nanotechnology applications in countries like China, Japan, and South Korea.

The semiconductor and electronics industry represents the largest market segment for AFM technology, accounting for nearly 35% of the total market share. This dominance stems from the critical need for nanoscale surface characterization in semiconductor manufacturing, where consistent AFM results directly impact quality control processes and yield optimization. As semiconductor devices continue to shrink in size, the demand for reliable AFM techniques with consistent results becomes increasingly crucial.

Life sciences and pharmaceutical research constitute the second-largest application segment, with growing adoption rates for studying biological samples, drug delivery systems, and biomaterials. The ability to achieve consistent AFM results in varying environmental conditions is particularly valuable for researchers working with sensitive biological specimens. Market analysis indicates that pharmaceutical companies are increasingly investing in advanced AFM systems that offer reproducible results for drug development and quality assurance.

Materials science applications represent another significant market segment, where AFM is extensively used for surface characterization, mechanical property measurements, and failure analysis. Industries such as aerospace, automotive, and energy storage rely on consistent AFM results to validate material performance and ensure product reliability. The growing focus on advanced materials development, including composites and nanomaterials, has further expanded the demand for reliable AFM techniques.

Academic and research institutions continue to be major consumers of AFM technology, driving innovation and expanding application boundaries. The educational sector's demand for user-friendly AFM systems that deliver consistent results regardless of operator expertise has led to the development of automated calibration systems and standardized protocols.

Regional market analysis reveals that North America and Europe currently dominate the AFM market, accounting for approximately 60% of global revenue. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding semiconductor manufacturing capabilities, increasing R&D investments, and growing adoption of nanotechnology applications in countries like China, Japan, and South Korea.

Current AFM Challenges and Technical Limitations

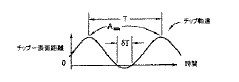

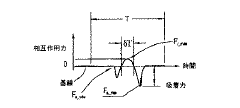

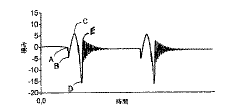

Despite significant advancements in Atomic Force Microscopy (AFM) technology over the past three decades, several persistent challenges continue to limit the achievement of consistent results across experiments and laboratories. One of the most significant limitations is tip-sample interaction variability, which introduces inconsistencies in measurements. AFM tips undergo wear and contamination during scanning, causing gradual changes in tip geometry and surface chemistry that affect force interactions and ultimately image quality.

Environmental factors present another major challenge, as temperature fluctuations, humidity variations, and acoustic vibrations can significantly impact measurement stability. Even minor environmental changes can cause thermal drift in the piezoelectric scanners, leading to image distortion and reduced precision in nanoscale measurements. This is particularly problematic for time-series experiments requiring extended observation periods.

Calibration inconsistencies across instruments represent a substantial obstacle to reproducibility. Different calibration methods and standards used across laboratories result in systematic variations in force measurements and dimensional analysis. The lack of universally accepted calibration protocols makes cross-laboratory data comparison difficult and undermines confidence in published results.

Sample preparation techniques vary widely among researchers, introducing another source of variability. Differences in sample mounting, cleaning procedures, and storage conditions can significantly alter surface properties and measurement outcomes. This variability is especially pronounced when working with biological samples or environmentally sensitive materials.

Operator expertise and technique differences contribute substantially to result inconsistency. AFM requires significant technical skill, with parameters such as scanning speed, feedback settings, and imaging mode selection heavily influencing data quality. The subjective nature of parameter optimization creates a dependency on operator experience that complicates standardization efforts.

Data processing and analysis methods further compound reproducibility issues. The diversity of filtering algorithms, flattening procedures, and feature extraction methods leads to different interpretations of the same raw data. Without standardized analysis protocols, meaningful comparison between studies becomes challenging.

Technical limitations in current AFM systems include scanner nonlinearities and hysteresis effects that introduce positional inaccuracies. Additionally, the trade-off between scanning speed and image resolution remains a significant constraint, particularly for dynamic biological processes requiring both high temporal and spatial resolution. These fundamental limitations necessitate careful experimental design and awareness of inherent measurement uncertainties.

Environmental factors present another major challenge, as temperature fluctuations, humidity variations, and acoustic vibrations can significantly impact measurement stability. Even minor environmental changes can cause thermal drift in the piezoelectric scanners, leading to image distortion and reduced precision in nanoscale measurements. This is particularly problematic for time-series experiments requiring extended observation periods.

Calibration inconsistencies across instruments represent a substantial obstacle to reproducibility. Different calibration methods and standards used across laboratories result in systematic variations in force measurements and dimensional analysis. The lack of universally accepted calibration protocols makes cross-laboratory data comparison difficult and undermines confidence in published results.

Sample preparation techniques vary widely among researchers, introducing another source of variability. Differences in sample mounting, cleaning procedures, and storage conditions can significantly alter surface properties and measurement outcomes. This variability is especially pronounced when working with biological samples or environmentally sensitive materials.

Operator expertise and technique differences contribute substantially to result inconsistency. AFM requires significant technical skill, with parameters such as scanning speed, feedback settings, and imaging mode selection heavily influencing data quality. The subjective nature of parameter optimization creates a dependency on operator experience that complicates standardization efforts.

Data processing and analysis methods further compound reproducibility issues. The diversity of filtering algorithms, flattening procedures, and feature extraction methods leads to different interpretations of the same raw data. Without standardized analysis protocols, meaningful comparison between studies becomes challenging.

Technical limitations in current AFM systems include scanner nonlinearities and hysteresis effects that introduce positional inaccuracies. Additionally, the trade-off between scanning speed and image resolution remains a significant constraint, particularly for dynamic biological processes requiring both high temporal and spatial resolution. These fundamental limitations necessitate careful experimental design and awareness of inherent measurement uncertainties.

Best Practices for AFM Measurement Consistency

01 Calibration methods for AFM consistency

Various calibration techniques are employed to ensure consistency in atomic force microscopy measurements. These methods include using reference standards, automated calibration procedures, and compensation algorithms to correct for instrument drift and environmental variations. Proper calibration is essential for obtaining reproducible and reliable AFM data across different samples and measurement conditions.- Calibration methods for AFM consistency: Various calibration techniques are employed to ensure consistency in atomic force microscopy measurements. These methods include using reference standards, automated calibration procedures, and compensation algorithms to correct for instrument drift and environmental variations. Proper calibration is essential for obtaining reproducible and reliable AFM data across different samples and measurement sessions.

- Environmental control systems for AFM stability: Environmental factors significantly impact AFM measurement consistency. Systems designed to control temperature, humidity, vibration, and acoustic noise help maintain stable measurement conditions. These control systems include isolation platforms, temperature-regulated chambers, and humidity controllers that minimize external disturbances, ensuring more consistent and reliable AFM measurements.

- Advanced probe technologies for measurement consistency: Specialized probe designs and materials enhance measurement consistency in atomic force microscopy. These include probes with improved wear resistance, self-calibrating cantilevers, and functionalized tips that maintain consistent interaction with sample surfaces. Advanced probe technologies reduce tip degradation during scanning and provide more uniform force application across measurements.

- Software algorithms for data processing and consistency: Sophisticated software algorithms play a crucial role in ensuring AFM measurement consistency. These include drift correction algorithms, noise filtering techniques, and automated data processing methods that standardize analysis procedures. The software solutions help normalize raw data, correct for instrumental artifacts, and enable consistent interpretation of AFM measurements across different operators and instruments.

- Feedback control systems for force regulation: Advanced feedback control systems maintain consistent tip-sample interactions during AFM measurements. These systems continuously monitor and adjust the applied force to compensate for variations in sample topography and mechanical properties. Improved feedback mechanisms with faster response times and higher sensitivity ensure more uniform force application throughout the scanning process, resulting in more consistent and accurate AFM measurements.

02 Environmental control systems for AFM

Environmental factors significantly impact AFM measurement consistency. Specialized systems have been developed to control temperature, humidity, vibration, and electromagnetic interference during AFM operation. These environmental control systems help maintain stable measurement conditions, reducing artifacts and improving the reproducibility of AFM data, particularly for sensitive samples or high-resolution imaging.Expand Specific Solutions03 Advanced probe technologies for consistent measurements

Innovations in AFM probe design and fabrication contribute to measurement consistency. These include specialized tip geometries, functionalized probes, and wear-resistant coatings that maintain tip shape over extended use. Advanced probe technologies help ensure consistent tip-sample interactions, reducing variability in force measurements and improving the reliability of topographical and mechanical property data.Expand Specific Solutions04 Software algorithms for data consistency

Sophisticated software algorithms have been developed to enhance AFM measurement consistency. These include drift correction, noise filtering, automated feature recognition, and statistical analysis tools. Such algorithms help process raw AFM data to compensate for instrumental artifacts, normalize measurements across different sessions, and extract consistent quantitative information from AFM images.Expand Specific Solutions05 Standardized protocols for AFM operation

Standardized protocols have been established to ensure consistency in AFM measurements across different instruments and operators. These protocols specify sample preparation methods, instrument settings, approach procedures, and data analysis techniques. Following standardized protocols helps minimize variability in AFM results, enabling more reliable comparisons between measurements performed at different times or locations.Expand Specific Solutions

Leading AFM Instrument Manufacturers and Research Groups

Atomic Force Microscopy (AFM) is currently in a mature growth phase, with increasing adoption across research and industrial applications. The global AFM market is estimated at approximately $500 million, with steady annual growth of 5-7%. The competitive landscape features established instrumentation leaders like Bruker Nano, JEOL, and Shimadzu providing comprehensive AFM solutions, while IBM and Applied Materials focus on advanced research applications. Academic institutions including Harvard, Yale, and Zhejiang University contribute significantly to methodology development. Recent technological advancements from Keysight Technologies and Agilent have improved measurement consistency, while specialized players like Carbon Nanoprobes and Artidis AG are developing novel probe technologies and biomedical applications, driving the field toward greater measurement reliability and expanded application areas.

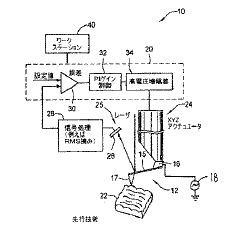

Leica Microsystems CMS GmbH

Technical Solution: Leica Microsystems has developed integrated AFM solutions that focus on achieving measurement consistency through their correlative microscopy approach. Their systems combine optical microscopy with AFM capabilities, allowing precise positioning and region-of-interest targeting that improves measurement reproducibility. Leica's AFM technology incorporates active Q-control for cantilever dynamics, enabling consistent oscillation parameters even when transitioning between different sample regions or materials. Their systems feature automated laser alignment and detector optimization routines that ensure consistent optical lever sensitivity across measurements. Leica has implemented advanced drift correction algorithms that use optical reference markers to maintain position accuracy during extended measurements. Their software includes automated parameter optimization based on sample characteristics, reducing operator variability while ensuring consistent image quality and force control across different users and experiments.

Strengths: Seamless integration with optical microscopy provides contextual information that improves targeting consistency; automated alignment procedures reduce setup variability; intuitive software interface reduces training requirements. Weaknesses: Primary focus on biological applications may limit versatility for material science applications; optical integration adds complexity and cost; fewer specialized AFM modes compared to dedicated AFM manufacturers.

Keysight Technologies, Inc.

Technical Solution: Keysight Technologies has pioneered the development of advanced AFM systems focused on measurement consistency through their 9500 and 7500 series microscopes. Their proprietary MAC Mode (Magnetic AC) technology uses a magnetically driven cantilever approach that eliminates the inconsistencies associated with traditional acoustic excitation methods. This provides more accurate amplitude and phase measurements, especially in liquid environments. Keysight's Quick Scan technology enables rapid imaging with automatic parameter optimization to maintain consistent image quality across varying sample types. Their systems incorporate active vibration isolation and temperature control systems that minimize environmental variations, a critical factor for achieving reproducible results. Keysight also offers automated tip characterization and calibration routines that account for tip wear and geometry changes during extended measurements, ensuring measurement consistency throughout experimental sessions.

Strengths: Superior performance in liquid environments makes it ideal for biological applications; integrated environmental controls reduce external variables; comprehensive software tools simplify complex measurements. Weaknesses: Systems require significant expertise for optimal operation despite automation features; higher initial investment compared to simpler systems; specialized magnetic cantilevers add to operational costs.

Critical Parameters Affecting AFM Measurement Reliability

Scanning probe microscope and method of operating the same

PatentActiveJP2018036272A

Innovation

- The implementation of Peak Force Tapping (PFT) Mode, which uses instantaneous interaction force control to minimize parasitic coupling and automate feedback adjustments, allowing for high-resolution imaging with minimal user intervention and reduced tip-sample forces.

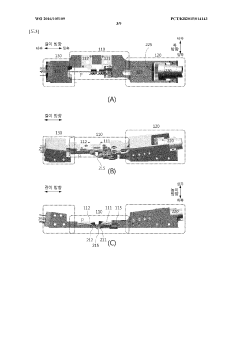

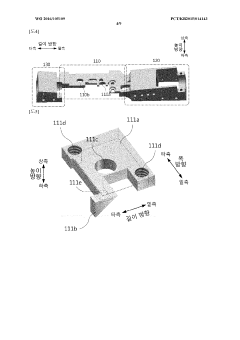

Head-integrated atomic force microscope and composite microscope including same

PatentWO2016105109A1

Innovation

- The development of a head-integrated atomic force microscope with an optimized arrangement of observation parts in a compact, lightweight integrated body, featuring a plate-shaped AFM head with a built-in mirror and light source, and a position-sensitive photo detector, which reduces weight, volume, and resonance frequency, allowing for improved alignment and high-speed scanning.

Standardization Efforts in AFM Methodology

The standardization of Atomic Force Microscopy (AFM) methodologies has become increasingly important as the technique has matured and found applications across diverse scientific disciplines. Several international organizations have spearheaded efforts to establish common protocols and guidelines for AFM measurements, notably the International Organization for Standardization (ISO) through its technical committee TC/201 on surface chemical analysis, which has published multiple standards specific to AFM operations.

The American Society for Testing and Materials (ASTM) has also contributed significantly through its E42 committee on surface analysis, developing standards for calibration procedures and measurement protocols. These standards address critical aspects such as probe characterization, scanner calibration, and environmental control parameters that directly impact measurement consistency.

In Europe, the European Materials Characterisation Council has established working groups dedicated to nanoscale measurements, including AFM standardization. Their efforts focus on creating reference materials and procedures that enable cross-laboratory validation of results, particularly important for industrial applications where reproducibility is paramount.

Academic consortia have complemented these formal standardization initiatives by developing open-source software tools for data processing and analysis. Notable examples include the OpenAFM project and GWYDDION, which implement standardized algorithms for image correction and feature extraction, reducing variability introduced during post-processing stages.

Manufacturer-led standardization has emerged as another important avenue, with major AFM instrument producers collaborating to establish common calibration methods and performance metrics. This industry-driven approach has helped address practical challenges in day-to-day operations that formal standards might overlook.

Recent developments include the creation of certified reference materials specifically designed for AFM calibration across different measurement modes. These materials provide traceable standards for parameters such as height, roughness, and mechanical properties, enabling more reliable inter-laboratory comparisons and quality assurance procedures.

Despite these advances, challenges remain in standardizing biological AFM applications, where sample preparation variability and the dynamic nature of specimens introduce additional complexity. Specialized working groups are now addressing these domain-specific challenges, developing protocols tailored to biological systems while maintaining alignment with broader AFM standardization frameworks.

The American Society for Testing and Materials (ASTM) has also contributed significantly through its E42 committee on surface analysis, developing standards for calibration procedures and measurement protocols. These standards address critical aspects such as probe characterization, scanner calibration, and environmental control parameters that directly impact measurement consistency.

In Europe, the European Materials Characterisation Council has established working groups dedicated to nanoscale measurements, including AFM standardization. Their efforts focus on creating reference materials and procedures that enable cross-laboratory validation of results, particularly important for industrial applications where reproducibility is paramount.

Academic consortia have complemented these formal standardization initiatives by developing open-source software tools for data processing and analysis. Notable examples include the OpenAFM project and GWYDDION, which implement standardized algorithms for image correction and feature extraction, reducing variability introduced during post-processing stages.

Manufacturer-led standardization has emerged as another important avenue, with major AFM instrument producers collaborating to establish common calibration methods and performance metrics. This industry-driven approach has helped address practical challenges in day-to-day operations that formal standards might overlook.

Recent developments include the creation of certified reference materials specifically designed for AFM calibration across different measurement modes. These materials provide traceable standards for parameters such as height, roughness, and mechanical properties, enabling more reliable inter-laboratory comparisons and quality assurance procedures.

Despite these advances, challenges remain in standardizing biological AFM applications, where sample preparation variability and the dynamic nature of specimens introduce additional complexity. Specialized working groups are now addressing these domain-specific challenges, developing protocols tailored to biological systems while maintaining alignment with broader AFM standardization frameworks.

Environmental Factors Impact on AFM Measurements

Environmental conditions significantly influence the accuracy and reproducibility of Atomic Force Microscopy (AFM) measurements. Temperature fluctuations represent one of the most critical factors affecting AFM performance. Even minor temperature variations can cause thermal drift in the scanning system, resulting in image distortion and measurement inaccuracies. Research indicates that a temperature stability of ±0.1°C is often necessary for high-resolution imaging, particularly for measurements extending beyond several minutes.

Humidity levels similarly impact AFM operations through multiple mechanisms. High humidity environments can lead to condensation on samples and tips, creating capillary forces that interfere with tip-sample interactions. Conversely, extremely low humidity may generate problematic electrostatic charges. Optimal humidity control between 30-50% is generally recommended for most applications, though specific samples may require customized environmental conditions.

Acoustic vibrations and mechanical disturbances constitute another significant challenge for AFM measurements. External vibrations from laboratory equipment, building systems, or human activity can be transmitted through the instrument, causing noise artifacts and reducing resolution. Implementation of vibration isolation systems becomes essential, with passive pneumatic tables providing basic protection and active vibration cancellation systems offering superior performance for demanding applications.

Air quality and particulate contamination must also be carefully managed. Airborne particles can deposit on samples or tips, compromising measurement integrity. Many advanced AFM setups incorporate HEPA filtration or operate within cleanroom environments to mitigate these risks. For particularly sensitive measurements, vacuum or controlled gas environments may be necessary to eliminate air-related artifacts.

Electromagnetic interference (EMI) from nearby electronic equipment, power lines, or wireless communication devices can introduce noise into AFM measurements. Proper electrical grounding, shielding, and strategic placement of the AFM system away from EMI sources help minimize these effects. In some cases, dedicated Faraday cages may be required to achieve optimal electromagnetic isolation.

Consistent AFM results therefore demand comprehensive environmental control strategies. Modern AFM facilities increasingly incorporate dedicated environmental chambers with integrated temperature, humidity, and vibration control systems. Real-time environmental monitoring coupled with automated compensation algorithms can further enhance measurement stability. For the most demanding applications, specialized facilities with foundation-level vibration isolation, EMI shielding, and precise climate control may be necessary to achieve the highest levels of measurement consistency and reproducibility.

Humidity levels similarly impact AFM operations through multiple mechanisms. High humidity environments can lead to condensation on samples and tips, creating capillary forces that interfere with tip-sample interactions. Conversely, extremely low humidity may generate problematic electrostatic charges. Optimal humidity control between 30-50% is generally recommended for most applications, though specific samples may require customized environmental conditions.

Acoustic vibrations and mechanical disturbances constitute another significant challenge for AFM measurements. External vibrations from laboratory equipment, building systems, or human activity can be transmitted through the instrument, causing noise artifacts and reducing resolution. Implementation of vibration isolation systems becomes essential, with passive pneumatic tables providing basic protection and active vibration cancellation systems offering superior performance for demanding applications.

Air quality and particulate contamination must also be carefully managed. Airborne particles can deposit on samples or tips, compromising measurement integrity. Many advanced AFM setups incorporate HEPA filtration or operate within cleanroom environments to mitigate these risks. For particularly sensitive measurements, vacuum or controlled gas environments may be necessary to eliminate air-related artifacts.

Electromagnetic interference (EMI) from nearby electronic equipment, power lines, or wireless communication devices can introduce noise into AFM measurements. Proper electrical grounding, shielding, and strategic placement of the AFM system away from EMI sources help minimize these effects. In some cases, dedicated Faraday cages may be required to achieve optimal electromagnetic isolation.

Consistent AFM results therefore demand comprehensive environmental control strategies. Modern AFM facilities increasingly incorporate dedicated environmental chambers with integrated temperature, humidity, and vibration control systems. Real-time environmental monitoring coupled with automated compensation algorithms can further enhance measurement stability. For the most demanding applications, specialized facilities with foundation-level vibration isolation, EMI shielding, and precise climate control may be necessary to achieve the highest levels of measurement consistency and reproducibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!