How To Quantify Mechanical Properties Using Atomic Force Microscopy — Criteria

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Mechanical Quantification Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Binnig, Quate, and Gerber. Initially developed as an imaging tool, AFM has transformed into a versatile platform for quantitative mechanical property measurements at the nanoscale. This technological evolution represents a paradigm shift from purely topographical imaging to comprehensive mechanical characterization of materials.

The fundamental principle of AFM mechanical quantification relies on measuring the interaction forces between a sharp probe and sample surface. These interactions, governed by various force fields including van der Waals forces, electrostatic forces, and mechanical contact forces, provide valuable insights into material properties such as elasticity, adhesion, viscoelasticity, and hardness.

Recent technological advancements have significantly enhanced AFM's capabilities for mechanical property quantification. The development of specialized cantilevers, improved feedback systems, and advanced operational modes like force spectroscopy, PeakForce QNM, and bimodal AFM have expanded the range of measurable properties and improved measurement accuracy. These innovations have enabled researchers to probe mechanical properties with unprecedented spatial resolution and force sensitivity.

The primary objective of mechanical property quantification using AFM is to establish reliable, reproducible, and accurate methodologies for characterizing materials across diverse fields. This includes developing standardized protocols for sample preparation, measurement procedures, and data analysis to ensure consistency and comparability of results across different laboratories and experimental setups.

Another critical goal is to bridge the gap between nanoscale measurements and macroscale material behavior. This involves developing robust theoretical frameworks and computational models that can effectively translate AFM-derived mechanical data into meaningful material parameters that correlate with bulk properties and functional performance.

The field is currently trending toward multiparametric characterization, where multiple mechanical properties are simultaneously measured to provide a more comprehensive understanding of material behavior. This approach is particularly valuable for complex, heterogeneous materials such as biological tissues, composite materials, and advanced functional materials.

Looking forward, the integration of AFM mechanical quantification with complementary techniques such as Raman spectroscopy, infrared spectroscopy, and electron microscopy represents a promising direction for obtaining correlative information about material structure, composition, and mechanical properties at matching spatial scales.

The fundamental principle of AFM mechanical quantification relies on measuring the interaction forces between a sharp probe and sample surface. These interactions, governed by various force fields including van der Waals forces, electrostatic forces, and mechanical contact forces, provide valuable insights into material properties such as elasticity, adhesion, viscoelasticity, and hardness.

Recent technological advancements have significantly enhanced AFM's capabilities for mechanical property quantification. The development of specialized cantilevers, improved feedback systems, and advanced operational modes like force spectroscopy, PeakForce QNM, and bimodal AFM have expanded the range of measurable properties and improved measurement accuracy. These innovations have enabled researchers to probe mechanical properties with unprecedented spatial resolution and force sensitivity.

The primary objective of mechanical property quantification using AFM is to establish reliable, reproducible, and accurate methodologies for characterizing materials across diverse fields. This includes developing standardized protocols for sample preparation, measurement procedures, and data analysis to ensure consistency and comparability of results across different laboratories and experimental setups.

Another critical goal is to bridge the gap between nanoscale measurements and macroscale material behavior. This involves developing robust theoretical frameworks and computational models that can effectively translate AFM-derived mechanical data into meaningful material parameters that correlate with bulk properties and functional performance.

The field is currently trending toward multiparametric characterization, where multiple mechanical properties are simultaneously measured to provide a more comprehensive understanding of material behavior. This approach is particularly valuable for complex, heterogeneous materials such as biological tissues, composite materials, and advanced functional materials.

Looking forward, the integration of AFM mechanical quantification with complementary techniques such as Raman spectroscopy, infrared spectroscopy, and electron microscopy represents a promising direction for obtaining correlative information about material structure, composition, and mechanical properties at matching spatial scales.

Market Applications and Demand for AFM Mechanical Characterization

The market for Atomic Force Microscopy (AFM) mechanical characterization has expanded significantly across multiple industries, driven by increasing demands for nanoscale material analysis. The biomedical sector represents one of the largest application areas, with AFM mechanical measurements being crucial for characterizing biological samples including cells, tissues, and biomaterials. This capability has proven invaluable for cancer research, where AFM can detect mechanical differences between normal and cancerous cells, and for drug development, where it helps evaluate drug effects on cellular mechanics.

In the semiconductor and electronics industry, AFM mechanical characterization has become essential for quality control and failure analysis. As device dimensions continue to shrink below 5nm, traditional characterization methods become inadequate, making AFM's nanoscale resolution increasingly valuable. The market in this sector is projected to grow substantially as manufacturers seek more precise methods to measure thin film properties, interface mechanics, and nanoscale defects.

The polymer and composite materials industry has also embraced AFM mechanical characterization for product development and quality assurance. Manufacturers utilize AFM to analyze local mechanical properties, phase separation, and interfacial adhesion in complex material systems. This application has seen particular growth in high-performance materials development for aerospace, automotive, and consumer electronics.

Nanomedicine represents an emerging market with significant potential, where AFM mechanical measurements help characterize drug delivery systems, evaluate cellular uptake mechanisms, and assess biocompatibility of nanomaterials. Research institutions and pharmaceutical companies are increasingly investing in AFM technology for these applications.

The global demand for AFM mechanical characterization is further stimulated by advancements in high-speed AFM technologies, which have reduced measurement times and increased throughput. This has expanded the practical applications beyond research laboratories into industrial quality control environments, broadening the potential market considerably.

Regional market analysis indicates strong growth in Asia-Pacific regions, particularly China, Japan, and South Korea, where significant investments in nanotechnology research and semiconductor manufacturing are driving AFM adoption. North America and Europe maintain substantial market shares, primarily led by biomedical research applications and materials science advancements.

Customer requirements are evolving toward more automated, user-friendly systems with improved data analysis capabilities. There is growing demand for AFM systems that can provide quantitative mechanical property measurements with higher throughput, better reproducibility, and simplified operation protocols that don't require extensive specialized training.

In the semiconductor and electronics industry, AFM mechanical characterization has become essential for quality control and failure analysis. As device dimensions continue to shrink below 5nm, traditional characterization methods become inadequate, making AFM's nanoscale resolution increasingly valuable. The market in this sector is projected to grow substantially as manufacturers seek more precise methods to measure thin film properties, interface mechanics, and nanoscale defects.

The polymer and composite materials industry has also embraced AFM mechanical characterization for product development and quality assurance. Manufacturers utilize AFM to analyze local mechanical properties, phase separation, and interfacial adhesion in complex material systems. This application has seen particular growth in high-performance materials development for aerospace, automotive, and consumer electronics.

Nanomedicine represents an emerging market with significant potential, where AFM mechanical measurements help characterize drug delivery systems, evaluate cellular uptake mechanisms, and assess biocompatibility of nanomaterials. Research institutions and pharmaceutical companies are increasingly investing in AFM technology for these applications.

The global demand for AFM mechanical characterization is further stimulated by advancements in high-speed AFM technologies, which have reduced measurement times and increased throughput. This has expanded the practical applications beyond research laboratories into industrial quality control environments, broadening the potential market considerably.

Regional market analysis indicates strong growth in Asia-Pacific regions, particularly China, Japan, and South Korea, where significant investments in nanotechnology research and semiconductor manufacturing are driving AFM adoption. North America and Europe maintain substantial market shares, primarily led by biomedical research applications and materials science advancements.

Customer requirements are evolving toward more automated, user-friendly systems with improved data analysis capabilities. There is growing demand for AFM systems that can provide quantitative mechanical property measurements with higher throughput, better reproducibility, and simplified operation protocols that don't require extensive specialized training.

Current Challenges in AFM-Based Mechanical Property Measurement

Despite significant advancements in Atomic Force Microscopy (AFM) technology, several critical challenges persist in accurately quantifying mechanical properties. One fundamental issue is the complex contact mechanics between the AFM tip and sample surface. The Hertz model, commonly used for data interpretation, assumes purely elastic deformation, homogeneous material properties, and a well-defined tip geometry—assumptions rarely met in real-world samples, particularly biological specimens or composite materials.

Tip characterization represents another significant challenge. The exact geometry and dimensions of AFM tips can vary considerably between manufacturers and even within the same batch. Tips also experience wear and contamination during measurements, altering their effective radius and mechanical properties. These variations directly impact force-distance curve interpretations and subsequent mechanical property calculations.

Sample preparation and environmental conditions introduce additional variables. Hydration levels, temperature fluctuations, and ionic strength can dramatically alter the mechanical response of biological samples. For polymers and soft materials, viscoelastic behaviors complicate measurements as these materials exhibit time-dependent mechanical responses that standard models fail to capture adequately.

Data processing and interpretation remain problematic areas. The conversion of raw force curves to quantitative mechanical properties involves multiple processing steps, each introducing potential errors. Different fitting algorithms and parameter selection criteria can yield significantly different results from identical raw data. This lack of standardization makes cross-laboratory comparisons challenging and raises questions about reproducibility.

Scale-dependent effects further complicate measurements. Nanoscale mechanical properties often differ from bulk properties due to surface effects, local heterogeneities, and structural hierarchies. Determining which scale is most relevant for specific applications presents a conceptual challenge that extends beyond technical limitations.

Calibration procedures, particularly for cantilever spring constants and deflection sensitivity, introduce systematic errors that propagate through all subsequent calculations. Current calibration methods can have uncertainties of 10-20%, directly affecting the accuracy of derived mechanical properties.

The integration of AFM with complementary techniques remains underdeveloped. Correlative approaches combining AFM with optical or electron microscopy, spectroscopic methods, or computational modeling could provide more comprehensive characterization but face technical hurdles in data integration and interpretation.

Addressing these challenges requires interdisciplinary approaches combining advances in instrumentation, theoretical modeling, and data analysis methodologies. Standardization efforts across the scientific community are essential to establish reliable protocols for mechanical property quantification using AFM.

Tip characterization represents another significant challenge. The exact geometry and dimensions of AFM tips can vary considerably between manufacturers and even within the same batch. Tips also experience wear and contamination during measurements, altering their effective radius and mechanical properties. These variations directly impact force-distance curve interpretations and subsequent mechanical property calculations.

Sample preparation and environmental conditions introduce additional variables. Hydration levels, temperature fluctuations, and ionic strength can dramatically alter the mechanical response of biological samples. For polymers and soft materials, viscoelastic behaviors complicate measurements as these materials exhibit time-dependent mechanical responses that standard models fail to capture adequately.

Data processing and interpretation remain problematic areas. The conversion of raw force curves to quantitative mechanical properties involves multiple processing steps, each introducing potential errors. Different fitting algorithms and parameter selection criteria can yield significantly different results from identical raw data. This lack of standardization makes cross-laboratory comparisons challenging and raises questions about reproducibility.

Scale-dependent effects further complicate measurements. Nanoscale mechanical properties often differ from bulk properties due to surface effects, local heterogeneities, and structural hierarchies. Determining which scale is most relevant for specific applications presents a conceptual challenge that extends beyond technical limitations.

Calibration procedures, particularly for cantilever spring constants and deflection sensitivity, introduce systematic errors that propagate through all subsequent calculations. Current calibration methods can have uncertainties of 10-20%, directly affecting the accuracy of derived mechanical properties.

The integration of AFM with complementary techniques remains underdeveloped. Correlative approaches combining AFM with optical or electron microscopy, spectroscopic methods, or computational modeling could provide more comprehensive characterization but face technical hurdles in data integration and interpretation.

Addressing these challenges requires interdisciplinary approaches combining advances in instrumentation, theoretical modeling, and data analysis methodologies. Standardization efforts across the scientific community are essential to establish reliable protocols for mechanical property quantification using AFM.

Established Protocols for Mechanical Property Quantification

01 AFM techniques for measuring mechanical properties

Atomic Force Microscopy (AFM) can be used to measure various mechanical properties of materials at the nanoscale. These techniques involve applying controlled forces to samples and measuring the resulting deformations. The methods include force spectroscopy, nanoindentation, and dynamic modes that can quantify elasticity, hardness, stiffness, and viscoelastic properties of materials with high spatial resolution.- AFM techniques for measuring mechanical properties: Atomic Force Microscopy (AFM) can be used to measure various mechanical properties of materials at the nanoscale. These techniques involve applying controlled forces to sample surfaces and analyzing the resulting deformations. Methods include force spectroscopy, nanoindentation, and dynamic modes that can determine elasticity, hardness, stiffness, and viscoelastic properties of materials with high spatial resolution.

- AFM probe modifications for mechanical property measurements: Specialized AFM probes can be designed and modified to enhance mechanical property measurements. These modifications include functionalized tips, cantilevers with specific spring constants, and probes with integrated sensors. Such customized probes enable more accurate and sensitive measurements of mechanical properties across different sample types, from soft biological materials to hard semiconductor surfaces.

- Data processing and analysis methods for AFM mechanical measurements: Advanced algorithms and computational methods are essential for processing and analyzing AFM mechanical property data. These include force curve analysis, statistical methods for heterogeneous samples, and mathematical models that convert raw AFM data into quantitative mechanical properties. Such methods help overcome challenges related to tip-sample interactions, surface roughness, and environmental factors that can affect measurement accuracy.

- Combined AFM and spectroscopy techniques for comprehensive material characterization: Integrating AFM with other analytical techniques such as Raman spectroscopy, infrared spectroscopy, or fluorescence microscopy enables simultaneous measurement of mechanical properties and chemical composition. These hybrid approaches provide comprehensive material characterization at the nanoscale, allowing researchers to correlate mechanical behavior with chemical structure and composition for advanced material development and analysis.

- AFM applications for biological and soft material mechanical properties: AFM techniques have been adapted for measuring mechanical properties of biological samples and soft materials under physiological or controlled environmental conditions. These applications include cell mechanics, tissue elasticity mapping, and biomolecular interactions. Special considerations for sample preparation, force application, and data interpretation are required when working with these delicate and often heterogeneous materials to obtain meaningful mechanical property measurements.

02 AFM probe modifications for mechanical property measurements

Specialized modifications to AFM probes enhance the accuracy and capabilities of mechanical property measurements. These modifications include functionalized tips, cantilevers with specific spring constants, and probes designed for particular sample types. Advanced probe designs allow for more precise control of applied forces and improved sensitivity in detecting mechanical responses from various materials.Expand Specific Solutions03 Data processing and analysis methods for AFM mechanical measurements

Sophisticated data processing algorithms and analysis methods are essential for extracting meaningful mechanical property information from AFM measurements. These include force curve analysis, statistical methods for handling large datasets, calibration techniques, and mathematical models that convert raw AFM data into quantitative mechanical properties. Advanced software solutions help researchers interpret complex nanomechanical behaviors observed in various materials.Expand Specific Solutions04 Combined AFM and spectroscopy techniques for comprehensive material characterization

Integrating AFM with complementary spectroscopic techniques provides comprehensive characterization of both mechanical and chemical properties of materials. These hybrid approaches combine mechanical property measurements with chemical composition analysis, enabling researchers to correlate structure-property relationships at the nanoscale. Such combined techniques offer deeper insights into material behavior for applications in materials science, biology, and nanotechnology.Expand Specific Solutions05 Environmental and in-situ AFM for dynamic mechanical property studies

Environmental and in-situ AFM setups allow for studying mechanical properties under various conditions such as different temperatures, humidity levels, or in liquid environments. These specialized systems enable real-time observation of mechanical property changes during dynamic processes like chemical reactions, phase transitions, or biological interactions. Such capabilities are crucial for understanding how materials behave under realistic operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Groups in AFM Technology

The atomic force microscopy (AFM) mechanical property quantification market is in a growth phase, characterized by increasing adoption across materials science and biomedical research. The competitive landscape features established scientific instrument manufacturers like Bruker Nano, Oxford Instruments Asylum Research, and JEOL Ltd. dominating with comprehensive AFM solutions. Academic institutions including Beihang University, Tianjin University, and University of California are advancing methodological innovations, while corporate players such as Samsung Electronics, IBM, and Hitachi are developing application-specific technologies. The market exhibits moderate technological maturity with standardized approaches for elastic modulus measurement, though challenges remain in viscoelastic characterization and high-throughput analysis, driving ongoing R&D collaboration between industry and academic research centers.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed comprehensive solutions for quantifying mechanical properties using Atomic Force Microscopy (AFM). Their PeakForce QNM (Quantitative Nanomechanical Mapping) technology enables simultaneous imaging and mapping of multiple mechanical properties including modulus, adhesion, deformation, and dissipation with nanoscale resolution. The system employs a controlled force-distance curve at each pixel, maintaining peak forces to protect both tip and sample. Bruker's advanced algorithms automatically extract mechanical properties in real-time, allowing for direct correlation between topographical features and mechanical characteristics. Their FastForce Volume technology further enhances this capability by collecting complete force curves at each pixel with significantly improved speed compared to traditional force-volume methods. Bruker has also developed specialized probes with well-defined tip geometries and spring constants, crucial for accurate quantitative measurements. Their systems include built-in calibration protocols that account for cantilever spring constant, tip radius, and deflection sensitivity to ensure measurement reliability.

Strengths: Industry-leading resolution and accuracy in mechanical property mapping; comprehensive suite of calibration tools; specialized probes designed specifically for nanomechanical measurements; high-speed data acquisition capabilities. Weaknesses: Higher cost compared to basic AFM systems; complex operation requiring specialized training; potential artifacts in measurements on highly heterogeneous samples.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has pioneered the development of AFM-based nanomechanical characterization through their NanoIndenter and scanning probe microscopy systems. Their approach integrates traditional nanoindentation principles with AFM capabilities, allowing for precise force control and displacement measurements. Agilent's systems feature proprietary continuous stiffness measurement (CSM) technology that applies a small oscillation during indentation to continuously measure contact stiffness throughout the experiment, rather than just during unloading. This enables depth-dependent mechanical property mapping with exceptional accuracy. Their technology incorporates advanced calibration protocols that account for machine compliance, thermal drift, and tip area function to ensure measurement reliability. Agilent has also developed specialized software algorithms that can extract elastic modulus, hardness, creep parameters, and viscoelastic properties from force-displacement data using various contact mechanics models (Hertz, DMT, JKR, etc.) depending on the sample characteristics. Their systems are particularly noted for high force sensitivity and displacement resolution.

Strengths: Exceptional force and displacement resolution; robust calibration procedures; versatile application across hard and soft materials; advanced data analysis capabilities for extracting multiple mechanical parameters. Weaknesses: Systems typically require controlled environmental conditions for optimal performance; measurements can be time-consuming for comprehensive mapping; potential tip wear issues during extended measurements.

Critical Analysis of AFM Force Spectroscopy Techniques

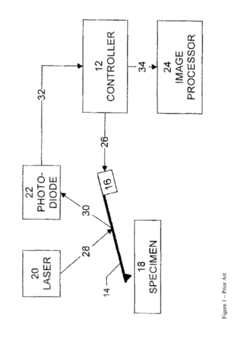

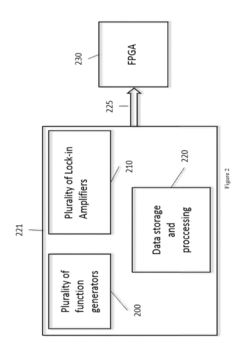

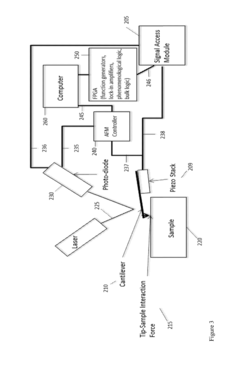

A method to measure nanoscale mechanical properties using atomic force microscopy without initially characterizing cantilever tip geometry

PatentInactiveUS20180364277A1

Innovation

- The method employs harmonic amplitude spectrum atomic force microscopy (HAS-AFM) with a field programmable gate array (FPGA) to drive the cantilever at multiple frequencies and apply a novel model of dynamic contact mechanics to determine reduced Young's modulus and bulk damping parameters by analyzing cantilever response, accounting for sample dynamics and eliminating the need for separate tip geometry characterization.

Method and apparatus of electrical property measurement using an AFM operating in peak force tapping mode

PatentPendingEP3293527A3

Innovation

- The integration of Peak Force Tapping Mode (PFT mode) with KPFM allows for simultaneous high-resolution mechanical and electrical property measurements using probes with lower spring constants and homogeneous tips, enhancing sensitivity and accuracy by correlating mechanical and electrical properties at the nanoscale.

Standardization and Calibration Considerations for AFM Measurements

Standardization and calibration represent critical foundations for reliable atomic force microscopy (AFM) measurements of mechanical properties. The scientific community has recognized the need for unified protocols to ensure reproducibility and comparability of results across different laboratories and instrument configurations. Currently, several international organizations including ISO, ASTM, and NIST are developing comprehensive standards specifically for AFM-based mechanical characterization, though this standardization process remains incomplete.

Proper calibration of the AFM system forms the cornerstone of accurate quantitative measurements. The cantilever spring constant calibration deserves particular attention, with the thermal noise method emerging as the most widely accepted approach. This method analyzes the thermal fluctuations of the cantilever to determine its spring constant, typically achieving accuracy within 10-15%. Alternative methods include the Sader method and reference cantilever techniques, each with specific advantages for different experimental conditions.

Tip geometry characterization represents another crucial calibration aspect that directly impacts mechanical property calculations. Blind indentation into reference materials with known properties allows for inverse determination of tip shape functions. Common reference materials include fused silica, sapphire, and highly oriented pyrolytic graphite (HOPG), selected for their well-defined and stable mechanical properties. Regular verification of tip geometry is essential as tips inevitably degrade during measurements.

Environmental control during calibration procedures significantly influences measurement accuracy. Temperature fluctuations can alter cantilever properties and sample mechanics, while humidity affects adhesion forces and contact mechanics. Leading laboratories implement temperature control within ±0.5°C and humidity regulation within ±5% to minimize these environmental variables.

Calibration frequency represents a practical consideration that balances measurement accuracy with research efficiency. Best practices suggest performing full system calibration weekly, with daily verification measurements on reference samples to detect any drift or system changes. More frequent calibration becomes necessary when working with particularly soft samples (modulus <10 MPa) or when pursuing high-precision measurements with error margins below 5%.

Traceability to international standards remains an evolving challenge in AFM mechanical measurements. Current approaches typically establish traceability through reference materials characterized by multiple independent techniques. The development of certified reference materials specifically designed for AFM mechanical calibration represents an active research area, with promising candidates including polymer-based materials with precisely controlled mechanical gradients.

Proper calibration of the AFM system forms the cornerstone of accurate quantitative measurements. The cantilever spring constant calibration deserves particular attention, with the thermal noise method emerging as the most widely accepted approach. This method analyzes the thermal fluctuations of the cantilever to determine its spring constant, typically achieving accuracy within 10-15%. Alternative methods include the Sader method and reference cantilever techniques, each with specific advantages for different experimental conditions.

Tip geometry characterization represents another crucial calibration aspect that directly impacts mechanical property calculations. Blind indentation into reference materials with known properties allows for inverse determination of tip shape functions. Common reference materials include fused silica, sapphire, and highly oriented pyrolytic graphite (HOPG), selected for their well-defined and stable mechanical properties. Regular verification of tip geometry is essential as tips inevitably degrade during measurements.

Environmental control during calibration procedures significantly influences measurement accuracy. Temperature fluctuations can alter cantilever properties and sample mechanics, while humidity affects adhesion forces and contact mechanics. Leading laboratories implement temperature control within ±0.5°C and humidity regulation within ±5% to minimize these environmental variables.

Calibration frequency represents a practical consideration that balances measurement accuracy with research efficiency. Best practices suggest performing full system calibration weekly, with daily verification measurements on reference samples to detect any drift or system changes. More frequent calibration becomes necessary when working with particularly soft samples (modulus <10 MPa) or when pursuing high-precision measurements with error margins below 5%.

Traceability to international standards remains an evolving challenge in AFM mechanical measurements. Current approaches typically establish traceability through reference materials characterized by multiple independent techniques. The development of certified reference materials specifically designed for AFM mechanical calibration represents an active research area, with promising candidates including polymer-based materials with precisely controlled mechanical gradients.

Data Processing and Analytical Model Limitations

The quantification of mechanical properties using Atomic Force Microscopy (AFM) faces significant challenges in data processing and analytical model limitations. Current AFM data processing methodologies often struggle with signal-to-noise ratio issues, particularly when measuring soft biological samples or nanoscale materials with subtle mechanical variations. These noise factors can substantially impact the accuracy of derived mechanical properties, necessitating sophisticated filtering algorithms that may inadvertently remove meaningful data features.

Statistical analysis of force curves presents another critical limitation, as conventional averaging methods may obscure heterogeneities in sample mechanical properties. This becomes especially problematic when analyzing composite materials or biological specimens with naturally occurring mechanical gradients at the nanoscale. The development of spatially resolved statistical approaches remains an active area of research but has not yet reached widespread implementation.

Analytical models used to interpret AFM force-distance curves contain inherent assumptions that may not hold across all material types. The Hertz model, while widely applied, assumes purely elastic deformation, homogeneity, and isotropic material properties—conditions rarely met in complex biological samples or advanced composite materials. Modified models like the JKR (Johnson-Kendall-Roberts) or DMT (Derjaguin-Müller-Toporov) attempt to account for adhesion forces but introduce additional parameters that complicate data interpretation.

Contact point determination represents a persistent challenge in AFM mechanical property quantification. Small errors in identifying the precise moment of tip-sample contact can propagate through calculations, leading to significant deviations in measured elastic moduli. Current algorithmic approaches for contact point determination still lack robustness across diverse sample types and experimental conditions.

Time-dependent mechanical behaviors such as viscoelasticity and creep are inadequately captured by standard AFM analytical frameworks. Most models assume instantaneous material response, whereas biological materials and polymers exhibit complex time-dependent behaviors. Advanced models incorporating viscoelastic parameters exist but require more complex experimental protocols and data fitting procedures that have not been standardized across the field.

Calibration uncertainties further compound these limitations, as cantilever spring constant determination methods (thermal tuning, Sader method, reference cantilever) each introduce their own systematic errors. These calibration uncertainties can propagate through the entire analytical pipeline, affecting the absolute accuracy of reported mechanical properties and complicating inter-laboratory comparisons of AFM mechanical measurements.

Statistical analysis of force curves presents another critical limitation, as conventional averaging methods may obscure heterogeneities in sample mechanical properties. This becomes especially problematic when analyzing composite materials or biological specimens with naturally occurring mechanical gradients at the nanoscale. The development of spatially resolved statistical approaches remains an active area of research but has not yet reached widespread implementation.

Analytical models used to interpret AFM force-distance curves contain inherent assumptions that may not hold across all material types. The Hertz model, while widely applied, assumes purely elastic deformation, homogeneity, and isotropic material properties—conditions rarely met in complex biological samples or advanced composite materials. Modified models like the JKR (Johnson-Kendall-Roberts) or DMT (Derjaguin-Müller-Toporov) attempt to account for adhesion forces but introduce additional parameters that complicate data interpretation.

Contact point determination represents a persistent challenge in AFM mechanical property quantification. Small errors in identifying the precise moment of tip-sample contact can propagate through calculations, leading to significant deviations in measured elastic moduli. Current algorithmic approaches for contact point determination still lack robustness across diverse sample types and experimental conditions.

Time-dependent mechanical behaviors such as viscoelasticity and creep are inadequately captured by standard AFM analytical frameworks. Most models assume instantaneous material response, whereas biological materials and polymers exhibit complex time-dependent behaviors. Advanced models incorporating viscoelastic parameters exist but require more complex experimental protocols and data fitting procedures that have not been standardized across the field.

Calibration uncertainties further compound these limitations, as cantilever spring constant determination methods (thermal tuning, Sader method, reference cantilever) each introduce their own systematic errors. These calibration uncertainties can propagate through the entire analytical pipeline, affecting the absolute accuracy of reported mechanical properties and complicating inter-laboratory comparisons of AFM mechanical measurements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!