How To Customize Atomic Force Microscopy Software For Enhanced Imaging

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Technology Background and Enhancement Objectives

Atomic Force Microscopy (AFM) emerged in the mid-1980s as a revolutionary imaging technique capable of visualizing surfaces at the nanoscale. Since its invention by Gerd Binnig, Calvin Quate, and Christoph Gerber in 1986, AFM technology has evolved from a basic imaging tool to a sophisticated platform for nanoscale characterization across multiple scientific disciplines. The fundamental principle of AFM involves scanning a sharp probe across a sample surface while measuring the interaction forces, enabling the creation of topographical maps with unprecedented resolution.

The evolution of AFM technology has been marked by significant advancements in both hardware components and software capabilities. Early AFM systems were limited by slow scanning speeds, restricted imaging modes, and basic data processing capabilities. However, over the past three decades, continuous innovations have led to dramatic improvements in resolution, scanning speed, and versatility, expanding AFM applications from basic surface imaging to complex material characterization, biological studies, and nanomanipulation.

Software development has been a critical factor in AFM advancement, transitioning from simple data acquisition systems to sophisticated platforms capable of real-time processing, advanced filtering, and multi-dimensional data analysis. Despite these improvements, current commercial AFM software often presents limitations in customization, specialized analysis capabilities, and integration with other analytical techniques, creating barriers for researchers with unique experimental requirements.

The primary objective of AFM software customization is to overcome these limitations by developing tailored solutions that enhance imaging capabilities, improve data processing efficiency, and expand analytical functionalities. Specifically, customization aims to optimize image resolution by implementing advanced feedback algorithms, reduce noise through sophisticated filtering techniques, and enable specialized analysis for specific research applications.

Another crucial enhancement objective involves improving the user experience through intuitive interfaces, automated workflows, and intelligent data management systems. These improvements would significantly reduce the learning curve associated with AFM operation and data analysis, making this powerful technology more accessible to researchers across various disciplines.

Integration capabilities represent another key enhancement target, focusing on developing software interfaces that seamlessly connect AFM data with complementary analytical techniques and external databases. This integration would facilitate comprehensive multi-technique analysis and enable more robust interpretation of experimental results within broader scientific contexts.

The long-term technological goal extends beyond incremental improvements to fundamentally transform AFM capabilities through machine learning algorithms, automated feature recognition, and predictive modeling. These advanced computational approaches could potentially revolutionize AFM imaging by enabling autonomous operation, real-time defect identification, and predictive material characterization, significantly expanding the scope and impact of AFM technology across scientific and industrial applications.

The evolution of AFM technology has been marked by significant advancements in both hardware components and software capabilities. Early AFM systems were limited by slow scanning speeds, restricted imaging modes, and basic data processing capabilities. However, over the past three decades, continuous innovations have led to dramatic improvements in resolution, scanning speed, and versatility, expanding AFM applications from basic surface imaging to complex material characterization, biological studies, and nanomanipulation.

Software development has been a critical factor in AFM advancement, transitioning from simple data acquisition systems to sophisticated platforms capable of real-time processing, advanced filtering, and multi-dimensional data analysis. Despite these improvements, current commercial AFM software often presents limitations in customization, specialized analysis capabilities, and integration with other analytical techniques, creating barriers for researchers with unique experimental requirements.

The primary objective of AFM software customization is to overcome these limitations by developing tailored solutions that enhance imaging capabilities, improve data processing efficiency, and expand analytical functionalities. Specifically, customization aims to optimize image resolution by implementing advanced feedback algorithms, reduce noise through sophisticated filtering techniques, and enable specialized analysis for specific research applications.

Another crucial enhancement objective involves improving the user experience through intuitive interfaces, automated workflows, and intelligent data management systems. These improvements would significantly reduce the learning curve associated with AFM operation and data analysis, making this powerful technology more accessible to researchers across various disciplines.

Integration capabilities represent another key enhancement target, focusing on developing software interfaces that seamlessly connect AFM data with complementary analytical techniques and external databases. This integration would facilitate comprehensive multi-technique analysis and enable more robust interpretation of experimental results within broader scientific contexts.

The long-term technological goal extends beyond incremental improvements to fundamentally transform AFM capabilities through machine learning algorithms, automated feature recognition, and predictive modeling. These advanced computational approaches could potentially revolutionize AFM imaging by enabling autonomous operation, real-time defect identification, and predictive material characterization, significantly expanding the scope and impact of AFM technology across scientific and industrial applications.

Market Analysis for Advanced AFM Software Solutions

The global market for advanced Atomic Force Microscopy (AFM) software solutions is experiencing robust growth, driven by increasing demand for high-resolution imaging across multiple industries. Current market valuation stands at approximately 500 million USD, with projections indicating a compound annual growth rate of 8.5% over the next five years. This growth trajectory is primarily fueled by expanding applications in semiconductor manufacturing, materials science, and life sciences research.

Customer demand analysis reveals distinct market segments with varying requirements. Academic and research institutions, representing about 40% of the market, prioritize flexibility and customization capabilities to support diverse experimental protocols. Industrial users, particularly in semiconductor and electronics manufacturing, demand software solutions with automated defect detection and analysis features to enhance production quality control processes. The pharmaceutical and biotechnology sector shows increasing interest in AFM software that can facilitate nanoscale characterization of biological samples with minimal sample preparation.

Regional market assessment indicates North America currently leads with approximately 35% market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the fastest growth rate at 10.2% annually, driven by expanding research infrastructure in China, Japan, and South Korea, along with increasing industrial applications in semiconductor manufacturing.

Competitive landscape analysis identifies several key players dominating the market, including established scientific instrument manufacturers who bundle proprietary software with their AFM hardware. However, a notable trend is the emergence of specialized software developers offering platform-independent solutions with enhanced data processing capabilities and user-friendly interfaces. These specialized vendors are gaining market share by addressing the growing demand for customizable software that can integrate with existing hardware systems.

Customer pain points identified through market research include limited interoperability between different manufacturers' systems, complex user interfaces requiring specialized training, and insufficient automation for routine imaging tasks. Additionally, there is growing demand for advanced data analysis capabilities, including 3D visualization, statistical analysis tools, and machine learning integration for automated feature recognition.

Market forecasts suggest particularly strong growth in software solutions offering open architecture for customization, cloud-based data storage and analysis capabilities, and integration with complementary analytical techniques. The subscription-based software model is gaining traction, with an estimated 30% of new implementations adopting this approach over traditional perpetual licensing.

Customer demand analysis reveals distinct market segments with varying requirements. Academic and research institutions, representing about 40% of the market, prioritize flexibility and customization capabilities to support diverse experimental protocols. Industrial users, particularly in semiconductor and electronics manufacturing, demand software solutions with automated defect detection and analysis features to enhance production quality control processes. The pharmaceutical and biotechnology sector shows increasing interest in AFM software that can facilitate nanoscale characterization of biological samples with minimal sample preparation.

Regional market assessment indicates North America currently leads with approximately 35% market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region demonstrates the fastest growth rate at 10.2% annually, driven by expanding research infrastructure in China, Japan, and South Korea, along with increasing industrial applications in semiconductor manufacturing.

Competitive landscape analysis identifies several key players dominating the market, including established scientific instrument manufacturers who bundle proprietary software with their AFM hardware. However, a notable trend is the emergence of specialized software developers offering platform-independent solutions with enhanced data processing capabilities and user-friendly interfaces. These specialized vendors are gaining market share by addressing the growing demand for customizable software that can integrate with existing hardware systems.

Customer pain points identified through market research include limited interoperability between different manufacturers' systems, complex user interfaces requiring specialized training, and insufficient automation for routine imaging tasks. Additionally, there is growing demand for advanced data analysis capabilities, including 3D visualization, statistical analysis tools, and machine learning integration for automated feature recognition.

Market forecasts suggest particularly strong growth in software solutions offering open architecture for customization, cloud-based data storage and analysis capabilities, and integration with complementary analytical techniques. The subscription-based software model is gaining traction, with an estimated 30% of new implementations adopting this approach over traditional perpetual licensing.

Current AFM Software Limitations and Technical Challenges

Despite significant advancements in Atomic Force Microscopy (AFM) technology, current software solutions present several limitations that impede optimal imaging performance and research capabilities. Commercial AFM software packages typically offer standardized functionality designed for general use cases, resulting in inflexible interfaces that cannot be easily adapted to specific research requirements or specialized imaging scenarios. This one-size-fits-all approach significantly restricts researchers' ability to implement novel imaging techniques or customize data processing algorithms.

Data processing capabilities represent another major challenge in existing AFM software. Most commercial solutions employ proprietary algorithms that operate as "black boxes," preventing researchers from understanding or modifying the underlying processing methods. This lack of transparency becomes particularly problematic when investigating novel materials or structures that may require specialized processing approaches not anticipated by software developers.

Integration limitations further compound these challenges, as many AFM software packages operate within closed ecosystems with limited compatibility with external tools and data formats. Researchers often struggle to incorporate data from complementary analytical techniques or export AFM data to specialized analysis software, creating workflow bottlenecks and impeding comprehensive material characterization efforts.

Real-time processing capabilities remain insufficient in most current AFM software implementations. The computational demands of advanced imaging modes often result in significant delays between data acquisition and visualization, preventing researchers from making timely adjustments during experiments. This limitation is particularly detrimental when studying dynamic processes or when sample degradation occurs rapidly.

User interface complexity presents an additional barrier, with many AFM software packages featuring steep learning curves and unintuitive controls. This complexity not only reduces productivity but also increases the likelihood of operator error, potentially compromising data quality and experimental reproducibility. The situation is exacerbated by inadequate customization options for the user interface, forcing researchers to adapt their workflows to the software rather than vice versa.

From a technical perspective, most current AFM software lacks robust programming interfaces that would enable advanced users to extend functionality. The absence of comprehensive APIs or scripting capabilities severely limits the potential for automation, batch processing, or implementation of novel analytical approaches. This constraint is particularly restrictive for research groups working at the cutting edge of nanoscale characterization, where standard software capabilities may be insufficient.

Resource utilization inefficiencies also plague existing AFM software, with many packages failing to leverage modern computing architectures effectively. Multi-threading capabilities, GPU acceleration, and distributed computing support remain underutilized, resulting in suboptimal performance when processing large datasets or implementing computationally intensive imaging modes.

Data processing capabilities represent another major challenge in existing AFM software. Most commercial solutions employ proprietary algorithms that operate as "black boxes," preventing researchers from understanding or modifying the underlying processing methods. This lack of transparency becomes particularly problematic when investigating novel materials or structures that may require specialized processing approaches not anticipated by software developers.

Integration limitations further compound these challenges, as many AFM software packages operate within closed ecosystems with limited compatibility with external tools and data formats. Researchers often struggle to incorporate data from complementary analytical techniques or export AFM data to specialized analysis software, creating workflow bottlenecks and impeding comprehensive material characterization efforts.

Real-time processing capabilities remain insufficient in most current AFM software implementations. The computational demands of advanced imaging modes often result in significant delays between data acquisition and visualization, preventing researchers from making timely adjustments during experiments. This limitation is particularly detrimental when studying dynamic processes or when sample degradation occurs rapidly.

User interface complexity presents an additional barrier, with many AFM software packages featuring steep learning curves and unintuitive controls. This complexity not only reduces productivity but also increases the likelihood of operator error, potentially compromising data quality and experimental reproducibility. The situation is exacerbated by inadequate customization options for the user interface, forcing researchers to adapt their workflows to the software rather than vice versa.

From a technical perspective, most current AFM software lacks robust programming interfaces that would enable advanced users to extend functionality. The absence of comprehensive APIs or scripting capabilities severely limits the potential for automation, batch processing, or implementation of novel analytical approaches. This constraint is particularly restrictive for research groups working at the cutting edge of nanoscale characterization, where standard software capabilities may be insufficient.

Resource utilization inefficiencies also plague existing AFM software, with many packages failing to leverage modern computing architectures effectively. Multi-threading capabilities, GPU acceleration, and distributed computing support remain underutilized, resulting in suboptimal performance when processing large datasets or implementing computationally intensive imaging modes.

Existing AFM Software Customization Approaches

01 Image processing and enhancement algorithms

Advanced software algorithms are used to process and enhance atomic force microscopy (AFM) images, improving clarity and resolution. These algorithms can reduce noise, enhance contrast, and apply various filters to extract more detailed information from raw AFM data. The enhanced imaging capabilities allow researchers to better visualize and analyze nanoscale structures and surface properties that might otherwise be difficult to discern in the original scans.- Image processing and enhancement algorithms: Advanced software algorithms are used to process and enhance atomic force microscopy (AFM) images, improving clarity, resolution, and contrast. These algorithms can reduce noise, apply filters, and perform mathematical transformations to extract more information from raw AFM data. Enhanced imaging techniques allow for better visualization of surface features and nanostructures that might otherwise be difficult to discern in the original scan data.

- Real-time data acquisition and analysis: Software solutions for atomic force microscopy that enable real-time data acquisition, processing, and analysis during scanning operations. These systems allow researchers to monitor image quality as it develops, make adjustments to scanning parameters on the fly, and perform immediate analysis of surface features. Real-time capabilities reduce experiment time and improve efficiency by eliminating the need for multiple scans or post-processing steps.

- 3D visualization and topographical mapping: Software tools that transform AFM data into three-dimensional visualizations and topographical maps, providing enhanced understanding of sample surfaces. These tools offer various rendering options, color mapping, and perspective controls to highlight specific surface features. Advanced 3D visualization enables more intuitive interpretation of complex surface structures and facilitates the measurement of heights, depths, and other dimensional characteristics at the nanoscale.

- Multimodal data integration and correlation: Software platforms that integrate and correlate AFM data with information from other analytical techniques, such as optical microscopy, Raman spectroscopy, or electron microscopy. These systems align and overlay multiple data types to provide comprehensive sample characterization. By correlating structural, chemical, and physical properties measured by different techniques, researchers can gain deeper insights into material properties and behaviors at the nanoscale.

- Automated operation and artifact correction: Software solutions that automate AFM operation and correct imaging artifacts to improve data quality and reproducibility. These systems can automatically optimize scanning parameters, detect and compensate for tip-sample interactions, and correct common artifacts such as bow, tilt, and thermal drift. Automation reduces operator dependence and enables consistent high-quality imaging across multiple samples and experiments, while artifact correction ensures that measurements accurately represent the true sample topography.

02 Real-time data acquisition and processing

Software solutions for atomic force microscopy that enable real-time data acquisition and processing during scanning operations. These systems can dynamically adjust scanning parameters based on feedback from the probe, allowing for immediate visualization and analysis of surface features. Real-time processing capabilities reduce the time required for image acquisition and enable researchers to make adjustments during experiments rather than discovering issues after completion.Expand Specific Solutions03 3D visualization and topographical mapping

Specialized software tools that transform AFM data into three-dimensional visualizations and detailed topographical maps. These tools provide enhanced perspective on surface features by converting two-dimensional scan data into interactive 3D models that can be rotated, measured, and analyzed from multiple angles. The software may include height-coding color schemes, cross-sectional analysis, and roughness calculations to better characterize surface morphology.Expand Specific Solutions04 Multi-parameter data correlation and analysis

Software systems that enable correlation and simultaneous analysis of multiple AFM measurement parameters. These solutions can combine mechanical, electrical, magnetic, and topographical data to provide comprehensive characterization of samples. By integrating different measurement modes and data types, researchers can establish relationships between various surface properties and gain deeper insights into material characteristics and behaviors at the nanoscale.Expand Specific Solutions05 Automated operation and artifact correction

Software tools that automate AFM operation and implement intelligent artifact correction algorithms. These systems can automatically identify and remove common imaging artifacts such as tip convolution effects, scanner nonlinearities, and thermal drift. Automation features may include probe approach, parameter optimization, and scan area selection, reducing operator dependency and improving reproducibility of results while maintaining high image quality.Expand Specific Solutions

Leading AFM Software Providers and Research Institutions

The atomic force microscopy (AFM) software customization market is in a growth phase, with increasing demand for enhanced imaging capabilities across research and industrial applications. The market size is expanding as AFM technology becomes essential in nanotechnology, materials science, and semiconductor industries. Leading players include established instrumentation companies like Bruker Nano, Leica Microsystems, and Keysight Technologies, who offer comprehensive software solutions with customization options. Academic institutions such as MIT, McGill University, and research organizations like CNRS and NASA are driving innovation through open-source developments. The technology is maturing with semiconductor industry players (GLOBALFOUNDRIES, Texas Instruments, Seagate) pushing for specialized industrial applications, while software integration capabilities from companies like NanoFocus and nano analytik are enhancing the ecosystem's technical sophistication.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed NanoScope software platform with extensive customization capabilities for atomic force microscopy. Their approach integrates modular software architecture allowing researchers to develop custom analysis routines through an open API framework. The platform supports real-time data processing with PeakForce Tapping technology that enables simultaneous acquisition of multiple sample properties while protecting delicate samples[1]. Bruker's software customization includes Python scripting integration for automated workflows and custom algorithms implementation. Their latest versions feature machine learning modules for automated feature recognition and noise reduction, significantly enhancing image quality in challenging environments[3]. The software allows for comprehensive force curve analysis with customizable fitting models and parameter extraction, essential for nanomechanical characterization.

Strengths: Industry-leading comprehensive software ecosystem with extensive API access; seamless integration with hardware for optimal performance; strong support for third-party plugin development. Weaknesses: Higher learning curve for advanced customization; premium pricing structure may limit accessibility for smaller research groups.

Veeco Instruments, Inc.

Technical Solution: Veeco has pioneered the Dimension software platform for AFM customization, focusing on modular architecture that enables researchers to modify imaging parameters and analysis workflows. Their approach centers on an extensible framework where users can develop custom algorithms for specific applications through C++ and Python interfaces. The platform features advanced image correction capabilities including automated plane fitting, line-by-line correction, and custom filtering options to enhance image quality[2]. Veeco's software includes specialized modules for nanolithography applications with precise control over tip movement and force application. Their recent developments incorporate real-time data processing capabilities that allow for on-the-fly modification of scanning parameters based on emerging features, particularly valuable for heterogeneous samples. The software supports batch processing of multiple images with user-defined analysis sequences for high-throughput research applications.

Strengths: Excellent balance between user-friendly interface and advanced customization options; strong focus on automation capabilities for complex experiments; robust image processing tools. Weaknesses: Some advanced features require separate module purchases; integration with third-party analysis tools can be challenging.

Key Algorithms for Enhanced AFM Image Processing

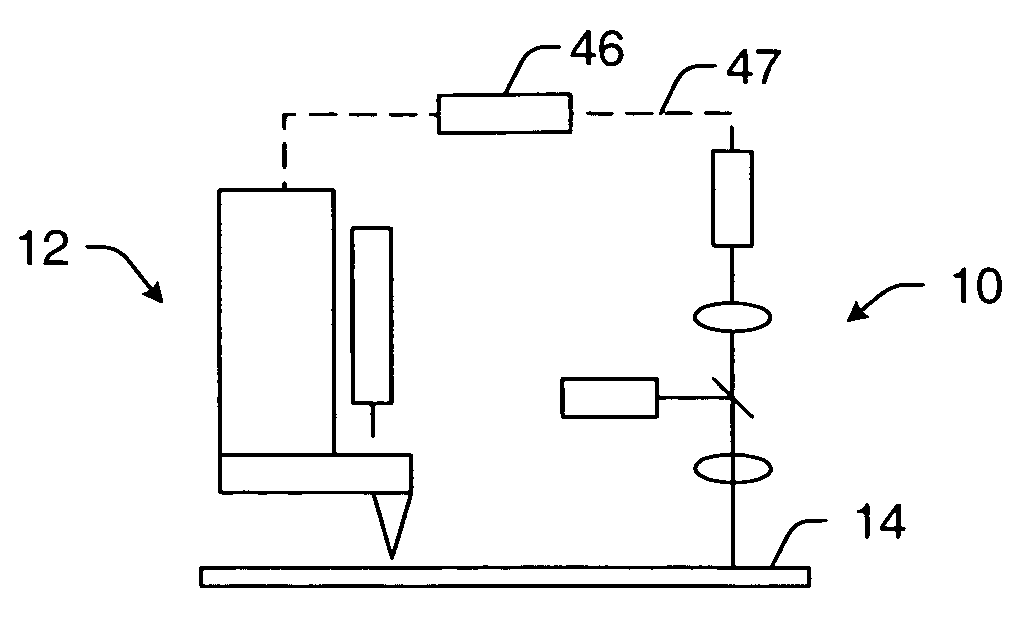

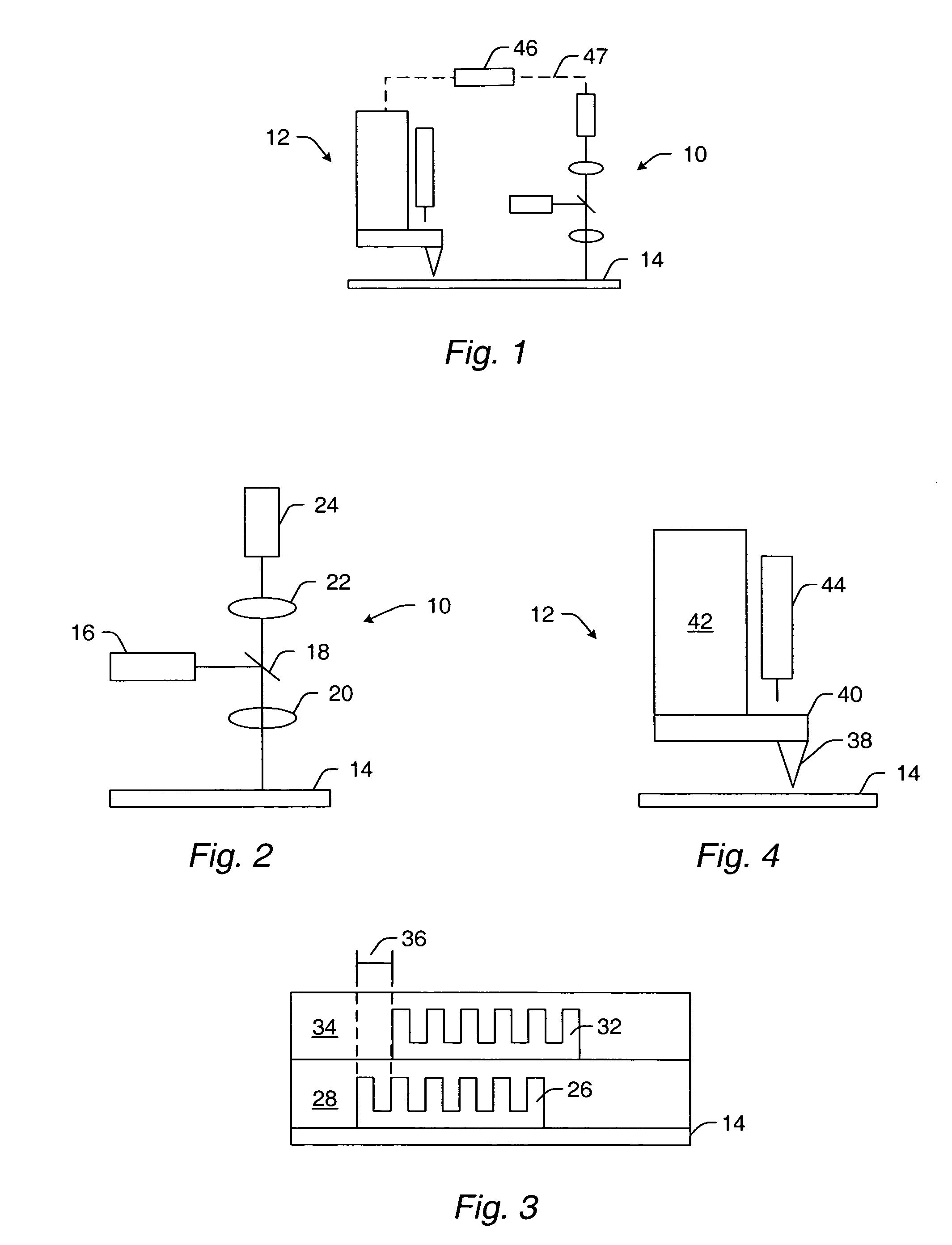

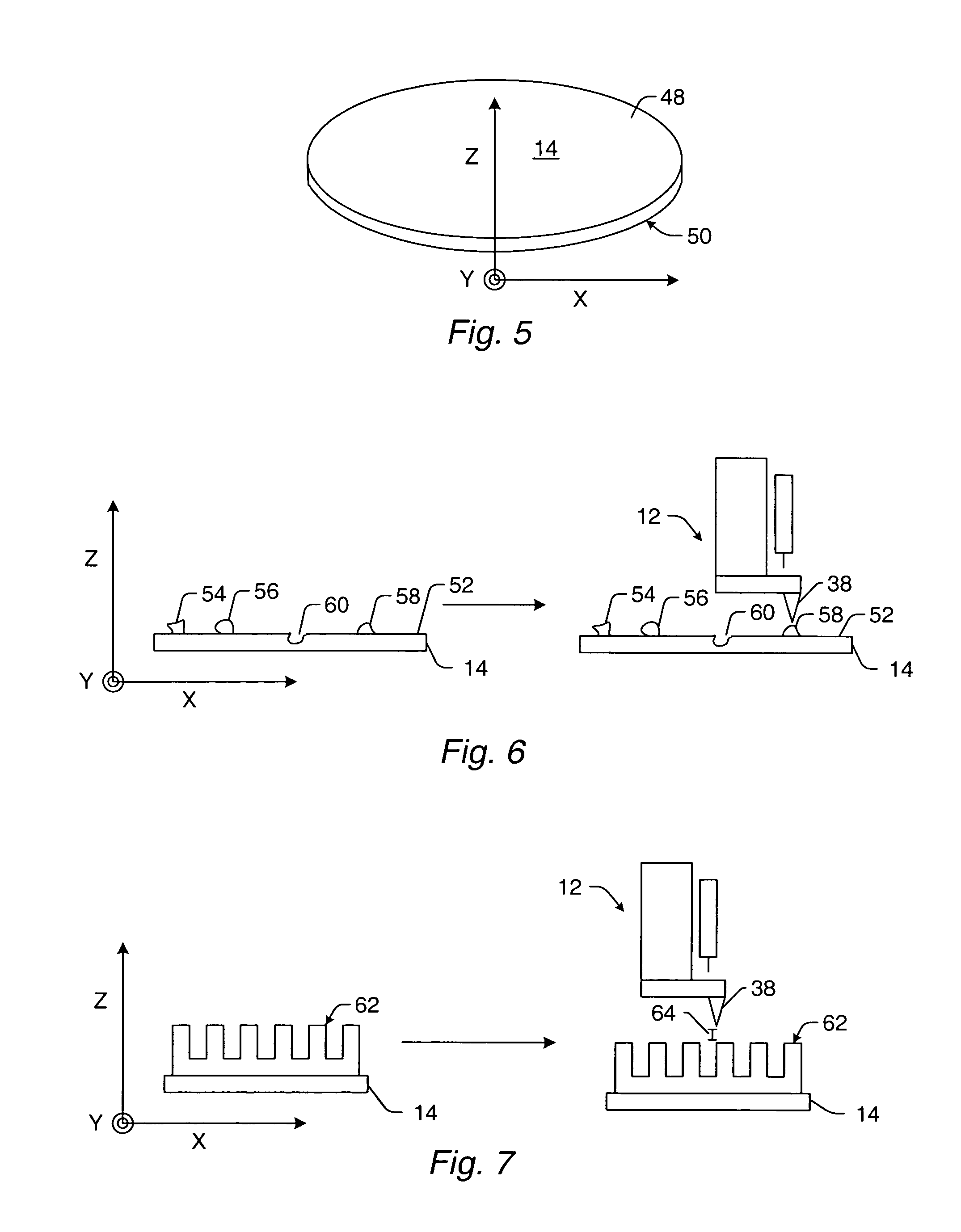

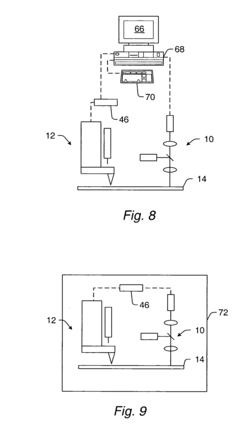

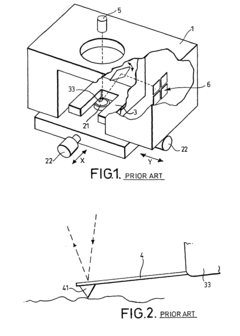

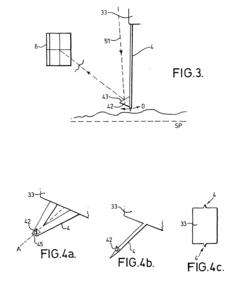

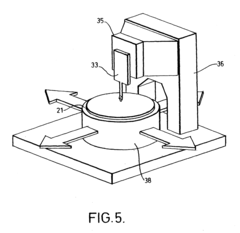

Methods and systems for analyzing a specimen using atomic force microscopy profiling in combination with an optical technique

PatentActiveUS7430898B1

Innovation

- Integration of an optical subsystem with an AFM to generate positional information and guide the probe to specific locations on a specimen's surface, allowing for faster and more precise positioning of the AFM probe using servo systems and three-dimensional imaging, thereby enhancing the AFM's suitability for in-line measurements.

Methods and apparatus for atomic force microscopy

PatentInactiveUS20030160170A1

Innovation

- The cantilever probe is arranged with its axis perpendicular to the sample presentation plane, featuring a rearwardly-directed reflection surface for beam detection, allowing lateral oscillation and enhanced access to sample surfaces, including steep features, and enabling true tip-sample distance control through axial adjustment.

Integration with Machine Learning for Automated Image Analysis

The integration of machine learning with Atomic Force Microscopy (AFM) software represents a significant advancement in automated image analysis capabilities. Machine learning algorithms can be trained to recognize patterns, features, and anomalies in AFM data that might be overlooked by human operators or traditional image processing techniques. This integration enables real-time image enhancement, noise reduction, and feature extraction, substantially improving the quality and interpretability of AFM images.

Recent developments in convolutional neural networks (CNNs) have shown particular promise for AFM image analysis. These networks can be trained on large datasets of AFM images to automatically identify and classify surface structures, defects, and molecular arrangements. For example, researchers at MIT and Stanford have demonstrated CNNs capable of distinguishing between different types of protein structures with accuracy rates exceeding 95%, significantly outperforming conventional analysis methods.

Implementation of machine learning in AFM software typically involves three key components: data preprocessing, model training, and inference integration. The preprocessing stage normalizes AFM data and extracts relevant features, while model training utilizes annotated datasets to develop accurate prediction algorithms. The inference integration component embeds the trained model within the AFM software architecture, enabling real-time analysis during scanning operations.

Several open-source frameworks now facilitate this integration, including TensorFlow and PyTorch libraries specifically designed for microscopy applications. These frameworks provide pre-built neural network architectures that can be customized for specific AFM imaging requirements. Commercial solutions from companies like Bruker and Oxford Instruments have also begun incorporating machine learning capabilities into their AFM software packages.

A particularly valuable application is automated tip artifact detection and correction. Machine learning algorithms can identify imaging artifacts caused by tip degradation and apply appropriate corrections in real-time, maintaining image quality throughout extended scanning sessions. This capability significantly reduces the need for operator intervention and improves experimental throughput.

Unsupervised learning techniques, such as autoencoders and generative adversarial networks, offer additional benefits for AFM image enhancement. These approaches can effectively denoise images, reconstruct missing data, and even generate synthetic training data to improve model performance. When combined with transfer learning methods, these techniques allow AFM software to adapt quickly to new sample types with minimal additional training.

The computational requirements for machine learning integration vary depending on the complexity of the models employed. While basic feature recognition can be performed on standard laboratory computers, more sophisticated real-time analysis may require dedicated GPU acceleration. Cloud-based processing solutions offer a scalable alternative, enabling advanced analysis capabilities without significant hardware investments.

Recent developments in convolutional neural networks (CNNs) have shown particular promise for AFM image analysis. These networks can be trained on large datasets of AFM images to automatically identify and classify surface structures, defects, and molecular arrangements. For example, researchers at MIT and Stanford have demonstrated CNNs capable of distinguishing between different types of protein structures with accuracy rates exceeding 95%, significantly outperforming conventional analysis methods.

Implementation of machine learning in AFM software typically involves three key components: data preprocessing, model training, and inference integration. The preprocessing stage normalizes AFM data and extracts relevant features, while model training utilizes annotated datasets to develop accurate prediction algorithms. The inference integration component embeds the trained model within the AFM software architecture, enabling real-time analysis during scanning operations.

Several open-source frameworks now facilitate this integration, including TensorFlow and PyTorch libraries specifically designed for microscopy applications. These frameworks provide pre-built neural network architectures that can be customized for specific AFM imaging requirements. Commercial solutions from companies like Bruker and Oxford Instruments have also begun incorporating machine learning capabilities into their AFM software packages.

A particularly valuable application is automated tip artifact detection and correction. Machine learning algorithms can identify imaging artifacts caused by tip degradation and apply appropriate corrections in real-time, maintaining image quality throughout extended scanning sessions. This capability significantly reduces the need for operator intervention and improves experimental throughput.

Unsupervised learning techniques, such as autoencoders and generative adversarial networks, offer additional benefits for AFM image enhancement. These approaches can effectively denoise images, reconstruct missing data, and even generate synthetic training data to improve model performance. When combined with transfer learning methods, these techniques allow AFM software to adapt quickly to new sample types with minimal additional training.

The computational requirements for machine learning integration vary depending on the complexity of the models employed. While basic feature recognition can be performed on standard laboratory computers, more sophisticated real-time analysis may require dedicated GPU acceleration. Cloud-based processing solutions offer a scalable alternative, enabling advanced analysis capabilities without significant hardware investments.

Open-Source vs. Proprietary AFM Software Ecosystems

The AFM software landscape is distinctly divided between proprietary solutions offered by instrument manufacturers and open-source alternatives developed by research communities. Proprietary software packages such as Bruker's NanoScope, Asylum Research's MFP-3D, and JPK's SPM software provide comprehensive, integrated environments specifically optimized for their respective hardware. These solutions offer streamlined workflows, regular updates, and dedicated technical support, which significantly reduces implementation barriers for new users.

However, proprietary systems often impose limitations on customization depth, with modification capabilities restricted to predefined parameters and analysis methods. Users frequently encounter "black box" algorithms that limit understanding of underlying data processing mechanisms. Additionally, these systems typically require substantial licensing fees and may restrict data portability across different platforms.

In contrast, open-source AFM software ecosystems such as Gwyddion, WSXM, and OpenSPM provide unprecedented flexibility for customization. These platforms expose core functionality through documented APIs and modular architectures, enabling researchers to modify existing algorithms or implement entirely new imaging techniques. The collaborative nature of open-source development has accelerated innovation in specialized imaging modes and analysis techniques that might otherwise remain undeveloped in commercial systems.

The open-source approach also facilitates cross-disciplinary collaboration, allowing physicists, computer scientists, and biologists to contribute complementary expertise to software development. This collaborative model has proven particularly valuable for addressing niche research applications that may not represent sufficient market opportunity for commercial development.

Despite these advantages, open-source solutions typically require greater technical expertise for implementation and customization. Users must navigate documentation of varying quality and may encounter compatibility issues across different hardware platforms. The absence of centralized support structures can present significant challenges for researchers without programming backgrounds.

Recent trends indicate growing convergence between these ecosystems, with proprietary vendors increasingly offering API access and scripting capabilities, while open-source projects are developing more user-friendly interfaces. Several research institutions have successfully implemented hybrid approaches, utilizing proprietary software for routine operations while leveraging open-source tools for specialized analysis and custom imaging modes.

When considering AFM software customization strategies, organizations must evaluate their technical capabilities, specific imaging requirements, and long-term research objectives to determine the optimal balance between proprietary reliability and open-source flexibility.

However, proprietary systems often impose limitations on customization depth, with modification capabilities restricted to predefined parameters and analysis methods. Users frequently encounter "black box" algorithms that limit understanding of underlying data processing mechanisms. Additionally, these systems typically require substantial licensing fees and may restrict data portability across different platforms.

In contrast, open-source AFM software ecosystems such as Gwyddion, WSXM, and OpenSPM provide unprecedented flexibility for customization. These platforms expose core functionality through documented APIs and modular architectures, enabling researchers to modify existing algorithms or implement entirely new imaging techniques. The collaborative nature of open-source development has accelerated innovation in specialized imaging modes and analysis techniques that might otherwise remain undeveloped in commercial systems.

The open-source approach also facilitates cross-disciplinary collaboration, allowing physicists, computer scientists, and biologists to contribute complementary expertise to software development. This collaborative model has proven particularly valuable for addressing niche research applications that may not represent sufficient market opportunity for commercial development.

Despite these advantages, open-source solutions typically require greater technical expertise for implementation and customization. Users must navigate documentation of varying quality and may encounter compatibility issues across different hardware platforms. The absence of centralized support structures can present significant challenges for researchers without programming backgrounds.

Recent trends indicate growing convergence between these ecosystems, with proprietary vendors increasingly offering API access and scripting capabilities, while open-source projects are developing more user-friendly interfaces. Several research institutions have successfully implemented hybrid approaches, utilizing proprietary software for routine operations while leveraging open-source tools for specialized analysis and custom imaging modes.

When considering AFM software customization strategies, organizations must evaluate their technical capabilities, specific imaging requirements, and long-term research objectives to determine the optimal balance between proprietary reliability and open-source flexibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!