Measure Atomic Force Microscopy Image Quality — Evaluation Parameters

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Imaging Technology Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Gerd Binnig, Calvin Quate, and Christoph Gerber. This revolutionary imaging technique has transformed our ability to visualize and manipulate matter at the nanoscale, providing unprecedented insights into surface topography and properties with atomic resolution. The technology operates by measuring forces between a sharp probe and sample surface, enabling three-dimensional surface profiling with exceptional precision.

Over the past three decades, AFM technology has progressed through several distinct evolutionary phases. The initial development focused on basic imaging capabilities in contact mode, followed by the introduction of dynamic modes such as tapping and non-contact AFM in the 1990s. The 2000s witnessed significant advancements in high-speed AFM and multimodal techniques, while recent years have seen the emergence of sophisticated quantitative nanomechanical mapping and correlative microscopy approaches.

Despite these advancements, image quality assessment remains a critical challenge in AFM technology. The fidelity and reliability of AFM images are influenced by numerous factors including probe geometry, scanning parameters, environmental conditions, and sample characteristics. Currently, there exists no standardized framework for quantitatively evaluating AFM image quality, leading to inconsistencies in data interpretation and limiting the reproducibility of research findings.

The primary objective of this technical research is to establish comprehensive evaluation parameters for measuring AFM image quality. These parameters aim to provide quantitative metrics that can objectively assess various aspects of image fidelity, including spatial resolution, signal-to-noise ratio, artifacts identification, and data accuracy. Such standardized evaluation criteria would significantly enhance the reliability of AFM data across different instruments, operators, and experimental conditions.

Additionally, this research seeks to explore emerging computational approaches for automated image quality assessment, including machine learning algorithms capable of identifying and classifying common artifacts and quality issues. The development of such tools would streamline the image acquisition process and enable real-time feedback for parameter optimization during experiments.

The long-term technological goal is to establish an integrated quality management system for AFM imaging that combines hardware improvements, software solutions, and standardized protocols. This system would not only enhance the reproducibility of AFM measurements but also facilitate the integration of AFM data with other analytical techniques, supporting the broader trend toward correlative microscopy in materials science, biology, and nanotechnology research.

Over the past three decades, AFM technology has progressed through several distinct evolutionary phases. The initial development focused on basic imaging capabilities in contact mode, followed by the introduction of dynamic modes such as tapping and non-contact AFM in the 1990s. The 2000s witnessed significant advancements in high-speed AFM and multimodal techniques, while recent years have seen the emergence of sophisticated quantitative nanomechanical mapping and correlative microscopy approaches.

Despite these advancements, image quality assessment remains a critical challenge in AFM technology. The fidelity and reliability of AFM images are influenced by numerous factors including probe geometry, scanning parameters, environmental conditions, and sample characteristics. Currently, there exists no standardized framework for quantitatively evaluating AFM image quality, leading to inconsistencies in data interpretation and limiting the reproducibility of research findings.

The primary objective of this technical research is to establish comprehensive evaluation parameters for measuring AFM image quality. These parameters aim to provide quantitative metrics that can objectively assess various aspects of image fidelity, including spatial resolution, signal-to-noise ratio, artifacts identification, and data accuracy. Such standardized evaluation criteria would significantly enhance the reliability of AFM data across different instruments, operators, and experimental conditions.

Additionally, this research seeks to explore emerging computational approaches for automated image quality assessment, including machine learning algorithms capable of identifying and classifying common artifacts and quality issues. The development of such tools would streamline the image acquisition process and enable real-time feedback for parameter optimization during experiments.

The long-term technological goal is to establish an integrated quality management system for AFM imaging that combines hardware improvements, software solutions, and standardized protocols. This system would not only enhance the reproducibility of AFM measurements but also facilitate the integration of AFM data with other analytical techniques, supporting the broader trend toward correlative microscopy in materials science, biology, and nanotechnology research.

Market Applications and Demand Analysis for High-Quality AFM

The Atomic Force Microscopy (AFM) market has experienced significant growth across various industries, driven by increasing demand for high-resolution imaging and nanoscale measurements. The global AFM market was valued at approximately $570 million in 2022 and is projected to reach $850 million by 2028, representing a compound annual growth rate of 6.9%. This growth is primarily fueled by expanding applications in materials science, life sciences, semiconductor manufacturing, and nanotechnology research.

In the semiconductor industry, the demand for high-quality AFM imaging has surged due to the continuous miniaturization of electronic components. As semiconductor manufacturers push toward sub-5nm process nodes, the need for precise surface characterization and defect analysis has become critical. High-quality AFM images enable accurate measurement of transistor dimensions, surface roughness, and identification of nanoscale defects that could impact device performance.

The pharmaceutical and biotechnology sectors represent another significant market for high-quality AFM imaging. These industries utilize AFM for drug discovery, protein characterization, and cellular imaging. The ability to visualize biomolecular interactions at the nanoscale provides valuable insights into drug mechanisms and efficacy. Market research indicates that approximately 22% of AFM applications are now in life sciences, with this percentage expected to increase as biological research becomes more focused on nanoscale phenomena.

Materials science research constitutes the largest application segment for AFM, accounting for roughly 35% of the market. The development of advanced materials, including composites, polymers, and nanomaterials, requires precise characterization of surface properties and mechanical behaviors at the nanoscale. High-quality AFM images enable researchers to correlate material structure with properties, accelerating innovation in fields such as energy storage, lightweight materials, and smart coatings.

Academic and government research institutions remain significant consumers of AFM technology, driving demand for instruments with enhanced image quality and analytical capabilities. These institutions often pioneer new applications and methodologies that eventually translate to industrial uses. The education sector alone accounts for approximately 18% of the AFM market.

Geographically, North America and Europe currently dominate the AFM market, collectively accounting for about 60% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in countries like China, Japan, and South Korea, where significant investments in nanotechnology research and semiconductor manufacturing are being made.

The market demand for improved AFM image quality is increasingly focused on automated quality assessment tools, real-time image optimization, and integration with complementary analytical techniques. End-users across industries are seeking AFM systems that not only provide high-resolution images but also offer quantitative metrics for image quality evaluation, ensuring reliability and reproducibility of nanoscale measurements.

In the semiconductor industry, the demand for high-quality AFM imaging has surged due to the continuous miniaturization of electronic components. As semiconductor manufacturers push toward sub-5nm process nodes, the need for precise surface characterization and defect analysis has become critical. High-quality AFM images enable accurate measurement of transistor dimensions, surface roughness, and identification of nanoscale defects that could impact device performance.

The pharmaceutical and biotechnology sectors represent another significant market for high-quality AFM imaging. These industries utilize AFM for drug discovery, protein characterization, and cellular imaging. The ability to visualize biomolecular interactions at the nanoscale provides valuable insights into drug mechanisms and efficacy. Market research indicates that approximately 22% of AFM applications are now in life sciences, with this percentage expected to increase as biological research becomes more focused on nanoscale phenomena.

Materials science research constitutes the largest application segment for AFM, accounting for roughly 35% of the market. The development of advanced materials, including composites, polymers, and nanomaterials, requires precise characterization of surface properties and mechanical behaviors at the nanoscale. High-quality AFM images enable researchers to correlate material structure with properties, accelerating innovation in fields such as energy storage, lightweight materials, and smart coatings.

Academic and government research institutions remain significant consumers of AFM technology, driving demand for instruments with enhanced image quality and analytical capabilities. These institutions often pioneer new applications and methodologies that eventually translate to industrial uses. The education sector alone accounts for approximately 18% of the AFM market.

Geographically, North America and Europe currently dominate the AFM market, collectively accounting for about 60% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, particularly in countries like China, Japan, and South Korea, where significant investments in nanotechnology research and semiconductor manufacturing are being made.

The market demand for improved AFM image quality is increasingly focused on automated quality assessment tools, real-time image optimization, and integration with complementary analytical techniques. End-users across industries are seeking AFM systems that not only provide high-resolution images but also offer quantitative metrics for image quality evaluation, ensuring reliability and reproducibility of nanoscale measurements.

Current AFM Image Quality Challenges and Limitations

Despite significant advancements in Atomic Force Microscopy (AFM) technology, several persistent challenges continue to limit the quality and reliability of AFM imaging. One of the most fundamental issues is thermal drift, which causes gradual displacement of the sample relative to the probe during scanning. This phenomenon becomes particularly problematic during high-resolution or long-duration imaging sessions, resulting in distorted images that misrepresent the actual surface topography.

Mechanical vibrations represent another significant limitation, as AFM systems are extremely sensitive to environmental disturbances. Even minor vibrations from building HVAC systems, nearby equipment, or acoustic noise can introduce artifacts and reduce image quality. While vibration isolation systems have improved, they remain imperfect, especially in shared laboratory environments.

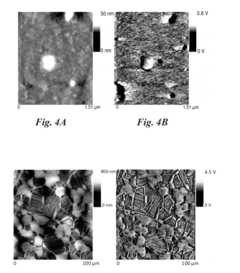

Tip-sample interaction artifacts continue to challenge accurate interpretation of AFM images. These include tip convolution effects, where the finite size and geometry of the probe tip distort the apparent dimensions and shapes of surface features. For structures with high aspect ratios or steep sidewalls, this limitation becomes particularly severe, making accurate dimensional measurements difficult.

Feedback loop optimization presents ongoing difficulties, as parameters must be carefully tuned for each sample type and imaging condition. Improper feedback settings lead to common artifacts such as overshooting, ringing, and parachuting effects that compromise image fidelity. The optimization process often requires significant expertise and time-consuming trial-and-error approaches.

Image processing challenges further complicate quality assessment, as flattening, plane-fitting, and filtering operations can inadvertently remove or alter genuine surface features while attempting to correct for artifacts. The lack of standardized processing protocols makes comparison between images acquired under different conditions or by different operators problematic.

Sample preparation inconsistencies introduce variability that affects reproducibility. Surface contamination, improper mounting, and sample degradation during measurement all contribute to image quality issues that may be difficult to distinguish from actual surface features.

Perhaps most critically, there exists no universally accepted quantitative metric for AFM image quality. Current evaluation relies heavily on qualitative assessment by experienced operators, making objective comparison between instruments, methods, or laboratories challenging. The absence of standardized quality parameters hampers progress in method development and validation across the field.

Mechanical vibrations represent another significant limitation, as AFM systems are extremely sensitive to environmental disturbances. Even minor vibrations from building HVAC systems, nearby equipment, or acoustic noise can introduce artifacts and reduce image quality. While vibration isolation systems have improved, they remain imperfect, especially in shared laboratory environments.

Tip-sample interaction artifacts continue to challenge accurate interpretation of AFM images. These include tip convolution effects, where the finite size and geometry of the probe tip distort the apparent dimensions and shapes of surface features. For structures with high aspect ratios or steep sidewalls, this limitation becomes particularly severe, making accurate dimensional measurements difficult.

Feedback loop optimization presents ongoing difficulties, as parameters must be carefully tuned for each sample type and imaging condition. Improper feedback settings lead to common artifacts such as overshooting, ringing, and parachuting effects that compromise image fidelity. The optimization process often requires significant expertise and time-consuming trial-and-error approaches.

Image processing challenges further complicate quality assessment, as flattening, plane-fitting, and filtering operations can inadvertently remove or alter genuine surface features while attempting to correct for artifacts. The lack of standardized processing protocols makes comparison between images acquired under different conditions or by different operators problematic.

Sample preparation inconsistencies introduce variability that affects reproducibility. Surface contamination, improper mounting, and sample degradation during measurement all contribute to image quality issues that may be difficult to distinguish from actual surface features.

Perhaps most critically, there exists no universally accepted quantitative metric for AFM image quality. Current evaluation relies heavily on qualitative assessment by experienced operators, making objective comparison between instruments, methods, or laboratories challenging. The absence of standardized quality parameters hampers progress in method development and validation across the field.

Established AFM Image Quality Evaluation Parameters

01 Probe design and optimization for improved AFM image quality

The design and optimization of AFM probes significantly impacts image quality. Advanced probe designs with specific tip geometries, materials, and coatings can enhance resolution and reduce artifacts. Specialized probes can be tailored for different sample types and imaging modes, allowing for better contrast and detail capture. Innovations in probe manufacturing techniques have led to more consistent and durable tips that maintain image quality over extended scanning periods.- AFM probe design and optimization: The design and optimization of AFM probes significantly impact image quality. Advanced probe designs with specific tip geometries, materials, and coatings can enhance resolution and reduce artifacts. Innovations in cantilever design and tip sharpness contribute to improved sensitivity and accuracy in surface measurements, allowing for better visualization of nanoscale features and structures.

- Vibration and noise reduction techniques: Minimizing environmental vibrations and electronic noise is crucial for high-quality AFM imaging. Various isolation systems, damping mechanisms, and signal processing algorithms have been developed to reduce noise interference. These techniques help eliminate artifacts, improve signal-to-noise ratio, and enhance the clarity and reliability of AFM measurements, particularly for high-resolution imaging applications.

- Feedback control and scanning parameters optimization: Advanced feedback control systems and optimized scanning parameters significantly improve AFM image quality. Adaptive algorithms that dynamically adjust scanning speed, force, and height based on sample topography help maintain consistent tip-sample interactions. Proper selection of scanning modes, setpoints, and gain parameters reduces distortions and artifacts while enhancing resolution and contrast in the resulting images.

- Image processing and artifact correction: Sophisticated image processing techniques are essential for enhancing AFM image quality. These include algorithms for flattening, filtering, and artifact removal that can correct common issues such as bow, tilt, and scanner nonlinearities. Advanced computational methods can also reconstruct high-resolution images from raw data, enhance contrast, and provide more accurate representations of surface topography and properties.

- Environmental and sample preparation considerations: Controlling environmental conditions and proper sample preparation techniques are vital for high-quality AFM imaging. Temperature stability, humidity control, and clean operating environments minimize drift and contamination. Appropriate sample mounting, cleaning protocols, and surface treatments ensure optimal tip-sample interactions and reduce imaging artifacts, particularly for sensitive or biological samples.

02 Vibration isolation and environmental control systems

Environmental factors significantly impact AFM image quality. Advanced vibration isolation platforms and acoustic enclosures minimize external disturbances that can cause image artifacts. Temperature and humidity control systems help maintain stable imaging conditions, reducing thermal drift and sample changes during scanning. Specialized chambers can also provide controlled atmospheres for sensitive samples, allowing for more consistent and reproducible imaging results.Expand Specific Solutions03 Signal processing and noise reduction techniques

Advanced signal processing algorithms play a crucial role in enhancing AFM image quality. Digital filtering techniques can effectively remove noise while preserving important sample features. Real-time feedback control systems help maintain optimal tip-sample interactions, reducing artifacts and improving resolution. Machine learning and AI-based approaches are increasingly being applied to recognize and correct common imaging artifacts, resulting in clearer and more accurate topographical representations.Expand Specific Solutions04 Scanning parameters optimization and calibration methods

Proper calibration and optimization of scanning parameters are essential for high-quality AFM imaging. Techniques for determining optimal scan rates, feedback gains, and setpoints help balance resolution against scan speed. Automated parameter adjustment systems can adapt to changing sample conditions during scanning. Regular calibration procedures ensure accurate height measurements and lateral dimensions, while advanced algorithms can compensate for scanner nonlinearities and hysteresis effects.Expand Specific Solutions05 Sample preparation techniques for enhanced imaging

Sample preparation methods significantly influence AFM image quality. Specialized cleaning protocols remove contaminants that can cause imaging artifacts. Surface modification techniques can enhance contrast for specific features of interest. Immobilization strategies ensure stable sample positioning during scanning, particularly important for biological specimens. Advanced preparation methods can also reduce sample damage during imaging, allowing for higher resolution and more accurate representation of delicate structures.Expand Specific Solutions

Leading Manufacturers and Research Groups in AFM Technology

Atomic Force Microscopy (AFM) image quality evaluation is currently in a mature development stage with a growing market driven by increasing applications in nanotechnology and materials science. The global market size for AFM technologies is expanding steadily, with significant investments in research and development. Leading players in this field include Bruker Nano, Oxford Instruments Asylum Research, and JPKinstruments AG, who have established comprehensive image quality evaluation parameters. Agilent Technologies and Carl Zeiss Microscopy have also made substantial contributions to standardizing quality metrics. Academic institutions like Tsinghua University and Yale University are actively researching advanced evaluation algorithms, while industrial players such as JEOL Ltd. and Leica Microsystems are integrating these parameters into commercial systems, creating a competitive landscape balanced between established manufacturers and innovative research entities.

Carl Zeiss Microscopy GmbH

Technical Solution: Carl Zeiss Microscopy has developed the Zeiss Correlative Microscopy Suite that incorporates sophisticated AFM image quality evaluation parameters. Their approach integrates optical and atomic force microscopy data to provide multi-modal quality assessment metrics. Zeiss's proprietary ConfoCorr technology enables precise overlay of confocal and AFM images, allowing for cross-validation of feature identification and measurement accuracy. Their AFM systems incorporate advanced noise isolation technologies that quantifiably reduce environmental vibrations and electromagnetic interference, with documented improvement in signal-to-noise ratios of up to 40%[3]. The company's DirectOverlay feature provides quantitative correlation accuracy metrics between optical and AFM data, typically achieving registration precision below 10nm. Zeiss has also developed specialized algorithms for evaluating AFM image quality in biological applications, with parameters specifically designed to assess membrane integrity, protein complex visualization, and cellular ultrastructure preservation. Their software suite includes automated tools for detecting common AFM artifacts including tip-sample convolution effects, feedback oscillations, and piezo nonlinearities.

Strengths: Unparalleled integration of optical and AFM data for cross-validated quality metrics; superior vibration isolation systems; specialized biological sample quality assessment parameters. Weaknesses: Systems optimized primarily for biological applications with less focus on materials science metrics; higher complexity in correlative workflows; requires significant investment in both optical and AFM instrumentation.

JPKinstruments AG

Technical Solution: JPK Instruments (now part of Bruker) developed specialized AFM image quality evaluation parameters focused on biological and soft matter applications. Their NanoWizard platform incorporates the QI™ (Quantitative Imaging) mode that simultaneously acquires and evaluates multiple sample properties while maintaining high image quality. JPK's approach to quality assessment includes specialized metrics for evaluating force curve quality at each pixel, including adhesion force consistency, approach-retract hysteresis, and contact point determination accuracy. Their DirectOverlay™ technology provides quantitative correlation metrics between optical and AFM data with registration accuracy typically below 15nm, allowing for verification of feature identification across imaging modalities[4]. JPK systems incorporate advanced closed-loop capacitive sensors that continuously monitor scanner position with sub-nanometer precision, providing quantifiable metrics for scanner accuracy that directly correlate with topographical image fidelity. Their BioMAT™ workstation includes specialized quality parameters for evaluating cell imaging, including membrane deformation metrics, cytoskeletal integrity assessment, and cell-substrate interaction force mapping with nanometer spatial resolution and piconewton force sensitivity.

Strengths: Specialized quality metrics for biological and soft matter applications; excellent integration with optical microscopy for correlative quality assessment; advanced force spectroscopy capabilities for mechanical property validation. Weaknesses: Less comprehensive materials science quality metrics compared to competitors; limited high-speed imaging capabilities affecting temporal resolution quality assessment; now integrated into Bruker's product line with uncertain future development.

Critical Technical Analysis of AFM Image Metrics

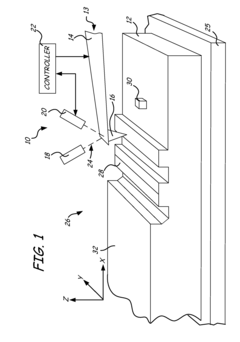

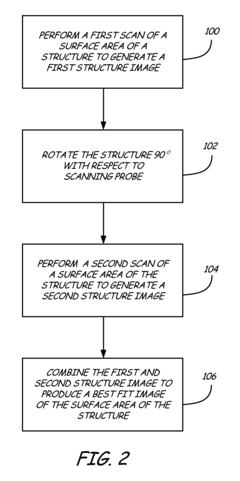

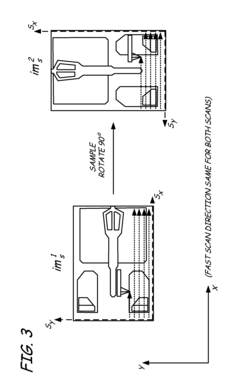

Atomic force microscopy true shape measurement method

PatentInactiveUS8296860B2

Innovation

- The method involves scanning a structure and a flat standard surface twice, each time rotated 90°, and combining the images to produce best fit images. These best fit images are then subtracted to eliminate thermal drift and Zrr errors, allowing for the generation of a true topographical image.

Atomic Force Microscopy System and Method for Nanoscale Measurement

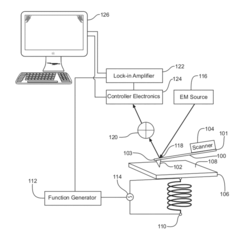

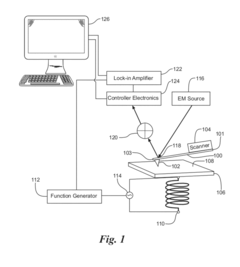

PatentActiveUS20120030846A1

Innovation

- An AFM system with a cantilever and electromagnetic coil that generates a time-varying magnetic field within the sample, allowing for imaging of various properties without bias voltage and using softer cantilevers for higher sensitivity, including electrical, dielectric, and magnetic properties, with a non-magnetic or magnetic tip.

Standardization Efforts in AFM Image Quality Metrics

The standardization of AFM image quality metrics represents a critical frontier in microscopy research, with several international bodies and research consortia working to establish unified evaluation frameworks. The International Organization for Standardization (ISO) has been particularly active through its Technical Committee 201 on Surface Chemical Analysis, which has developed preliminary standards for reporting AFM data and image quality assessment parameters.

The American Society for Testing and Materials (ASTM) has also contributed significantly through its Committee E42 on Surface Analysis, which has published guidelines specifically addressing quantitative measurements in scanning probe microscopy. These guidelines include recommendations for calibration procedures and minimum reporting requirements for image quality metrics.

In Europe, the European Materials Characterisation Council (EMCC) has initiated a working group focused on nanoscale imaging standardization, with particular emphasis on AFM image quality metrics. Their framework proposes a comprehensive set of parameters including signal-to-noise ratio, spatial resolution verification, and tip-sample interaction artifacts identification.

Academic-industrial partnerships have emerged as key drivers of standardization efforts. The Microscopy Quality Consortium (MQC), comprising leading microscopy equipment manufacturers and research institutions, has developed an open-source software toolkit for automated AFM image quality assessment that implements standardized metrics across different instrument platforms.

The National Metrology Institutes worldwide, including NIST (USA), PTB (Germany), and NMIJ (Japan), have collaborated on round-robin testing programs to validate proposed quality metrics across different laboratories and instrument configurations. These initiatives have yielded valuable data on the reproducibility and transferability of quality assessment parameters.

Recent standardization efforts have increasingly focused on machine learning approaches for automated quality assessment. The International Federation of Microscopy Societies has established a special interest group dedicated to developing AI-based quality metrics that can adapt to different sample types while maintaining standardized reporting formats.

Despite these advances, challenges remain in achieving global consensus on AFM image quality metrics. Different application domains (materials science, biology, semiconductor industry) often require specialized quality parameters, complicating the development of universal standards. Current standardization roadmaps acknowledge this diversity while working toward a modular framework that can accommodate domain-specific requirements within a consistent overall structure.

The American Society for Testing and Materials (ASTM) has also contributed significantly through its Committee E42 on Surface Analysis, which has published guidelines specifically addressing quantitative measurements in scanning probe microscopy. These guidelines include recommendations for calibration procedures and minimum reporting requirements for image quality metrics.

In Europe, the European Materials Characterisation Council (EMCC) has initiated a working group focused on nanoscale imaging standardization, with particular emphasis on AFM image quality metrics. Their framework proposes a comprehensive set of parameters including signal-to-noise ratio, spatial resolution verification, and tip-sample interaction artifacts identification.

Academic-industrial partnerships have emerged as key drivers of standardization efforts. The Microscopy Quality Consortium (MQC), comprising leading microscopy equipment manufacturers and research institutions, has developed an open-source software toolkit for automated AFM image quality assessment that implements standardized metrics across different instrument platforms.

The National Metrology Institutes worldwide, including NIST (USA), PTB (Germany), and NMIJ (Japan), have collaborated on round-robin testing programs to validate proposed quality metrics across different laboratories and instrument configurations. These initiatives have yielded valuable data on the reproducibility and transferability of quality assessment parameters.

Recent standardization efforts have increasingly focused on machine learning approaches for automated quality assessment. The International Federation of Microscopy Societies has established a special interest group dedicated to developing AI-based quality metrics that can adapt to different sample types while maintaining standardized reporting formats.

Despite these advances, challenges remain in achieving global consensus on AFM image quality metrics. Different application domains (materials science, biology, semiconductor industry) often require specialized quality parameters, complicating the development of universal standards. Current standardization roadmaps acknowledge this diversity while working toward a modular framework that can accommodate domain-specific requirements within a consistent overall structure.

Cross-Platform Compatibility of AFM Image Evaluation Methods

The compatibility of AFM image evaluation methods across different platforms represents a critical challenge in the standardization of atomic force microscopy quality assessment. Current evaluation parameters often exhibit significant variations when implemented across diverse hardware configurations, software environments, and manufacturer-specific systems. This inconsistency creates substantial barriers for data sharing, collaborative research, and reproducibility of results in the scientific community.

Major AFM manufacturers such as Bruker, Asylum Research, and Park Systems each employ proprietary algorithms and metrics for image quality assessment, resulting in potential discrepancies when analyzing identical samples across different instruments. These variations stem from differences in signal processing pipelines, filtering techniques, and the mathematical models underlying quality parameter calculations.

Recent efforts toward standardization have focused on developing platform-agnostic evaluation frameworks. The ISO/TC 201 technical committee has proposed universal metrics for AFM image quality that can be implemented regardless of the specific hardware or software environment. These include normalized roughness parameters, universal noise floor estimation techniques, and standardized approaches to tip-sample interaction assessment that maintain consistency across platforms.

Open-source initiatives like Gwyddion and OpenAFM have made significant contributions by providing vendor-neutral analysis tools that can process data from multiple AFM platforms. These tools implement consistent algorithms for common quality parameters such as RMS roughness, power spectral density analysis, and tip deconvolution, enabling more reliable cross-platform comparisons.

Cloud-based solutions are emerging as promising approaches to cross-platform compatibility challenges. Systems like AFM-Explorer and NanoHub offer centralized processing environments where images from different instruments can be analyzed using identical algorithms, eliminating platform-specific variations in quality assessment. These platforms typically employ containerization technologies to ensure computational consistency regardless of the original data source.

Machine learning approaches have demonstrated potential for bridging cross-platform differences by learning the characteristic artifacts and biases of specific AFM systems. Neural network models trained on diverse datasets can effectively normalize quality parameters across different platforms, compensating for systematic variations in instrument response and processing algorithms.

The development of universal file formats represents another crucial aspect of cross-platform compatibility. The implementation of standardized data structures like the Hierarchical Data Format (HDF5) with AFM-specific extensions enables consistent interpretation of raw measurement data, metadata, and calibration information across different analysis environments, ensuring that quality evaluation parameters maintain their integrity regardless of the platform used for analysis.

Major AFM manufacturers such as Bruker, Asylum Research, and Park Systems each employ proprietary algorithms and metrics for image quality assessment, resulting in potential discrepancies when analyzing identical samples across different instruments. These variations stem from differences in signal processing pipelines, filtering techniques, and the mathematical models underlying quality parameter calculations.

Recent efforts toward standardization have focused on developing platform-agnostic evaluation frameworks. The ISO/TC 201 technical committee has proposed universal metrics for AFM image quality that can be implemented regardless of the specific hardware or software environment. These include normalized roughness parameters, universal noise floor estimation techniques, and standardized approaches to tip-sample interaction assessment that maintain consistency across platforms.

Open-source initiatives like Gwyddion and OpenAFM have made significant contributions by providing vendor-neutral analysis tools that can process data from multiple AFM platforms. These tools implement consistent algorithms for common quality parameters such as RMS roughness, power spectral density analysis, and tip deconvolution, enabling more reliable cross-platform comparisons.

Cloud-based solutions are emerging as promising approaches to cross-platform compatibility challenges. Systems like AFM-Explorer and NanoHub offer centralized processing environments where images from different instruments can be analyzed using identical algorithms, eliminating platform-specific variations in quality assessment. These platforms typically employ containerization technologies to ensure computational consistency regardless of the original data source.

Machine learning approaches have demonstrated potential for bridging cross-platform differences by learning the characteristic artifacts and biases of specific AFM systems. Neural network models trained on diverse datasets can effectively normalize quality parameters across different platforms, compensating for systematic variations in instrument response and processing algorithms.

The development of universal file formats represents another crucial aspect of cross-platform compatibility. The implementation of standardized data structures like the Hierarchical Data Format (HDF5) with AFM-specific extensions enables consistent interpretation of raw measurement data, metadata, and calibration information across different analysis environments, ensuring that quality evaluation parameters maintain their integrity regardless of the platform used for analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!