Atomic Force Microscopy Vs Second Harmonic Generation: Resolution, Detail

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM and SHG Technology Background and Objectives

Atomic Force Microscopy (AFM) and Second Harmonic Generation (SHG) represent two distinct yet complementary approaches in advanced microscopy techniques that have revolutionized our ability to visualize and characterize materials at the nanoscale. Since its invention in 1986 by Binnig, Quate, and Gerber, AFM has evolved from a simple imaging tool to a sophisticated platform capable of measuring various surface properties including topography, mechanical characteristics, and electrical properties with nanometer resolution.

The development trajectory of AFM has seen significant advancements in probe design, feedback mechanisms, and operational modes, enabling its application across diverse fields from materials science to biological research. Concurrently, SHG microscopy, based on nonlinear optical phenomena discovered in the 1960s, has emerged as a powerful technique for studying non-centrosymmetric structures and interfaces without the need for exogenous labels.

Recent technological innovations have pushed both techniques toward higher resolution capabilities. AFM has achieved atomic resolution in certain conditions, while SHG microscopy has demonstrated sub-diffraction imaging capabilities through various enhancement approaches. The convergence of these technologies with computational methods has further expanded their analytical power.

The primary objective of comparing AFM and SHG lies in understanding their complementary strengths in resolution and detail capabilities. AFM excels in providing three-dimensional surface topography with nanometer precision but is limited by scanning speed and tip-sample interactions. Conversely, SHG offers non-invasive optical sectioning with chemical specificity but faces challenges in spatial resolution compared to AFM.

Industry trends indicate growing demand for multimodal imaging solutions that combine the strengths of both techniques. The integration of AFM with optical techniques, including SHG, represents a frontier in microscopy development, aiming to provide comprehensive characterization of materials across multiple dimensions and properties.

The technological evolution of both AFM and SHG continues to be driven by demands from emerging fields such as nanomedicine, quantum computing, and advanced materials development. Researchers are actively pursuing improvements in temporal resolution for AFM and spatial resolution for SHG to address current limitations.

Understanding the fundamental principles, historical development, and current capabilities of these technologies provides essential context for evaluating their respective strengths and limitations in various applications, ultimately guiding future innovation in high-resolution microscopy techniques.

The development trajectory of AFM has seen significant advancements in probe design, feedback mechanisms, and operational modes, enabling its application across diverse fields from materials science to biological research. Concurrently, SHG microscopy, based on nonlinear optical phenomena discovered in the 1960s, has emerged as a powerful technique for studying non-centrosymmetric structures and interfaces without the need for exogenous labels.

Recent technological innovations have pushed both techniques toward higher resolution capabilities. AFM has achieved atomic resolution in certain conditions, while SHG microscopy has demonstrated sub-diffraction imaging capabilities through various enhancement approaches. The convergence of these technologies with computational methods has further expanded their analytical power.

The primary objective of comparing AFM and SHG lies in understanding their complementary strengths in resolution and detail capabilities. AFM excels in providing three-dimensional surface topography with nanometer precision but is limited by scanning speed and tip-sample interactions. Conversely, SHG offers non-invasive optical sectioning with chemical specificity but faces challenges in spatial resolution compared to AFM.

Industry trends indicate growing demand for multimodal imaging solutions that combine the strengths of both techniques. The integration of AFM with optical techniques, including SHG, represents a frontier in microscopy development, aiming to provide comprehensive characterization of materials across multiple dimensions and properties.

The technological evolution of both AFM and SHG continues to be driven by demands from emerging fields such as nanomedicine, quantum computing, and advanced materials development. Researchers are actively pursuing improvements in temporal resolution for AFM and spatial resolution for SHG to address current limitations.

Understanding the fundamental principles, historical development, and current capabilities of these technologies provides essential context for evaluating their respective strengths and limitations in various applications, ultimately guiding future innovation in high-resolution microscopy techniques.

Market Applications and Demand Analysis

The market for advanced microscopy and imaging technologies has witnessed substantial growth in recent years, driven by increasing demands across multiple sectors including materials science, semiconductor manufacturing, biomedical research, and nanotechnology. The global advanced microscopy market was valued at approximately $6.3 billion in 2022 and is projected to reach $9.7 billion by 2027, growing at a CAGR of 7.5%.

Within this expanding market, both Atomic Force Microscopy (AFM) and Second Harmonic Generation (SHG) technologies occupy distinct yet overlapping niches, with different demand drivers and application profiles. AFM has established a strong presence in industrial quality control, semiconductor manufacturing, and materials research, where its ability to provide three-dimensional surface profiles at nanoscale resolution addresses critical measurement needs.

The demand for AFM systems is particularly robust in the semiconductor industry, where the continuous miniaturization of components requires increasingly precise measurement capabilities. This sector alone accounts for approximately 35% of the total AFM market. Materials science applications represent another 28%, while biological applications constitute about 20% of current market demand.

SHG microscopy, while representing a smaller market segment, has experienced accelerated growth, particularly in biomedical research and pharmaceutical development. The non-invasive nature of SHG and its ability to visualize non-centrosymmetric structures without labeling has created significant demand in tissue imaging, particularly for collagen and muscle fiber analysis. The pharmaceutical industry has increasingly adopted SHG for drug discovery applications, with an estimated market growth rate of 12% annually in this sector.

Academic and research institutions represent the largest customer segment for both technologies, accounting for approximately 45% of total sales. However, industrial applications are growing at a faster rate, particularly for AFM systems in quality control and failure analysis workflows.

Regional analysis reveals that North America currently leads the market for both technologies, accounting for approximately 38% of global demand, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding semiconductor manufacturing capabilities and increasing research investments in China, South Korea, and Taiwan.

Customer feedback indicates growing demand for integrated systems that combine multiple imaging modalities, suggesting potential market opportunities for hybrid AFM-SHG systems that could leverage the complementary strengths of both technologies. Additionally, there is increasing demand for automated analysis capabilities and user-friendly interfaces that reduce the expertise required to operate these sophisticated instruments.

Within this expanding market, both Atomic Force Microscopy (AFM) and Second Harmonic Generation (SHG) technologies occupy distinct yet overlapping niches, with different demand drivers and application profiles. AFM has established a strong presence in industrial quality control, semiconductor manufacturing, and materials research, where its ability to provide three-dimensional surface profiles at nanoscale resolution addresses critical measurement needs.

The demand for AFM systems is particularly robust in the semiconductor industry, where the continuous miniaturization of components requires increasingly precise measurement capabilities. This sector alone accounts for approximately 35% of the total AFM market. Materials science applications represent another 28%, while biological applications constitute about 20% of current market demand.

SHG microscopy, while representing a smaller market segment, has experienced accelerated growth, particularly in biomedical research and pharmaceutical development. The non-invasive nature of SHG and its ability to visualize non-centrosymmetric structures without labeling has created significant demand in tissue imaging, particularly for collagen and muscle fiber analysis. The pharmaceutical industry has increasingly adopted SHG for drug discovery applications, with an estimated market growth rate of 12% annually in this sector.

Academic and research institutions represent the largest customer segment for both technologies, accounting for approximately 45% of total sales. However, industrial applications are growing at a faster rate, particularly for AFM systems in quality control and failure analysis workflows.

Regional analysis reveals that North America currently leads the market for both technologies, accounting for approximately 38% of global demand, followed by Europe (27%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding semiconductor manufacturing capabilities and increasing research investments in China, South Korea, and Taiwan.

Customer feedback indicates growing demand for integrated systems that combine multiple imaging modalities, suggesting potential market opportunities for hybrid AFM-SHG systems that could leverage the complementary strengths of both technologies. Additionally, there is increasing demand for automated analysis capabilities and user-friendly interfaces that reduce the expertise required to operate these sophisticated instruments.

Current Technical Limitations and Challenges

Despite significant advancements in both Atomic Force Microscopy (AFM) and Second Harmonic Generation (SHG) technologies, each faces distinct technical limitations that impact their effectiveness in high-resolution imaging applications. AFM, while offering exceptional spatial resolution down to the atomic level, struggles with several operational constraints. The scanning speed remains a significant bottleneck, with typical imaging times ranging from minutes to hours depending on the scan area and resolution requirements, making real-time observations of dynamic processes challenging.

Sample preparation for AFM presents another hurdle, as measurements typically require flat, stable surfaces. Highly rough or soft samples can lead to tip-sample interaction artifacts, compromising data reliability. The physical contact between the probe tip and sample surface can potentially damage delicate biological specimens or alter sensitive surface structures, limiting applications in certain fields.

Environmental sensitivity also affects AFM performance, with thermal drift and vibrations introducing measurement errors that require sophisticated isolation systems. Additionally, the tip geometry and condition significantly influence image quality, with tip wear and contamination leading to resolution degradation over time and necessitating frequent replacements.

SHG microscopy faces its own set of challenges, primarily related to signal strength and specificity. The second harmonic signal is inherently weak, typically 10^-6 to 10^-8 of the fundamental input intensity, requiring high-power laser sources that may cause photodamage to sensitive samples. This becomes particularly problematic when imaging biological tissues where phototoxicity must be minimized.

The non-linear optical process in SHG is highly dependent on molecular orientation and symmetry, resulting in signal generation only from non-centrosymmetric structures. This selectivity, while advantageous for specific applications, limits its universal applicability compared to AFM. Furthermore, SHG typically provides lower spatial resolution than AFM, with practical limits around 200-300 nm due to the diffraction limit, though super-resolution techniques are gradually improving this boundary.

Technical integration challenges exist for both technologies. AFM systems require precise mechanical components and sophisticated feedback mechanisms, making miniaturization and integration with other analytical techniques difficult. SHG systems demand complex optical setups with precise alignment and specialized components, including femtosecond lasers and sensitive detectors, resulting in substantial system costs and maintenance requirements.

Cross-platform standardization remains underdeveloped, with limited protocols for comparing results between different AFM or SHG systems, hampering data reproducibility and collaborative research efforts. These technical limitations collectively represent the current frontiers that researchers must address to further advance these powerful imaging technologies.

Sample preparation for AFM presents another hurdle, as measurements typically require flat, stable surfaces. Highly rough or soft samples can lead to tip-sample interaction artifacts, compromising data reliability. The physical contact between the probe tip and sample surface can potentially damage delicate biological specimens or alter sensitive surface structures, limiting applications in certain fields.

Environmental sensitivity also affects AFM performance, with thermal drift and vibrations introducing measurement errors that require sophisticated isolation systems. Additionally, the tip geometry and condition significantly influence image quality, with tip wear and contamination leading to resolution degradation over time and necessitating frequent replacements.

SHG microscopy faces its own set of challenges, primarily related to signal strength and specificity. The second harmonic signal is inherently weak, typically 10^-6 to 10^-8 of the fundamental input intensity, requiring high-power laser sources that may cause photodamage to sensitive samples. This becomes particularly problematic when imaging biological tissues where phototoxicity must be minimized.

The non-linear optical process in SHG is highly dependent on molecular orientation and symmetry, resulting in signal generation only from non-centrosymmetric structures. This selectivity, while advantageous for specific applications, limits its universal applicability compared to AFM. Furthermore, SHG typically provides lower spatial resolution than AFM, with practical limits around 200-300 nm due to the diffraction limit, though super-resolution techniques are gradually improving this boundary.

Technical integration challenges exist for both technologies. AFM systems require precise mechanical components and sophisticated feedback mechanisms, making miniaturization and integration with other analytical techniques difficult. SHG systems demand complex optical setups with precise alignment and specialized components, including femtosecond lasers and sensitive detectors, resulting in substantial system costs and maintenance requirements.

Cross-platform standardization remains underdeveloped, with limited protocols for comparing results between different AFM or SHG systems, hampering data reproducibility and collaborative research efforts. These technical limitations collectively represent the current frontiers that researchers must address to further advance these powerful imaging technologies.

Comparative Resolution Capabilities and Methodologies

01 AFM resolution capabilities and advancements

Atomic Force Microscopy (AFM) offers nanoscale resolution capabilities, allowing for detailed surface imaging at the atomic level. Recent advancements have improved resolution to sub-nanometer levels, enabling visualization of molecular structures and surface topography with exceptional precision. These improvements include enhanced probe designs, vibration isolation systems, and feedback control mechanisms that minimize noise and increase sensitivity. The high-resolution capabilities make AFM particularly valuable for characterizing material surfaces, biological samples, and nanostructures.- AFM resolution capabilities and advancements: Atomic Force Microscopy (AFM) offers nanoscale resolution capabilities, allowing for detailed surface imaging at the atomic level. Recent advancements have improved resolution to sub-nanometer levels, enabling visualization of molecular structures and surface topography with exceptional precision. These improvements include enhanced probe designs, vibration isolation systems, and feedback control mechanisms that minimize artifacts and noise, resulting in clearer images with higher resolution.

- SHG imaging resolution and optical capabilities: Second Harmonic Generation (SHG) microscopy provides unique optical resolution capabilities for non-centrosymmetric structures. This label-free imaging technique offers sub-micron resolution with high contrast for specific biological structures like collagen and cell membranes. SHG microscopy can achieve diffraction-limited resolution while providing molecular specificity based on nonlinear optical properties, making it valuable for studying structural organization in tissues and materials without fluorescent labeling.

- Combined AFM-SHG systems for multi-modal imaging: Integration of Atomic Force Microscopy with Second Harmonic Generation creates powerful multi-modal imaging platforms that combine mechanical and optical information. These hybrid systems leverage the nanoscale topographical resolution of AFM with the molecular specificity of SHG, enabling correlative analysis of surface structures and their nonlinear optical properties. This combination allows researchers to simultaneously obtain complementary data sets that provide more comprehensive characterization of samples than either technique alone.

- Advanced probe technologies for enhanced resolution: Specialized probe technologies have significantly enhanced the resolution capabilities of both AFM and SHG microscopy. For AFM, functionalized tips, carbon nanotube probes, and quantum-limited sensors have improved force sensitivity and spatial resolution. In SHG applications, advanced optical configurations and specialized probes enable better signal collection and reduced background noise. These technological advancements allow for more detailed imaging of surface features and molecular structures at unprecedented resolution levels.

- Environmental and sample preparation factors affecting resolution: Environmental conditions and sample preparation techniques significantly impact the resolution capabilities of both AFM and SHG imaging. Factors such as temperature stability, vibration isolation, humidity control, and sample surface preparation are critical for achieving optimal resolution. Advanced environmental control systems and specialized sample preparation protocols have been developed to minimize artifacts and maximize the detail capabilities of these microscopy techniques, particularly for sensitive biological samples or nanomaterials.

02 SHG imaging resolution and optical capabilities

Second Harmonic Generation (SHG) microscopy provides unique optical resolution capabilities by converting two photons of the same frequency into a single photon with twice the energy. This non-linear optical technique offers diffraction-limited resolution with the ability to image structures without labeling. SHG is particularly effective for visualizing non-centrosymmetric structures such as collagen fibers and cell membranes. The technique provides excellent contrast in biological tissues and can achieve resolution in the hundreds of nanometers range, with recent advances pushing toward better resolution through improved optical configurations and detection methods.Expand Specific Solutions03 Combined AFM-SHG systems for enhanced imaging

Integration of Atomic Force Microscopy with Second Harmonic Generation creates powerful hybrid imaging systems that combine the high spatial resolution of AFM with the optical specificity of SHG. These combined systems enable correlative microscopy where mechanical and optical properties can be measured simultaneously at the same sample location. The integration overcomes limitations of each individual technique, providing comprehensive characterization of samples with nanoscale resolution of surface features alongside molecular-specific optical contrast. Such systems are particularly valuable for investigating biological samples and advanced materials where both structural and functional information is required.Expand Specific Solutions04 Sample preparation and environmental factors affecting resolution

The resolution capabilities of both AFM and SHG are significantly influenced by sample preparation techniques and environmental conditions. Factors such as sample flatness, cleanliness, humidity, and temperature stability can dramatically impact measurement quality. For AFM, proper mounting to minimize vibration and drift is crucial, while for SHG, optical clarity of the sample and surrounding medium affects resolution. Advanced sample preparation protocols have been developed to optimize imaging conditions, including specialized substrates, fixation methods for biological samples, and environmental control chambers that maintain stable conditions during measurement to achieve the highest possible resolution.Expand Specific Solutions05 Data processing and resolution enhancement techniques

Advanced data processing algorithms and computational techniques have been developed to enhance the effective resolution of both AFM and SHG imaging. These include deconvolution methods, noise filtering, signal averaging, and machine learning approaches that can extract more information from raw measurement data. For AFM, tip deconvolution algorithms compensate for probe geometry effects, while for SHG, phase-sensitive detection and spectral filtering improve signal-to-noise ratios. These computational approaches, combined with hardware improvements, push the resolution limits beyond what would be physically possible with the raw instrumentation alone, enabling visualization of previously undetectable features.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The comparative analysis of Atomic Force Microscopy (AFM) versus Second Harmonic Generation (SHG) imaging technologies reveals a competitive landscape in advanced microscopy. The market is in a growth phase, with increasing applications in materials science, semiconductor, and biological research driving expansion. Market size is projected to grow significantly as research institutions and industries adopt these technologies for nanoscale imaging. In terms of technical maturity, AFM is more established with key players like Bruker Nano, Veeco Instruments, and KLA Corp. offering commercial solutions, while SHG technology is emerging with research leadership from institutions like California Institute of Technology, Northwestern University, and companies like IBM. The competitive dynamics are shifting as both technologies evolve to address resolution limitations and specialized applications.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced AFM technologies that push the boundaries of resolution capabilities. Their PeakForce Tapping technology enables atomic resolution imaging while protecting delicate samples from damage. The company's latest AFM systems incorporate proprietary algorithms for noise reduction and signal processing, achieving sub-nanometer resolution in three dimensions. Bruker's FastScan technology allows for high-speed imaging without sacrificing resolution, enabling researchers to capture dynamic processes at the nanoscale. Their systems also integrate multiple measurement modes, allowing simultaneous acquisition of mechanical, electrical, and chemical properties alongside topographical data. Bruker has recently enhanced their AFM capabilities with AI-assisted image processing and analysis tools that improve data interpretation and feature recognition[1][3].

Strengths: Industry-leading resolution capabilities with sub-nanometer precision; comprehensive suite of measurement modes; robust software ecosystem for data analysis. Weaknesses: High cost of acquisition and maintenance; steep learning curve for new users; limited penetration depth compared to some other techniques.

Veeco Instruments, Inc.

Technical Solution: Veeco Instruments has pioneered hybrid AFM-optical systems that combine the strengths of both techniques. Their Dimension series AFMs feature proprietary closed-loop scanning technology that eliminates drift and hysteresis effects, enabling precise positioning and measurement repeatability at the nanoscale. Veeco's BlueDrive photothermal excitation technology provides more stable and accurate cantilever tuning compared to traditional piezo-driven systems, resulting in more reliable force measurements and improved resolution. The company has also developed specialized AFM probes with ultra-sharp tips that can achieve atomic resolution on suitable samples. Veeco's systems incorporate advanced noise isolation and vibration dampening technologies, allowing researchers to approach theoretical resolution limits in real-world laboratory environments. Their latest systems feature automated probe approach and parameter optimization, making high-resolution imaging more accessible to non-specialist users[2][4].

Strengths: Excellent stability and drift compensation; user-friendly interface suitable for multi-user facilities; comprehensive application support. Weaknesses: Less specialized for certain niche applications compared to competitors; higher initial investment compared to some alternatives; limited integration with certain third-party accessories.

Key Patents and Scientific Breakthroughs

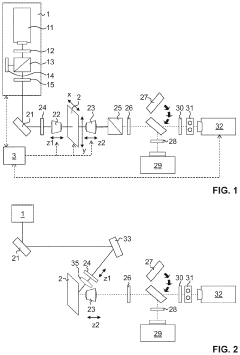

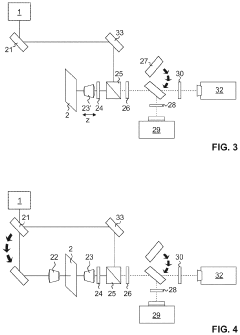

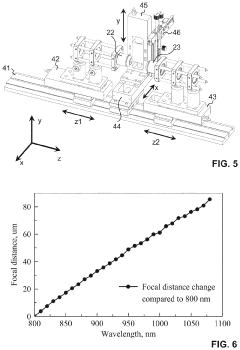

Automated system for wide-field multiphoton microscope

PatentInactiveUS20210341720A1

Innovation

- An automated method using a wide-field multiphoton microscope with a tunable excitation wavelength, incorporating a wavelength separator and autoalignment procedures to optimize the sample's position relative to the illumination and collection beam paths, ensuring high intensity and quality of images or spectra across a wide range of wavelengths.

Higher harmonics atomic force microscope

PatentWO2006136705A1

Innovation

- The solution involves operating the atomic force microscope on higher order harmonics of the lever arm, rather than the fundamental frequency, allowing for the adjustment of the oscillation frequency to optimize the quality factor and reduce response time, enabling faster scanning by selecting suitable harmonics automatically based on an operating threshold.

Sample Preparation Requirements and Considerations

Sample preparation represents a critical determinant in the efficacy and reliability of both Atomic Force Microscopy (AFM) and Second Harmonic Generation (SHG) imaging techniques. The divergent physical principles underlying these methodologies necessitate distinct preparation protocols that significantly impact resolution outcomes and detail capture capabilities.

For AFM analysis, sample surface characteristics demand meticulous attention. Specimens must exhibit minimal roughness, typically below 10 nm, to prevent tip artifacts that compromise resolution. Surface cleanliness is paramount, requiring rigorous cleaning protocols involving organic solvents, plasma treatment, or UV-ozone exposure to remove contaminants that could interfere with tip-sample interactions. Additionally, sample immobilization on atomically flat substrates such as mica, HOPG, or silicon wafers is essential to prevent movement during scanning.

SHG microscopy imposes different preparation requirements, primarily focused on optical properties rather than surface topography. Samples must possess non-centrosymmetric structures or interfaces to generate second harmonic signals effectively. Unlike AFM, SHG permits examination of specimens in their native state without extensive physical modification, offering advantages for biological samples. However, optical clarity becomes crucial, necessitating protocols that minimize light scattering and absorption.

Environmental conditions during preparation significantly impact both techniques. AFM samples often require controlled humidity (30-40%) to minimize capillary forces between tip and sample, while temperature stability prevents thermal drift that degrades resolution. SHG preparation must account for potential photodamage, particularly when using high-intensity laser illumination, requiring appropriate antioxidants or photoprotective agents for sensitive biological specimens.

The dimensional constraints differ markedly between methodologies. AFM sample thickness is relatively unrestricted, though mounting considerations apply, whereas SHG effectiveness depends on optical penetration depth, typically limiting optimal imaging to specimens under 100 μm thick unless specialized multi-photon configurations are employed.

Comparative analysis reveals that AFM preparation protocols prioritize surface properties and mechanical stability, while SHG emphasizes optical characteristics and structural asymmetry. This fundamental difference explains why AFM excels at nanoscale topographical resolution of properly prepared surfaces, while SHG offers superior capabilities for label-free visualization of specific molecular arrangements in minimally processed samples.

Recent advances in correlative microscopy have stimulated development of hybrid preparation protocols that satisfy requirements for both techniques, enabling complementary analysis of identical sample regions and expanding the analytical capabilities beyond what either technique could achieve independently.

For AFM analysis, sample surface characteristics demand meticulous attention. Specimens must exhibit minimal roughness, typically below 10 nm, to prevent tip artifacts that compromise resolution. Surface cleanliness is paramount, requiring rigorous cleaning protocols involving organic solvents, plasma treatment, or UV-ozone exposure to remove contaminants that could interfere with tip-sample interactions. Additionally, sample immobilization on atomically flat substrates such as mica, HOPG, or silicon wafers is essential to prevent movement during scanning.

SHG microscopy imposes different preparation requirements, primarily focused on optical properties rather than surface topography. Samples must possess non-centrosymmetric structures or interfaces to generate second harmonic signals effectively. Unlike AFM, SHG permits examination of specimens in their native state without extensive physical modification, offering advantages for biological samples. However, optical clarity becomes crucial, necessitating protocols that minimize light scattering and absorption.

Environmental conditions during preparation significantly impact both techniques. AFM samples often require controlled humidity (30-40%) to minimize capillary forces between tip and sample, while temperature stability prevents thermal drift that degrades resolution. SHG preparation must account for potential photodamage, particularly when using high-intensity laser illumination, requiring appropriate antioxidants or photoprotective agents for sensitive biological specimens.

The dimensional constraints differ markedly between methodologies. AFM sample thickness is relatively unrestricted, though mounting considerations apply, whereas SHG effectiveness depends on optical penetration depth, typically limiting optimal imaging to specimens under 100 μm thick unless specialized multi-photon configurations are employed.

Comparative analysis reveals that AFM preparation protocols prioritize surface properties and mechanical stability, while SHG emphasizes optical characteristics and structural asymmetry. This fundamental difference explains why AFM excels at nanoscale topographical resolution of properly prepared surfaces, while SHG offers superior capabilities for label-free visualization of specific molecular arrangements in minimally processed samples.

Recent advances in correlative microscopy have stimulated development of hybrid preparation protocols that satisfy requirements for both techniques, enabling complementary analysis of identical sample regions and expanding the analytical capabilities beyond what either technique could achieve independently.

Cost-Benefit Analysis of AFM versus SHG Implementation

When evaluating the implementation of Atomic Force Microscopy (AFM) versus Second Harmonic Generation (SHG) technologies, cost-benefit analysis reveals significant differences in initial investment, operational expenses, and long-term value proposition.

Initial equipment acquisition represents the most substantial cost differential. AFM systems typically range from $100,000 to $500,000 depending on capabilities and resolution requirements, while SHG microscopy systems generally command higher prices between $250,000 and $750,000 due to their complex optical components and laser systems. This price premium for SHG must be carefully weighed against specific application requirements.

Operational costs further differentiate these technologies. AFM requires regular probe replacement ($30-100 per probe) with frequency determined by usage intensity and sample characteristics. Additionally, AFM systems need periodic calibration and maintenance, adding approximately $5,000-15,000 annually. Conversely, SHG systems incur higher energy consumption costs due to high-powered lasers and have maintenance requirements for optical components and laser systems averaging $10,000-20,000 annually.

Personnel requirements represent another significant cost factor. AFM operation typically requires technicians with mechanical and surface science expertise, while SHG demands specialists with advanced optical physics knowledge. This expertise differential often translates to higher personnel costs for SHG implementation, with specialized training programs adding $3,000-8,000 per operator.

Sample preparation costs vary considerably between technologies. AFM often requires minimal sample preparation for many applications, though specialized studies may need additional processing. SHG typically demands more elaborate sample preparation protocols, particularly for biological specimens, potentially increasing per-sample analysis costs by 20-40%.

Return on investment calculations reveal application-dependent advantages. For routine surface characterization and nanoscale imaging, AFM typically delivers superior cost-efficiency. However, SHG offers compelling value for specialized applications requiring non-invasive optical sectioning of biological samples or specific molecular orientation studies, despite higher implementation costs.

Scalability considerations further impact long-term value assessment. AFM systems generally offer modular upgrade paths, allowing incremental capability expansion. SHG systems, while less modular, often integrate more readily with other optical imaging modalities, potentially offering greater ecosystem benefits in comprehensive imaging laboratories.

The optimal technology choice ultimately depends on specific application requirements, existing infrastructure, personnel expertise, and long-term research or production objectives. Organizations must carefully balance immediate cost constraints against long-term analytical capabilities when selecting between these complementary but distinct imaging technologies.

Initial equipment acquisition represents the most substantial cost differential. AFM systems typically range from $100,000 to $500,000 depending on capabilities and resolution requirements, while SHG microscopy systems generally command higher prices between $250,000 and $750,000 due to their complex optical components and laser systems. This price premium for SHG must be carefully weighed against specific application requirements.

Operational costs further differentiate these technologies. AFM requires regular probe replacement ($30-100 per probe) with frequency determined by usage intensity and sample characteristics. Additionally, AFM systems need periodic calibration and maintenance, adding approximately $5,000-15,000 annually. Conversely, SHG systems incur higher energy consumption costs due to high-powered lasers and have maintenance requirements for optical components and laser systems averaging $10,000-20,000 annually.

Personnel requirements represent another significant cost factor. AFM operation typically requires technicians with mechanical and surface science expertise, while SHG demands specialists with advanced optical physics knowledge. This expertise differential often translates to higher personnel costs for SHG implementation, with specialized training programs adding $3,000-8,000 per operator.

Sample preparation costs vary considerably between technologies. AFM often requires minimal sample preparation for many applications, though specialized studies may need additional processing. SHG typically demands more elaborate sample preparation protocols, particularly for biological specimens, potentially increasing per-sample analysis costs by 20-40%.

Return on investment calculations reveal application-dependent advantages. For routine surface characterization and nanoscale imaging, AFM typically delivers superior cost-efficiency. However, SHG offers compelling value for specialized applications requiring non-invasive optical sectioning of biological samples or specific molecular orientation studies, despite higher implementation costs.

Scalability considerations further impact long-term value assessment. AFM systems generally offer modular upgrade paths, allowing incremental capability expansion. SHG systems, while less modular, often integrate more readily with other optical imaging modalities, potentially offering greater ecosystem benefits in comprehensive imaging laboratories.

The optimal technology choice ultimately depends on specific application requirements, existing infrastructure, personnel expertise, and long-term research or production objectives. Organizations must carefully balance immediate cost constraints against long-term analytical capabilities when selecting between these complementary but distinct imaging technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!