Measure Atomic Force Microscopy Probe Flexibility — Performance Criteria

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Probe Flexibility Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986, becoming an indispensable tool for nanoscale imaging and force measurements across multiple scientific disciplines. The flexibility of AFM probes represents a critical parameter that directly influences measurement accuracy, resolution, and reliability. Understanding and quantifying this flexibility has become increasingly important as applications of AFM expand into more complex and demanding fields such as biological imaging, nanomechanical testing, and semiconductor quality control.

The evolution of AFM probe technology has followed a trajectory from simple silicon or silicon nitride cantilevers to highly specialized probes with tailored mechanical properties. Early AFM systems utilized relatively stiff probes, limiting their application in soft matter research. The technological progression has since focused on developing probes with optimized spring constants, resonance frequencies, and tip geometries to address specific measurement requirements.

Current research indicates a growing demand for standardized methods to characterize probe flexibility across different operational environments. This need stems from the observation that probe performance can vary significantly under different conditions, such as temperature fluctuations, medium changes (air to liquid), or prolonged usage, affecting measurement reproducibility and data interpretation.

The primary objective of this technical research is to establish comprehensive performance criteria for measuring AFM probe flexibility that can be universally applied across different AFM systems and applications. These criteria aim to enhance measurement reliability, facilitate cross-platform comparability of results, and provide manufacturers with standardized benchmarks for probe development.

Secondary objectives include identifying the relationship between probe flexibility and specific application requirements, developing predictive models for probe behavior under various experimental conditions, and exploring novel materials and designs that could optimize flexibility characteristics for emerging applications.

The technological significance of this research extends beyond immediate measurement improvements. Enhanced understanding of probe flexibility dynamics could enable new AFM-based analytical techniques, particularly in fields requiring precise force control such as single-molecule studies, cellular mechanics, and nanofabrication. Additionally, standardized flexibility metrics would facilitate more effective communication between research groups and accelerate collaborative innovation in nanoscale characterization methodologies.

Recent advancements in computational modeling and nanofabrication techniques have created new opportunities to address longstanding challenges in probe flexibility characterization. These developments, combined with the increasing integration of AFM with complementary analytical techniques, underscore the timeliness and potential impact of establishing robust performance criteria for AFM probe flexibility measurements.

The evolution of AFM probe technology has followed a trajectory from simple silicon or silicon nitride cantilevers to highly specialized probes with tailored mechanical properties. Early AFM systems utilized relatively stiff probes, limiting their application in soft matter research. The technological progression has since focused on developing probes with optimized spring constants, resonance frequencies, and tip geometries to address specific measurement requirements.

Current research indicates a growing demand for standardized methods to characterize probe flexibility across different operational environments. This need stems from the observation that probe performance can vary significantly under different conditions, such as temperature fluctuations, medium changes (air to liquid), or prolonged usage, affecting measurement reproducibility and data interpretation.

The primary objective of this technical research is to establish comprehensive performance criteria for measuring AFM probe flexibility that can be universally applied across different AFM systems and applications. These criteria aim to enhance measurement reliability, facilitate cross-platform comparability of results, and provide manufacturers with standardized benchmarks for probe development.

Secondary objectives include identifying the relationship between probe flexibility and specific application requirements, developing predictive models for probe behavior under various experimental conditions, and exploring novel materials and designs that could optimize flexibility characteristics for emerging applications.

The technological significance of this research extends beyond immediate measurement improvements. Enhanced understanding of probe flexibility dynamics could enable new AFM-based analytical techniques, particularly in fields requiring precise force control such as single-molecule studies, cellular mechanics, and nanofabrication. Additionally, standardized flexibility metrics would facilitate more effective communication between research groups and accelerate collaborative innovation in nanoscale characterization methodologies.

Recent advancements in computational modeling and nanofabrication techniques have created new opportunities to address longstanding challenges in probe flexibility characterization. These developments, combined with the increasing integration of AFM with complementary analytical techniques, underscore the timeliness and potential impact of establishing robust performance criteria for AFM probe flexibility measurements.

Market Applications and Demand Analysis

The Atomic Force Microscopy (AFM) probe flexibility measurement market has experienced significant growth in recent years, driven by increasing demand for nanoscale characterization across multiple industries. The global market for AFM technologies was valued at approximately 570 million USD in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030, with probe flexibility measurement solutions representing a crucial segment within this market.

Materials science and semiconductor industries constitute the largest application segments, collectively accounting for over 45% of the market share. In semiconductor manufacturing, precise measurement of AFM probe flexibility has become essential for quality control processes, particularly as device dimensions continue to shrink below 5nm. The ability to accurately characterize surface properties at the atomic level directly impacts yield rates and device performance, creating sustained demand for advanced probe flexibility measurement solutions.

Life sciences represent another rapidly expanding application area, with pharmaceutical companies and research institutions increasingly adopting AFM technologies for biomolecular imaging and nanomechanical characterization. The market for AFM applications in biological sciences is growing at approximately 8.2% annually, outpacing the overall market growth rate. This acceleration is driven by the need for more precise mechanical property measurements of biological samples, where probe flexibility directly impacts measurement accuracy and sample preservation.

Academic and research institutions remain significant consumers of AFM probe flexibility measurement technologies, accounting for approximately 30% of the market. The continuous pursuit of fundamental research in nanotechnology, quantum materials, and surface science sustains demand for increasingly sophisticated probe characterization methods that can deliver reliable performance criteria.

Geographically, North America and Europe currently dominate the market with a combined share of approximately 65%, though Asia-Pacific represents the fastest-growing region with particularly strong demand emerging from China, Japan, and South Korea. This regional growth is primarily driven by expanding semiconductor manufacturing capabilities and increasing R&D investments in nanotechnology.

Customer requirements are increasingly focused on measurement repeatability, calibration stability, and integration with automated workflows. End-users across industries are demanding solutions that can provide quantitative performance criteria for probe flexibility rather than qualitative assessments. This shift is particularly evident in industrial applications where standardization and measurement traceability have become critical considerations for quality assurance systems.

The market also shows growing demand for multi-parameter measurement capabilities that can simultaneously characterize probe flexibility alongside other mechanical properties, enabling more comprehensive performance evaluation and reducing overall characterization time.

Materials science and semiconductor industries constitute the largest application segments, collectively accounting for over 45% of the market share. In semiconductor manufacturing, precise measurement of AFM probe flexibility has become essential for quality control processes, particularly as device dimensions continue to shrink below 5nm. The ability to accurately characterize surface properties at the atomic level directly impacts yield rates and device performance, creating sustained demand for advanced probe flexibility measurement solutions.

Life sciences represent another rapidly expanding application area, with pharmaceutical companies and research institutions increasingly adopting AFM technologies for biomolecular imaging and nanomechanical characterization. The market for AFM applications in biological sciences is growing at approximately 8.2% annually, outpacing the overall market growth rate. This acceleration is driven by the need for more precise mechanical property measurements of biological samples, where probe flexibility directly impacts measurement accuracy and sample preservation.

Academic and research institutions remain significant consumers of AFM probe flexibility measurement technologies, accounting for approximately 30% of the market. The continuous pursuit of fundamental research in nanotechnology, quantum materials, and surface science sustains demand for increasingly sophisticated probe characterization methods that can deliver reliable performance criteria.

Geographically, North America and Europe currently dominate the market with a combined share of approximately 65%, though Asia-Pacific represents the fastest-growing region with particularly strong demand emerging from China, Japan, and South Korea. This regional growth is primarily driven by expanding semiconductor manufacturing capabilities and increasing R&D investments in nanotechnology.

Customer requirements are increasingly focused on measurement repeatability, calibration stability, and integration with automated workflows. End-users across industries are demanding solutions that can provide quantitative performance criteria for probe flexibility rather than qualitative assessments. This shift is particularly evident in industrial applications where standardization and measurement traceability have become critical considerations for quality assurance systems.

The market also shows growing demand for multi-parameter measurement capabilities that can simultaneously characterize probe flexibility alongside other mechanical properties, enabling more comprehensive performance evaluation and reducing overall characterization time.

Current Challenges in AFM Probe Flexibility Measurement

Despite significant advancements in Atomic Force Microscopy (AFM) technology, measuring probe flexibility remains a complex challenge with several persistent obstacles. Current methodologies for quantifying cantilever spring constants and tip flexibility suffer from reproducibility issues, with measurement variations often exceeding 20% between different calibration attempts on identical probes. This inconsistency significantly impacts the reliability of force measurements in applications requiring precise nanomechanical characterization.

The lack of standardized calibration protocols represents another major hurdle. Various techniques—including thermal tuning, Sader method, reference spring method, and added mass method—each present their own limitations and assumptions that may not hold true across different experimental conditions. This methodological fragmentation makes cross-laboratory comparisons challenging and hinders the establishment of universal performance benchmarks.

Environmental sensitivity further complicates flexibility measurements. Ambient conditions, particularly humidity and temperature fluctuations, can dramatically alter cantilever properties. Studies have shown that relative humidity changes of just 10% can modify measured spring constants by up to 5%, while temperature variations of 5°C can cause deviations exceeding 3%. These environmental dependencies are often inadequately addressed in measurement protocols.

Tip-sample interaction artifacts introduce additional measurement uncertainties. Contact mechanics at the nanoscale involve complex phenomena including adhesion, viscoelasticity, and surface roughness effects that can confound flexibility measurements. Current models struggle to decouple these interaction forces from the intrinsic mechanical properties of the probe itself, leading to systematic errors in flexibility characterization.

The geometric complexity of modern AFM probes presents another significant challenge. As probe designs evolve beyond simple rectangular cantilevers to include triangular, picket-shaped, and functionalized tips, traditional flexibility models based on simplified beam theory become increasingly inadequate. These geometric variations can introduce measurement errors exceeding 15% when standard calibration methods are applied without appropriate corrections.

Material heterogeneity in probe fabrication further complicates accurate flexibility determination. Variations in coating thickness, material composition, and manufacturing tolerances lead to probe-to-probe inconsistencies that are difficult to quantify. Current characterization techniques often fail to account for these material variations, particularly in multi-layered or composite probe structures.

Real-time monitoring of probe flexibility changes during experiments remains largely unaddressed. Probe properties can evolve during measurement due to tip wear, contamination, or material fatigue, yet most calibration approaches rely on pre-experiment characterization without accounting for these dynamic changes. This temporal disconnect between calibration and actual measurement represents a significant blind spot in current methodologies.

The lack of standardized calibration protocols represents another major hurdle. Various techniques—including thermal tuning, Sader method, reference spring method, and added mass method—each present their own limitations and assumptions that may not hold true across different experimental conditions. This methodological fragmentation makes cross-laboratory comparisons challenging and hinders the establishment of universal performance benchmarks.

Environmental sensitivity further complicates flexibility measurements. Ambient conditions, particularly humidity and temperature fluctuations, can dramatically alter cantilever properties. Studies have shown that relative humidity changes of just 10% can modify measured spring constants by up to 5%, while temperature variations of 5°C can cause deviations exceeding 3%. These environmental dependencies are often inadequately addressed in measurement protocols.

Tip-sample interaction artifacts introduce additional measurement uncertainties. Contact mechanics at the nanoscale involve complex phenomena including adhesion, viscoelasticity, and surface roughness effects that can confound flexibility measurements. Current models struggle to decouple these interaction forces from the intrinsic mechanical properties of the probe itself, leading to systematic errors in flexibility characterization.

The geometric complexity of modern AFM probes presents another significant challenge. As probe designs evolve beyond simple rectangular cantilevers to include triangular, picket-shaped, and functionalized tips, traditional flexibility models based on simplified beam theory become increasingly inadequate. These geometric variations can introduce measurement errors exceeding 15% when standard calibration methods are applied without appropriate corrections.

Material heterogeneity in probe fabrication further complicates accurate flexibility determination. Variations in coating thickness, material composition, and manufacturing tolerances lead to probe-to-probe inconsistencies that are difficult to quantify. Current characterization techniques often fail to account for these material variations, particularly in multi-layered or composite probe structures.

Real-time monitoring of probe flexibility changes during experiments remains largely unaddressed. Probe properties can evolve during measurement due to tip wear, contamination, or material fatigue, yet most calibration approaches rely on pre-experiment characterization without accounting for these dynamic changes. This temporal disconnect between calibration and actual measurement represents a significant blind spot in current methodologies.

Established Methodologies for Probe Flexibility Assessment

01 Cantilever design for probe flexibility control

The design of the cantilever significantly impacts the flexibility of atomic force microscopy probes. Various geometric parameters such as length, width, thickness, and shape can be optimized to achieve desired flexibility characteristics. Materials selection also plays a crucial role in determining the spring constant and resonant frequency of the cantilever. These design considerations enable precise control over probe flexibility for different scanning modes and sample types.- Probe design for flexibility control: Various designs of atomic force microscopy probes can be implemented to control flexibility. These designs include modifications to the cantilever geometry, dimensions, and material composition to achieve desired mechanical properties. Optimizing the probe's spring constant and resonant frequency allows for precise control of flexibility, which is crucial for different scanning modes and sample types. Innovative designs may incorporate tapered structures or variable thickness profiles to enhance performance.

- Material selection for probe flexibility: The choice of materials significantly impacts the flexibility characteristics of AFM probes. Silicon, silicon nitride, and polymer-based materials offer different mechanical properties that can be selected based on application requirements. Composite materials and specialized coatings can be applied to modify the probe's flexibility while maintaining other desired properties. Material selection also affects the probe's durability, sensitivity, and compatibility with various imaging environments.

- Calibration and measurement of probe flexibility: Accurate calibration and measurement techniques are essential for characterizing AFM probe flexibility. Methods include thermal tuning, reference cantilever comparison, and force-distance curve analysis to determine spring constants. Advanced algorithms and computational models help in processing measurement data to obtain precise flexibility parameters. Calibration standards and reference materials enable consistent and reliable flexibility measurements across different instruments and experimental conditions.

- Dynamic control of probe flexibility during operation: Systems and methods for dynamically adjusting probe flexibility during AFM operation enhance imaging capabilities. These include active feedback mechanisms, piezoelectric elements, and electromagnetic actuators that can modify the effective stiffness of the probe in real-time. Dynamic flexibility control allows for adaptation to changing sample topography and mechanical properties, reducing sample damage and improving image resolution. Multi-frequency and multi-harmonic techniques can be employed to extract additional information about sample properties.

- Specialized flexible probes for specific applications: Specialized AFM probes with tailored flexibility characteristics are designed for specific applications such as biological imaging, nanomechanical measurements, and high-resolution topography. These include ultra-soft probes for delicate biological samples, functionalized probes for chemical sensing, and high-aspect-ratio probes for deep trench imaging. The flexibility of these specialized probes is optimized to balance sensitivity, resolution, and sample interaction forces for their intended application domains.

02 Multi-frequency and dynamic flexibility adjustment

Advanced AFM systems incorporate mechanisms for adjusting probe flexibility dynamically during operation. These systems allow for multi-frequency measurements where the probe can be operated at different resonant modes simultaneously or sequentially. Dynamic adjustment of probe flexibility enables adaptation to changing sample conditions and measurement requirements, improving imaging resolution and reducing sample damage during scanning.Expand Specific Solutions03 Specialized probe materials for enhanced flexibility properties

Novel materials are being developed specifically for AFM probe applications to achieve optimal flexibility characteristics. These include composite materials, specialized polymers, and nanomaterials that provide unique combinations of flexibility, durability, and sensitivity. The incorporation of these advanced materials allows for improved probe performance in specialized applications such as biological sample imaging, where gentle interaction with soft samples is critical.Expand Specific Solutions04 Calibration and measurement of probe flexibility

Accurate calibration and measurement of probe flexibility parameters are essential for quantitative AFM measurements. Various techniques have been developed to determine spring constants, resonant frequencies, and other flexibility-related properties of AFM probes. These include thermal noise method, reference cantilever method, and dimensional analysis approaches. Precise calibration ensures reproducible measurements and enables quantitative analysis of sample mechanical properties.Expand Specific Solutions05 Environmental effects on probe flexibility

Environmental conditions significantly impact the flexibility characteristics of AFM probes. Factors such as temperature, humidity, and surrounding medium (air, liquid, vacuum) can alter the mechanical properties of the cantilever. Advanced AFM systems incorporate environmental control mechanisms to maintain consistent probe flexibility during measurements. Understanding and controlling these environmental effects is crucial for achieving reliable and reproducible AFM results.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Atomic Force Microscopy (AFM) probe flexibility measurement is currently in a growth phase, with increasing market demand driven by nanotechnology applications. The global market for AFM technologies is expanding steadily, estimated to reach several billion dollars by 2025. Technologically, this field is approaching maturity with established measurement protocols, though innovation continues in probe design and measurement accuracy. Leading organizations include research institutions like Centre National de la Recherche Scientifique and Korea Institute of Machinery & Materials, alongside commercial players such as Bruker Nano and JPKinstruments AG. Universities including Tsinghua, Fudan, and Sorbonne contribute significant academic research, while companies like Canon and Riken develop commercial applications. The competitive landscape features collaboration between academic and industrial entities, with increasing focus on standardization of performance criteria.

Centre National de la Recherche Scientifique

Technical Solution: The Centre National de la Recherche Scientifique (CNRS) has developed a comprehensive multi-parameter approach to AFM probe flexibility measurement. Their methodology combines experimental techniques with theoretical modeling to achieve high-accuracy characterization of cantilever mechanical properties. The CNRS approach utilizes laser Doppler vibrometry for direct measurement of cantilever vibration modes, complemented by finite element analysis to model cantilever behavior under various loading conditions. Their technology incorporates interferometric methods for precise determination of cantilever deflection sensitivity, eliminating common calibration errors associated with hard surface contact methods. CNRS researchers have developed specialized algorithms that account for non-ideal cantilever behavior, including non-uniform cross-sections and material anisotropy effects on flexibility measurements. Their approach includes multi-mode analysis techniques that extract mechanical properties from higher resonance modes, providing more comprehensive characterization than single-mode methods. The system also features environmental control capabilities that minimize thermal drift and humidity effects on cantilever properties[7][9]. CNRS has pioneered reference cantilever methods where pre-calibrated cantilevers serve as transfer standards for calibrating working probes, significantly improving measurement traceability.

Strengths: Exceptional measurement accuracy through combined experimental-theoretical approach; comprehensive characterization of complex cantilever behaviors; strong metrological foundation with traceability to physical standards. Weaknesses: Complex implementation requiring specialized equipment beyond standard AFM systems; time-intensive calibration procedures limiting throughput; higher expertise requirements for proper implementation and data interpretation.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced PeakForce Quantitative Nanomechanical Mapping (QNM) technology for measuring atomic force microscopy (AFM) probe flexibility. Their approach incorporates real-time force curve analysis at each pixel, allowing precise control of peak forces and extraction of quantitative mechanical properties. The system automatically calibrates cantilever spring constants using thermal tuning methods and employs proprietary algorithms to account for cantilever deflection sensitivity variations. Bruker's technology includes specialized probe characterization routines that measure probe tip radius, cantilever geometry, and resonance properties to ensure accurate force measurements. Their ScanAsyst feature provides automatic image optimization by continuously monitoring image quality and adjusting scanning parameters accordingly, which helps maintain consistent probe performance during measurements[1][3]. The system also incorporates reference calibration standards with known mechanical properties to validate probe flexibility measurements across different experimental conditions.

Strengths: Industry-leading calibration algorithms providing high measurement accuracy; automated parameter optimization reducing user dependency; comprehensive probe characterization capabilities. Weaknesses: Proprietary systems requiring significant investment; complex calibration procedures requiring specialized training; potential overreliance on automated features limiting customization for novel research applications.

Critical Patents and Literature on Cantilever Mechanics

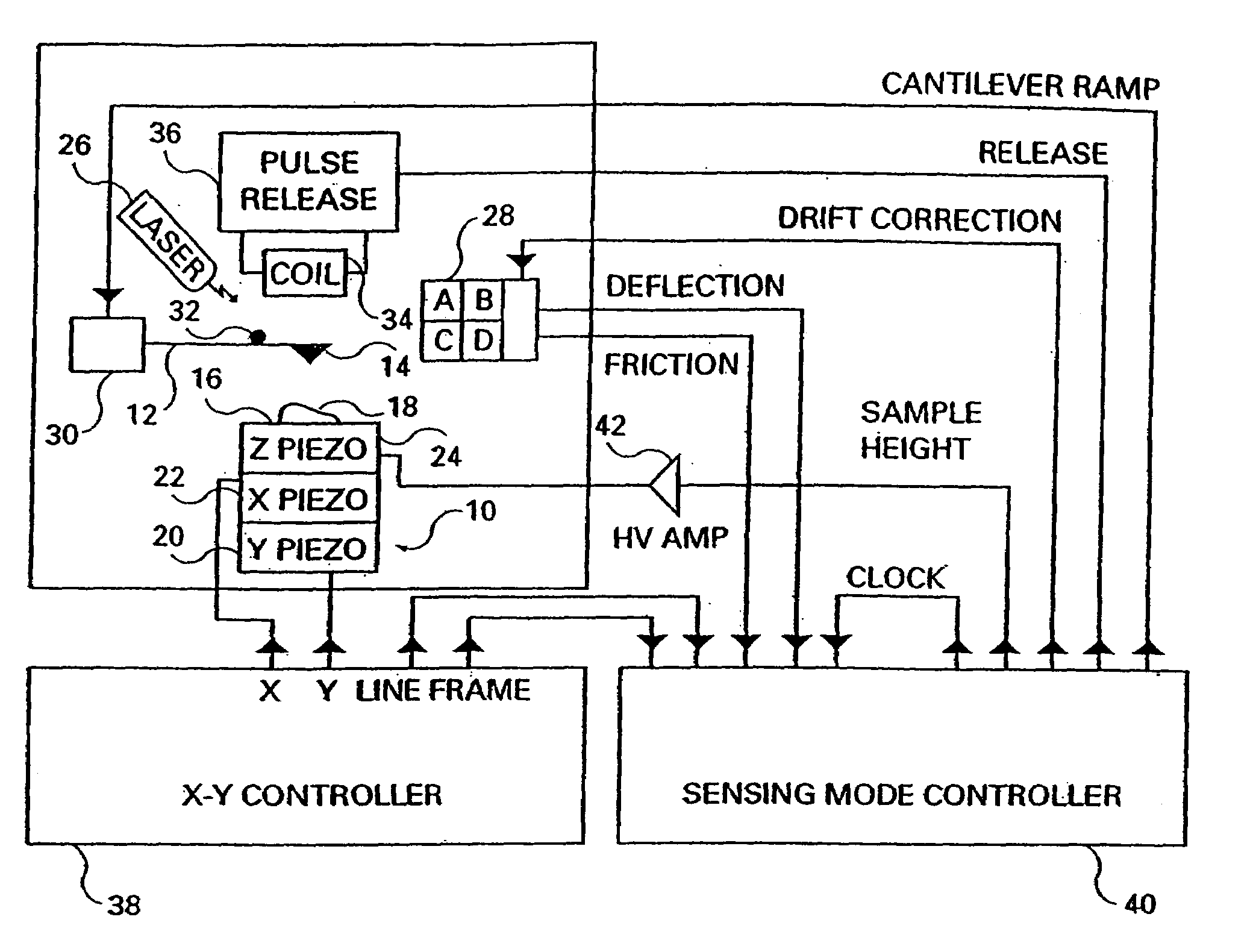

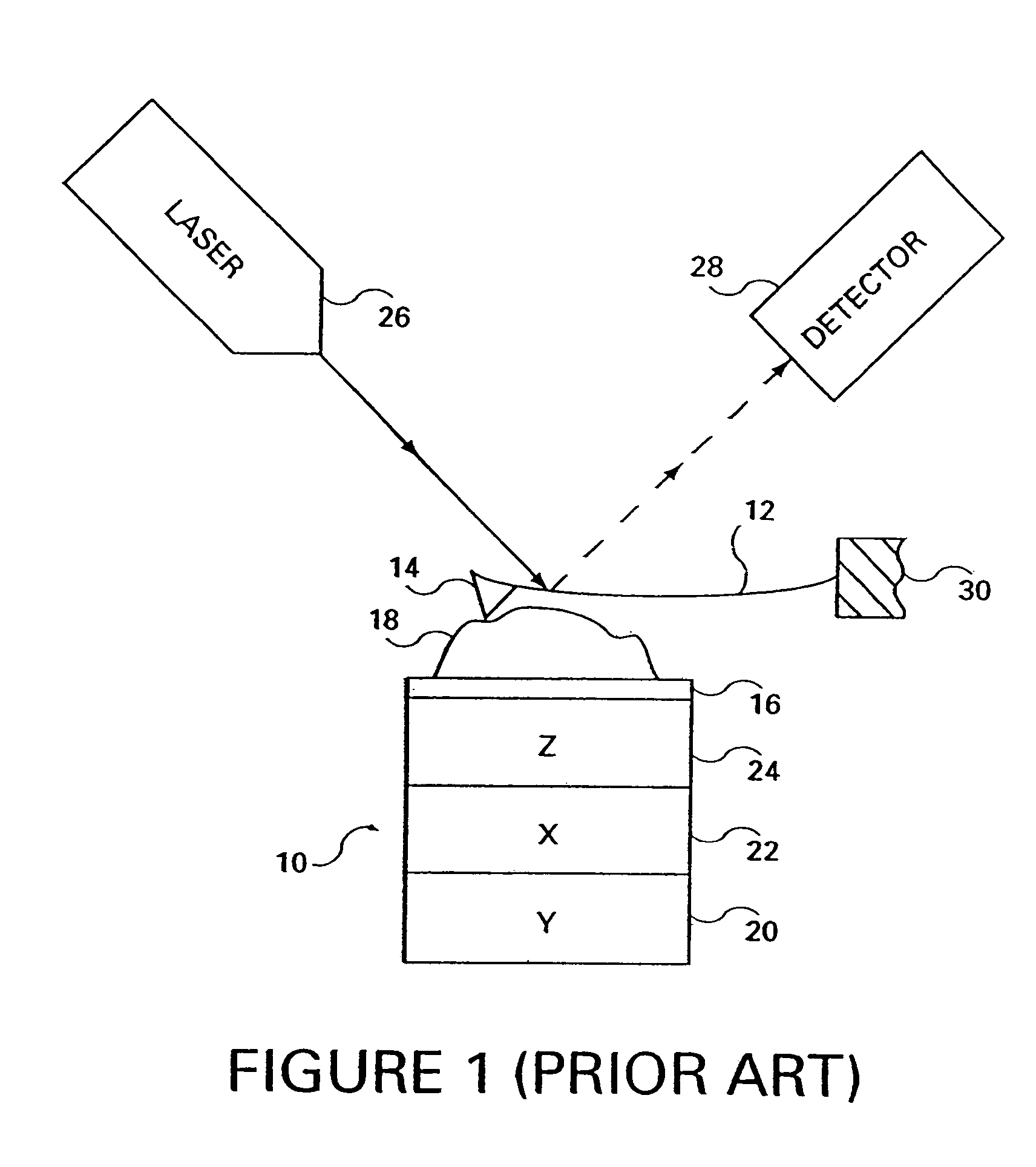

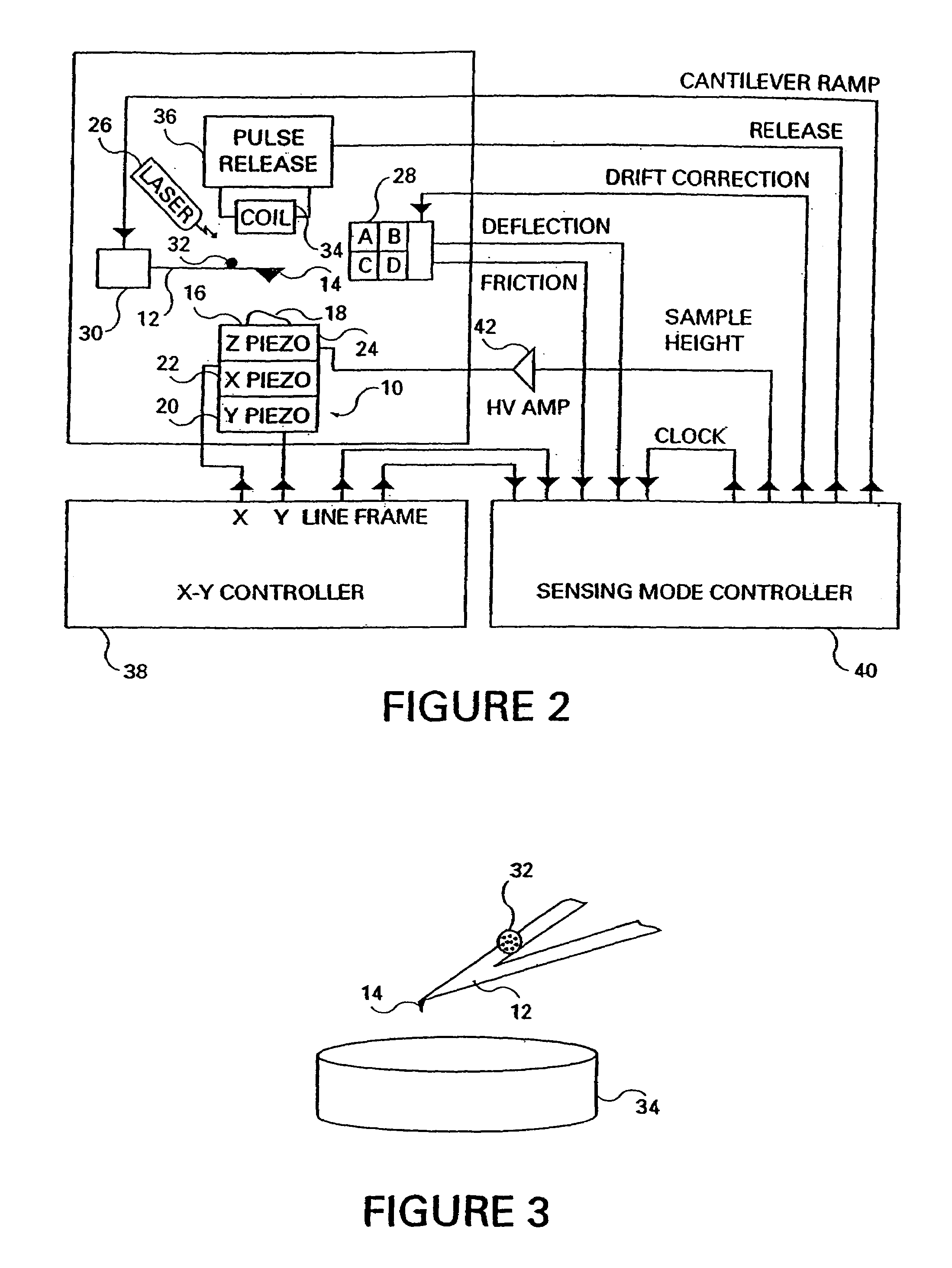

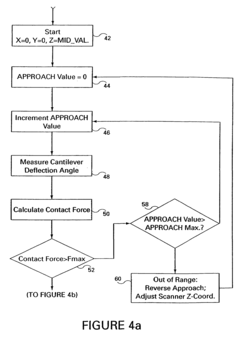

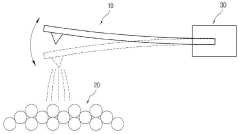

Sensing mode atomic force microscope

PatentInactiveUS7095020B2

Innovation

- An advanced atomic force microscope with a low spring force cantilever and a magnetic particle system that allows for controlled, minimal contact forces and simultaneous measurement of contact and adhesion forces, using a sensing mode controller to manage cantilever deflection and magnetic field for precise probe tip control, enabling non-destructive imaging and force measurement in biological environments.

Measurement method of atomic force microscope in liquid using general cantilever and atomic force microscope using the same

PatentInactiveKR1020130027958A

Innovation

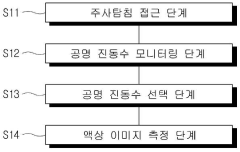

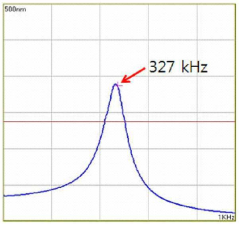

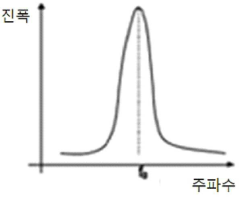

- A method involving resonance frequency monitoring and selection using a general scanning probe, followed by applying the selected frequency as the driving frequency for liquid image measurement, allowing high-resolution imaging.

Standardization Efforts in AFM Probe Characterization

The standardization of AFM probe characterization represents a critical advancement in ensuring reliability and reproducibility across atomic force microscopy measurements. Currently, several international organizations are spearheading efforts to establish uniform protocols for evaluating probe flexibility and performance. The International Organization for Standardization (ISO) has developed the ISO/TC 201 technical committee specifically addressing surface chemical analysis, with subcommittee SC 9 focusing on scanning probe microscopy.

ASTM International has also contributed significantly through its E42 committee on Surface Analysis, which has published several standards relevant to AFM probe characterization. These standards provide guidelines for determining spring constants, resonant frequencies, and tip geometries—all crucial parameters affecting measurement accuracy.

The National Institute of Standards and Technology (NIST) in the United States has established reference materials and calibration procedures specifically designed for AFM probe characterization. Their approach includes standardized cantilever arrays with known mechanical properties that serve as calibration references for researchers worldwide.

In Europe, the European Materials Characterisation Council (EMCC) has initiated a working group dedicated to nanomechanical testing standardization, which encompasses AFM probe flexibility measurements. Their framework emphasizes traceability to SI units and uncertainty quantification in probe characterization.

Industry consortia have also emerged to address standardization needs. The AFM Standardization Consortium, comprising instrument manufacturers, academic institutions, and industrial users, works collaboratively to develop consensus-based protocols for probe characterization that balance scientific rigor with practical implementation.

These standardization efforts typically address several key aspects: thermal noise method calibration, reference cantilever calibration, dimensional measurement protocols, and environmental condition specifications during characterization. The thermal noise method, in particular, has gained widespread acceptance as a non-destructive approach to determining cantilever spring constants.

Recent developments include the creation of digital repositories for probe characteristics, allowing researchers to access standardized probe data and measurement protocols. The Virtual AFM Probe Database initiative exemplifies this trend, offering a centralized resource for validated probe specifications across different manufacturers and models.

Despite these advances, challenges remain in achieving global harmonization of standards, particularly regarding the characterization of specialized probes for emerging applications such as biological AFM and high-speed imaging. Future standardization efforts will likely focus on addressing these gaps while incorporating machine learning approaches for automated probe characterization and quality assessment.

ASTM International has also contributed significantly through its E42 committee on Surface Analysis, which has published several standards relevant to AFM probe characterization. These standards provide guidelines for determining spring constants, resonant frequencies, and tip geometries—all crucial parameters affecting measurement accuracy.

The National Institute of Standards and Technology (NIST) in the United States has established reference materials and calibration procedures specifically designed for AFM probe characterization. Their approach includes standardized cantilever arrays with known mechanical properties that serve as calibration references for researchers worldwide.

In Europe, the European Materials Characterisation Council (EMCC) has initiated a working group dedicated to nanomechanical testing standardization, which encompasses AFM probe flexibility measurements. Their framework emphasizes traceability to SI units and uncertainty quantification in probe characterization.

Industry consortia have also emerged to address standardization needs. The AFM Standardization Consortium, comprising instrument manufacturers, academic institutions, and industrial users, works collaboratively to develop consensus-based protocols for probe characterization that balance scientific rigor with practical implementation.

These standardization efforts typically address several key aspects: thermal noise method calibration, reference cantilever calibration, dimensional measurement protocols, and environmental condition specifications during characterization. The thermal noise method, in particular, has gained widespread acceptance as a non-destructive approach to determining cantilever spring constants.

Recent developments include the creation of digital repositories for probe characteristics, allowing researchers to access standardized probe data and measurement protocols. The Virtual AFM Probe Database initiative exemplifies this trend, offering a centralized resource for validated probe specifications across different manufacturers and models.

Despite these advances, challenges remain in achieving global harmonization of standards, particularly regarding the characterization of specialized probes for emerging applications such as biological AFM and high-speed imaging. Future standardization efforts will likely focus on addressing these gaps while incorporating machine learning approaches for automated probe characterization and quality assessment.

Material Science Innovations for Enhanced Probe Performance

Recent advancements in material science have revolutionized the development of Atomic Force Microscopy (AFM) probes, significantly enhancing their performance characteristics. Traditional silicon and silicon nitride probes are increasingly being supplemented or replaced by novel materials that offer superior mechanical properties, particularly in terms of flexibility measurement and control.

Carbon-based materials represent one of the most promising frontiers in probe development. Carbon nanotubes (CNTs) exhibit exceptional mechanical properties with Young's modulus values exceeding 1 TPa, while maintaining remarkable flexibility. This combination allows for more precise force measurements and improved interaction with delicate sample surfaces. Similarly, graphene-reinforced composites are emerging as viable alternatives, offering customizable flexibility profiles through precise manipulation of graphene concentration and orientation within the composite matrix.

Functionalized polymer coatings represent another significant innovation pathway. These coatings can be engineered to provide specific surface properties while maintaining or enhancing the underlying probe's flexibility characteristics. Particularly noteworthy are stimuli-responsive polymers that can alter their mechanical properties in response to environmental changes, enabling dynamic flexibility adjustment during measurement processes.

Ceramic-metal hybrid materials are gaining attention for specialized AFM applications requiring both flexibility and durability. These materials combine the wear resistance of ceramics with the ductility of metals, resulting in probes with extended operational lifespans and consistent flexibility parameters over time. Recent developments in atomic layer deposition techniques have enabled the creation of nanolaminates with precisely controlled layer thicknesses, allowing for unprecedented customization of probe mechanical properties.

Biomimetic materials inspired by natural structures are also showing promise. Materials that emulate the hierarchical organization found in biological systems, such as spider silk or plant cellulose, can provide unique combinations of strength and flexibility that are particularly valuable for biological AFM applications. These materials often exhibit non-linear elastic responses similar to those found in biological tissues, potentially improving measurement accuracy in biomolecular studies.

The integration of shape memory alloys and piezoelectric materials into probe designs represents a frontier in active flexibility control. These smart materials can transform electrical signals into mechanical responses, allowing for real-time adjustment of probe flexibility during measurement. This capability is particularly valuable for samples with varying mechanical properties or for sequential measurements requiring different flexibility parameters without probe replacement.

Carbon-based materials represent one of the most promising frontiers in probe development. Carbon nanotubes (CNTs) exhibit exceptional mechanical properties with Young's modulus values exceeding 1 TPa, while maintaining remarkable flexibility. This combination allows for more precise force measurements and improved interaction with delicate sample surfaces. Similarly, graphene-reinforced composites are emerging as viable alternatives, offering customizable flexibility profiles through precise manipulation of graphene concentration and orientation within the composite matrix.

Functionalized polymer coatings represent another significant innovation pathway. These coatings can be engineered to provide specific surface properties while maintaining or enhancing the underlying probe's flexibility characteristics. Particularly noteworthy are stimuli-responsive polymers that can alter their mechanical properties in response to environmental changes, enabling dynamic flexibility adjustment during measurement processes.

Ceramic-metal hybrid materials are gaining attention for specialized AFM applications requiring both flexibility and durability. These materials combine the wear resistance of ceramics with the ductility of metals, resulting in probes with extended operational lifespans and consistent flexibility parameters over time. Recent developments in atomic layer deposition techniques have enabled the creation of nanolaminates with precisely controlled layer thicknesses, allowing for unprecedented customization of probe mechanical properties.

Biomimetic materials inspired by natural structures are also showing promise. Materials that emulate the hierarchical organization found in biological systems, such as spider silk or plant cellulose, can provide unique combinations of strength and flexibility that are particularly valuable for biological AFM applications. These materials often exhibit non-linear elastic responses similar to those found in biological tissues, potentially improving measurement accuracy in biomolecular studies.

The integration of shape memory alloys and piezoelectric materials into probe designs represents a frontier in active flexibility control. These smart materials can transform electrical signals into mechanical responses, allowing for real-time adjustment of probe flexibility during measurement. This capability is particularly valuable for samples with varying mechanical properties or for sequential measurements requiring different flexibility parameters without probe replacement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!