Atomic Force Microscopy Vs Neutron Reflectometry: Application Insights

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM and NR Technology Background and Objectives

Atomic Force Microscopy (AFM) and Neutron Reflectometry (NR) represent two distinct yet complementary analytical techniques that have revolutionized surface and interface characterization across multiple scientific disciplines. Developed in the mid-1980s, AFM emerged as a breakthrough scanning probe microscopy technique capable of achieving atomic-level resolution by measuring forces between a sharp tip and sample surface. Meanwhile, NR evolved from neutron scattering techniques, gaining prominence in the 1990s as a powerful method for investigating buried interfaces and thin film structures at the nanoscale.

The evolution of these technologies has followed different trajectories, with AFM experiencing rapid commercialization and widespread adoption across industries, while NR has remained primarily within specialized research facilities due to its reliance on neutron sources. Recent technological advancements have significantly enhanced the capabilities of both techniques, with AFM expanding into multimodal operations and NR benefiting from improved neutron sources and data analysis algorithms.

Current market trends indicate growing demand for non-destructive, high-resolution surface characterization tools across semiconductor, materials science, and biological research sectors. The complementary nature of AFM and NR presents unique opportunities for integrated analytical approaches, particularly for complex multilayer systems where surface topography and internal structure both play critical roles in material performance.

The primary technical objective of this investigation is to establish a comprehensive comparative framework for AFM and NR applications, identifying their respective strengths, limitations, and optimal use cases. This includes evaluating resolution capabilities, sample preparation requirements, data acquisition times, and interpretation methodologies across various application domains.

Additionally, we aim to explore emerging hybrid approaches that leverage the complementary strengths of both techniques, potentially offering more comprehensive characterization solutions than either method alone. This includes correlative microscopy approaches where AFM topographical data is combined with NR depth profiling to create more complete material characterizations.

Future technological developments are expected to focus on improving accessibility of NR techniques through compact neutron sources, enhancing AFM capabilities through advanced probe designs and measurement modes, and developing integrated data analysis platforms that can synthesize information from multiple characterization techniques. The convergence of machine learning algorithms with these analytical methods represents a particularly promising direction for automated feature recognition and anomaly detection.

Understanding the fundamental principles, current capabilities, and future trajectories of these technologies is essential for identifying strategic research and development opportunities that align with evolving market needs across multiple industries, from semiconductor manufacturing to pharmaceutical development.

The evolution of these technologies has followed different trajectories, with AFM experiencing rapid commercialization and widespread adoption across industries, while NR has remained primarily within specialized research facilities due to its reliance on neutron sources. Recent technological advancements have significantly enhanced the capabilities of both techniques, with AFM expanding into multimodal operations and NR benefiting from improved neutron sources and data analysis algorithms.

Current market trends indicate growing demand for non-destructive, high-resolution surface characterization tools across semiconductor, materials science, and biological research sectors. The complementary nature of AFM and NR presents unique opportunities for integrated analytical approaches, particularly for complex multilayer systems where surface topography and internal structure both play critical roles in material performance.

The primary technical objective of this investigation is to establish a comprehensive comparative framework for AFM and NR applications, identifying their respective strengths, limitations, and optimal use cases. This includes evaluating resolution capabilities, sample preparation requirements, data acquisition times, and interpretation methodologies across various application domains.

Additionally, we aim to explore emerging hybrid approaches that leverage the complementary strengths of both techniques, potentially offering more comprehensive characterization solutions than either method alone. This includes correlative microscopy approaches where AFM topographical data is combined with NR depth profiling to create more complete material characterizations.

Future technological developments are expected to focus on improving accessibility of NR techniques through compact neutron sources, enhancing AFM capabilities through advanced probe designs and measurement modes, and developing integrated data analysis platforms that can synthesize information from multiple characterization techniques. The convergence of machine learning algorithms with these analytical methods represents a particularly promising direction for automated feature recognition and anomaly detection.

Understanding the fundamental principles, current capabilities, and future trajectories of these technologies is essential for identifying strategic research and development opportunities that align with evolving market needs across multiple industries, from semiconductor manufacturing to pharmaceutical development.

Market Applications and Research Demand Analysis

The market for advanced surface characterization techniques has witnessed significant growth in recent years, driven by increasing demands across various scientific and industrial sectors. Atomic Force Microscopy (AFM) and Neutron Reflectometry (NR) represent two distinct yet complementary approaches that serve different market segments with unique value propositions.

In the materials science sector, AFM has established a dominant position with an estimated market value exceeding $500 million globally. This technique's ability to provide high-resolution topographical imaging at the nanoscale has created substantial demand in semiconductor manufacturing, where process control and defect analysis are critical for maintaining production yields. The semiconductor industry alone accounts for approximately 35% of the total AFM market consumption.

Neutron Reflectometry, while representing a smaller market segment valued at approximately $120 million, has experienced accelerated growth rates of 12-15% annually over the past five years. This growth is primarily driven by research institutions and specialized industrial laboratories focused on soft matter interfaces, magnetic thin films, and biological membranes. The pharmaceutical and biotechnology sectors have emerged as significant adopters, utilizing NR for drug delivery system development and biomaterial interface studies.

Regional analysis reveals distinct adoption patterns. North America leads in AFM implementation across both industrial and research applications, while European institutions demonstrate stronger preference for Neutron Reflectometry, supported by major neutron source facilities like the Institut Laue-Langevin in France and ISIS in the UK. The Asia-Pacific region, particularly China and South Korea, shows the fastest growth rate for both technologies, with annual increases of 18-20% in research infrastructure investments.

Market forecasts indicate a shifting landscape in application demands. While traditional applications in materials characterization remain strong, emerging fields such as quantum computing, spintronics, and advanced energy storage materials are creating new market opportunities. These applications require increasingly sophisticated surface analysis capabilities that combine the strengths of both AFM and NR techniques.

Research funding trends further illuminate market dynamics, with government initiatives in quantum technologies allocating substantial resources toward advanced characterization methods. The European Quantum Flagship program and similar initiatives in the US and China have designated specific funding streams for surface analysis techniques, benefiting both AFM and NR technology development.

Industry surveys indicate that end-users increasingly seek integrated analytical solutions rather than standalone instruments, driving manufacturers toward developing complementary platforms that can provide correlated data from multiple characterization techniques. This trend suggests potential market convergence between AFM and NR technologies in specialized research applications, particularly for complex multilayer systems and dynamic interface studies.

In the materials science sector, AFM has established a dominant position with an estimated market value exceeding $500 million globally. This technique's ability to provide high-resolution topographical imaging at the nanoscale has created substantial demand in semiconductor manufacturing, where process control and defect analysis are critical for maintaining production yields. The semiconductor industry alone accounts for approximately 35% of the total AFM market consumption.

Neutron Reflectometry, while representing a smaller market segment valued at approximately $120 million, has experienced accelerated growth rates of 12-15% annually over the past five years. This growth is primarily driven by research institutions and specialized industrial laboratories focused on soft matter interfaces, magnetic thin films, and biological membranes. The pharmaceutical and biotechnology sectors have emerged as significant adopters, utilizing NR for drug delivery system development and biomaterial interface studies.

Regional analysis reveals distinct adoption patterns. North America leads in AFM implementation across both industrial and research applications, while European institutions demonstrate stronger preference for Neutron Reflectometry, supported by major neutron source facilities like the Institut Laue-Langevin in France and ISIS in the UK. The Asia-Pacific region, particularly China and South Korea, shows the fastest growth rate for both technologies, with annual increases of 18-20% in research infrastructure investments.

Market forecasts indicate a shifting landscape in application demands. While traditional applications in materials characterization remain strong, emerging fields such as quantum computing, spintronics, and advanced energy storage materials are creating new market opportunities. These applications require increasingly sophisticated surface analysis capabilities that combine the strengths of both AFM and NR techniques.

Research funding trends further illuminate market dynamics, with government initiatives in quantum technologies allocating substantial resources toward advanced characterization methods. The European Quantum Flagship program and similar initiatives in the US and China have designated specific funding streams for surface analysis techniques, benefiting both AFM and NR technology development.

Industry surveys indicate that end-users increasingly seek integrated analytical solutions rather than standalone instruments, driving manufacturers toward developing complementary platforms that can provide correlated data from multiple characterization techniques. This trend suggests potential market convergence between AFM and NR technologies in specialized research applications, particularly for complex multilayer systems and dynamic interface studies.

Current Technical Capabilities and Limitations

Atomic Force Microscopy (AFM) currently offers unparalleled spatial resolution down to the atomic level, enabling researchers to visualize and manipulate individual atoms and molecules on surfaces. This technique excels in ambient conditions, providing three-dimensional surface topography with minimal sample preparation requirements. Modern AFM systems have achieved vertical resolution below 0.1 nm and lateral resolution of approximately 1 nm, making them invaluable for nanoscale characterization across multiple disciplines.

Despite these capabilities, AFM faces significant limitations in imaging speed, typically requiring minutes to hours for high-resolution scans. This temporal constraint restricts its application in dynamic processes occurring at sub-second timescales. Additionally, AFM primarily characterizes surface properties, with limited penetration depth, and can potentially damage delicate biological samples during measurement.

Neutron Reflectometry (NR), conversely, offers exceptional capabilities for probing buried interfaces and thin films with depth resolution of 0.5-1 nm. This non-destructive technique provides detailed information about layer thickness, roughness, and composition across interfaces spanning several hundred nanometers. NR particularly excels in distinguishing between light elements and isotopes, making it uniquely suited for studying hydrogen-containing materials and biological systems.

The technique's sensitivity to magnetic properties through polarized neutron reflectometry represents another significant advantage, enabling detailed studies of magnetic thin films and multilayers critical for spintronics and data storage applications. NR measurements can also be conducted under various environmental conditions, including different temperatures, pressures, and in liquid environments.

However, NR faces substantial limitations in accessibility and infrastructure requirements. The technique necessitates neutron sources from nuclear reactors or spallation facilities, which are limited to approximately 50 locations worldwide. Measurement times typically range from hours to days, significantly longer than many competing techniques. Sample requirements are also demanding, often requiring large surface areas (several cm²) and specialized sample environments.

Resolution constraints represent another limitation, as NR provides excellent depth resolution but limited lateral resolution, making it unsuitable for imaging localized features across a surface. Data interpretation presents additional challenges, requiring complex modeling and often yielding non-unique solutions that demand complementary techniques for validation.

The complementary nature of AFM and NR becomes evident when considering their respective strengths and limitations, suggesting significant potential for combined methodological approaches in advanced materials characterization.

Despite these capabilities, AFM faces significant limitations in imaging speed, typically requiring minutes to hours for high-resolution scans. This temporal constraint restricts its application in dynamic processes occurring at sub-second timescales. Additionally, AFM primarily characterizes surface properties, with limited penetration depth, and can potentially damage delicate biological samples during measurement.

Neutron Reflectometry (NR), conversely, offers exceptional capabilities for probing buried interfaces and thin films with depth resolution of 0.5-1 nm. This non-destructive technique provides detailed information about layer thickness, roughness, and composition across interfaces spanning several hundred nanometers. NR particularly excels in distinguishing between light elements and isotopes, making it uniquely suited for studying hydrogen-containing materials and biological systems.

The technique's sensitivity to magnetic properties through polarized neutron reflectometry represents another significant advantage, enabling detailed studies of magnetic thin films and multilayers critical for spintronics and data storage applications. NR measurements can also be conducted under various environmental conditions, including different temperatures, pressures, and in liquid environments.

However, NR faces substantial limitations in accessibility and infrastructure requirements. The technique necessitates neutron sources from nuclear reactors or spallation facilities, which are limited to approximately 50 locations worldwide. Measurement times typically range from hours to days, significantly longer than many competing techniques. Sample requirements are also demanding, often requiring large surface areas (several cm²) and specialized sample environments.

Resolution constraints represent another limitation, as NR provides excellent depth resolution but limited lateral resolution, making it unsuitable for imaging localized features across a surface. Data interpretation presents additional challenges, requiring complex modeling and often yielding non-unique solutions that demand complementary techniques for validation.

The complementary nature of AFM and NR becomes evident when considering their respective strengths and limitations, suggesting significant potential for combined methodological approaches in advanced materials characterization.

Comparative Methodologies and Implementation Approaches

01 Combined AFM and neutron reflectometry for surface analysis

The integration of atomic force microscopy (AFM) and neutron reflectometry provides complementary surface characterization capabilities. While AFM offers high-resolution topographical imaging at the nanoscale, neutron reflectometry provides depth-resolved structural information about thin films and interfaces. This combination allows researchers to correlate surface morphology with compositional depth profiles, enabling comprehensive analysis of complex material systems and interfaces.- Combined AFM and neutron reflectometry techniques for surface analysis: The integration of atomic force microscopy (AFM) and neutron reflectometry provides complementary surface characterization capabilities. While AFM offers high-resolution topographical imaging at the nanoscale, neutron reflectometry provides depth-sensitive structural information about thin films and interfaces. This combination allows researchers to correlate surface morphology with compositional depth profiles, enabling comprehensive analysis of complex material systems and interfaces.

- Instrumentation advancements for AFM and neutron reflectometry: Technological innovations in instrumentation have enhanced the capabilities of both atomic force microscopy and neutron reflectometry. These advancements include improved probe designs, more sensitive detectors, and sophisticated control systems that enable higher resolution, greater accuracy, and expanded functionality. Modern instruments often feature integrated environmental controls allowing measurements under various conditions such as controlled temperature, humidity, or in liquid environments, expanding their application range across multiple scientific disciplines.

- In-situ and real-time measurements using AFM with neutron techniques: In-situ and real-time measurement capabilities combine atomic force microscopy with neutron reflectometry to study dynamic processes at surfaces and interfaces. This approach allows researchers to observe structural changes during chemical reactions, phase transitions, or under applied external stimuli such as temperature, pressure, or electric fields. The ability to simultaneously collect complementary data sets provides unique insights into kinetic processes and transient phenomena that would be impossible to capture with static or ex-situ measurements.

- Soft matter and biological applications: Atomic force microscopy and neutron reflectometry are particularly valuable for investigating soft matter systems and biological interfaces. These techniques enable characterization of polymer films, lipid membranes, protein adsorption, and biomaterial interfaces with nanoscale resolution. The non-destructive nature of neutron reflectometry, combined with the high-resolution imaging capabilities of AFM, provides crucial information about structure-function relationships in biological systems, helping advance fields such as drug delivery, biosensors, and biomimetic materials.

- Data analysis and computational methods: Advanced data analysis and computational methods are essential for interpreting the complex datasets generated by atomic force microscopy and neutron reflectometry experiments. These include sophisticated algorithms for image processing, statistical analysis, and model fitting to extract meaningful physical parameters from raw data. Machine learning approaches are increasingly being applied to identify patterns and correlations in multidimensional datasets. Simulation techniques help bridge experimental observations with theoretical models, providing deeper insights into the underlying physical and chemical processes at surfaces and interfaces.

02 Instrumentation advancements for microscopy techniques

Technological innovations in instrumentation have enhanced the capabilities of both atomic force microscopy and neutron reflectometry. These advancements include improved probe designs, more sensitive detection systems, and enhanced environmental control chambers. Such developments have led to higher resolution, better signal-to-noise ratios, and the ability to perform measurements under various conditions, expanding the range of materials and phenomena that can be studied using these complementary techniques.Expand Specific Solutions03 Analysis of soft matter and biological interfaces

Atomic force microscopy and neutron reflectometry are particularly valuable for investigating soft matter systems and biological interfaces. These techniques enable the characterization of lipid membranes, polymer films, protein adsorption, and biomaterial interfaces. The non-destructive nature of neutron reflectometry complements the high-resolution imaging capabilities of AFM, allowing researchers to study delicate biological structures and their interactions with surfaces under physiologically relevant conditions.Expand Specific Solutions04 In-situ and environmental measurements

Both atomic force microscopy and neutron reflectometry can be adapted for in-situ measurements under various environmental conditions. This capability allows researchers to study dynamic processes such as surface reactions, phase transitions, and material responses to external stimuli in real-time. Environmental chambers and specialized sample cells enable measurements in liquid media, controlled atmospheres, or under applied fields, providing insights into material behavior under realistic operating conditions.Expand Specific Solutions05 Advanced data analysis and correlation methods

Sophisticated data analysis methods have been developed to extract maximum information from atomic force microscopy and neutron reflectometry measurements. These include multivariate statistical approaches, machine learning algorithms, and computational modeling techniques that help correlate and interpret data from these complementary techniques. Such methods enable researchers to bridge different length scales and develop more comprehensive understanding of complex material systems, from atomic-scale interactions to macroscopic properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The Atomic Force Microscopy (AFM) versus Neutron Reflectometry (NR) landscape represents a mature yet evolving field within surface characterization technologies. The market is characterized by established academic institutions (University of California, Purdue Research Foundation, National University of Singapore) collaborating with specialized equipment manufacturers (Bruker Nano, JEOL, Shimadzu, Keysight Technologies). While AFM has reached commercial maturity with widespread applications in materials science and biology, NR remains predominantly in research settings due to infrastructure requirements. Leading companies like Oxford Instruments Asylum Research and Bruker Nano dominate the AFM segment, while neutron reflectometry capabilities are concentrated at major research facilities supported by organizations like CNRS and NASA. The complementary nature of these techniques is driving integration efforts, with research institutions like Technische Universität München and Osaka University pioneering combined methodologies for comprehensive surface analysis.

JEOL Ltd.

Technical Solution: JEOL's approach to Atomic Force Microscopy (AFM) centers on their hybrid systems that integrate AFM with scanning electron microscopy (SEM) and transmission electron microscopy (TEM). Their ClairScope™ technology enables atmospheric scanning electron microscopy with AFM capabilities, allowing simultaneous topographical and compositional analysis at nanoscale resolution. JEOL has developed specialized cantilever probes with ultra-sharp tips (radius <10 nm) that enhance lateral resolution for precise surface characterization. Their systems incorporate advanced feedback mechanisms that maintain constant tip-sample forces, reducing sample damage while improving measurement accuracy. For biological applications, JEOL's AFM solutions feature temperature-controlled sample stages and liquid cells that enable in-situ imaging of biological processes under physiological conditions. Their proprietary software suite provides comprehensive data analysis tools including 3D visualization, roughness analysis, and particle sizing capabilities.

Strengths: JEOL's integrated AFM-electron microscopy systems provide complementary data from multiple techniques simultaneously, offering comprehensive sample characterization. Their specialized probes and feedback systems enable high-resolution imaging with minimal sample damage. Weaknesses: Their AFM systems tend to be more complex and expensive than standalone instruments, requiring specialized training. The integration with electron microscopy limits some applications requiring fully non-destructive analysis.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has pioneered advanced AFM technologies with their MultiMode and Dimension series instruments that offer nanometer-scale resolution for surface characterization. Their PeakForce Tapping® technology represents a significant innovation that automatically controls the peak force applied to samples, enabling simultaneous acquisition of multiple mechanical properties while protecting delicate samples. For biological applications, Bruker has developed the BioScope Resolve® system that integrates with inverted optical microscopes for correlative imaging of living cells. In contrast to neutron reflectometry, Bruker's AFM systems provide direct spatial mapping of surface properties with resolution down to the atomic scale. Their FastScan® technology has dramatically improved imaging speeds (up to 125 Hz line rates), addressing traditional AFM speed limitations. Bruker has also developed specialized AFM modes including PeakForce QNM® for quantitative nanomechanical mapping and PeakForce TUNA™/KPFM for electrical characterization, expanding AFM applications beyond topographical imaging to comprehensive surface property analysis.

Strengths: Bruker's AFM systems offer exceptional versatility with numerous specialized imaging modes and accessories for diverse applications. Their PeakForce technology provides superior force control, enabling high-resolution imaging of even the most delicate samples. Their systems feature user-friendly software interfaces that simplify operation. Weaknesses: High-end Bruker AFM systems represent significant capital investments. Some specialized modes require additional expensive accessories and probes, increasing operational costs.

Critical Patents and Scientific Breakthroughs

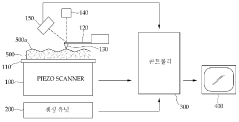

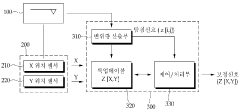

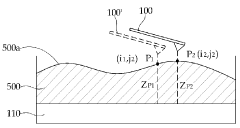

Atomic force microscope and method for correcting scan image thereof

PatentInactiveKR1020090088645A

Innovation

- An atomic force microscope equipped with a sensing unit to detect real-time XY positions and a controller to correct image distortion by converting measured data values using a lookup table, allowing for high-speed operation without feedback delays.

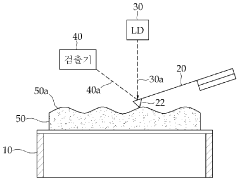

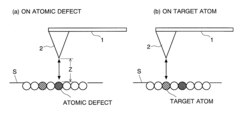

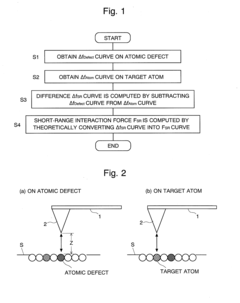

Atomic force microscope and interaction force measurement method using atomic force microscope

PatentInactiveUS20100071099A1

Innovation

- A frequency modulation atomic force microscope method that computes the difference between Δf curves obtained on a target atom and an atomic defect to isolate the short-range interaction force, allowing for measurement within a shorter range scale (up to 1 nm) and reducing the need for bias voltage compensation, thereby minimizing electrostatic influence and accelerating computational processes.

Sample Preparation Challenges and Solutions

Sample preparation represents a critical determinant of success in both Atomic Force Microscopy (AFM) and Neutron Reflectometry (NR) techniques, with each method presenting unique challenges that require specialized solutions. The fundamental difference in sample requirements stems from their distinct operational principles: AFM directly interacts with sample surfaces at the nanoscale, while NR involves neutron beams penetrating and reflecting from interfaces within layered structures.

For AFM applications, surface cleanliness and flatness are paramount concerns. Contamination at even the nanometer scale can significantly distort measurements and lead to artifacts in imaging. Common preparation challenges include the removal of particulates, organic residues, and moisture without altering the sample's native structure. Solutions have evolved through specialized cleaning protocols involving sequential solvent treatments, plasma cleaning, and in some cases, ultrasonication techniques calibrated to specific sample compositions.

Substrate selection presents another critical consideration for AFM, with mica, highly oriented pyrolytic graphite (HOPG), and silicon wafers serving as preferred options due to their atomically flat surfaces. For biological samples, additional complexities arise in maintaining physiological relevance while achieving sufficient immobilization to withstand scanning forces.

Neutron Reflectometry, conversely, demands larger sample areas (typically several square centimeters) with exceptional uniformity across interfaces. The technique's sensitivity to hydrogen content creates unique preparation challenges, particularly for studies involving biological membranes or polymer interfaces. Deuteration strategies have emerged as essential solutions, where hydrogen atoms are selectively replaced with deuterium to create contrast variation without significantly altering molecular behavior.

Sample environment control represents another significant challenge for NR experiments. Maintaining precise temperature, humidity, or pressure conditions during measurements that may last several hours requires specialized sample cells and environmental chambers. Recent innovations include microfluidic platforms that enable in-situ studies of dynamic interfacial processes.

The convergence of these techniques has driven development of hybrid preparation protocols that satisfy the requirements of both methods. Silicon substrates with controlled surface chemistry have emerged as versatile platforms compatible with both AFM and NR investigations. Additionally, advances in cryogenic preparation techniques have opened new possibilities for studying delicate biological structures in their near-native states across both methodologies.

Standardization efforts remain ongoing, with several international collaborations working to establish best practices for sample preparation that maximize reproducibility and facilitate meaningful comparisons between AFM and NR data sets. These developments continue to expand the complementary application of these powerful analytical techniques across materials science, biology, and nanotechnology.

For AFM applications, surface cleanliness and flatness are paramount concerns. Contamination at even the nanometer scale can significantly distort measurements and lead to artifacts in imaging. Common preparation challenges include the removal of particulates, organic residues, and moisture without altering the sample's native structure. Solutions have evolved through specialized cleaning protocols involving sequential solvent treatments, plasma cleaning, and in some cases, ultrasonication techniques calibrated to specific sample compositions.

Substrate selection presents another critical consideration for AFM, with mica, highly oriented pyrolytic graphite (HOPG), and silicon wafers serving as preferred options due to their atomically flat surfaces. For biological samples, additional complexities arise in maintaining physiological relevance while achieving sufficient immobilization to withstand scanning forces.

Neutron Reflectometry, conversely, demands larger sample areas (typically several square centimeters) with exceptional uniformity across interfaces. The technique's sensitivity to hydrogen content creates unique preparation challenges, particularly for studies involving biological membranes or polymer interfaces. Deuteration strategies have emerged as essential solutions, where hydrogen atoms are selectively replaced with deuterium to create contrast variation without significantly altering molecular behavior.

Sample environment control represents another significant challenge for NR experiments. Maintaining precise temperature, humidity, or pressure conditions during measurements that may last several hours requires specialized sample cells and environmental chambers. Recent innovations include microfluidic platforms that enable in-situ studies of dynamic interfacial processes.

The convergence of these techniques has driven development of hybrid preparation protocols that satisfy the requirements of both methods. Silicon substrates with controlled surface chemistry have emerged as versatile platforms compatible with both AFM and NR investigations. Additionally, advances in cryogenic preparation techniques have opened new possibilities for studying delicate biological structures in their near-native states across both methodologies.

Standardization efforts remain ongoing, with several international collaborations working to establish best practices for sample preparation that maximize reproducibility and facilitate meaningful comparisons between AFM and NR data sets. These developments continue to expand the complementary application of these powerful analytical techniques across materials science, biology, and nanotechnology.

Cost-Benefit Analysis and Accessibility Factors

When evaluating the implementation of Atomic Force Microscopy (AFM) versus Neutron Reflectometry (NR) technologies, cost-benefit analysis and accessibility factors play crucial roles in decision-making processes for research institutions and industrial applications.

The initial investment for AFM systems typically ranges from $100,000 to $500,000, depending on capabilities and resolution requirements. In contrast, neutron reflectometry facilities require substantial infrastructure investments, often exceeding $10-20 million, as they necessitate neutron sources such as nuclear reactors or spallation sources. This significant cost differential creates an immediate accessibility barrier for many institutions considering these technologies.

Operational expenses further widen this gap. AFM maintenance costs average $5,000-15,000 annually, with minimal specialized facility requirements beyond vibration isolation and temperature control. NR operations, however, demand specialized facilities with radiation shielding, cooling systems, and highly trained personnel, resulting in operational costs that can exceed $1 million annually. Additionally, neutron sources require substantial energy inputs, contributing to higher operational expenses.

Sample preparation costs and complexity also differ markedly. AFM samples require minimal preparation, often costing less than $100 per sample with rapid turnaround times. NR samples demand specialized preparation techniques, including isotopic labeling with deuterium, increasing per-sample costs to $500-2,000 and extending preparation timeframes significantly.

Accessibility considerations extend beyond financial factors. AFM instruments are commercially available from multiple vendors, can be installed in standard laboratory spaces, and typically require training periods of 1-2 weeks for basic operation. Conversely, NR facilities are limited to approximately 20 major facilities worldwide, necessitating competitive proposal submissions with acceptance rates below 30% and waiting periods of 6-12 months for instrument time.

The return on investment timeline varies substantially between these technologies. AFM systems typically demonstrate ROI within 2-5 years through regular usage across multiple research projects. NR facilities, due to their specialized nature and high costs, may require decades to justify their investment, making them viable primarily for national laboratories or large research consortia rather than individual institutions.

These cost-benefit considerations directly impact research planning, with AFM enabling rapid, iterative investigations while NR experiments require extensive advance planning and often represent significant milestones in research programs. The accessibility differential has led to the development of collaborative networks and remote access protocols for NR facilities, partially mitigating these limitations while maintaining the complementary relationship between these powerful analytical techniques.

The initial investment for AFM systems typically ranges from $100,000 to $500,000, depending on capabilities and resolution requirements. In contrast, neutron reflectometry facilities require substantial infrastructure investments, often exceeding $10-20 million, as they necessitate neutron sources such as nuclear reactors or spallation sources. This significant cost differential creates an immediate accessibility barrier for many institutions considering these technologies.

Operational expenses further widen this gap. AFM maintenance costs average $5,000-15,000 annually, with minimal specialized facility requirements beyond vibration isolation and temperature control. NR operations, however, demand specialized facilities with radiation shielding, cooling systems, and highly trained personnel, resulting in operational costs that can exceed $1 million annually. Additionally, neutron sources require substantial energy inputs, contributing to higher operational expenses.

Sample preparation costs and complexity also differ markedly. AFM samples require minimal preparation, often costing less than $100 per sample with rapid turnaround times. NR samples demand specialized preparation techniques, including isotopic labeling with deuterium, increasing per-sample costs to $500-2,000 and extending preparation timeframes significantly.

Accessibility considerations extend beyond financial factors. AFM instruments are commercially available from multiple vendors, can be installed in standard laboratory spaces, and typically require training periods of 1-2 weeks for basic operation. Conversely, NR facilities are limited to approximately 20 major facilities worldwide, necessitating competitive proposal submissions with acceptance rates below 30% and waiting periods of 6-12 months for instrument time.

The return on investment timeline varies substantially between these technologies. AFM systems typically demonstrate ROI within 2-5 years through regular usage across multiple research projects. NR facilities, due to their specialized nature and high costs, may require decades to justify their investment, making them viable primarily for national laboratories or large research consortia rather than individual institutions.

These cost-benefit considerations directly impact research planning, with AFM enabling rapid, iterative investigations while NR experiments require extensive advance planning and often represent significant milestones in research programs. The accessibility differential has led to the development of collaborative networks and remote access protocols for NR facilities, partially mitigating these limitations while maintaining the complementary relationship between these powerful analytical techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!