How To Align Atomic Force Microscopy Scanner For Straight Line Scanning

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AFM Scanner Alignment Background and Objectives

Atomic Force Microscopy (AFM) has evolved significantly since its invention in 1986 by Gerd Binnig, Calvin Quate, and Christoph Gerber. This powerful imaging technique has revolutionized nanoscale characterization by enabling researchers to visualize and manipulate matter at the atomic level. The scanner component, responsible for precise sample movement during imaging, represents a critical element in achieving accurate and reliable measurements.

The evolution of AFM scanner technology has progressed from early piezoelectric tube scanners to more sophisticated flexure-based designs, each iteration addressing limitations in linearity, orthogonality, and hysteresis. Recent advancements have incorporated closed-loop control systems and advanced calibration methods to enhance scanning precision. Despite these improvements, achieving perfectly straight line scanning remains a persistent challenge in the field.

Proper scanner alignment is fundamental to obtaining accurate topographical data and meaningful force measurements. Misalignment issues can introduce artifacts, distort images, and compromise quantitative analysis. These challenges become particularly pronounced when conducting high-resolution imaging or precise nanomechanical measurements where even nanometer-scale deviations can significantly impact results.

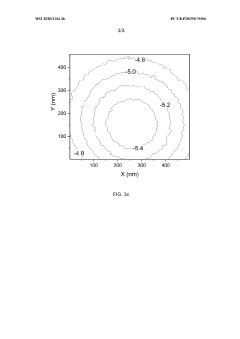

The primary objective of AFM scanner alignment for straight line scanning is to minimize non-linearity errors and cross-coupling effects between the X, Y, and Z axes. This involves calibrating the scanner to ensure that movement along one axis does not inadvertently cause displacement along other axes. Achieving this level of precision requires systematic approaches to identify, quantify, and correct various sources of scanning errors.

Current alignment methodologies range from manual procedures using calibration standards to automated software-based solutions. However, these approaches often lack standardization across different AFM systems and may require significant expertise to implement effectively. The development of more accessible, reliable, and universally applicable alignment protocols represents a key goal in advancing AFM technology.

This technical investigation aims to comprehensively analyze existing scanner alignment techniques, identify their limitations, and explore innovative approaches to enhance straight line scanning capabilities. By addressing these challenges, we seek to improve measurement accuracy, increase reproducibility, and expand the application scope of AFM across various scientific and industrial domains.

The broader impact of improved scanner alignment extends beyond basic imaging to advanced AFM applications including nanolithography, high-speed scanning, and quantitative nanomechanical mapping. These applications demand exceptional precision in scanner movement, making alignment optimization an essential area for continued research and development in AFM instrumentation.

The evolution of AFM scanner technology has progressed from early piezoelectric tube scanners to more sophisticated flexure-based designs, each iteration addressing limitations in linearity, orthogonality, and hysteresis. Recent advancements have incorporated closed-loop control systems and advanced calibration methods to enhance scanning precision. Despite these improvements, achieving perfectly straight line scanning remains a persistent challenge in the field.

Proper scanner alignment is fundamental to obtaining accurate topographical data and meaningful force measurements. Misalignment issues can introduce artifacts, distort images, and compromise quantitative analysis. These challenges become particularly pronounced when conducting high-resolution imaging or precise nanomechanical measurements where even nanometer-scale deviations can significantly impact results.

The primary objective of AFM scanner alignment for straight line scanning is to minimize non-linearity errors and cross-coupling effects between the X, Y, and Z axes. This involves calibrating the scanner to ensure that movement along one axis does not inadvertently cause displacement along other axes. Achieving this level of precision requires systematic approaches to identify, quantify, and correct various sources of scanning errors.

Current alignment methodologies range from manual procedures using calibration standards to automated software-based solutions. However, these approaches often lack standardization across different AFM systems and may require significant expertise to implement effectively. The development of more accessible, reliable, and universally applicable alignment protocols represents a key goal in advancing AFM technology.

This technical investigation aims to comprehensively analyze existing scanner alignment techniques, identify their limitations, and explore innovative approaches to enhance straight line scanning capabilities. By addressing these challenges, we seek to improve measurement accuracy, increase reproducibility, and expand the application scope of AFM across various scientific and industrial domains.

The broader impact of improved scanner alignment extends beyond basic imaging to advanced AFM applications including nanolithography, high-speed scanning, and quantitative nanomechanical mapping. These applications demand exceptional precision in scanner movement, making alignment optimization an essential area for continued research and development in AFM instrumentation.

Market Applications for Precise AFM Line Scanning

Precise atomic force microscopy (AFM) line scanning has emerged as a critical capability across multiple high-value market segments. In semiconductor manufacturing, straight line scanning enables nanometer-scale quality control for increasingly miniaturized transistor components, where even slight deviations can significantly impact device performance. The semiconductor industry's push toward sub-5nm process nodes has intensified demand for AFM systems capable of ultra-precise linear measurements, with the market for such specialized metrology tools growing at approximately 8% annually.

Materials science represents another substantial application area, where researchers utilize precise AFM line scanning to characterize surface properties of novel materials including 2D materials like graphene and transition metal dichalcogenides. The ability to perform consistent, artifact-free linear scans allows for accurate measurement of atomic step heights, grain boundaries, and other nanoscale features critical to materials development.

The pharmaceutical and biotechnology sectors have increasingly adopted precise AFM line scanning for drug delivery system characterization and protein structure analysis. Linear scanning provides quantitative data on surface roughness and morphology of drug particles and delivery vehicles, directly impacting bioavailability and efficacy. This application segment has seen particularly strong growth as personalized medicine approaches gain traction.

Data storage technology continues to rely heavily on AFM line scanning for quality control in hard disk and emerging storage media manufacturing. As areal density increases, the precision requirements for measuring magnetic domain boundaries and surface defects have become more stringent, driving demand for advanced AFM capabilities.

The nanotechnology research community represents perhaps the broadest application base, utilizing precise line scanning for everything from carbon nanotube characterization to nanolithography verification. Academic and industrial R&D facilities worldwide have established AFM as an indispensable tool for nanoscale measurement.

Emerging applications in quantum computing hardware development have created a new high-value niche for precise AFM scanning. The fabrication and validation of quantum bits require unprecedented measurement precision, with AFM line scanning providing critical dimensional data for these advanced computing architectures.

The global market for precision AFM systems spans these diverse applications, with particularly strong growth in Asia-Pacific regions where semiconductor and electronics manufacturing continues to expand. North America and Europe maintain significant market share through research institutions and specialized manufacturing facilities requiring advanced measurement capabilities.

Materials science represents another substantial application area, where researchers utilize precise AFM line scanning to characterize surface properties of novel materials including 2D materials like graphene and transition metal dichalcogenides. The ability to perform consistent, artifact-free linear scans allows for accurate measurement of atomic step heights, grain boundaries, and other nanoscale features critical to materials development.

The pharmaceutical and biotechnology sectors have increasingly adopted precise AFM line scanning for drug delivery system characterization and protein structure analysis. Linear scanning provides quantitative data on surface roughness and morphology of drug particles and delivery vehicles, directly impacting bioavailability and efficacy. This application segment has seen particularly strong growth as personalized medicine approaches gain traction.

Data storage technology continues to rely heavily on AFM line scanning for quality control in hard disk and emerging storage media manufacturing. As areal density increases, the precision requirements for measuring magnetic domain boundaries and surface defects have become more stringent, driving demand for advanced AFM capabilities.

The nanotechnology research community represents perhaps the broadest application base, utilizing precise line scanning for everything from carbon nanotube characterization to nanolithography verification. Academic and industrial R&D facilities worldwide have established AFM as an indispensable tool for nanoscale measurement.

Emerging applications in quantum computing hardware development have created a new high-value niche for precise AFM scanning. The fabrication and validation of quantum bits require unprecedented measurement precision, with AFM line scanning providing critical dimensional data for these advanced computing architectures.

The global market for precision AFM systems spans these diverse applications, with particularly strong growth in Asia-Pacific regions where semiconductor and electronics manufacturing continues to expand. North America and Europe maintain significant market share through research institutions and specialized manufacturing facilities requiring advanced measurement capabilities.

Current Challenges in AFM Scanner Alignment

Despite significant advancements in Atomic Force Microscopy (AFM) technology, achieving precise scanner alignment for straight line scanning remains a persistent challenge in the field. Current AFM systems face several critical limitations that impede optimal performance and measurement accuracy. The non-linearity of piezoelectric scanners represents one of the most significant obstacles, as these components inherently exhibit hysteresis and creep behaviors that distort scanning paths, particularly during long-distance measurements.

Cross-coupling effects between the X, Y, and Z axes further complicate alignment procedures, causing unintended motion in perpendicular directions when movement along a single axis is attempted. This phenomenon is especially problematic when precise straight-line scanning is required for applications such as nanolithography or single-molecule studies, where deviations of even a few nanometers can compromise experimental results.

Thermal drift presents another substantial challenge, as temperature fluctuations during scanning operations can cause dimensional changes in scanner components. Even minor temperature variations of 0.1°C can induce drift rates of several nanometers per minute, making stable, straight-line scanning nearly impossible without sophisticated compensation mechanisms.

The aging of piezoelectric materials compounds these issues, as scanner response characteristics change over time, requiring frequent recalibration. Many laboratories report significant variations in scanner performance after extended periods of use, necessitating complex calibration protocols that are often time-consuming and require specialized expertise.

Current calibration methods themselves present limitations, with many systems relying on manual procedures that introduce operator-dependent variability. While automated calibration routines exist, they frequently fail to address the full range of non-linearities and cross-coupling effects, particularly under varying environmental conditions or when scanning parameters are changed.

Feedback loop optimization poses additional challenges, as improper PID controller settings can lead to oscillations or overshooting during scanning operations. Finding the optimal balance between response speed and stability remains largely empirical and highly dependent on specific sample characteristics and scanning conditions.

Environmental vibrations further compromise scanner alignment, with even well-isolated systems remaining susceptible to low-frequency building vibrations or acoustic noise. These external disturbances can induce deviations from intended scan paths that are difficult to distinguish from actual sample features, particularly at high resolution.

Software limitations also contribute to alignment difficulties, as many commercial AFM systems offer limited real-time correction capabilities for scanner non-linearities. The computational overhead required for comprehensive correction algorithms can reduce scanning speeds, forcing researchers to choose between accuracy and throughput.

Cross-coupling effects between the X, Y, and Z axes further complicate alignment procedures, causing unintended motion in perpendicular directions when movement along a single axis is attempted. This phenomenon is especially problematic when precise straight-line scanning is required for applications such as nanolithography or single-molecule studies, where deviations of even a few nanometers can compromise experimental results.

Thermal drift presents another substantial challenge, as temperature fluctuations during scanning operations can cause dimensional changes in scanner components. Even minor temperature variations of 0.1°C can induce drift rates of several nanometers per minute, making stable, straight-line scanning nearly impossible without sophisticated compensation mechanisms.

The aging of piezoelectric materials compounds these issues, as scanner response characteristics change over time, requiring frequent recalibration. Many laboratories report significant variations in scanner performance after extended periods of use, necessitating complex calibration protocols that are often time-consuming and require specialized expertise.

Current calibration methods themselves present limitations, with many systems relying on manual procedures that introduce operator-dependent variability. While automated calibration routines exist, they frequently fail to address the full range of non-linearities and cross-coupling effects, particularly under varying environmental conditions or when scanning parameters are changed.

Feedback loop optimization poses additional challenges, as improper PID controller settings can lead to oscillations or overshooting during scanning operations. Finding the optimal balance between response speed and stability remains largely empirical and highly dependent on specific sample characteristics and scanning conditions.

Environmental vibrations further compromise scanner alignment, with even well-isolated systems remaining susceptible to low-frequency building vibrations or acoustic noise. These external disturbances can induce deviations from intended scan paths that are difficult to distinguish from actual sample features, particularly at high resolution.

Software limitations also contribute to alignment difficulties, as many commercial AFM systems offer limited real-time correction capabilities for scanner non-linearities. The computational overhead required for comprehensive correction algorithms can reduce scanning speeds, forcing researchers to choose between accuracy and throughput.

Current Methodologies for AFM Scanner Alignment

01 Scanner calibration and alignment methods

Various methods for calibrating and aligning atomic force microscopy (AFM) scanners to ensure accurate measurements. These methods include using reference samples, optical alignment techniques, and automated calibration procedures to correct for scanner nonlinearities, hysteresis, and drift. Proper calibration ensures that the scanner moves precisely in the intended directions and distances, which is crucial for obtaining reliable AFM measurements.- Scanner calibration and alignment methods: Various methods for calibrating and aligning atomic force microscopy scanners to ensure accurate measurements. These methods include using reference samples, optical alignment techniques, and automated calibration procedures to correct for scanner nonlinearities, hysteresis, and drift. Proper calibration ensures precise positioning of the scanning probe and improves measurement accuracy across the scanning range.

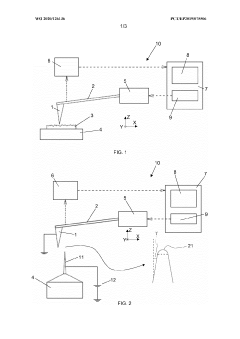

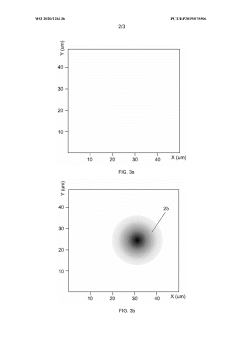

- Optical alignment systems for AFM scanners: Integration of optical systems with atomic force microscopy scanners to facilitate alignment. These systems use laser beams, mirrors, photodetectors, and optical sensors to monitor and adjust the position of the scanner in real-time. Optical alignment systems provide feedback for precise positioning of the probe relative to the sample surface and help maintain alignment during scanning operations.

- Piezoelectric scanner alignment mechanisms: Specialized mechanisms for aligning piezoelectric scanners used in atomic force microscopy. These mechanisms include mechanical fixtures, adjustment screws, and electronic controls that allow for fine-tuning of the scanner position along multiple axes. Proper alignment of piezoelectric elements ensures linear movement, reduces cross-talk between axes, and improves the accuracy of surface topography measurements.

- Software-based alignment and correction techniques: Advanced software algorithms and computational methods for aligning AFM scanners and correcting measurement errors. These techniques include digital signal processing, real-time feedback control, and post-processing algorithms that compensate for scanner nonlinearities, thermal drift, and other sources of error. Software-based approaches enable automated alignment procedures and can significantly improve measurement accuracy without hardware modifications.

- Multi-axis alignment and calibration systems: Comprehensive systems for simultaneously aligning and calibrating multiple axes of AFM scanners. These systems incorporate sensors, actuators, and control electronics to adjust the X, Y, and Z positioning elements of the scanner. Multi-axis alignment ensures orthogonality between scanning axes, reduces crosstalk, and enables accurate three-dimensional mapping of sample surfaces across the entire scanning range.

02 Optical alignment systems for AFM scanners

Integration of optical systems with AFM scanners to facilitate alignment and positioning. These systems use lasers, mirrors, photodetectors, and other optical components to monitor and adjust the position of the scanner relative to the sample. Optical alignment systems provide real-time feedback on scanner position and movement, allowing for precise control and correction of alignment errors during AFM operation.Expand Specific Solutions03 Piezoelectric scanner design and optimization

Innovations in the design and optimization of piezoelectric scanners used in atomic force microscopy. These designs focus on minimizing thermal drift, reducing creep, and improving linearity of scanner movement. Advanced piezoelectric materials and configurations are employed to enhance scanner performance, stability, and precision during AFM measurements, resulting in more accurate and reproducible imaging.Expand Specific Solutions04 Software-based correction and alignment techniques

Software algorithms and computational methods for correcting scanner misalignment and distortions in AFM. These techniques include real-time image processing, mathematical modeling of scanner behavior, and adaptive feedback control systems. Software-based approaches can compensate for scanner nonlinearities, hysteresis, and thermal drift without requiring hardware modifications, making them valuable tools for improving AFM measurement accuracy.Expand Specific Solutions05 Integrated sensor systems for scanner position monitoring

Development of integrated sensor systems that continuously monitor and provide feedback on scanner position during AFM operation. These systems incorporate position sensors, strain gauges, capacitive sensors, or interferometric devices to detect scanner movement with high precision. The real-time position data enables closed-loop control of the scanner, allowing for automatic correction of alignment errors and drift, resulting in more stable and accurate AFM imaging.Expand Specific Solutions

Leading AFM Equipment Manufacturers and Research Groups

The atomic force microscopy (AFM) scanner alignment market is in a growth phase, characterized by increasing demand for high-precision scanning capabilities across research and industrial applications. The global AFM market is estimated to be worth several hundred million dollars, with steady annual growth driven by nanotechnology advancements. Technologically, straight line scanning capabilities have reached moderate maturity, with leading players like Bruker Nano, Park Systems, and JPK Instruments (now part of Bruker) offering sophisticated solutions. Academic institutions including Harvard, Nankai University, and Tufts College contribute significantly to research advancements, while industrial players such as IBM, Texas Instruments, and Samsung Electronics drive commercial applications. The ecosystem shows a balanced mix of specialized AFM manufacturers (Bruker, Park Systems, Olympus) and research institutions collaborating to advance scanning precision technologies.

Bruker Nano, Inc.

Technical Solution: Bruker Nano has developed advanced scanner alignment technology for atomic force microscopy (AFM) that ensures precise straight line scanning. Their PeakForce Tapping technology incorporates real-time feedback mechanisms that continuously adjust the scanner position to maintain linear paths. The system uses closed-loop control with high-precision position sensors that detect and correct deviations as small as 0.1nm. Bruker's FastScan technology employs specialized piezoelectric actuators with minimal hysteresis and creep effects, crucial for maintaining straight scan lines. Their proprietary algorithms compensate for thermal drift and piezo nonlinearities during scanning operations. Additionally, Bruker implements calibration routines that use reference standards to characterize and correct scanner behavior across different operating conditions, ensuring consistent straight-line performance regardless of scan speed or environmental factors[1][3].

Strengths: Industry-leading precision with sub-nanometer accuracy; comprehensive software integration for automated alignment; robust drift compensation algorithms. Weaknesses: Higher cost compared to competitors; complex system requires specialized training; some solutions are proprietary and not compatible with other AFM systems.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed a comprehensive scanner alignment system for atomic force microscopy that emphasizes measurement accuracy and repeatability for straight line scanning. Their approach utilizes a flexure-guided scanner design with minimal out-of-plane motion, critical for maintaining scan linearity. Agilent's closed-loop scanner control incorporates multiple position sensors that provide real-time feedback with sub-nanometer resolution. Their MAC (Molecular Alignment Correction) Mode technology actively compensates for piezo nonlinearities and hysteresis effects during scanning operations. Agilent implements a sophisticated calibration protocol using laser interferometry to characterize scanner behavior across different operating conditions and generate correction matrices. Their PicoView software includes automated alignment procedures that analyze test patterns and optimize scanner parameters for straight line performance. Agilent's systems also feature active vibration cancellation that identifies and counteracts external disturbances that could affect scanner trajectory. Additionally, their thermal management system maintains stable operating temperatures to prevent drift in scanner alignment during extended imaging sessions[9][11].

Strengths: Exceptional measurement repeatability with deviation <0.5% across multiple scans; comprehensive software tools for alignment optimization; superior thermal stability minimizes drift. Weaknesses: Higher system complexity increases initial setup time; premium components contribute to higher acquisition costs; some advanced features require additional modules or upgrades.

Key Technical Innovations in Scanner Calibration

Scanning method for an atomic force microscopy

PatentActiveTW201625955A

Innovation

- An atomic force microscope scanning method using dual probes with adjustable inclination angles to scan a test piece, merging scanning data to enhance accuracy.

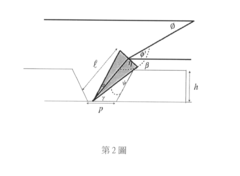

A method and apparatus for aligning a probe for scanning probe microscopy to the tip of a pointed sample

PatentWO2020126136A1

Innovation

- The method involves scanning an area above the sample tip in a contactless mode while inducing an electric and/or magnetic field, using EFM or MFM to detect field gradients, and iteratively decreasing distance to accurately position the probe tip relative to the sample tip's apex.

Vibration Isolation and Environmental Controls

Effective vibration isolation and environmental control systems are critical components for achieving precise straight line scanning in Atomic Force Microscopy (AFM). External vibrations, even at nanometer scales, can significantly distort measurement results and compromise the accuracy of the scanning process. Industry-standard isolation systems typically employ active and passive damping technologies to minimize mechanical interference from the surrounding environment.

Passive isolation systems utilize materials with high damping coefficients, such as rubber, elastomers, or pneumatic supports, to absorb vibrations before they reach the AFM scanner. These systems are particularly effective at attenuating high-frequency vibrations (>10 Hz). For more sophisticated applications, active vibration isolation systems that incorporate sensors and feedback mechanisms can detect and counteract vibrations in real-time, offering superior performance across a broader frequency spectrum.

Temperature stability represents another crucial environmental factor affecting AFM scanner alignment. Thermal drift can cause dimensional changes in scanner components, leading to positional errors during straight line scanning. Advanced AFM systems implement temperature-controlled enclosures that maintain stability within ±0.1°C, significantly reducing thermal drift effects. Some high-precision systems incorporate real-time thermal compensation algorithms that adjust scanner positioning based on temperature sensor data.

Acoustic isolation is equally important, as sound waves can induce mechanical vibrations in the AFM system. Acoustic enclosures constructed with sound-absorbing materials can reduce ambient noise by 20-30 dB, effectively minimizing this source of interference. In particularly sensitive applications, AFM systems may be installed in specially designed rooms with acoustic dampening wall treatments and controlled airflow systems.

Electromagnetic interference (EMI) can also affect scanner alignment by inducing currents in electronic components or creating forces on magnetic parts. Faraday cages and magnetic shielding are commonly employed to protect AFM systems from external electromagnetic fields. Additionally, proper grounding techniques and specialized power conditioning equipment help eliminate electrical noise that might otherwise affect scanner positioning accuracy.

Humidity control systems are increasingly incorporated into advanced AFM setups, as fluctuations in relative humidity can affect both sample properties and scanner performance. Maintaining relative humidity within ±2% helps ensure consistent scanning conditions, particularly for biological samples or hygroscopic materials where water absorption can alter mechanical properties.

Implementation of comprehensive environmental monitoring systems allows operators to correlate environmental changes with scanner performance, facilitating troubleshooting and system optimization. Modern AFM facilities often integrate multiple environmental control systems with centralized monitoring and data logging capabilities to maintain optimal scanning conditions continuously.

Passive isolation systems utilize materials with high damping coefficients, such as rubber, elastomers, or pneumatic supports, to absorb vibrations before they reach the AFM scanner. These systems are particularly effective at attenuating high-frequency vibrations (>10 Hz). For more sophisticated applications, active vibration isolation systems that incorporate sensors and feedback mechanisms can detect and counteract vibrations in real-time, offering superior performance across a broader frequency spectrum.

Temperature stability represents another crucial environmental factor affecting AFM scanner alignment. Thermal drift can cause dimensional changes in scanner components, leading to positional errors during straight line scanning. Advanced AFM systems implement temperature-controlled enclosures that maintain stability within ±0.1°C, significantly reducing thermal drift effects. Some high-precision systems incorporate real-time thermal compensation algorithms that adjust scanner positioning based on temperature sensor data.

Acoustic isolation is equally important, as sound waves can induce mechanical vibrations in the AFM system. Acoustic enclosures constructed with sound-absorbing materials can reduce ambient noise by 20-30 dB, effectively minimizing this source of interference. In particularly sensitive applications, AFM systems may be installed in specially designed rooms with acoustic dampening wall treatments and controlled airflow systems.

Electromagnetic interference (EMI) can also affect scanner alignment by inducing currents in electronic components or creating forces on magnetic parts. Faraday cages and magnetic shielding are commonly employed to protect AFM systems from external electromagnetic fields. Additionally, proper grounding techniques and specialized power conditioning equipment help eliminate electrical noise that might otherwise affect scanner positioning accuracy.

Humidity control systems are increasingly incorporated into advanced AFM setups, as fluctuations in relative humidity can affect both sample properties and scanner performance. Maintaining relative humidity within ±2% helps ensure consistent scanning conditions, particularly for biological samples or hygroscopic materials where water absorption can alter mechanical properties.

Implementation of comprehensive environmental monitoring systems allows operators to correlate environmental changes with scanner performance, facilitating troubleshooting and system optimization. Modern AFM facilities often integrate multiple environmental control systems with centralized monitoring and data logging capabilities to maintain optimal scanning conditions continuously.

Software Solutions for Automated Scanner Alignment

Automated scanner alignment software represents a significant advancement in atomic force microscopy (AFM) operations, addressing the critical challenge of maintaining straight line scanning paths. These sophisticated software solutions utilize real-time feedback mechanisms and algorithmic corrections to compensate for scanner nonlinearities and piezoelectric hysteresis effects that traditionally cause scanning distortions.

Modern AFM software packages now commonly incorporate closed-loop control systems that continuously monitor scanner position through sensor data. These systems compare actual scanner trajectories against intended paths, applying immediate corrections to maintain linear scanning. Leading commercial solutions include Bruker's NanoScope software with its PeakForce QNM technology and Asylum Research's MFP-3D software suite featuring their proprietary DirectDrive technology.

Machine learning algorithms have recently emerged as powerful tools for scanner alignment, learning from historical scanning data to predict and preemptively correct potential deviations. These adaptive systems progressively improve alignment accuracy through continuous operation, reducing the need for manual calibration procedures that traditionally consume valuable research time.

Cross-correlation analysis techniques implemented in software allow for post-acquisition correction of scanning artifacts. These methods compare forward and backward scans to identify and mathematically compensate for systematic distortions, producing more accurate topographical representations without requiring hardware modifications.

Open-source alternatives such as Gwyddion and OpenAFM have democratized access to advanced alignment capabilities. These platforms offer plugin architectures that allow researchers to implement custom alignment algorithms tailored to specific experimental requirements, fostering innovation in the AFM community.

Integration with digital signal processors (DSPs) has enabled real-time processing capabilities that were previously unattainable. Modern AFM systems utilize dedicated computational hardware to execute complex alignment calculations with microsecond response times, essential for high-speed scanning applications where alignment errors compound rapidly.

Cloud-based calibration databases represent the newest frontier in alignment technology, allowing instruments to access collective knowledge from similar systems worldwide. These databases store optimal alignment parameters for various sample types and environmental conditions, providing intelligent starting points that significantly reduce setup time for new experiments.

Modern AFM software packages now commonly incorporate closed-loop control systems that continuously monitor scanner position through sensor data. These systems compare actual scanner trajectories against intended paths, applying immediate corrections to maintain linear scanning. Leading commercial solutions include Bruker's NanoScope software with its PeakForce QNM technology and Asylum Research's MFP-3D software suite featuring their proprietary DirectDrive technology.

Machine learning algorithms have recently emerged as powerful tools for scanner alignment, learning from historical scanning data to predict and preemptively correct potential deviations. These adaptive systems progressively improve alignment accuracy through continuous operation, reducing the need for manual calibration procedures that traditionally consume valuable research time.

Cross-correlation analysis techniques implemented in software allow for post-acquisition correction of scanning artifacts. These methods compare forward and backward scans to identify and mathematically compensate for systematic distortions, producing more accurate topographical representations without requiring hardware modifications.

Open-source alternatives such as Gwyddion and OpenAFM have democratized access to advanced alignment capabilities. These platforms offer plugin architectures that allow researchers to implement custom alignment algorithms tailored to specific experimental requirements, fostering innovation in the AFM community.

Integration with digital signal processors (DSPs) has enabled real-time processing capabilities that were previously unattainable. Modern AFM systems utilize dedicated computational hardware to execute complex alignment calculations with microsecond response times, essential for high-speed scanning applications where alignment errors compound rapidly.

Cloud-based calibration databases represent the newest frontier in alignment technology, allowing instruments to access collective knowledge from similar systems worldwide. These databases store optimal alignment parameters for various sample types and environmental conditions, providing intelligent starting points that significantly reduce setup time for new experiments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!