Battery Pack Design for Electric Vehicle Range Optimization

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EV Battery Pack Evolution and Range Objectives

The evolution of battery pack design for electric vehicles has undergone significant transformation since the early 2000s. Initially, EV battery packs were rudimentary assemblies of consumer-grade cells with limited energy density, resulting in electric vehicles with ranges rarely exceeding 100 miles. The Tesla Roadster in 2008 marked a pivotal shift, utilizing thousands of cylindrical lithium-ion cells in a novel configuration that achieved over 200 miles of range, demonstrating the potential for high-performance electric vehicles.

The subsequent decade witnessed accelerated development in battery technology, with energy density improving at approximately 5-8% annually. By 2015, mainstream EVs like the Nissan Leaf and Tesla Model S had established range benchmarks of 80-265 miles, while contemporary models now routinely offer 250-400 miles on a single charge. This progression reflects both technological advancement and evolving consumer expectations regarding practical EV usability.

Battery pack design objectives have evolved beyond simply maximizing range to encompass a complex matrix of interdependent factors. Primary among these is energy density optimization—both volumetric (kWh/L) and gravimetric (kWh/kg)—which directly impacts vehicle range, weight distribution, and interior space utilization. Modern pack designs target energy densities exceeding 160 Wh/kg at the pack level, with industry leaders pushing toward 200 Wh/kg.

Thermal management has emerged as a critical design consideration, with sophisticated systems now employed to maintain optimal cell temperature ranges (typically 15-35°C) across varied operating conditions. This not only preserves battery longevity but also enables consistent performance and range predictability regardless of ambient conditions—addressing a significant consumer concern regarding EV practicality.

Safety engineering has become increasingly sophisticated, with pack designs incorporating multiple redundant protection mechanisms against thermal runaway, physical damage, and electrical faults. These systems must balance maximum protection with minimal weight penalties that would otherwise reduce vehicle range.

The industry has established ambitious technical targets for next-generation battery packs, including energy densities exceeding 300 Wh/kg, 80% capacity retention after 1,000+ cycles, and fast-charging capabilities supporting 10-80% charge in under 20 minutes. These objectives are driven by the goal of achieving cost parity with internal combustion vehicles while offering comparable or superior range and refueling convenience—widely considered the tipping point for mass EV adoption.

The subsequent decade witnessed accelerated development in battery technology, with energy density improving at approximately 5-8% annually. By 2015, mainstream EVs like the Nissan Leaf and Tesla Model S had established range benchmarks of 80-265 miles, while contemporary models now routinely offer 250-400 miles on a single charge. This progression reflects both technological advancement and evolving consumer expectations regarding practical EV usability.

Battery pack design objectives have evolved beyond simply maximizing range to encompass a complex matrix of interdependent factors. Primary among these is energy density optimization—both volumetric (kWh/L) and gravimetric (kWh/kg)—which directly impacts vehicle range, weight distribution, and interior space utilization. Modern pack designs target energy densities exceeding 160 Wh/kg at the pack level, with industry leaders pushing toward 200 Wh/kg.

Thermal management has emerged as a critical design consideration, with sophisticated systems now employed to maintain optimal cell temperature ranges (typically 15-35°C) across varied operating conditions. This not only preserves battery longevity but also enables consistent performance and range predictability regardless of ambient conditions—addressing a significant consumer concern regarding EV practicality.

Safety engineering has become increasingly sophisticated, with pack designs incorporating multiple redundant protection mechanisms against thermal runaway, physical damage, and electrical faults. These systems must balance maximum protection with minimal weight penalties that would otherwise reduce vehicle range.

The industry has established ambitious technical targets for next-generation battery packs, including energy densities exceeding 300 Wh/kg, 80% capacity retention after 1,000+ cycles, and fast-charging capabilities supporting 10-80% charge in under 20 minutes. These objectives are driven by the goal of achieving cost parity with internal combustion vehicles while offering comparable or superior range and refueling convenience—widely considered the tipping point for mass EV adoption.

Market Analysis for Extended-Range Electric Vehicles

The extended-range electric vehicle (EREV) market has witnessed significant growth over the past decade, driven by increasing environmental concerns, government regulations, and technological advancements in battery systems. As of 2023, the global EREV market is valued at approximately 45 billion USD, with projections indicating a compound annual growth rate of 24% through 2030, potentially reaching 205 billion USD by the end of the decade.

Consumer demand for extended-range vehicles has been primarily fueled by range anxiety concerns associated with traditional battery electric vehicles (BEVs). Market research indicates that 78% of potential electric vehicle buyers consider driving range as their top priority when making purchasing decisions. Extended-range vehicles, which typically offer 300-500 miles of total range compared to 200-300 miles for standard BEVs, address this critical consumer pain point.

Regional market analysis reveals varying adoption patterns. North America currently leads the EREV market with 38% market share, followed by Europe (32%) and Asia-Pacific (25%). China, specifically, has emerged as the fastest-growing market with government subsidies targeting extended-range technologies and infrastructure development. The European market is experiencing rapid growth due to stringent emission regulations and substantial investments in charging infrastructure.

Vehicle segments show distinct market dynamics. The mid-size sedan and SUV categories dominate the EREV market, collectively accounting for 65% of sales. However, the light commercial vehicle segment is experiencing the fastest growth at 32% annually, driven by fleet operators seeking to reduce operational costs while maintaining operational flexibility.

Consumer demographic analysis reveals that EREV buyers tend to be higher-income professionals (average household income exceeding 120,000 USD annually), aged 35-55, with daily commutes exceeding 30 miles. This demographic values the combination of electric driving for daily commutes with the security of extended range for occasional longer journeys.

Price sensitivity remains a significant market factor. The average price premium for extended-range capabilities (compared to standard BEVs) ranges from 8,000-15,000 USD. Market research indicates willingness to pay this premium decreases substantially beyond the 15,000 USD threshold, suggesting a critical price ceiling for manufacturers to consider in battery pack design and overall vehicle engineering.

Competition in this space is intensifying with traditional automakers and new entrants developing proprietary battery pack designs specifically optimized for range extension. Market concentration remains moderate with the top five manufacturers controlling 62% of global sales, though this concentration is expected to decrease as more competitors enter the space with innovative battery solutions.

Consumer demand for extended-range vehicles has been primarily fueled by range anxiety concerns associated with traditional battery electric vehicles (BEVs). Market research indicates that 78% of potential electric vehicle buyers consider driving range as their top priority when making purchasing decisions. Extended-range vehicles, which typically offer 300-500 miles of total range compared to 200-300 miles for standard BEVs, address this critical consumer pain point.

Regional market analysis reveals varying adoption patterns. North America currently leads the EREV market with 38% market share, followed by Europe (32%) and Asia-Pacific (25%). China, specifically, has emerged as the fastest-growing market with government subsidies targeting extended-range technologies and infrastructure development. The European market is experiencing rapid growth due to stringent emission regulations and substantial investments in charging infrastructure.

Vehicle segments show distinct market dynamics. The mid-size sedan and SUV categories dominate the EREV market, collectively accounting for 65% of sales. However, the light commercial vehicle segment is experiencing the fastest growth at 32% annually, driven by fleet operators seeking to reduce operational costs while maintaining operational flexibility.

Consumer demographic analysis reveals that EREV buyers tend to be higher-income professionals (average household income exceeding 120,000 USD annually), aged 35-55, with daily commutes exceeding 30 miles. This demographic values the combination of electric driving for daily commutes with the security of extended range for occasional longer journeys.

Price sensitivity remains a significant market factor. The average price premium for extended-range capabilities (compared to standard BEVs) ranges from 8,000-15,000 USD. Market research indicates willingness to pay this premium decreases substantially beyond the 15,000 USD threshold, suggesting a critical price ceiling for manufacturers to consider in battery pack design and overall vehicle engineering.

Competition in this space is intensifying with traditional automakers and new entrants developing proprietary battery pack designs specifically optimized for range extension. Market concentration remains moderate with the top five manufacturers controlling 62% of global sales, though this concentration is expected to decrease as more competitors enter the space with innovative battery solutions.

Current Battery Technologies and Range Limitations

The current landscape of electric vehicle (EV) battery technology is dominated by lithium-ion batteries, which have become the industry standard due to their relatively high energy density, acceptable charging rates, and improving cost structures. Despite significant advancements, these batteries still present limitations in energy density, typically ranging from 100-265 Wh/kg, which directly constrains vehicle range capabilities. Most commercial EVs today achieve ranges between 200-400 miles under optimal conditions, with premium models pushing toward the upper end of this spectrum.

Temperature sensitivity remains a critical challenge for existing battery technologies. Performance degradation is particularly pronounced in cold weather conditions, where range reductions of 20-40% are commonly observed. This limitation significantly impacts consumer confidence in regions with seasonal temperature variations and creates additional engineering challenges for thermal management systems.

Charging infrastructure limitations compound these range constraints. While DC fast charging networks continue to expand globally, the current battery technologies still require 20-40 minutes to achieve an 80% charge even under optimal conditions. This creates a fundamental difference in refueling experience compared to conventional vehicles, contributing to "range anxiety" among potential adopters.

Battery degradation presents another significant limitation to EV range optimization. Current lithium-ion technologies typically experience capacity loss of 2-3% annually under normal usage patterns, with accelerated degradation occurring with frequent fast charging or operation in extreme temperature conditions. This progressive reduction in available energy storage directly impacts vehicle range over the ownership lifecycle.

Weight efficiency remains suboptimal with current battery designs. Battery packs typically constitute 25-35% of total vehicle weight, creating a challenging engineering trade-off between range and overall vehicle performance. This weight penalty affects not only efficiency but also vehicle dynamics and structural design requirements.

Cost considerations continue to influence battery pack design decisions. Despite significant cost reductions over the past decade (from approximately $1,000/kWh to $130-150/kWh currently), battery packs remain the most expensive component in EVs. This economic reality often forces manufacturers to compromise between offering extended range and maintaining competitive price points.

Emerging technologies such as solid-state batteries, lithium-sulfur, and lithium-air systems promise theoretical energy densities 2-5 times greater than current lithium-ion solutions, potentially revolutionizing EV range capabilities. However, these technologies face significant challenges in stability, manufacturing scalability, and cycle life that have thus far prevented commercial deployment.

Temperature sensitivity remains a critical challenge for existing battery technologies. Performance degradation is particularly pronounced in cold weather conditions, where range reductions of 20-40% are commonly observed. This limitation significantly impacts consumer confidence in regions with seasonal temperature variations and creates additional engineering challenges for thermal management systems.

Charging infrastructure limitations compound these range constraints. While DC fast charging networks continue to expand globally, the current battery technologies still require 20-40 minutes to achieve an 80% charge even under optimal conditions. This creates a fundamental difference in refueling experience compared to conventional vehicles, contributing to "range anxiety" among potential adopters.

Battery degradation presents another significant limitation to EV range optimization. Current lithium-ion technologies typically experience capacity loss of 2-3% annually under normal usage patterns, with accelerated degradation occurring with frequent fast charging or operation in extreme temperature conditions. This progressive reduction in available energy storage directly impacts vehicle range over the ownership lifecycle.

Weight efficiency remains suboptimal with current battery designs. Battery packs typically constitute 25-35% of total vehicle weight, creating a challenging engineering trade-off between range and overall vehicle performance. This weight penalty affects not only efficiency but also vehicle dynamics and structural design requirements.

Cost considerations continue to influence battery pack design decisions. Despite significant cost reductions over the past decade (from approximately $1,000/kWh to $130-150/kWh currently), battery packs remain the most expensive component in EVs. This economic reality often forces manufacturers to compromise between offering extended range and maintaining competitive price points.

Emerging technologies such as solid-state batteries, lithium-sulfur, and lithium-air systems promise theoretical energy densities 2-5 times greater than current lithium-ion solutions, potentially revolutionizing EV range capabilities. However, these technologies face significant challenges in stability, manufacturing scalability, and cycle life that have thus far prevented commercial deployment.

Current Battery Pack Design Solutions

01 Battery management systems for extended range

Advanced battery management systems (BMS) are crucial for optimizing battery pack range in electric vehicles. These systems monitor and control various parameters such as cell voltage, temperature, and state of charge to maximize efficiency and prevent degradation. By implementing sophisticated algorithms for power distribution and thermal management, BMS technology can significantly extend the operational range of battery packs while ensuring safety and longevity.- Battery management systems for extended range: Advanced battery management systems (BMS) are crucial for optimizing battery pack range in electric vehicles. These systems monitor and control various parameters such as cell voltage, temperature, and state of charge to maximize efficiency and extend driving range. By implementing sophisticated algorithms for power distribution and consumption management, BMS can significantly improve the overall range performance of battery packs while ensuring safety and longevity.

- Battery cell configuration and arrangement: The physical configuration and arrangement of battery cells within a pack significantly impacts its range capabilities. Innovative cell arrangements that optimize space utilization, thermal management, and electrical connectivity can lead to higher energy density and extended range. These configurations may include series-parallel connections, modular designs, or specialized geometric arrangements that balance weight distribution while maximizing energy storage capacity.

- Thermal management solutions: Effective thermal management is essential for maintaining optimal battery pack range. Systems that regulate temperature across the battery pack prevent performance degradation in extreme conditions and extend the usable range. These solutions may include liquid cooling circuits, heat exchangers, insulation materials, or active temperature control mechanisms that ensure cells operate within their ideal temperature window, thereby maximizing energy output and range.

- Range extension through regenerative systems: Regenerative systems capture and convert kinetic energy back into electrical energy during deceleration or braking, effectively extending the range of battery packs. These systems can significantly improve overall efficiency by recovering energy that would otherwise be lost as heat. Advanced regenerative technologies may include variable recuperation levels, intelligent energy recovery algorithms, or integration with vehicle dynamics systems to maximize the amount of energy recaptured during operation.

- Battery chemistry and material innovations: Advancements in battery chemistry and materials directly impact the energy density and range capabilities of battery packs. Novel electrode materials, electrolyte formulations, and cell construction techniques can significantly increase the amount of energy stored per unit volume or weight. These innovations may include silicon-based anodes, solid-state electrolytes, lithium-sulfur chemistries, or other emerging technologies that push the boundaries of energy storage capacity and extend the practical range of battery-powered vehicles.

02 Battery cell configuration and arrangement

The physical configuration and arrangement of battery cells within a pack significantly impacts its range capabilities. Innovative cell designs, connection methods, and spatial arrangements can optimize energy density while minimizing weight and volume. Strategic cell grouping and interconnection patterns allow for more efficient power delivery and heat dissipation, resulting in extended range performance and improved overall battery pack efficiency.Expand Specific Solutions03 Thermal management solutions

Effective thermal management is essential for maximizing battery pack range. Advanced cooling and heating systems maintain optimal operating temperatures across all cells, preventing performance degradation in extreme conditions. These solutions include liquid cooling circuits, phase-change materials, and intelligent thermal control algorithms that balance temperature distribution throughout the pack, thereby extending range by ensuring cells operate within their ideal temperature window.Expand Specific Solutions04 Energy recovery and regenerative systems

Systems that capture and reuse energy during vehicle operation can significantly extend battery pack range. Regenerative braking technologies convert kinetic energy back into electrical energy during deceleration, while other recovery systems harvest energy from vehicle suspension movement or thermal gradients. These technologies reduce energy waste and continuously replenish the battery pack during operation, effectively increasing the overall driving range without requiring larger battery capacity.Expand Specific Solutions05 Battery chemistry and material innovations

Advancements in battery chemistry and materials are fundamental to increasing battery pack range. Novel electrode materials, electrolyte formulations, and separator designs improve energy density while maintaining or enhancing cycle life. Silicon-carbon composite anodes, high-nickel cathodes, and solid-state electrolytes represent cutting-edge developments that enable higher capacity, faster charging, and greater energy efficiency, all contributing to extended range capabilities.Expand Specific Solutions

Leading EV Battery Manufacturers and OEMs

The electric vehicle battery pack design market is currently in a growth phase, with increasing competition among established automotive manufacturers and specialized battery technology companies. The market size is expanding rapidly, driven by global EV adoption and range optimization demands. Technologically, the field shows varying maturity levels, with companies like BYD, CATL, and LG Energy Solution leading with advanced lithium-ion technologies and integrated battery management systems. Traditional automakers including Mercedes-Benz, Hyundai, and Ford are investing heavily in proprietary battery designs, while newer entrants like Rivian and Nikola are developing innovative approaches. The competitive landscape is characterized by strategic partnerships between vehicle manufacturers and battery specialists, with Asian companies currently dominating production capacity and technological implementation.

BYD Co., Ltd.

Technical Solution: BYD's Blade Battery technology represents a significant advancement in battery pack design for EV range optimization. The battery utilizes lithium iron phosphate (LFP) chemistry arranged in a unique cell-to-pack (CTP) architecture that eliminates the need for conventional module structures. This design increases energy density by 50% compared to traditional LFP packs, achieving up to 180 Wh/kg at the pack level. The blade-shaped cells are arranged in arrays and directly integrated into the battery pack, maximizing space utilization with a volume utilization rate exceeding 60%, significantly higher than conventional designs. BYD's thermal management system incorporates liquid cooling channels between cells, maintaining optimal operating temperatures across the entire pack even during fast charging or high-discharge scenarios. The company's battery management system (BMS) employs AI algorithms to predict and optimize energy consumption based on driving patterns, terrain, and environmental conditions, further extending effective range.

Strengths: Superior thermal stability and safety performance with virtually zero risk of thermal runaway; exceptional longevity with over 3,000 charge cycles; structural integration that contributes to vehicle chassis rigidity. Weaknesses: Lower energy density compared to NMC/NCA alternatives limiting absolute maximum range; heavier weight compared to some competing technologies; proprietary architecture limits compatibility with third-party systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's CTP (cell-to-pack) technology eliminates conventional module structures in battery pack design, achieving a volume utilization rate of 72%, approximately 15-20% higher than traditional designs. Their third-generation CTP technology, known as Qilin Battery, further advances this approach with an energy density of 255 Wh/kg, enabling driving ranges exceeding 1,000 km on a single charge. The design incorporates multi-dimensional liquid cooling systems with large cooling plates positioned between cells, achieving four times the heat transfer area of conventional designs. This allows for rapid charging capabilities (10-80% in 10 minutes) without compromising battery longevity. CATL's battery management system employs cloud-based analytics and machine learning algorithms to optimize charging and discharging patterns based on environmental conditions, driving habits, and route topography. Their integrated thermal expansion management system accommodates cell expansion during charging cycles while maintaining structural integrity, significantly reducing stress on individual cells and extending pack lifespan.

Strengths: Industry-leading energy density enabling exceptional range; superior thermal management allowing for ultra-fast charging capabilities; advanced BMS with predictive analytics for optimized performance across varying conditions. Weaknesses: Higher production costs compared to conventional designs; complex manufacturing processes requiring specialized equipment; potential challenges in serviceability due to the highly integrated design approach.

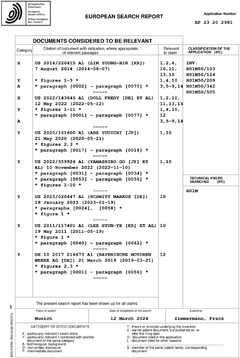

Key Patents in EV Battery Range Optimization

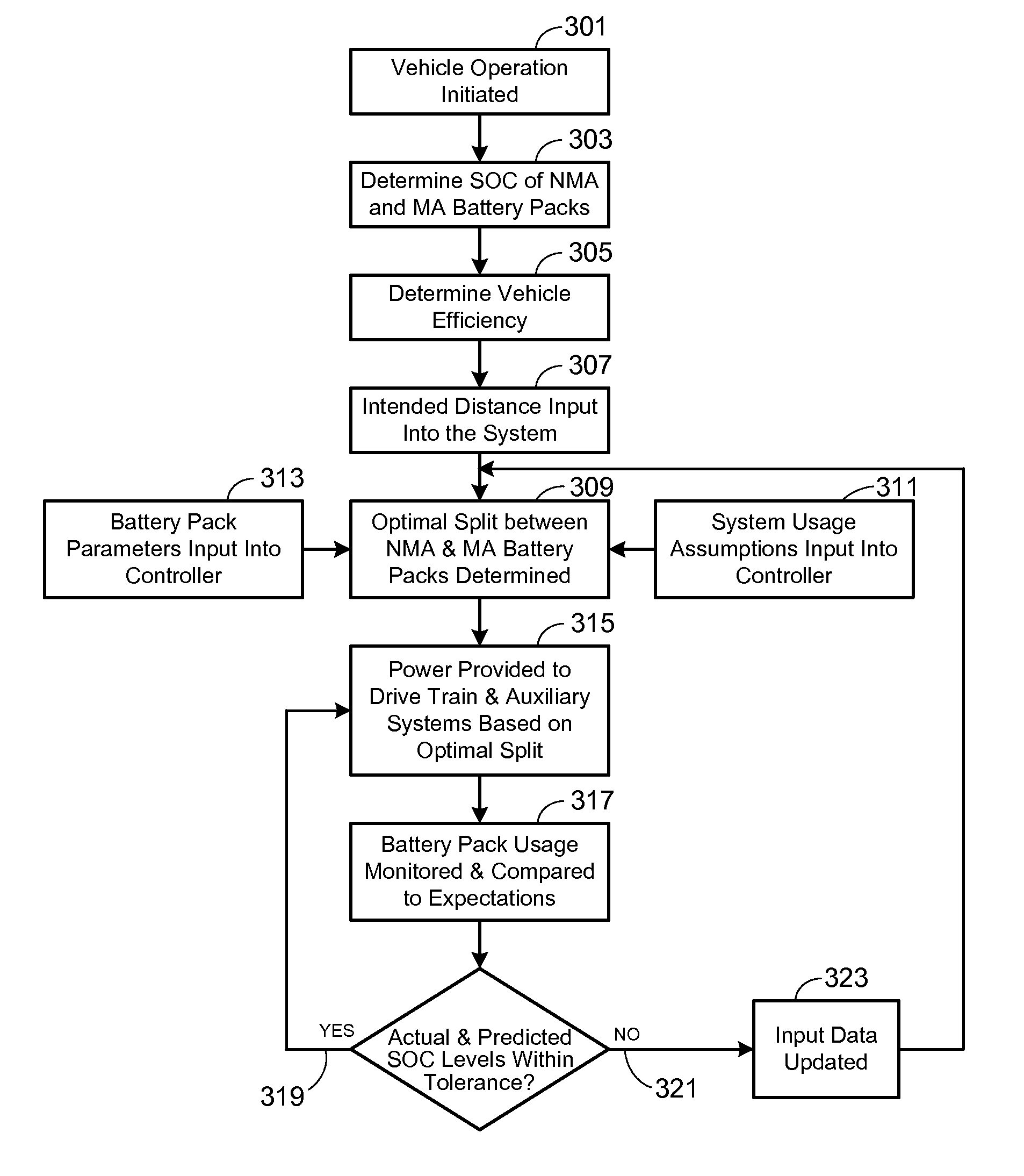

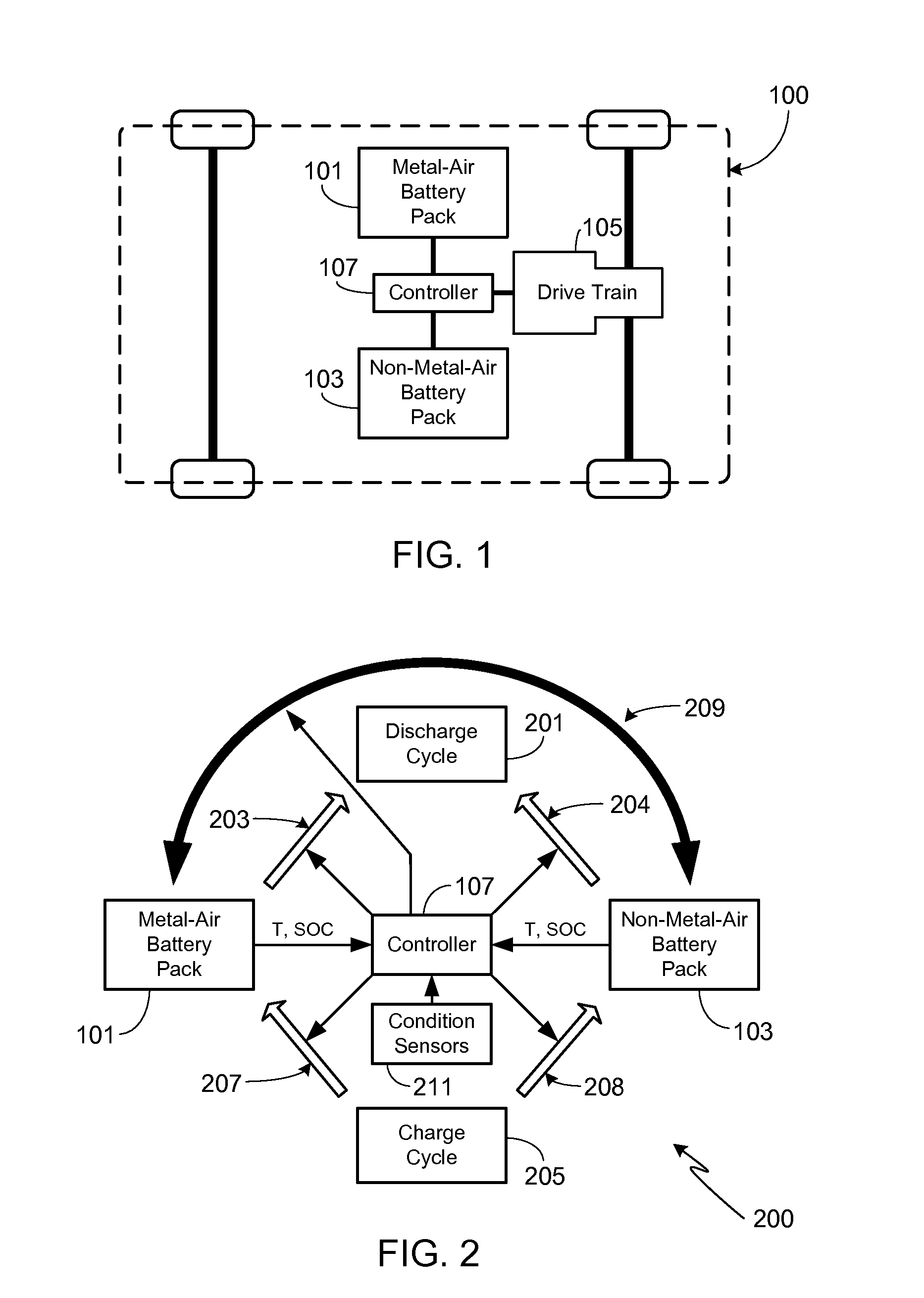

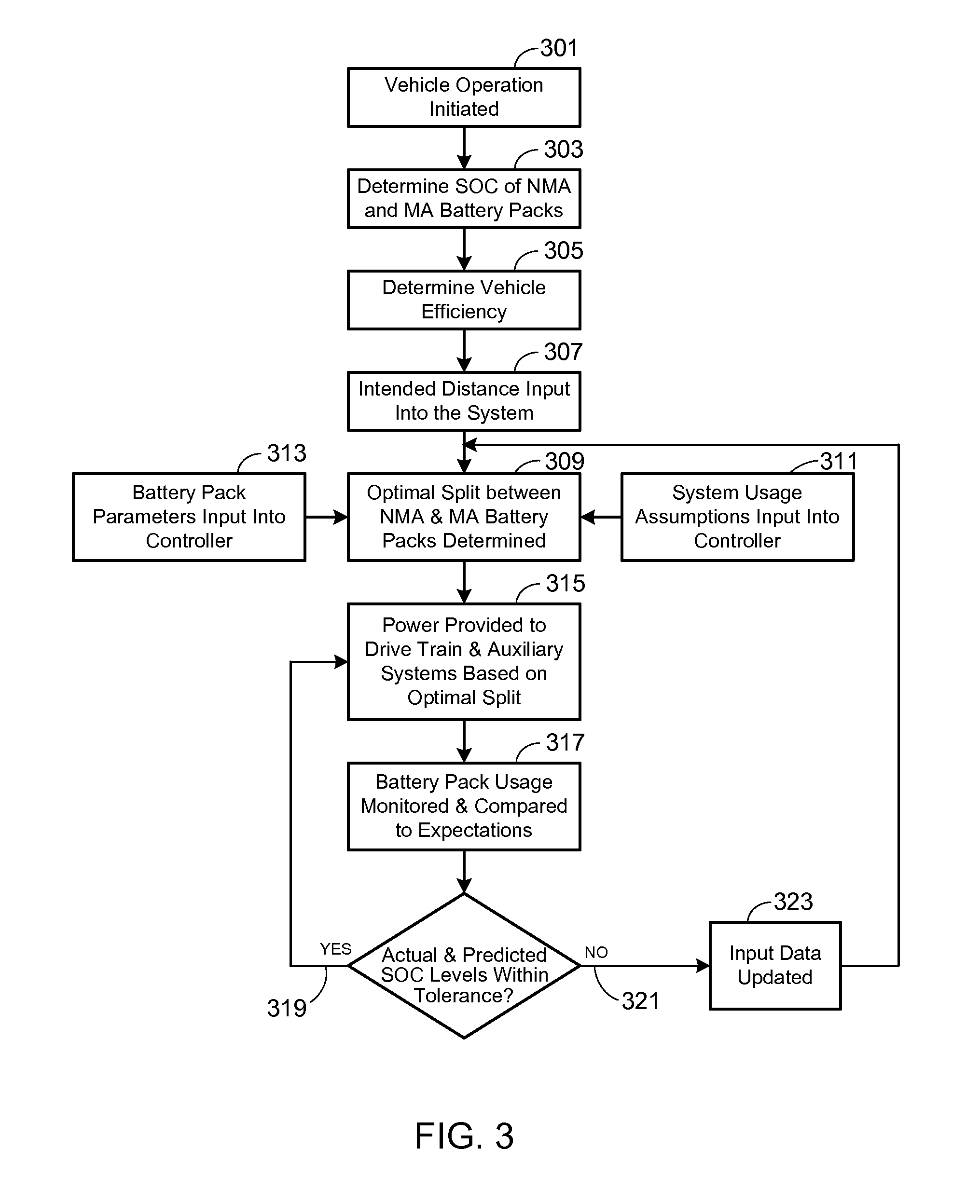

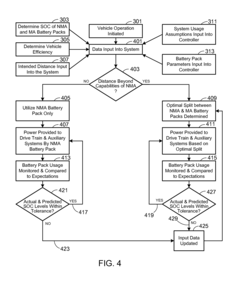

Efficient Dual Source Battery Pack System for an Electric Vehicle

PatentActiveUS20120041625A1

Innovation

- A dual battery system combining a metal-air battery pack with a conventional battery pack, where a controller optimizes power distribution by determining the state-of-charge and vehicle efficiency to minimize the use of the less efficient metal-air cells while ensuring sufficient power for the vehicle's travel distance, setting acceleration and speed limits based on battery conditions.

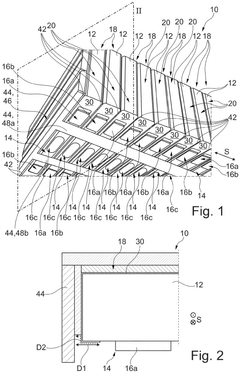

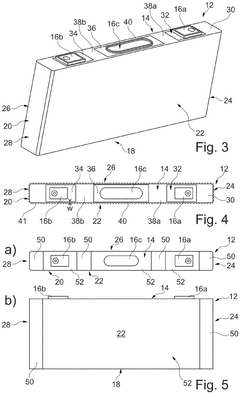

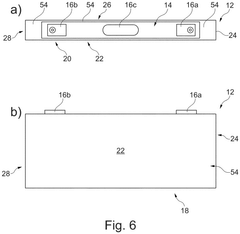

Battery pack for an electric vehicle, battery cell, and use of a battery pack

PatentPendingEP4539213A1

Innovation

- A battery pack design that incorporates prismatic battery cells with an electrically insulative coating, allowing for direct mechanical connection between cells and structural members using adhesive, while maintaining electrical isolation.

Thermal Management Systems Impact on Range

Thermal management systems play a critical role in optimizing the range of electric vehicles by maintaining battery packs within optimal operating temperature windows. Battery performance is highly temperature-dependent, with efficiency losses occurring at both low and high temperature extremes. At low temperatures, chemical reactions within cells slow down, increasing internal resistance and reducing available capacity. Conversely, high temperatures accelerate degradation mechanisms and pose safety risks through thermal runaway events.

Advanced thermal management solutions employ various approaches to address these challenges. Liquid cooling systems circulate coolant through channels integrated within battery modules, providing superior heat transfer capabilities compared to air-based systems. These systems enable more precise temperature control across the entire pack, minimizing cell-to-cell temperature variations that can lead to imbalanced aging and reduced overall pack capacity.

Active heating elements have emerged as essential components for cold-climate operation. By pre-conditioning battery packs before driving and maintaining temperatures during operation, these systems can recover up to 30% of range that would otherwise be lost in sub-zero conditions. The integration of heat pumps further improves efficiency by transferring heat from power electronics and motors to battery systems when needed.

Thermal insulation technologies represent another advancement in range optimization. Multi-layer insulation materials with low thermal conductivity help retain heat in cold environments and prevent rapid heating in hot conditions. This passive approach reduces the energy demands on active thermal management systems, directly translating to extended driving range.

Smart thermal management control algorithms continuously optimize system operation based on driving conditions, ambient temperature, and battery state. These algorithms predict heating and cooling needs, balancing thermal management energy consumption against battery performance benefits. Studies indicate that intelligent thermal management can improve range by 8-15% compared to conventional systems, particularly in extreme climate conditions.

The integration of phase change materials (PCMs) within battery packs represents an emerging approach to thermal management. These materials absorb excess heat during high-load operation and release it when temperatures drop, effectively serving as thermal buffers. This passive regulation reduces the power requirements of active cooling systems and helps maintain more consistent cell temperatures during rapid charging events.

As battery technology evolves toward higher energy densities and faster charging capabilities, thermal management systems must advance in parallel. Next-generation systems will likely incorporate direct immersion cooling, enhanced thermal interface materials, and AI-driven predictive controls to further optimize the delicate balance between battery performance, longevity, and available driving range.

Advanced thermal management solutions employ various approaches to address these challenges. Liquid cooling systems circulate coolant through channels integrated within battery modules, providing superior heat transfer capabilities compared to air-based systems. These systems enable more precise temperature control across the entire pack, minimizing cell-to-cell temperature variations that can lead to imbalanced aging and reduced overall pack capacity.

Active heating elements have emerged as essential components for cold-climate operation. By pre-conditioning battery packs before driving and maintaining temperatures during operation, these systems can recover up to 30% of range that would otherwise be lost in sub-zero conditions. The integration of heat pumps further improves efficiency by transferring heat from power electronics and motors to battery systems when needed.

Thermal insulation technologies represent another advancement in range optimization. Multi-layer insulation materials with low thermal conductivity help retain heat in cold environments and prevent rapid heating in hot conditions. This passive approach reduces the energy demands on active thermal management systems, directly translating to extended driving range.

Smart thermal management control algorithms continuously optimize system operation based on driving conditions, ambient temperature, and battery state. These algorithms predict heating and cooling needs, balancing thermal management energy consumption against battery performance benefits. Studies indicate that intelligent thermal management can improve range by 8-15% compared to conventional systems, particularly in extreme climate conditions.

The integration of phase change materials (PCMs) within battery packs represents an emerging approach to thermal management. These materials absorb excess heat during high-load operation and release it when temperatures drop, effectively serving as thermal buffers. This passive regulation reduces the power requirements of active cooling systems and helps maintain more consistent cell temperatures during rapid charging events.

As battery technology evolves toward higher energy densities and faster charging capabilities, thermal management systems must advance in parallel. Next-generation systems will likely incorporate direct immersion cooling, enhanced thermal interface materials, and AI-driven predictive controls to further optimize the delicate balance between battery performance, longevity, and available driving range.

Sustainability and Recycling Considerations

The sustainability of battery pack design for electric vehicles has become a critical consideration as the EV market expands globally. Current lithium-ion battery production involves significant environmental impacts, including resource extraction, energy-intensive manufacturing processes, and potential end-of-life waste challenges. A comprehensive life cycle assessment reveals that battery production can account for up to 40% of an electric vehicle's total carbon footprint, highlighting the importance of sustainable design approaches.

Battery pack designs that prioritize sustainability incorporate several key strategies. Material selection focuses on reducing dependence on rare earth elements and conflict minerals, with emerging alternatives including lithium iron phosphate (LFP) chemistries that eliminate cobalt usage. Structural efficiency in pack design minimizes overall material requirements while maintaining necessary thermal management and safety features. Additionally, designs that facilitate easy disassembly at end-of-life significantly enhance recycling potential.

The recyclability of battery components presents both challenges and opportunities. Current recycling processes recover approximately 50-70% of battery materials, with technological innovations pushing toward 90%+ recovery rates. Direct recycling methods that preserve cathode structures show particular promise for reducing energy requirements and maintaining material value. Battery pack designs that separate different material types and provide easy access to high-value components can dramatically improve recycling economics.

Second-life applications represent an important intermediate step between initial vehicle use and recycling. Battery packs that retain 70-80% of original capacity can serve effectively in stationary storage applications for 5-10 additional years. Modular designs that facilitate capacity testing and reconfiguration of individual modules support this transition, extending total battery lifecycle and improving sustainability metrics.

Regulatory frameworks increasingly influence battery pack design considerations. The European Union's proposed Battery Regulation mandates carbon footprint declarations, minimum recycled content requirements, and producer responsibility for end-of-life management. Similar regulations are emerging in North America and Asia, creating a global push toward standardized sustainability metrics and design practices that facilitate recycling.

Future battery pack designs will likely incorporate "design for disassembly" principles from inception, with standardized connection systems, material labeling, and structural elements that can be separated without specialized tools. Emerging technologies such as water-soluble binders and self-disassembling mechanisms activated at end-of-life show promise for revolutionizing recycling processes and dramatically improving material recovery rates.

Battery pack designs that prioritize sustainability incorporate several key strategies. Material selection focuses on reducing dependence on rare earth elements and conflict minerals, with emerging alternatives including lithium iron phosphate (LFP) chemistries that eliminate cobalt usage. Structural efficiency in pack design minimizes overall material requirements while maintaining necessary thermal management and safety features. Additionally, designs that facilitate easy disassembly at end-of-life significantly enhance recycling potential.

The recyclability of battery components presents both challenges and opportunities. Current recycling processes recover approximately 50-70% of battery materials, with technological innovations pushing toward 90%+ recovery rates. Direct recycling methods that preserve cathode structures show particular promise for reducing energy requirements and maintaining material value. Battery pack designs that separate different material types and provide easy access to high-value components can dramatically improve recycling economics.

Second-life applications represent an important intermediate step between initial vehicle use and recycling. Battery packs that retain 70-80% of original capacity can serve effectively in stationary storage applications for 5-10 additional years. Modular designs that facilitate capacity testing and reconfiguration of individual modules support this transition, extending total battery lifecycle and improving sustainability metrics.

Regulatory frameworks increasingly influence battery pack design considerations. The European Union's proposed Battery Regulation mandates carbon footprint declarations, minimum recycled content requirements, and producer responsibility for end-of-life management. Similar regulations are emerging in North America and Asia, creating a global push toward standardized sustainability metrics and design practices that facilitate recycling.

Future battery pack designs will likely incorporate "design for disassembly" principles from inception, with standardized connection systems, material labeling, and structural elements that can be separated without specialized tools. Emerging technologies such as water-soluble binders and self-disassembling mechanisms activated at end-of-life show promise for revolutionizing recycling processes and dramatically improving material recovery rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!