Research on the Impact of Battery Pack Design on Urban Sustainability

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Pack Design Evolution and Objectives

Battery pack design has undergone significant evolution since the early development of electric vehicles (EVs) in the late 20th century. Initially, battery packs were rudimentary assemblies of lead-acid cells with limited energy density, resulting in EVs with restricted range and performance. The transition to nickel-metal hydride (NiMH) batteries in the early 2000s marked the first major advancement, offering improved energy density and reliability, though still falling short of requirements for mainstream adoption.

The paradigm shift occurred with the commercialization of lithium-ion technology around 2008-2010, enabling the development of battery packs with substantially higher energy density, longer cycle life, and improved thermal characteristics. This technological leap catalyzed the modern EV revolution, with companies like Tesla pioneering innovative approaches to battery pack architecture, including the groundbreaking "skateboard" design that integrated the battery pack into the vehicle's structural platform.

Current battery pack design has evolved to address multiple objectives simultaneously: maximizing energy density, ensuring thermal stability, extending operational lifespan, enhancing safety protocols, and improving sustainability metrics. The integration of sophisticated battery management systems (BMS) has become standard practice, enabling real-time monitoring and optimization of cell performance, which directly impacts urban sustainability through improved efficiency and reduced waste.

In the urban context, battery pack design objectives have expanded beyond vehicle performance to encompass broader sustainability goals. Modern designs increasingly prioritize recyclability and second-life applications, recognizing that urban sustainability requires circular economy approaches to battery lifecycle management. Designs now incorporate considerations for ease of disassembly, material recovery, and repurposing of components after their primary automotive use, such as in stationary energy storage systems supporting urban grid stability.

The trajectory of battery pack evolution points toward several key objectives for future development. These include achieving energy densities exceeding 400 Wh/kg at the pack level (compared to current averages of 150-200 Wh/kg), reducing reliance on critical raw materials like cobalt and nickel, implementing design-for-recycling principles from conception, and developing modular architectures that facilitate maintenance and component replacement rather than wholesale pack disposal.

Ultimately, the evolution of battery pack design reflects a growing recognition that urban sustainability depends not only on vehicle electrification itself but on how battery systems are designed, manufactured, utilized, and eventually recycled or repurposed. The technical objectives now extend beyond performance metrics to encompass the entire lifecycle environmental impact, with particular emphasis on urban air quality, resource conservation, and circular material flows within metropolitan ecosystems.

The paradigm shift occurred with the commercialization of lithium-ion technology around 2008-2010, enabling the development of battery packs with substantially higher energy density, longer cycle life, and improved thermal characteristics. This technological leap catalyzed the modern EV revolution, with companies like Tesla pioneering innovative approaches to battery pack architecture, including the groundbreaking "skateboard" design that integrated the battery pack into the vehicle's structural platform.

Current battery pack design has evolved to address multiple objectives simultaneously: maximizing energy density, ensuring thermal stability, extending operational lifespan, enhancing safety protocols, and improving sustainability metrics. The integration of sophisticated battery management systems (BMS) has become standard practice, enabling real-time monitoring and optimization of cell performance, which directly impacts urban sustainability through improved efficiency and reduced waste.

In the urban context, battery pack design objectives have expanded beyond vehicle performance to encompass broader sustainability goals. Modern designs increasingly prioritize recyclability and second-life applications, recognizing that urban sustainability requires circular economy approaches to battery lifecycle management. Designs now incorporate considerations for ease of disassembly, material recovery, and repurposing of components after their primary automotive use, such as in stationary energy storage systems supporting urban grid stability.

The trajectory of battery pack evolution points toward several key objectives for future development. These include achieving energy densities exceeding 400 Wh/kg at the pack level (compared to current averages of 150-200 Wh/kg), reducing reliance on critical raw materials like cobalt and nickel, implementing design-for-recycling principles from conception, and developing modular architectures that facilitate maintenance and component replacement rather than wholesale pack disposal.

Ultimately, the evolution of battery pack design reflects a growing recognition that urban sustainability depends not only on vehicle electrification itself but on how battery systems are designed, manufactured, utilized, and eventually recycled or repurposed. The technical objectives now extend beyond performance metrics to encompass the entire lifecycle environmental impact, with particular emphasis on urban air quality, resource conservation, and circular material flows within metropolitan ecosystems.

Urban Market Demand for Sustainable Energy Storage

The urban energy storage market is experiencing unprecedented growth driven by the convergence of electrification trends, renewable energy integration, and sustainability initiatives in metropolitan areas. Current market analysis indicates that global urban energy storage demand is projected to reach 300 GWh by 2030, with a compound annual growth rate exceeding 25% over the next decade. This acceleration is particularly evident in densely populated urban centers where grid constraints and peak demand challenges necessitate distributed storage solutions.

Battery energy storage systems (BESS) have emerged as the dominant technology addressing this demand, with lithium-ion configurations capturing approximately 85% of new urban installations. The market is increasingly segmented between utility-scale applications for grid stabilization and smaller distributed systems for commercial buildings, residential complexes, and community microgrids. This diversification reflects the evolving needs of urban energy ecosystems seeking resilience against climate-related disruptions.

Consumer behavior studies reveal growing willingness among urban residents to invest in sustainable energy solutions, with 67% of surveyed metropolitan households expressing interest in home energy storage systems when coupled with renewable generation. This consumer sentiment is reinforced by municipal policies in major global cities that increasingly mandate or incentivize energy storage deployment in new construction projects and retrofits.

Commercial real estate developers represent another significant market driver, with 78% of new urban commercial developments incorporating some form of energy storage to achieve sustainability certifications, reduce operational costs, and enhance property values. The ability to participate in demand response programs and energy arbitrage opportunities provides additional revenue streams that improve return on investment calculations.

Transportation electrification is creating substantial derivative demand for urban energy storage. The proliferation of electric vehicle charging infrastructure requires complementary storage systems to mitigate grid impacts and optimize charging economics. Public charging hubs in urban environments are increasingly designed with integrated battery systems sized at 250-500 kWh to balance grid loads and enhance charging speeds without requiring costly distribution upgrades.

Market research indicates that urban consumers and businesses prioritize specific attributes in energy storage solutions: space efficiency ranks highest in dense urban environments, followed by safety considerations, aesthetic integration with urban architecture, and operational noise levels. These preferences are directly influencing battery pack design parameters, with premium valuations assigned to solutions that effectively address urban-specific constraints.

The market is further characterized by strong regional variations, with Asian megacities leading in deployment volume, European urban centers emphasizing integration with existing infrastructure, and North American cities focusing on resilience applications. This regional diversification necessitates customized battery pack designs that accommodate local regulatory frameworks, available space constraints, and specific urban sustainability objectives.

Battery energy storage systems (BESS) have emerged as the dominant technology addressing this demand, with lithium-ion configurations capturing approximately 85% of new urban installations. The market is increasingly segmented between utility-scale applications for grid stabilization and smaller distributed systems for commercial buildings, residential complexes, and community microgrids. This diversification reflects the evolving needs of urban energy ecosystems seeking resilience against climate-related disruptions.

Consumer behavior studies reveal growing willingness among urban residents to invest in sustainable energy solutions, with 67% of surveyed metropolitan households expressing interest in home energy storage systems when coupled with renewable generation. This consumer sentiment is reinforced by municipal policies in major global cities that increasingly mandate or incentivize energy storage deployment in new construction projects and retrofits.

Commercial real estate developers represent another significant market driver, with 78% of new urban commercial developments incorporating some form of energy storage to achieve sustainability certifications, reduce operational costs, and enhance property values. The ability to participate in demand response programs and energy arbitrage opportunities provides additional revenue streams that improve return on investment calculations.

Transportation electrification is creating substantial derivative demand for urban energy storage. The proliferation of electric vehicle charging infrastructure requires complementary storage systems to mitigate grid impacts and optimize charging economics. Public charging hubs in urban environments are increasingly designed with integrated battery systems sized at 250-500 kWh to balance grid loads and enhance charging speeds without requiring costly distribution upgrades.

Market research indicates that urban consumers and businesses prioritize specific attributes in energy storage solutions: space efficiency ranks highest in dense urban environments, followed by safety considerations, aesthetic integration with urban architecture, and operational noise levels. These preferences are directly influencing battery pack design parameters, with premium valuations assigned to solutions that effectively address urban-specific constraints.

The market is further characterized by strong regional variations, with Asian megacities leading in deployment volume, European urban centers emphasizing integration with existing infrastructure, and North American cities focusing on resilience applications. This regional diversification necessitates customized battery pack designs that accommodate local regulatory frameworks, available space constraints, and specific urban sustainability objectives.

Current Battery Pack Technologies and Challenges

Battery pack technology has evolved significantly over the past decade, with lithium-ion batteries dominating the market due to their high energy density, relatively long cycle life, and decreasing costs. However, current battery pack designs face several critical challenges that impact urban sustainability. The energy density of commercial lithium-ion cells typically ranges from 250-300 Wh/kg, which remains insufficient for many urban applications requiring longer ranges or higher power outputs without significant weight penalties.

Thermal management represents one of the most pressing challenges in battery pack design. Urban environments, characterized by high ambient temperatures and stop-start traffic patterns, create thermal stress that accelerates battery degradation. Current cooling systems, whether air, liquid, or phase-change material based, often add significant weight and complexity to battery packs, reducing overall energy efficiency and increasing manufacturing costs by approximately 10-15%.

Safety concerns continue to plague battery pack implementation in urban settings. Thermal runaway events, though rare (occurring in approximately 1 in 10 million cells), can have catastrophic consequences in densely populated areas. Current battery management systems (BMS) employ sophisticated algorithms to monitor cell voltages, temperatures, and state of charge, but still struggle with accurate prediction of failure modes under extreme urban operating conditions.

Resource constraints present another significant challenge. Contemporary battery packs rely heavily on critical materials including lithium, cobalt, nickel, and graphite. The geopolitical concentration of these resources—with over 60% of cobalt sourced from the Democratic Republic of Congo and more than 50% of lithium reserves located in the "Lithium Triangle" of South America—creates supply vulnerabilities that threaten sustainable urban implementation.

Recycling infrastructure remains woefully inadequate for the projected volume of end-of-life battery packs. Current recycling processes recover only 50-60% of valuable materials, with significant energy expenditure and environmental impact. Urban deployment of battery technologies requires closed-loop systems that have yet to be fully developed at commercial scale.

The form factor limitations of current battery pack designs also constrain urban applications. Rigid, rectangular modules limit integration possibilities in space-constrained urban vehicles and infrastructure. Emerging technologies like structural batteries and flexible form factors remain in early development stages, with energy densities typically 40-50% lower than conventional designs.

Manufacturing scalability presents additional challenges, with current production methods requiring significant energy inputs and generating substantial carbon emissions—approximately 75-80 kg CO2e per kWh of battery capacity produced. This carbon debt must be overcome through operational efficiency to achieve net sustainability benefits in urban environments.

Thermal management represents one of the most pressing challenges in battery pack design. Urban environments, characterized by high ambient temperatures and stop-start traffic patterns, create thermal stress that accelerates battery degradation. Current cooling systems, whether air, liquid, or phase-change material based, often add significant weight and complexity to battery packs, reducing overall energy efficiency and increasing manufacturing costs by approximately 10-15%.

Safety concerns continue to plague battery pack implementation in urban settings. Thermal runaway events, though rare (occurring in approximately 1 in 10 million cells), can have catastrophic consequences in densely populated areas. Current battery management systems (BMS) employ sophisticated algorithms to monitor cell voltages, temperatures, and state of charge, but still struggle with accurate prediction of failure modes under extreme urban operating conditions.

Resource constraints present another significant challenge. Contemporary battery packs rely heavily on critical materials including lithium, cobalt, nickel, and graphite. The geopolitical concentration of these resources—with over 60% of cobalt sourced from the Democratic Republic of Congo and more than 50% of lithium reserves located in the "Lithium Triangle" of South America—creates supply vulnerabilities that threaten sustainable urban implementation.

Recycling infrastructure remains woefully inadequate for the projected volume of end-of-life battery packs. Current recycling processes recover only 50-60% of valuable materials, with significant energy expenditure and environmental impact. Urban deployment of battery technologies requires closed-loop systems that have yet to be fully developed at commercial scale.

The form factor limitations of current battery pack designs also constrain urban applications. Rigid, rectangular modules limit integration possibilities in space-constrained urban vehicles and infrastructure. Emerging technologies like structural batteries and flexible form factors remain in early development stages, with energy densities typically 40-50% lower than conventional designs.

Manufacturing scalability presents additional challenges, with current production methods requiring significant energy inputs and generating substantial carbon emissions—approximately 75-80 kg CO2e per kWh of battery capacity produced. This carbon debt must be overcome through operational efficiency to achieve net sustainability benefits in urban environments.

Contemporary Battery Pack Design Solutions

01 Energy storage systems for urban infrastructure

Battery pack designs that integrate with urban infrastructure to enhance sustainability. These systems are designed to store energy from renewable sources and provide power during peak demand periods, reducing strain on urban power grids. The designs incorporate features for efficient energy management, grid stabilization, and support for smart city applications, contributing to more sustainable urban environments.- Energy Storage Solutions for Urban Infrastructure: Battery pack designs optimized for urban infrastructure applications, focusing on energy storage systems that support sustainable city development. These designs integrate with urban power grids to provide backup power, peak shaving capabilities, and support for renewable energy integration in urban environments. The systems are engineered to maximize energy density while minimizing spatial footprint, making them suitable for deployment in space-constrained urban settings.

- Modular Battery Systems for Urban Mobility: Modular battery pack designs specifically engineered for urban transportation solutions, including electric vehicles, public transit systems, and micro-mobility options. These battery systems feature interchangeable components that facilitate easy maintenance, replacement, and scalability. The modular approach enhances sustainability by extending battery life cycles, enabling component-level repairs, and supporting battery second-life applications in urban settings.

- Thermal Management for Urban Battery Applications: Advanced thermal management systems for battery packs deployed in urban environments, addressing the unique challenges of heat dissipation in densely populated areas. These designs incorporate innovative cooling technologies, temperature regulation mechanisms, and thermal isolation strategies to optimize battery performance and longevity while ensuring safety in urban settings. The systems are engineered to operate efficiently across varying urban climate conditions and usage patterns.

- Smart Battery Management Systems for Urban Sustainability: Intelligent battery management systems that enhance urban sustainability through advanced monitoring, predictive maintenance, and grid integration capabilities. These systems utilize sensors, data analytics, and connectivity features to optimize battery performance, extend operational lifespans, and enable participation in smart city initiatives. The management systems support demand response programs, virtual power plant functionality, and integration with urban renewable energy sources.

- Sustainable Materials and Manufacturing for Urban Battery Packs: Environmentally conscious approaches to battery pack design focusing on sustainable materials, manufacturing processes, and end-of-life considerations for urban applications. These designs incorporate recycled or renewable materials, reduce toxic components, and facilitate disassembly for recycling. The manufacturing processes are optimized to minimize carbon footprint, water usage, and waste generation, aligning with circular economy principles and urban sustainability goals.

02 Modular battery systems for urban mobility

Modular battery pack designs specifically tailored for urban transportation solutions. These systems feature interchangeable components that can be easily swapped, repaired, or upgraded, extending the lifecycle of urban mobility solutions. The modular approach allows for flexible deployment across various urban transportation modes, including electric vehicles, e-bikes, and public transit systems, promoting sustainable urban mobility.Expand Specific Solutions03 Thermal management for urban battery installations

Advanced thermal management solutions for battery packs deployed in urban environments. These designs address the challenges of heat dissipation in densely populated areas where space is limited and ambient temperatures can fluctuate widely. The systems incorporate innovative cooling mechanisms, temperature monitoring, and safety features to ensure optimal battery performance and longevity while minimizing environmental impact in urban settings.Expand Specific Solutions04 Sustainable materials and manufacturing for urban battery packs

Battery pack designs that emphasize sustainable materials and manufacturing processes suitable for urban applications. These approaches focus on reducing environmental footprint through the use of recyclable materials, eco-friendly production methods, and designs that facilitate end-of-life recycling. The innovations address the full lifecycle of battery systems, from raw material sourcing to disposal, supporting circular economy principles in urban environments.Expand Specific Solutions05 Smart battery management systems for urban applications

Intelligent battery management systems designed specifically for urban sustainability challenges. These systems incorporate advanced monitoring, predictive analytics, and adaptive control algorithms to optimize battery performance in urban settings. The technologies enable integration with smart city infrastructure, demand response capabilities, and grid services, enhancing the resilience and sustainability of urban energy systems while extending battery life and improving safety.Expand Specific Solutions

Leading Battery Pack Manufacturers and Innovators

The battery pack design market for urban sustainability is in a growth phase, with increasing demand driven by electric vehicle adoption and renewable energy integration. The market size is expanding rapidly, projected to reach significant scale by 2030. Technologically, companies are at varying maturity levels: established leaders like CATL, BYD, LG Energy Solution, and Samsung SDI possess advanced lithium-ion technology and large-scale production capabilities, while newer entrants like Farasis Energy and EVE Energy are rapidly innovating. Traditional automakers (Nissan) and tech companies (Apple) are also investing heavily in proprietary battery designs, focusing on energy density, thermal management, and sustainability to address urban environmental challenges.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed specialized battery pack designs for urban sustainability applications, focusing on their "Green Battery" initiative that reduces carbon emissions throughout the battery lifecycle. Their battery packs utilize a pouch cell design with integrated cooling channels that provides 40% better thermal efficiency in dense urban environments where heat dissipation is challenging. For urban applications requiring longevity, LG Energy Solution has pioneered silicon-carbon composite anodes that deliver up to 30% higher energy density while maintaining cycle life suitable for urban vehicle lifespans of 8-10 years. Their battery packs incorporate smart cell balancing technology that continuously monitors and adjusts individual cell performance, extending overall pack life by an estimated 20% in variable urban driving conditions. LG Energy Solution has also developed urban-specific battery management algorithms that adapt to traffic patterns and environmental conditions, optimizing energy usage based on machine learning models trained on city driving data. Additionally, their battery packs feature a modular design allowing for selective replacement of degraded components, reducing waste and extending useful life in urban fleet applications.

Strengths: Advanced thermal management specifically designed for urban heat island effects; sophisticated cell balancing technology; proven long-term reliability in commercial applications; established partnerships with major urban mobility providers. Weaknesses: Premium pricing affecting accessibility for some urban markets; complex manufacturing processes with higher environmental footprint; challenges in recycling some proprietary components.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has focused its urban sustainability efforts on developing "PRiMX" battery technology that specifically addresses the challenges of dense urban environments. Their battery packs feature a stacked prismatic cell design that optimizes space utilization in compact urban vehicles, achieving approximately 25% higher volumetric energy density than conventional designs. Samsung's urban battery solutions incorporate their Gen5 cathode technology with over 88% nickel content, reducing cobalt usage while maintaining stability through proprietary dopants and coatings. For urban thermal management, Samsung SDI has developed a dual-phase cooling system that combines direct liquid cooling for high-demand scenarios with passive cooling for standard operation, reducing energy consumption by an estimated 30% compared to traditional cooling systems. Their battery packs include advanced diagnostics that can predict potential failures 72-96 hours before occurrence based on electrochemical impedance spectroscopy, crucial for preventing disruptions in urban transportation networks. Samsung SDI has also pioneered urban-specific fast charging protocols that limit degradation during the rapid charging cycles typical in city environments, maintaining 80% capacity after 1,000 cycles at 4C charging rates.

Strengths: Excellent volumetric energy density for space-constrained urban applications; advanced predictive diagnostics; superior fast-charging capabilities; established global manufacturing footprint. Weaknesses: Higher cost structure affecting mass urban adoption; complex thermal management systems requiring specialized maintenance; less focus on LFP chemistry which offers cost advantages in some urban applications.

Key Patents and Innovations in Battery Pack Architecture

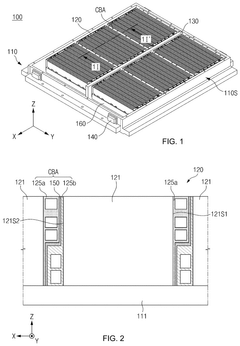

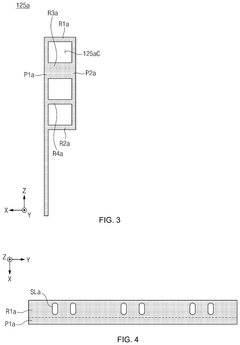

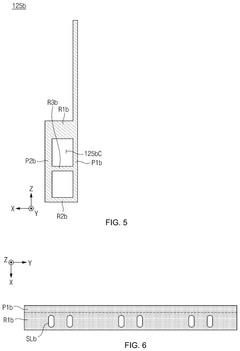

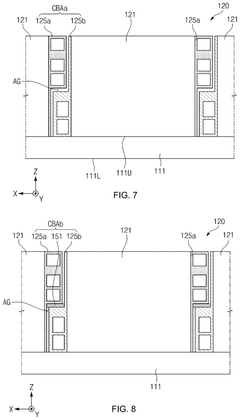

Battery Pack

PatentPendingUS20250233257A1

Innovation

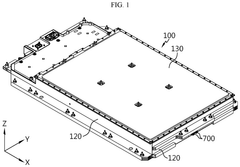

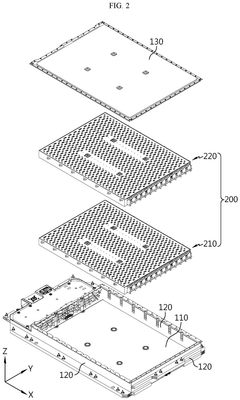

- A battery pack design featuring a housing with first and second battery assemblies, each comprising a cell stack and cross-beams with complementary shapes and thin plates and ribs, along with a heat insulator and air gaps to enhance energy density and thermal insulation.

Battery pack

PatentPendingEP4618252A1

Innovation

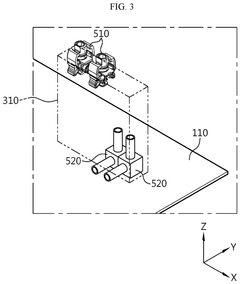

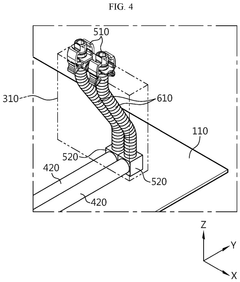

- A battery pack design featuring a case with a base plate, cell array structures, cooling tubes, and connectors that facilitate efficient assembly and cooling, including flexible cooling tubes to enhance space utilization and communication between components.

Environmental Impact Assessment of Battery Pack Lifecycles

Battery pack lifecycle assessment reveals significant environmental implications across production, use, and disposal phases. Raw material extraction for lithium-ion batteries involves mining operations that generate substantial carbon emissions, water pollution, and habitat disruption. Lithium extraction alone requires approximately 500,000 gallons of water per ton of lithium, predominantly affecting water-scarce regions in South America's "Lithium Triangle."

Manufacturing processes contribute heavily to the environmental footprint, with battery production generating 150-200 kg CO2-equivalent per kWh of battery capacity. Energy-intensive electrode production and cell assembly account for approximately 70% of manufacturing emissions. These impacts vary significantly based on the energy mix used in production facilities, with renewable energy integration potentially reducing manufacturing emissions by up to 50%.

During the operational phase, battery packs demonstrate environmental advantages through zero direct emissions when powering electric vehicles or storing renewable energy. However, the source of electricity for charging remains critical—coal-powered charging can offset up to 75% of potential environmental benefits compared to renewable energy sources.

End-of-life management presents both challenges and opportunities. Current recycling rates for lithium-ion batteries remain below 5% globally, with significant regional variations. Advanced hydrometallurgical recycling processes can recover up to 95% of critical materials like cobalt and nickel, but lithium recovery efficiency typically remains below 50%. Direct reuse applications for second-life batteries in stationary storage systems can extend useful life by 7-10 years, reducing overall lifecycle impacts by up to 40%.

Geographical factors significantly influence environmental impacts. Battery production concentrated in regions with coal-dependent electricity (particularly parts of Asia) generates approximately twice the emissions compared to production using predominantly renewable energy sources. Urban deployment contexts also affect lifecycle performance, with temperature extremes in certain urban environments reducing battery lifespan by up to 20%.

Recent lifecycle assessments indicate that next-generation battery designs incorporating silicon anodes and solid-state electrolytes could reduce production-phase environmental impacts by 30-40% while extending operational lifespans. These improvements, coupled with circular economy approaches to battery management, represent critical pathways toward enhancing the sustainability profile of battery systems in urban environments.

Manufacturing processes contribute heavily to the environmental footprint, with battery production generating 150-200 kg CO2-equivalent per kWh of battery capacity. Energy-intensive electrode production and cell assembly account for approximately 70% of manufacturing emissions. These impacts vary significantly based on the energy mix used in production facilities, with renewable energy integration potentially reducing manufacturing emissions by up to 50%.

During the operational phase, battery packs demonstrate environmental advantages through zero direct emissions when powering electric vehicles or storing renewable energy. However, the source of electricity for charging remains critical—coal-powered charging can offset up to 75% of potential environmental benefits compared to renewable energy sources.

End-of-life management presents both challenges and opportunities. Current recycling rates for lithium-ion batteries remain below 5% globally, with significant regional variations. Advanced hydrometallurgical recycling processes can recover up to 95% of critical materials like cobalt and nickel, but lithium recovery efficiency typically remains below 50%. Direct reuse applications for second-life batteries in stationary storage systems can extend useful life by 7-10 years, reducing overall lifecycle impacts by up to 40%.

Geographical factors significantly influence environmental impacts. Battery production concentrated in regions with coal-dependent electricity (particularly parts of Asia) generates approximately twice the emissions compared to production using predominantly renewable energy sources. Urban deployment contexts also affect lifecycle performance, with temperature extremes in certain urban environments reducing battery lifespan by up to 20%.

Recent lifecycle assessments indicate that next-generation battery designs incorporating silicon anodes and solid-state electrolytes could reduce production-phase environmental impacts by 30-40% while extending operational lifespans. These improvements, coupled with circular economy approaches to battery management, represent critical pathways toward enhancing the sustainability profile of battery systems in urban environments.

Urban Infrastructure Integration Strategies

The integration of battery pack systems into urban infrastructure represents a critical frontier in sustainable city development. Cities worldwide are exploring how battery technologies can be embedded within existing and new infrastructure to enhance energy efficiency, resilience, and environmental performance. Strategic placement of battery storage systems at key nodes within urban power grids enables load balancing during peak demand periods, reducing strain on conventional power generation facilities and minimizing the need for costly grid expansions.

Urban planners are increasingly adopting distributed energy storage approaches, incorporating battery packs into multiple infrastructure elements such as public buildings, transportation hubs, and community centers. This distribution creates a network of energy reservoirs that can be tapped during outages or high-demand periods, significantly enhancing urban resilience against power disruptions and natural disasters.

The physical design considerations of battery packs present both challenges and opportunities for urban integration. Modular battery systems allow for flexible deployment across varied urban environments, from dense city centers to suburban areas. Advanced cooling systems and fire suppression technologies are being incorporated into battery installations to address safety concerns in populated areas, with particular attention to thermal management in extreme climate conditions.

Regulatory frameworks are evolving to accommodate these new infrastructure elements, with cities developing specialized building codes and safety standards for battery installations. These frameworks must balance innovation with public safety, creating pathways for implementation while ensuring appropriate safeguards are in place.

Multi-functional infrastructure designs represent a promising frontier, where battery systems serve dual purposes. Examples include noise barriers along highways that incorporate solar panels and battery storage, or public seating areas in parks that double as charging stations powered by integrated battery systems. These approaches maximize limited urban space while providing multiple community benefits.

The economic implications of infrastructure integration extend beyond energy savings to include reduced maintenance costs, extended infrastructure lifespan, and new revenue streams from grid services. Cities are developing innovative financing mechanisms, including public-private partnerships and community ownership models, to fund these infrastructure investments while ensuring equitable access to their benefits across diverse neighborhoods and socioeconomic groups.

Urban planners are increasingly adopting distributed energy storage approaches, incorporating battery packs into multiple infrastructure elements such as public buildings, transportation hubs, and community centers. This distribution creates a network of energy reservoirs that can be tapped during outages or high-demand periods, significantly enhancing urban resilience against power disruptions and natural disasters.

The physical design considerations of battery packs present both challenges and opportunities for urban integration. Modular battery systems allow for flexible deployment across varied urban environments, from dense city centers to suburban areas. Advanced cooling systems and fire suppression technologies are being incorporated into battery installations to address safety concerns in populated areas, with particular attention to thermal management in extreme climate conditions.

Regulatory frameworks are evolving to accommodate these new infrastructure elements, with cities developing specialized building codes and safety standards for battery installations. These frameworks must balance innovation with public safety, creating pathways for implementation while ensuring appropriate safeguards are in place.

Multi-functional infrastructure designs represent a promising frontier, where battery systems serve dual purposes. Examples include noise barriers along highways that incorporate solar panels and battery storage, or public seating areas in parks that double as charging stations powered by integrated battery systems. These approaches maximize limited urban space while providing multiple community benefits.

The economic implications of infrastructure integration extend beyond energy savings to include reduced maintenance costs, extended infrastructure lifespan, and new revenue streams from grid services. Cities are developing innovative financing mechanisms, including public-private partnerships and community ownership models, to fund these infrastructure investments while ensuring equitable access to their benefits across diverse neighborhoods and socioeconomic groups.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!