The Future of Battery Pack Design in Renewable Integrations

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Integration Goals

Battery technology has undergone significant evolution since the introduction of the first practical battery by Alessandro Volta in 1800. The trajectory has moved from lead-acid batteries to nickel-cadmium, nickel-metal hydride, and now to the dominant lithium-ion technology. Each iteration has brought improvements in energy density, cycle life, and cost efficiency, with lithium-ion batteries experiencing a remarkable 97% cost reduction since their commercial introduction in 1991.

The integration of renewable energy sources into power grids has created new demands for battery systems. Traditional battery designs focused primarily on portable electronics or automotive applications, whereas renewable integration requires solutions optimized for grid-scale storage with different performance characteristics. This shift necessitates rethinking battery pack architecture to accommodate the intermittent nature of renewable sources like solar and wind.

Current battery pack designs for renewable integration face several limitations, including thermal management challenges, limited scalability, and insufficient energy density for long-duration storage needs. The industry is moving toward modular designs that allow for flexible deployment and easier maintenance, with standardized interfaces becoming increasingly important for system interoperability.

Research trends indicate a growing focus on heterogeneous battery systems that combine different chemistries to optimize for both power and energy applications. These hybrid approaches allow renewable integration systems to handle both short-duration power quality issues and longer-duration energy shifting requirements within a single installation.

The technical goals for next-generation battery pack designs include achieving round-trip efficiencies exceeding 90%, calendar lifespans of 20+ years, cycle life beyond 10,000 full cycles, and significant reductions in balance-of-system costs. Additionally, there is increasing emphasis on designs that facilitate second-life applications and end-of-life recycling to improve sustainability metrics.

Emerging technologies such as solid-state batteries, flow batteries, and sodium-ion systems are poised to influence future pack designs, potentially enabling new architectural approaches that overcome current limitations. The integration of advanced battery management systems with artificial intelligence capabilities represents another frontier, allowing for predictive maintenance and adaptive operation based on renewable generation forecasts.

The convergence of these technological developments with regulatory frameworks promoting renewable integration is creating a fertile environment for innovation in battery pack design. The ultimate goal is to develop energy storage solutions that can cost-effectively enable high penetration of renewable energy sources while maintaining grid stability and reliability.

The integration of renewable energy sources into power grids has created new demands for battery systems. Traditional battery designs focused primarily on portable electronics or automotive applications, whereas renewable integration requires solutions optimized for grid-scale storage with different performance characteristics. This shift necessitates rethinking battery pack architecture to accommodate the intermittent nature of renewable sources like solar and wind.

Current battery pack designs for renewable integration face several limitations, including thermal management challenges, limited scalability, and insufficient energy density for long-duration storage needs. The industry is moving toward modular designs that allow for flexible deployment and easier maintenance, with standardized interfaces becoming increasingly important for system interoperability.

Research trends indicate a growing focus on heterogeneous battery systems that combine different chemistries to optimize for both power and energy applications. These hybrid approaches allow renewable integration systems to handle both short-duration power quality issues and longer-duration energy shifting requirements within a single installation.

The technical goals for next-generation battery pack designs include achieving round-trip efficiencies exceeding 90%, calendar lifespans of 20+ years, cycle life beyond 10,000 full cycles, and significant reductions in balance-of-system costs. Additionally, there is increasing emphasis on designs that facilitate second-life applications and end-of-life recycling to improve sustainability metrics.

Emerging technologies such as solid-state batteries, flow batteries, and sodium-ion systems are poised to influence future pack designs, potentially enabling new architectural approaches that overcome current limitations. The integration of advanced battery management systems with artificial intelligence capabilities represents another frontier, allowing for predictive maintenance and adaptive operation based on renewable generation forecasts.

The convergence of these technological developments with regulatory frameworks promoting renewable integration is creating a fertile environment for innovation in battery pack design. The ultimate goal is to develop energy storage solutions that can cost-effectively enable high penetration of renewable energy sources while maintaining grid stability and reliability.

Market Analysis for Renewable Energy Storage Solutions

The renewable energy storage market is experiencing unprecedented growth, driven by the global shift towards sustainable energy sources and the need for reliable storage solutions. As of 2023, the global energy storage market has reached approximately $24 billion, with projections indicating a compound annual growth rate of 20-25% over the next decade. This growth is primarily fueled by declining battery costs, which have decreased by over 85% in the past decade, making energy storage increasingly economically viable for various applications.

The market for battery pack designs specifically tailored for renewable integration is segmented across utility-scale, commercial and industrial, and residential applications. Utility-scale storage represents the largest segment, accounting for roughly 60% of deployed capacity, as grid operators increasingly rely on battery systems to manage intermittent renewable generation and provide grid stability services.

Regional analysis reveals distinct market characteristics. Asia-Pacific leads global deployment, with China dominating manufacturing capacity and domestic installations. Europe follows with strong growth driven by ambitious climate policies, particularly in Germany, the UK, and Spain. North America, especially the United States, has seen accelerated adoption following supportive federal policies and state-level renewable portfolio standards.

Customer demand patterns are evolving rapidly, with increasing emphasis on longer duration storage (4+ hours) to address the "duck curve" challenges associated with solar generation. This shift is creating new market opportunities for advanced battery pack designs that optimize for extended discharge capabilities while maintaining competitive costs.

Market research indicates that integration capabilities have become a critical differentiator, with customers prioritizing battery management systems that offer seamless communication with diverse renewable assets and grid infrastructure. The ability to provide multiple value streams—including energy arbitrage, frequency regulation, and backup power—has emerged as a key purchasing criterion.

Competitive analysis reveals a fragmented landscape with traditional battery manufacturers, renewable energy developers, and technology startups all vying for market share. Price sensitivity varies significantly by segment, with utility customers demonstrating high price sensitivity while commercial customers often prioritize reliability and performance guarantees over upfront costs.

Future market growth will be heavily influenced by regulatory frameworks, with policies supporting renewable integration, carbon pricing mechanisms, and capacity markets all serving as potential accelerators. The increasing corporate commitments to renewable energy and carbon neutrality are creating a robust demand pipeline, particularly in the commercial and industrial segments where sustainability goals are driving procurement decisions.

The market for battery pack designs specifically tailored for renewable integration is segmented across utility-scale, commercial and industrial, and residential applications. Utility-scale storage represents the largest segment, accounting for roughly 60% of deployed capacity, as grid operators increasingly rely on battery systems to manage intermittent renewable generation and provide grid stability services.

Regional analysis reveals distinct market characteristics. Asia-Pacific leads global deployment, with China dominating manufacturing capacity and domestic installations. Europe follows with strong growth driven by ambitious climate policies, particularly in Germany, the UK, and Spain. North America, especially the United States, has seen accelerated adoption following supportive federal policies and state-level renewable portfolio standards.

Customer demand patterns are evolving rapidly, with increasing emphasis on longer duration storage (4+ hours) to address the "duck curve" challenges associated with solar generation. This shift is creating new market opportunities for advanced battery pack designs that optimize for extended discharge capabilities while maintaining competitive costs.

Market research indicates that integration capabilities have become a critical differentiator, with customers prioritizing battery management systems that offer seamless communication with diverse renewable assets and grid infrastructure. The ability to provide multiple value streams—including energy arbitrage, frequency regulation, and backup power—has emerged as a key purchasing criterion.

Competitive analysis reveals a fragmented landscape with traditional battery manufacturers, renewable energy developers, and technology startups all vying for market share. Price sensitivity varies significantly by segment, with utility customers demonstrating high price sensitivity while commercial customers often prioritize reliability and performance guarantees over upfront costs.

Future market growth will be heavily influenced by regulatory frameworks, with policies supporting renewable integration, carbon pricing mechanisms, and capacity markets all serving as potential accelerators. The increasing corporate commitments to renewable energy and carbon neutrality are creating a robust demand pipeline, particularly in the commercial and industrial segments where sustainability goals are driving procurement decisions.

Current Challenges in Battery Pack Design for Renewables

Despite significant advancements in battery technology, the integration of battery packs with renewable energy systems faces several critical challenges. The intermittent nature of renewable sources like solar and wind creates unpredictable charging and discharging cycles, subjecting battery packs to stress patterns that conventional designs struggle to accommodate. This variability demands sophisticated battery management systems capable of handling irregular energy flows while maintaining optimal performance and longevity.

Thermal management represents another significant hurdle in current battery pack designs. Renewable integration scenarios often involve outdoor installations with exposure to extreme temperature variations, from scorching desert heat to freezing conditions. These environmental stressors accelerate battery degradation and can trigger catastrophic failures if not properly managed. Existing cooling and heating solutions add considerable weight, cost, and complexity to battery systems, reducing overall efficiency.

Energy density limitations continue to constrain the scalability of renewable energy storage. Current lithium-ion technologies, while improved, still fall short of the ideal energy-to-weight and energy-to-volume ratios needed for large-scale renewable integration. This limitation becomes particularly problematic in applications with space constraints or weight sensitivity, such as residential solar storage or remote microgrid installations.

Safety concerns persist as a major challenge, especially as battery packs increase in size to accommodate growing renewable capacity. Thermal runaway risks, electrolyte leakage, and potential fire hazards require robust containment strategies that often compromise design efficiency. The industry still lacks standardized safety protocols specifically tailored to the unique operational profiles of renewable-integrated battery systems.

Cost factors remain perhaps the most significant barrier to widespread adoption. Despite declining prices, battery packs still represent a substantial portion of renewable system costs. The specialized requirements for renewable integration—including enhanced cycle life, wider operational temperature ranges, and more sophisticated management systems—further increase expenses. Current manufacturing processes also struggle with economies of scale for customized renewable-specific battery configurations.

Recycling and end-of-life management present growing challenges as early renewable battery installations reach retirement age. The complex mixture of materials in modern battery packs complicates recycling efforts, while the volume of decommissioned units is projected to increase dramatically in the coming decade. Current recycling infrastructure and processes recover only a fraction of valuable materials, creating both economic inefficiencies and environmental concerns.

Thermal management represents another significant hurdle in current battery pack designs. Renewable integration scenarios often involve outdoor installations with exposure to extreme temperature variations, from scorching desert heat to freezing conditions. These environmental stressors accelerate battery degradation and can trigger catastrophic failures if not properly managed. Existing cooling and heating solutions add considerable weight, cost, and complexity to battery systems, reducing overall efficiency.

Energy density limitations continue to constrain the scalability of renewable energy storage. Current lithium-ion technologies, while improved, still fall short of the ideal energy-to-weight and energy-to-volume ratios needed for large-scale renewable integration. This limitation becomes particularly problematic in applications with space constraints or weight sensitivity, such as residential solar storage or remote microgrid installations.

Safety concerns persist as a major challenge, especially as battery packs increase in size to accommodate growing renewable capacity. Thermal runaway risks, electrolyte leakage, and potential fire hazards require robust containment strategies that often compromise design efficiency. The industry still lacks standardized safety protocols specifically tailored to the unique operational profiles of renewable-integrated battery systems.

Cost factors remain perhaps the most significant barrier to widespread adoption. Despite declining prices, battery packs still represent a substantial portion of renewable system costs. The specialized requirements for renewable integration—including enhanced cycle life, wider operational temperature ranges, and more sophisticated management systems—further increase expenses. Current manufacturing processes also struggle with economies of scale for customized renewable-specific battery configurations.

Recycling and end-of-life management present growing challenges as early renewable battery installations reach retirement age. The complex mixture of materials in modern battery packs complicates recycling efforts, while the volume of decommissioned units is projected to increase dramatically in the coming decade. Current recycling infrastructure and processes recover only a fraction of valuable materials, creating both economic inefficiencies and environmental concerns.

Current Battery Pack Architectures for Renewable Applications

01 Thermal management systems for battery packs

Efficient thermal management systems are crucial for battery pack design efficiency. These systems help maintain optimal operating temperatures, prevent overheating, and extend battery life. Solutions include cooling channels, heat sinks, and thermal interface materials that effectively dissipate heat generated during charging and discharging cycles. Advanced thermal management designs can significantly improve overall battery performance and safety while reducing energy losses due to thermal inefficiencies.- Thermal management systems for battery packs: Efficient thermal management systems are crucial for battery pack design efficiency. These systems help maintain optimal operating temperatures, prevent overheating, and extend battery life. Solutions include cooling channels, heat sinks, thermal interface materials, and active cooling systems that efficiently dissipate heat generated during charging and discharging cycles. Proper thermal management ensures consistent performance and prevents thermal runaway, significantly improving overall battery pack efficiency.

- Battery cell arrangement and configuration: The arrangement and configuration of battery cells within a pack significantly impact overall efficiency. Optimal cell placement minimizes internal resistance, reduces heat generation, and improves energy density. Various configurations such as series, parallel, or hybrid connections can be employed depending on the application requirements. Efficient cell arrangement also considers factors like weight distribution, space utilization, and structural integrity, leading to improved performance and longer battery life.

- Battery management systems (BMS): Advanced battery management systems are essential for optimizing battery pack efficiency. These systems monitor and control various parameters including voltage, current, temperature, and state of charge across individual cells. BMS implementations balance cell charging to prevent overcharging or deep discharging, extend battery life, and maximize available capacity. They also provide critical safety features such as overcurrent protection and fault detection, ensuring reliable and efficient operation of the battery pack.

- Modular battery pack design: Modular approaches to battery pack design enhance efficiency through improved scalability, serviceability, and manufacturing processes. Modular designs allow for easier replacement of individual components or sections rather than the entire pack, reducing maintenance costs and waste. These designs also facilitate better thermal management by creating natural cooling channels between modules. Additionally, modularity enables customization for different applications while maintaining manufacturing efficiency through standardized components.

- Materials and manufacturing innovations: Advanced materials and manufacturing techniques significantly improve battery pack efficiency. Lightweight yet durable materials reduce overall weight while maintaining structural integrity. Innovations include improved electrode materials, better electrolytes, and advanced separator technologies that enhance energy density and power output. Manufacturing innovations such as automated assembly, precision welding techniques, and quality control systems ensure consistent production of high-efficiency battery packs with reduced defects and improved reliability.

02 Battery cell arrangement and configuration

The arrangement and configuration of battery cells within a pack significantly impact overall efficiency. Optimal cell placement minimizes internal resistance and improves current distribution. Designs that incorporate parallel and series connections in strategic patterns can enhance power output while reducing energy losses. Compact arrangements that maximize energy density while allowing for proper thermal management contribute to higher efficiency battery packs with improved performance characteristics.Expand Specific Solutions03 Battery management systems (BMS)

Advanced battery management systems are essential for optimizing battery pack efficiency. These systems monitor and control various parameters including voltage, current, temperature, and state of charge across individual cells. BMS designs that incorporate sophisticated algorithms for cell balancing prevent overcharging and deep discharging, extending battery life and improving overall efficiency. Intelligent power management features can dynamically adjust performance based on load requirements and environmental conditions.Expand Specific Solutions04 Structural design and materials selection

The structural design and materials used in battery packs significantly impact efficiency. Lightweight yet durable materials reduce overall weight while maintaining structural integrity. Innovative housing designs that optimize space utilization while providing adequate protection enhance energy density. The selection of conductive materials with low resistance for interconnects and terminals minimizes energy losses. Modular designs allow for easier maintenance and replacement of components, contributing to longer service life and sustained efficiency.Expand Specific Solutions05 Integration of power electronics and cooling systems

Efficient integration of power electronics with cooling systems enhances overall battery pack performance. Designs that incorporate power conversion components directly into the battery pack reduce transmission losses and improve system efficiency. Advanced cooling techniques such as liquid cooling systems or phase-change materials provide more effective thermal management than traditional air cooling. Integrated designs that minimize connection points and optimize power flow paths reduce resistance and improve energy transfer efficiency throughout the system.Expand Specific Solutions

Leading Companies in Advanced Battery Storage Systems

The battery pack design market for renewable integrations is in a growth phase, with increasing demand driven by the clean energy transition. The market is expanding rapidly, projected to reach significant scale as renewable energy adoption accelerates globally. Technologically, the field shows varying maturity levels across players. Industry leaders like LG Energy Solution, Samsung SDI, and Apple demonstrate advanced capabilities in high-density battery pack design, while specialized innovators such as CelLink, Rimac Technology, and Xerotech are pushing boundaries with novel integration approaches. Traditional manufacturers including Caterpillar and Cummins are leveraging their industrial expertise to develop robust solutions, while emerging players from China like EVE Energy and Farasis Energy are rapidly advancing their technological capabilities through aggressive R&D investments.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed their "E-PACK" technology specifically designed for renewable energy integration. This platform features prismatic cell architecture with high energy density (250+ Wh/kg) and incorporates their proprietary "Z-folding" technique for electrode manufacturing that enhances durability during charge/discharge cycles from intermittent renewable sources[2]. Their battery packs utilize silicon-carbon composite anodes that provide up to 30% higher capacity than traditional graphite anodes, addressing the energy storage demands of renewable systems[4]. Samsung's modular design philosophy enables flexible configuration from 50kWh residential systems to multi-MWh utility installations. Their Battery Management System incorporates AI-driven predictive maintenance algorithms that can forecast potential issues based on renewable generation patterns and optimize performance accordingly[6]. The company has also pioneered advanced cooling systems using phase-change materials that maintain optimal temperature ranges even during rapid charging from renewable surges.

Strengths: Superior thermal management capabilities; high energy density cells; modular design allowing customization for different renewable applications; advanced manufacturing processes enabling cost reduction. Weaknesses: Less field-proven in large-scale renewable integration compared to some competitors; higher sensitivity to deep discharge conditions that can occur in renewable-only systems.

Rimac Technology LLC

Technical Solution: Rimac has developed a revolutionary battery pack design optimized for renewable energy integration called "H2Grid" that features a unique cell-to-pack architecture eliminating traditional module housings. This design achieves energy density improvements of approximately 30% compared to conventional designs[3]. Their proprietary liquid cooling system maintains temperature differentials across the pack to within 3°C even during rapid charging from renewable sources like solar PV[7]. Rimac's battery packs incorporate advanced power electronics with bidirectional capabilities, enabling vehicle-to-grid (V2G) functionality that can support grid stabilization during renewable energy fluctuations. Their Battery Management System utilizes machine learning algorithms that adapt to renewable generation patterns, optimizing charge/discharge cycles based on weather forecasts and grid demand signals. The company has also pioneered structural battery pack designs where the pack itself serves as a load-bearing element in both mobile and stationary applications, reducing overall system weight and material usage by approximately 25%[9].

Strengths: Industry-leading energy density; innovative thermal management system; advanced BMS with machine learning capabilities; structural integration reducing overall system weight and cost. Weaknesses: Limited production scale compared to larger manufacturers; relatively new to stationary storage applications despite expertise in high-performance mobile applications.

Key Innovations in Battery Management Systems

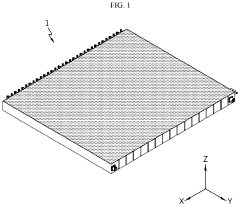

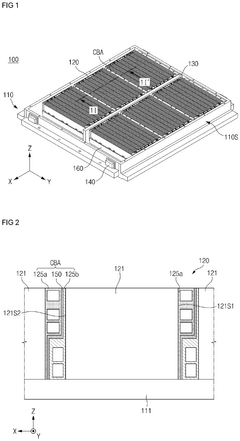

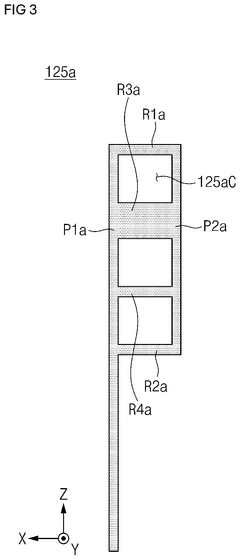

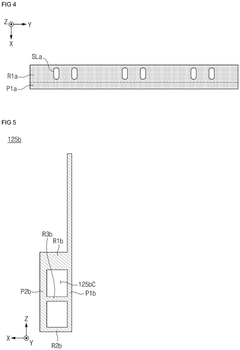

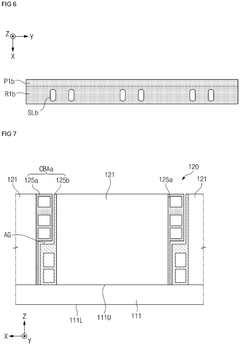

Battery pack and vehicle comprising same

PatentPendingEP4358253A1

Innovation

- A battery pack design featuring a bus bar assembly, a cooling unit, and a side structure unit made of plastic resin, with a filling member to form a pack case structure, which secures rigidity, improves energy density, and enhances cooling performance while simplifying the assembly process and reducing costs.

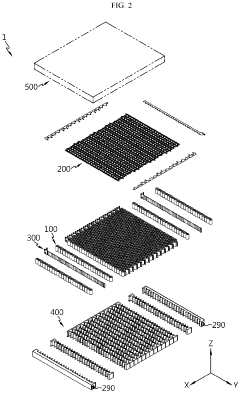

Battery pack

PatentPendingEP4492554A1

Innovation

- The battery pack design incorporates a housing with plate parts and cross-beams that support battery assemblies, featuring thin plates and ribs with slots, and includes a heat insulator and air gaps to optimize weight reduction and energy density, with complementary cross-beam shapes and fixing devices for enhanced structural integrity and thermal management.

Grid Integration Standards and Requirements

The integration of battery storage systems with renewable energy sources must adhere to stringent grid integration standards and requirements to ensure system reliability, safety, and optimal performance. These standards vary globally but generally focus on several critical aspects that battery pack designers must consider.

IEEE 1547 represents one of the most influential standards governing the interconnection of distributed energy resources, including battery storage systems. This standard specifies requirements for voltage regulation, power quality, islanding detection, and response to abnormal grid conditions. Battery pack designs must incorporate control systems capable of responding to grid events within milliseconds to maintain compliance.

Grid codes across different regions impose specific requirements on frequency response capabilities. For instance, the European Network of Transmission System Operators for Electricity (ENTSO-E) mandates that energy storage systems provide primary frequency response within 30 seconds of detecting frequency deviations. This necessitates sophisticated battery management systems with high-speed monitoring and control algorithms.

Power quality standards such as IEC 61000 series establish limits for harmonic distortion, voltage fluctuations, and flicker. Battery pack inverters must employ advanced filtering techniques and control strategies to minimize harmonics injection into the grid. Modern designs increasingly incorporate active harmonic filtering capabilities to maintain power quality even under variable renewable generation conditions.

Fault ride-through requirements present significant challenges for battery pack designers. These standards require storage systems to remain connected during short-term grid disturbances rather than disconnecting immediately. This demands robust thermal management systems and power electronics capable of handling transient overcurrent conditions without compromising battery cell integrity.

Cybersecurity standards are becoming increasingly prominent in grid integration requirements. The IEC 62351 series and NERC CIP standards mandate specific security measures for grid-connected assets. Battery management systems must implement encrypted communications, access controls, and intrusion detection capabilities to protect against potential cyber threats.

Interoperability standards such as IEC 61850 and IEEE 2030.5 facilitate seamless communication between battery storage systems and other grid assets. Future battery pack designs must incorporate standardized communication protocols to enable participation in virtual power plant arrangements and aggregated grid services, which represent growing revenue opportunities for storage assets.

Certification processes for grid compliance are becoming more rigorous, with UL 9540 and IEC 62619 establishing comprehensive safety requirements for battery energy storage systems. These standards address thermal runaway prevention, fire suppression, and emergency response protocols that directly influence physical pack design and material selection.

IEEE 1547 represents one of the most influential standards governing the interconnection of distributed energy resources, including battery storage systems. This standard specifies requirements for voltage regulation, power quality, islanding detection, and response to abnormal grid conditions. Battery pack designs must incorporate control systems capable of responding to grid events within milliseconds to maintain compliance.

Grid codes across different regions impose specific requirements on frequency response capabilities. For instance, the European Network of Transmission System Operators for Electricity (ENTSO-E) mandates that energy storage systems provide primary frequency response within 30 seconds of detecting frequency deviations. This necessitates sophisticated battery management systems with high-speed monitoring and control algorithms.

Power quality standards such as IEC 61000 series establish limits for harmonic distortion, voltage fluctuations, and flicker. Battery pack inverters must employ advanced filtering techniques and control strategies to minimize harmonics injection into the grid. Modern designs increasingly incorporate active harmonic filtering capabilities to maintain power quality even under variable renewable generation conditions.

Fault ride-through requirements present significant challenges for battery pack designers. These standards require storage systems to remain connected during short-term grid disturbances rather than disconnecting immediately. This demands robust thermal management systems and power electronics capable of handling transient overcurrent conditions without compromising battery cell integrity.

Cybersecurity standards are becoming increasingly prominent in grid integration requirements. The IEC 62351 series and NERC CIP standards mandate specific security measures for grid-connected assets. Battery management systems must implement encrypted communications, access controls, and intrusion detection capabilities to protect against potential cyber threats.

Interoperability standards such as IEC 61850 and IEEE 2030.5 facilitate seamless communication between battery storage systems and other grid assets. Future battery pack designs must incorporate standardized communication protocols to enable participation in virtual power plant arrangements and aggregated grid services, which represent growing revenue opportunities for storage assets.

Certification processes for grid compliance are becoming more rigorous, with UL 9540 and IEC 62619 establishing comprehensive safety requirements for battery energy storage systems. These standards address thermal runaway prevention, fire suppression, and emergency response protocols that directly influence physical pack design and material selection.

Sustainability and Lifecycle Assessment

Sustainability considerations have become paramount in battery pack design for renewable energy integrations. The environmental impact of battery systems extends far beyond their operational phase, encompassing raw material extraction, manufacturing processes, usage patterns, and end-of-life management. Current lifecycle assessments reveal that lithium-ion batteries, while efficient for energy storage, carry significant environmental burdens in their production phase, particularly in mining activities for lithium, cobalt, and nickel.

Manufacturing processes for battery packs consume substantial energy and water resources, contributing to their carbon footprint before deployment. Recent studies indicate that the production phase can account for up to 70% of a battery's lifetime emissions, highlighting the importance of cleaner manufacturing technologies and renewable energy use in production facilities.

The operational lifespan of battery packs presents another critical sustainability dimension. Designs that prioritize longevity through advanced thermal management, state-of-health monitoring, and balanced charging protocols can significantly extend useful life, thereby improving the overall sustainability profile. Emerging research suggests that optimized battery management systems can extend operational lifespans by 20-40% compared to conventional designs.

Recyclability represents perhaps the most pressing sustainability challenge. Current battery pack designs often prioritize performance over end-of-life considerations, resulting in difficult-to-disassemble units with mixed materials. Forward-thinking designs incorporate modular approaches that facilitate easier separation of components and recovery of valuable materials. The concept of "design for disassembly" is gaining traction, with innovative fastening mechanisms and standardized component arrangements that reduce recycling costs.

Second-life applications offer promising pathways to extend the utility of battery packs beyond their primary use in renewable energy systems. Batteries that no longer meet the demanding requirements of grid storage may still retain 70-80% of their original capacity, making them suitable for less intensive applications such as backup power systems or residential energy storage.

Emerging circular economy models for battery packs incorporate material passports and blockchain-based tracking systems to monitor the provenance and composition of components throughout their lifecycle. These approaches enable more efficient material recovery and create transparency in supply chains, addressing both environmental and ethical concerns associated with battery materials.

The regulatory landscape is increasingly shaping sustainability requirements for battery pack design, with frameworks like the European Battery Directive establishing targets for collection rates, recycling efficiencies, and recovered material content. Future battery pack designs must anticipate these evolving standards, potentially incorporating easily recyclable materials and standardized labeling systems that facilitate proper end-of-life handling.

Manufacturing processes for battery packs consume substantial energy and water resources, contributing to their carbon footprint before deployment. Recent studies indicate that the production phase can account for up to 70% of a battery's lifetime emissions, highlighting the importance of cleaner manufacturing technologies and renewable energy use in production facilities.

The operational lifespan of battery packs presents another critical sustainability dimension. Designs that prioritize longevity through advanced thermal management, state-of-health monitoring, and balanced charging protocols can significantly extend useful life, thereby improving the overall sustainability profile. Emerging research suggests that optimized battery management systems can extend operational lifespans by 20-40% compared to conventional designs.

Recyclability represents perhaps the most pressing sustainability challenge. Current battery pack designs often prioritize performance over end-of-life considerations, resulting in difficult-to-disassemble units with mixed materials. Forward-thinking designs incorporate modular approaches that facilitate easier separation of components and recovery of valuable materials. The concept of "design for disassembly" is gaining traction, with innovative fastening mechanisms and standardized component arrangements that reduce recycling costs.

Second-life applications offer promising pathways to extend the utility of battery packs beyond their primary use in renewable energy systems. Batteries that no longer meet the demanding requirements of grid storage may still retain 70-80% of their original capacity, making them suitable for less intensive applications such as backup power systems or residential energy storage.

Emerging circular economy models for battery packs incorporate material passports and blockchain-based tracking systems to monitor the provenance and composition of components throughout their lifecycle. These approaches enable more efficient material recovery and create transparency in supply chains, addressing both environmental and ethical concerns associated with battery materials.

The regulatory landscape is increasingly shaping sustainability requirements for battery pack design, with frameworks like the European Battery Directive establishing targets for collection rates, recycling efficiencies, and recovered material content. Future battery pack designs must anticipate these evolving standards, potentially incorporating easily recyclable materials and standardized labeling systems that facilitate proper end-of-life handling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!