Comparative Analysis of Battery Pack Design for E-Bike Applications

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

E-Bike Battery Evolution and Design Objectives

The evolution of battery technology for electric bicycles has undergone significant transformation since the early 1990s when e-bikes first gained commercial traction. Initially dominated by lead-acid batteries, the industry witnessed a gradual shift toward nickel-metal hydride (NiMH) systems in the early 2000s, offering improved energy density and reduced environmental impact. The revolutionary introduction of lithium-ion technology around 2005-2010 marked a pivotal moment, enabling dramatic weight reduction and extended range capabilities that catalyzed widespread e-bike adoption.

Today's e-bike battery landscape is characterized by diverse lithium-based chemistries, including lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium titanate (LTO), each offering distinct performance profiles suited to different application requirements. The evolution continues with emerging solid-state battery technologies promising further improvements in energy density, safety, and longevity.

The primary design objectives for modern e-bike battery packs center on five critical parameters: energy density, power delivery, cycle life, safety, and cost-effectiveness. Energy density (typically ranging from 100-250 Wh/kg) directly impacts the range capability and physical dimensions of the battery pack, while power delivery characteristics determine acceleration performance and hill-climbing ability. Contemporary designs must balance these performance metrics against durability requirements, with premium systems targeting 1,000+ charge cycles before significant capacity degradation.

Safety considerations have become increasingly paramount, driving innovations in thermal management systems, battery management systems (BMS), and cell isolation technologies. These advancements aim to mitigate risks associated with thermal runaway, overcharging, and physical damage. Simultaneously, manufacturers face mounting pressure to reduce costs, currently averaging $300-700 per kWh at the pack level, to enhance market competitiveness.

Integration objectives have evolved beyond mere functional requirements to encompass aesthetic and user experience considerations. Modern designs prioritize seamless frame integration, quick-release mechanisms, and intuitive user interfaces. Additionally, environmental sustainability has emerged as a critical design parameter, with increasing focus on recyclability, reduced toxic materials, and overall carbon footprint throughout the battery lifecycle.

The technical trajectory indicates continued refinement of lithium-based technologies in the near term, with incremental improvements in energy density and cost reduction. Looking further ahead, solid-state batteries and alternative chemistries utilizing more abundant materials represent promising avenues for addressing current limitations in performance, safety, and sustainability.

Today's e-bike battery landscape is characterized by diverse lithium-based chemistries, including lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium titanate (LTO), each offering distinct performance profiles suited to different application requirements. The evolution continues with emerging solid-state battery technologies promising further improvements in energy density, safety, and longevity.

The primary design objectives for modern e-bike battery packs center on five critical parameters: energy density, power delivery, cycle life, safety, and cost-effectiveness. Energy density (typically ranging from 100-250 Wh/kg) directly impacts the range capability and physical dimensions of the battery pack, while power delivery characteristics determine acceleration performance and hill-climbing ability. Contemporary designs must balance these performance metrics against durability requirements, with premium systems targeting 1,000+ charge cycles before significant capacity degradation.

Safety considerations have become increasingly paramount, driving innovations in thermal management systems, battery management systems (BMS), and cell isolation technologies. These advancements aim to mitigate risks associated with thermal runaway, overcharging, and physical damage. Simultaneously, manufacturers face mounting pressure to reduce costs, currently averaging $300-700 per kWh at the pack level, to enhance market competitiveness.

Integration objectives have evolved beyond mere functional requirements to encompass aesthetic and user experience considerations. Modern designs prioritize seamless frame integration, quick-release mechanisms, and intuitive user interfaces. Additionally, environmental sustainability has emerged as a critical design parameter, with increasing focus on recyclability, reduced toxic materials, and overall carbon footprint throughout the battery lifecycle.

The technical trajectory indicates continued refinement of lithium-based technologies in the near term, with incremental improvements in energy density and cost reduction. Looking further ahead, solid-state batteries and alternative chemistries utilizing more abundant materials represent promising avenues for addressing current limitations in performance, safety, and sustainability.

Market Demand Analysis for E-Bike Battery Solutions

The global e-bike market has experienced unprecedented growth in recent years, with battery technology serving as a critical differentiator in product offerings. Market research indicates that the e-bike sector is projected to reach $70 billion by 2027, growing at a CAGR of approximately 9.8% from 2022. This remarkable expansion is driven by increasing environmental consciousness, rising fuel costs, growing urbanization, and government initiatives promoting sustainable transportation alternatives.

Consumer demand for e-bike battery solutions has evolved significantly, with users now prioritizing longer range, faster charging capabilities, and lighter weight designs. Survey data reveals that 78% of potential e-bike buyers consider battery performance as the primary decision factor, ahead of motor power and frame design. The average consumer now expects a minimum range of 50-60 miles per charge, representing a 40% increase in expectations compared to just five years ago.

Regional market analysis shows distinct preference patterns. European consumers typically value integration and aesthetics, with sleek battery designs that blend seamlessly with the frame. North American users prioritize power and range for longer recreational rides, while Asian markets emphasize affordability and practicality for daily commuting. These regional variations necessitate tailored battery pack designs to meet specific market demands.

Price sensitivity remains a significant factor, with battery packs typically accounting for 30-35% of the total e-bike cost. Market research indicates a willingness to pay premium prices for advanced battery technology, but only when tangible benefits in performance, longevity, or convenience are clearly demonstrated. The sweet spot for consumer acceptance appears to be battery solutions that offer 20% improvement in key metrics without exceeding a 15% price increase.

Emerging market trends include growing demand for smart battery management systems that integrate with smartphone applications, providing real-time data on battery health, range estimation, and optimal charging schedules. Additionally, there is increasing consumer interest in sustainable battery solutions, with 65% of surveyed e-bike users expressing preference for batteries with lower environmental impact and established recycling programs.

Commercial applications represent a rapidly expanding segment, with delivery services and bike-sharing programs deploying large e-bike fleets. These commercial users have distinct requirements, prioritizing battery interchangeability, rapid charging capabilities, and robust battery management systems that can optimize fleet operations and minimize downtime.

Consumer demand for e-bike battery solutions has evolved significantly, with users now prioritizing longer range, faster charging capabilities, and lighter weight designs. Survey data reveals that 78% of potential e-bike buyers consider battery performance as the primary decision factor, ahead of motor power and frame design. The average consumer now expects a minimum range of 50-60 miles per charge, representing a 40% increase in expectations compared to just five years ago.

Regional market analysis shows distinct preference patterns. European consumers typically value integration and aesthetics, with sleek battery designs that blend seamlessly with the frame. North American users prioritize power and range for longer recreational rides, while Asian markets emphasize affordability and practicality for daily commuting. These regional variations necessitate tailored battery pack designs to meet specific market demands.

Price sensitivity remains a significant factor, with battery packs typically accounting for 30-35% of the total e-bike cost. Market research indicates a willingness to pay premium prices for advanced battery technology, but only when tangible benefits in performance, longevity, or convenience are clearly demonstrated. The sweet spot for consumer acceptance appears to be battery solutions that offer 20% improvement in key metrics without exceeding a 15% price increase.

Emerging market trends include growing demand for smart battery management systems that integrate with smartphone applications, providing real-time data on battery health, range estimation, and optimal charging schedules. Additionally, there is increasing consumer interest in sustainable battery solutions, with 65% of surveyed e-bike users expressing preference for batteries with lower environmental impact and established recycling programs.

Commercial applications represent a rapidly expanding segment, with delivery services and bike-sharing programs deploying large e-bike fleets. These commercial users have distinct requirements, prioritizing battery interchangeability, rapid charging capabilities, and robust battery management systems that can optimize fleet operations and minimize downtime.

Current Battery Pack Technologies and Challenges

The current landscape of e-bike battery pack technologies is dominated by lithium-ion (Li-ion) batteries, which have largely replaced older lead-acid and nickel-metal hydride (NiMH) systems due to their superior energy density, longer cycle life, and reduced weight. Modern e-bike battery packs typically range from 36V to 52V with capacities between 8Ah and 20Ah, delivering ranges of 20-100 miles depending on terrain, rider weight, and assistance level.

Despite their advantages, Li-ion battery packs for e-bikes face several significant challenges. Thermal management remains a critical issue, as batteries can experience thermal runaway during charging or high-discharge scenarios, particularly in extreme ambient temperatures. Most current designs employ passive cooling systems, which may be insufficient for high-performance applications or operation in hot climates.

Battery management systems (BMS) represent another technological challenge. Contemporary BMS designs must balance cell monitoring, protection against over-charging/discharging, and communication with the e-bike controller system. The sophistication of these systems varies widely across the market, with premium solutions offering Bluetooth connectivity and smartphone integration while budget options provide only basic protection functions.

Weight distribution and form factor present ongoing design challenges. Current battery pack configurations include frame-integrated, downtube-mounted, rear rack, and bottle-style options. Each configuration presents trade-offs between weight distribution, center of gravity, aerodynamics, and ease of removal for charging. The industry has not yet converged on an optimal standard, with manufacturers pursuing proprietary designs that often lack interchangeability.

Durability and environmental resistance remain problematic areas. E-bike battery packs must withstand vibration, shock, moisture, and temperature variations while maintaining structural integrity. Current enclosure designs typically use hard plastic or aluminum casings with varying degrees of water and dust resistance, though few achieve true waterproof status (IP67 or higher).

Manufacturing scalability and cost efficiency continue to challenge the industry. The complex assembly process involving cell selection, interconnection, thermal management, and BMS integration contributes to high production costs. Current manufacturing techniques often involve significant manual assembly, limiting economies of scale and contributing to the high cost of replacement battery packs, which typically range from $300-$800.

Recycling infrastructure for e-bike battery packs remains underdeveloped. Most current designs do not prioritize end-of-life disassembly or material recovery, creating environmental concerns as the first generation of e-bike batteries reaches end-of-life. The industry has yet to implement standardized recycling protocols or design-for-disassembly principles at scale.

Despite their advantages, Li-ion battery packs for e-bikes face several significant challenges. Thermal management remains a critical issue, as batteries can experience thermal runaway during charging or high-discharge scenarios, particularly in extreme ambient temperatures. Most current designs employ passive cooling systems, which may be insufficient for high-performance applications or operation in hot climates.

Battery management systems (BMS) represent another technological challenge. Contemporary BMS designs must balance cell monitoring, protection against over-charging/discharging, and communication with the e-bike controller system. The sophistication of these systems varies widely across the market, with premium solutions offering Bluetooth connectivity and smartphone integration while budget options provide only basic protection functions.

Weight distribution and form factor present ongoing design challenges. Current battery pack configurations include frame-integrated, downtube-mounted, rear rack, and bottle-style options. Each configuration presents trade-offs between weight distribution, center of gravity, aerodynamics, and ease of removal for charging. The industry has not yet converged on an optimal standard, with manufacturers pursuing proprietary designs that often lack interchangeability.

Durability and environmental resistance remain problematic areas. E-bike battery packs must withstand vibration, shock, moisture, and temperature variations while maintaining structural integrity. Current enclosure designs typically use hard plastic or aluminum casings with varying degrees of water and dust resistance, though few achieve true waterproof status (IP67 or higher).

Manufacturing scalability and cost efficiency continue to challenge the industry. The complex assembly process involving cell selection, interconnection, thermal management, and BMS integration contributes to high production costs. Current manufacturing techniques often involve significant manual assembly, limiting economies of scale and contributing to the high cost of replacement battery packs, which typically range from $300-$800.

Recycling infrastructure for e-bike battery packs remains underdeveloped. Most current designs do not prioritize end-of-life disassembly or material recovery, creating environmental concerns as the first generation of e-bike batteries reaches end-of-life. The industry has yet to implement standardized recycling protocols or design-for-disassembly principles at scale.

Contemporary E-Bike Battery Pack Architectures

01 Thermal Management Systems for Battery Packs

Effective thermal management is crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms that help dissipate heat generated during charging and discharging cycles. Advanced designs incorporate temperature sensors and control algorithms to regulate thermal conditions across the entire battery pack.- Thermal management systems for battery packs: Effective thermal management is crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms that help dissipate heat generated during charging and discharging cycles. Advanced designs incorporate temperature sensors and control systems to monitor and regulate thermal conditions across the battery pack.

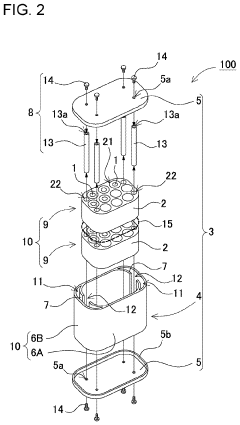

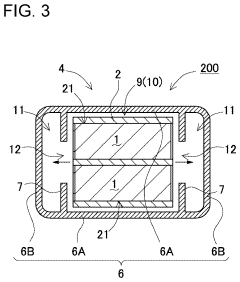

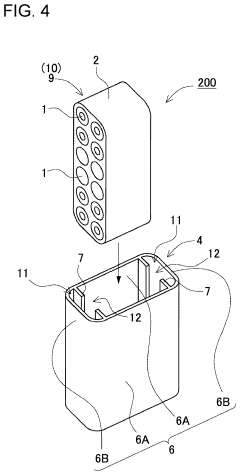

- Structural design and mechanical protection: Battery pack designs incorporate robust structural elements to protect cells from physical damage and environmental factors. This includes shock-absorbing materials, reinforced casings, and specialized mounting systems that minimize vibration and impact forces. The structural design also considers weight distribution, space optimization, and accessibility for maintenance while ensuring compliance with safety standards for various applications including automotive, consumer electronics, and industrial equipment.

- Battery management systems (BMS) integration: Modern battery pack designs integrate sophisticated battery management systems that monitor and control various parameters including voltage, current, temperature, and state of charge. These systems optimize battery performance, prevent overcharging or deep discharging, and implement cell balancing techniques to ensure uniform performance across all cells. Advanced BMS designs incorporate predictive algorithms for battery health monitoring and can communicate with external systems for diagnostics and maintenance.

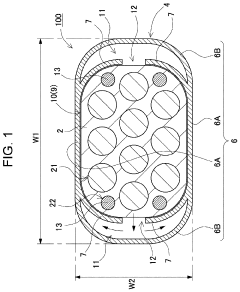

- Cell arrangement and interconnection methods: The arrangement and interconnection of individual cells within a battery pack significantly impact its overall performance, reliability, and safety. Designs consider series and parallel configurations to achieve desired voltage and capacity specifications. Advanced interconnection methods include bus bars, flexible circuits, and direct bonding techniques that minimize resistance, reduce heat generation, and improve current distribution. Cell arrangement also addresses space constraints and optimizes power density for specific applications.

- Safety features and failure mitigation: Battery pack designs incorporate multiple safety features to prevent catastrophic failures and mitigate risks. These include pressure relief mechanisms, thermal fuses, current limiters, and isolation systems that activate during abnormal conditions. Advanced designs implement redundant safety systems, fault detection algorithms, and rapid disconnection capabilities. Materials selection also plays a crucial role, with flame-retardant components and specialized separators that prevent thermal runaway propagation between cells.

02 Structural Design and Mechanical Protection

Battery pack designs incorporate robust structural elements to protect cells from physical damage and environmental factors. This includes shock-absorbing materials, reinforced casings, and specialized mounting systems that minimize vibration and impact forces. The mechanical design also considers weight distribution, space optimization, and accessibility for maintenance while ensuring compliance with safety standards for various applications from consumer electronics to electric vehicles.Expand Specific Solutions03 Battery Management Systems (BMS)

Advanced battery management systems are integrated into pack designs to monitor and control various parameters including voltage, current, temperature, and state of charge. These systems incorporate sophisticated algorithms for cell balancing, preventing overcharging or deep discharging, and optimizing overall performance. BMS designs also include communication interfaces for diagnostics, data logging, and integration with external systems, enhancing safety and extending battery lifespan.Expand Specific Solutions04 Cell Configuration and Interconnection Methods

Battery pack designs utilize various cell configurations (series, parallel, or hybrid arrangements) to achieve desired voltage, capacity, and power output. Innovative interconnection methods include bus bars, flexible circuits, and direct cell-to-cell connections that minimize resistance and heat generation. Advanced designs incorporate redundancy pathways, fusing mechanisms, and modular architectures that enhance reliability while allowing for scalability and easier maintenance or replacement of components.Expand Specific Solutions05 Safety Features and Failure Mitigation

Modern battery pack designs incorporate multiple layers of safety features to prevent catastrophic failures and mitigate risks. These include pressure relief mechanisms, thermal fuses, isolation switches, and containment structures that prevent thermal runaway propagation between cells. Advanced designs also feature early detection systems for abnormal conditions, emergency shutdown capabilities, and materials that minimize fire hazards or contain potential failures within localized areas of the pack.Expand Specific Solutions

Leading Manufacturers and Market Competition

The e-bike battery pack design market is currently in a growth phase, with an estimated global market size of $5-7 billion and projected annual growth of 12-15%. The competitive landscape features established players from diverse backgrounds: traditional battery manufacturers (Panasonic, Samsung SDI, LG Energy Solution), automotive companies (Bosch, Hyundai, Kia), power tool manufacturers (Makita, Koki Holdings), and specialized e-mobility firms (Biketec, BMZ Germany). Technology maturity varies across segments, with lithium-ion chemistry dominating but showing different levels of advancement. Leading innovators like Bosch, Panasonic, and LG Energy Solution have achieved higher energy density and thermal management capabilities, while newer entrants like Aulton New Energy and Shanghai Dianba are pioneering battery-swapping technologies, indicating an evolving competitive landscape with multiple technological approaches gaining traction.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced lithium-ion battery pack designs specifically optimized for e-bike applications. Their technology focuses on high energy density cells with up to 260Wh/kg, allowing for compact yet powerful battery packs. The company employs a modular design approach that enables scalable capacity options (typically 250Wh to 750Wh) to accommodate different e-bike categories from city commuters to mountain bikes. Their battery management system (BMS) incorporates cell balancing algorithms that extend overall pack lifespan by up to 30% compared to conventional systems. LG's proprietary thermal management solution uses phase-change materials to maintain optimal operating temperatures between 15-35°C even during high discharge rates, preventing thermal runaway while enabling fast charging capabilities (0-80% in approximately 1.5 hours). Their e-bike battery packs feature IP67 water and dust resistance ratings, making them suitable for various riding conditions.

Strengths: Superior energy density allowing for lighter weight packs; advanced thermal management system preventing overheating during fast charging; excellent cycle life (1000+ cycles at 80% capacity retention). Weaknesses: Premium pricing compared to competitors; proprietary connection systems limiting cross-compatibility with some e-bike models; slightly heavier than some specialized lightweight solutions.

Panasonic Energy Co. Ltd.

Technical Solution: Panasonic Energy has pioneered cylindrical cell-based battery pack designs for e-bike applications, leveraging their extensive experience as Tesla's primary cell supplier. Their e-bike battery solutions utilize 18650 or 21700 format cells arranged in custom configurations to optimize space utilization while maintaining structural integrity. Panasonic's battery packs feature a multi-layer protection system including mechanical cell separation, thermal barriers, and electronic safeguards that work in concert to prevent cascading failures. Their proprietary electrolyte formulations enable operation in extreme temperature ranges (-10°C to 60°C) without significant performance degradation. The company's battery packs incorporate smart power management that dynamically adjusts output based on riding conditions, terrain analysis, and user preferences, extending range by up to 15% compared to fixed-output systems. Panasonic has also developed quick-swap battery architectures that allow depleted packs to be exchanged in under 10 seconds, addressing range anxiety for commercial delivery applications and bike-sharing programs.

Strengths: Exceptional reliability and safety record; wide operating temperature range making them suitable for diverse climates; industry-leading energy efficiency and power management. Weaknesses: Cylindrical cell format results in slightly lower volumetric efficiency compared to pouch cell designs; higher initial manufacturing complexity leading to increased production costs; heavier than some competing solutions.

Key Innovations in E-Bike Battery Technology

Battery pack

PatentPendingUS20240145815A1

Innovation

- A battery pack design featuring a metal tubular heat-dissipating case with internally protruding heat-absorbing fins that absorb and dissipate thermal energy efficiently, guiding ejected matter through ducts to prevent further thermal runaway and ensure safe discharge.

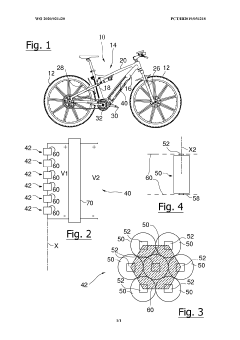

Battery pack for an electric bicycle

PatentWO2020021420A1

Innovation

- A modular battery pack design with K voltage generation modules arranged orthogonally along an axis, each comprising N batteries connected in parallel, with a voltage boosting circuit to achieve a standard output voltage, reducing bulk and weight while enhancing aerodynamics and rider comfort.

Safety Standards and Regulatory Compliance

The regulatory landscape for e-bike battery packs varies significantly across global markets, with standards focusing primarily on electrical safety, thermal management, and environmental protection. In the United States, UL 2271 and UL 2849 serve as the primary safety standards for light electric vehicle batteries, establishing requirements for cell construction, battery management systems, and thermal runaway prevention. The European Union enforces more stringent regulations through EN 50604-1 and the broader UN 38.3 transportation safety requirements, which mandate extensive testing protocols including altitude simulation, thermal cycling, and mechanical shock resistance.

Asian markets, particularly China and Japan, have developed their own comprehensive regulatory frameworks. China's GB/T 36972-2018 specifically addresses e-bike battery safety, while Japan's JIS C8714 focuses on lithium-ion battery performance and safety characteristics. These standards collectively emphasize protection against overcharging, short circuits, and physical damage—critical factors in preventing catastrophic battery failures.

Ingress protection (IP) ratings represent another crucial compliance aspect for e-bike applications. Most commercial e-bike batteries require a minimum IP65 rating, ensuring protection against dust and water jets from any direction. Premium designs often achieve IP67 certification, allowing temporary immersion in water—a significant advantage for all-weather commuting applications.

Battery Management System (BMS) certification requirements have become increasingly stringent, with regulations now mandating sophisticated cell balancing, temperature monitoring across multiple points, and redundant safety mechanisms. These systems must demonstrate fail-safe operation under various abuse conditions, including overcharge, over-discharge, and external short circuit scenarios.

Transportation regulations present additional compliance challenges for battery pack designers. UN 38.3 certification is universally required for air shipment, while regional variations in dangerous goods classification affect road and sea transport. The International Air Transport Association (IATA) has established specific packaging, labeling, and documentation requirements for lithium batteries, limiting state-of-charge during transport to reduce fire risks.

End-of-life considerations have gained regulatory importance, particularly in Europe where the Battery Directive 2006/66/EC mandates collection and recycling programs. Emerging regulations increasingly focus on design for disassembly, material recovery rates, and documentation of critical raw materials. Battery pack designs incorporating easily separable components and standardized cell formats demonstrate advantages in regulatory compliance and sustainability metrics.

Asian markets, particularly China and Japan, have developed their own comprehensive regulatory frameworks. China's GB/T 36972-2018 specifically addresses e-bike battery safety, while Japan's JIS C8714 focuses on lithium-ion battery performance and safety characteristics. These standards collectively emphasize protection against overcharging, short circuits, and physical damage—critical factors in preventing catastrophic battery failures.

Ingress protection (IP) ratings represent another crucial compliance aspect for e-bike applications. Most commercial e-bike batteries require a minimum IP65 rating, ensuring protection against dust and water jets from any direction. Premium designs often achieve IP67 certification, allowing temporary immersion in water—a significant advantage for all-weather commuting applications.

Battery Management System (BMS) certification requirements have become increasingly stringent, with regulations now mandating sophisticated cell balancing, temperature monitoring across multiple points, and redundant safety mechanisms. These systems must demonstrate fail-safe operation under various abuse conditions, including overcharge, over-discharge, and external short circuit scenarios.

Transportation regulations present additional compliance challenges for battery pack designers. UN 38.3 certification is universally required for air shipment, while regional variations in dangerous goods classification affect road and sea transport. The International Air Transport Association (IATA) has established specific packaging, labeling, and documentation requirements for lithium batteries, limiting state-of-charge during transport to reduce fire risks.

End-of-life considerations have gained regulatory importance, particularly in Europe where the Battery Directive 2006/66/EC mandates collection and recycling programs. Emerging regulations increasingly focus on design for disassembly, material recovery rates, and documentation of critical raw materials. Battery pack designs incorporating easily separable components and standardized cell formats demonstrate advantages in regulatory compliance and sustainability metrics.

Environmental Impact and Sustainability Considerations

The environmental footprint of e-bike battery packs represents a critical consideration in their design and lifecycle management. Battery manufacturing processes involve resource extraction and energy-intensive production methods that generate significant carbon emissions. Lithium-ion batteries, the predominant technology in e-bike applications, require materials like lithium, cobalt, and nickel, which are often mined using environmentally disruptive practices in ecologically sensitive regions. The extraction of these materials can lead to habitat destruction, water pollution, and soil degradation in mining areas.

Energy consumption during battery production constitutes another substantial environmental concern. The carbon footprint of manufacturing a typical e-bike battery pack ranges from 50-150 kg CO2 equivalent, depending on production methods and energy sources. Manufacturers implementing renewable energy in production facilities can reduce this impact by 30-40%, highlighting the importance of green manufacturing practices in the battery industry.

Battery lifespan directly influences sustainability metrics, with longer-lasting designs significantly reducing waste generation and resource consumption. Advanced battery management systems that optimize charging cycles and temperature control can extend operational life by 20-30%, thereby improving the overall environmental profile of e-bike battery packs. The difference between a battery lasting 500 cycles versus 1,000 cycles effectively halves the environmental impact per kilometer traveled.

End-of-life management presents both challenges and opportunities for sustainability. Currently, less than 5% of lithium-ion batteries globally undergo proper recycling processes. However, emerging recycling technologies demonstrate promising recovery rates: up to 95% for cobalt, 96% for lithium, and 98% for nickel. Designing battery packs with disassembly and material recovery in mind can significantly enhance recyclability and reduce waste.

Regulatory frameworks increasingly influence battery design considerations. The European Union's proposed Battery Regulation mandates carbon footprint declarations, minimum recycled content requirements, and extended producer responsibility. Similar regulations are emerging in North America and Asia, creating a global shift toward more sustainable battery technologies. Battery pack designs that anticipate these regulatory trends gain competitive advantages in international markets.

Comparative lifecycle assessments reveal that despite manufacturing impacts, e-bikes with properly designed battery systems offer substantial environmental benefits over their operational lifetime. An e-bike typically produces 2-5g CO2/km compared to 120-180g CO2/km for conventional automobiles. This represents a 96-98% reduction in operational emissions, offsetting initial manufacturing impacts within 6-18 months of regular use.

Energy consumption during battery production constitutes another substantial environmental concern. The carbon footprint of manufacturing a typical e-bike battery pack ranges from 50-150 kg CO2 equivalent, depending on production methods and energy sources. Manufacturers implementing renewable energy in production facilities can reduce this impact by 30-40%, highlighting the importance of green manufacturing practices in the battery industry.

Battery lifespan directly influences sustainability metrics, with longer-lasting designs significantly reducing waste generation and resource consumption. Advanced battery management systems that optimize charging cycles and temperature control can extend operational life by 20-30%, thereby improving the overall environmental profile of e-bike battery packs. The difference between a battery lasting 500 cycles versus 1,000 cycles effectively halves the environmental impact per kilometer traveled.

End-of-life management presents both challenges and opportunities for sustainability. Currently, less than 5% of lithium-ion batteries globally undergo proper recycling processes. However, emerging recycling technologies demonstrate promising recovery rates: up to 95% for cobalt, 96% for lithium, and 98% for nickel. Designing battery packs with disassembly and material recovery in mind can significantly enhance recyclability and reduce waste.

Regulatory frameworks increasingly influence battery design considerations. The European Union's proposed Battery Regulation mandates carbon footprint declarations, minimum recycled content requirements, and extended producer responsibility. Similar regulations are emerging in North America and Asia, creating a global shift toward more sustainable battery technologies. Battery pack designs that anticipate these regulatory trends gain competitive advantages in international markets.

Comparative lifecycle assessments reveal that despite manufacturing impacts, e-bikes with properly designed battery systems offer substantial environmental benefits over their operational lifetime. An e-bike typically produces 2-5g CO2/km compared to 120-180g CO2/km for conventional automobiles. This represents a 96-98% reduction in operational emissions, offsetting initial manufacturing impacts within 6-18 months of regular use.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!