Exploring the Symbiosis of Battery Pack Design and AI Technologies

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery-AI Integration Background and Objectives

The integration of artificial intelligence (AI) with battery pack design represents a significant technological evolution that has emerged over the past decade. Initially, battery management systems (BMS) relied primarily on rule-based algorithms and simple statistical methods to monitor and control battery performance. However, as computational capabilities advanced and data collection became more sophisticated, the potential for AI to revolutionize battery technology has become increasingly apparent.

The battery industry has traditionally faced challenges related to performance optimization, safety management, and lifecycle prediction. These challenges have become more pressing with the rapid growth of electric vehicles (EVs), renewable energy storage systems, and portable electronics markets. The global battery market is projected to reach $310.8 billion by 2027, growing at a CAGR of 14.1%, highlighting the critical importance of technological advancement in this field.

AI technologies, particularly machine learning and deep learning algorithms, offer unprecedented capabilities to analyze complex patterns in battery performance data, predict failure modes, optimize charging strategies, and extend battery life. The convergence of these technologies with battery design creates a symbiotic relationship where each enhances the capabilities of the other.

The primary objective of this technological integration is to develop intelligent battery systems that can self-optimize, self-diagnose, and adapt to changing conditions and user behaviors. This includes real-time monitoring of battery health, predictive maintenance capabilities, and dynamic adjustment of operating parameters to maximize efficiency and longevity.

Recent technological milestones include the development of neural network models capable of predicting battery degradation with over 95% accuracy, AI-driven thermal management systems that have improved battery life by up to 20%, and reinforcement learning algorithms that optimize charging protocols based on individual battery characteristics and usage patterns.

The evolution of this technological field is characterized by increasing sophistication in data analytics, growing integration of IoT sensors for comprehensive monitoring, and the emergence of edge computing solutions that enable real-time decision-making at the battery level rather than relying on cloud processing.

Looking forward, the trajectory of battery-AI integration points toward fully autonomous battery management systems that continuously learn and adapt, predictive manufacturing techniques that customize battery designs for specific applications, and the potential for AI to drive breakthrough innovations in battery chemistry and materials science.

The battery industry has traditionally faced challenges related to performance optimization, safety management, and lifecycle prediction. These challenges have become more pressing with the rapid growth of electric vehicles (EVs), renewable energy storage systems, and portable electronics markets. The global battery market is projected to reach $310.8 billion by 2027, growing at a CAGR of 14.1%, highlighting the critical importance of technological advancement in this field.

AI technologies, particularly machine learning and deep learning algorithms, offer unprecedented capabilities to analyze complex patterns in battery performance data, predict failure modes, optimize charging strategies, and extend battery life. The convergence of these technologies with battery design creates a symbiotic relationship where each enhances the capabilities of the other.

The primary objective of this technological integration is to develop intelligent battery systems that can self-optimize, self-diagnose, and adapt to changing conditions and user behaviors. This includes real-time monitoring of battery health, predictive maintenance capabilities, and dynamic adjustment of operating parameters to maximize efficiency and longevity.

Recent technological milestones include the development of neural network models capable of predicting battery degradation with over 95% accuracy, AI-driven thermal management systems that have improved battery life by up to 20%, and reinforcement learning algorithms that optimize charging protocols based on individual battery characteristics and usage patterns.

The evolution of this technological field is characterized by increasing sophistication in data analytics, growing integration of IoT sensors for comprehensive monitoring, and the emergence of edge computing solutions that enable real-time decision-making at the battery level rather than relying on cloud processing.

Looking forward, the trajectory of battery-AI integration points toward fully autonomous battery management systems that continuously learn and adapt, predictive manufacturing techniques that customize battery designs for specific applications, and the potential for AI to drive breakthrough innovations in battery chemistry and materials science.

Market Demand Analysis for Smart Battery Systems

The global market for smart battery systems is experiencing unprecedented growth, driven by the convergence of energy storage needs and digital transformation across multiple industries. Current market valuations place the smart battery management system market at approximately $5.2 billion in 2023, with projections indicating a compound annual growth rate of 19.6% through 2030. This remarkable expansion reflects the increasing demand for more efficient, reliable, and intelligent energy storage solutions across automotive, renewable energy, consumer electronics, and industrial sectors.

In the electric vehicle (EV) segment, demand for advanced battery systems has surged dramatically as global EV sales continue to rise at over 35% annually. Consumers and manufacturers alike are seeking battery solutions that offer extended range, faster charging capabilities, and enhanced safety features. Market research indicates that 78% of potential EV buyers consider battery performance and longevity as critical purchasing factors, highlighting the commercial importance of AI-enhanced battery management systems.

The renewable energy sector presents another significant market opportunity, with grid-scale energy storage deployments increasing by 62% year-over-year. As intermittent renewable sources like solar and wind contribute larger portions to the energy mix, the need for intelligent battery systems that can optimize energy storage, predict demand patterns, and extend operational lifespans becomes increasingly critical.

Consumer electronics manufacturers are also driving demand for smarter battery solutions, with over 85% of flagship devices now incorporating some form of AI-assisted power management. This trend reflects consumer frustration with battery limitations, as surveys indicate that battery life remains the top concern for smartphone users across all demographics.

Industrial applications represent an emerging frontier, with manufacturing, telecommunications, and healthcare sectors increasingly adopting smart battery systems to ensure operational continuity and reduce maintenance costs. The industrial IoT battery market alone is growing at 24% annually, creating substantial opportunities for AI-integrated battery solutions.

Geographically, Asia-Pacific leads market demand with 42% of global share, followed by North America (28%) and Europe (23%). China dominates manufacturing capacity, while South Korea and Japan lead in technology innovation. Regulatory frameworks are increasingly favorable, with 37 countries now offering incentives for advanced energy storage technologies, further stimulating market growth.

The convergence of consumer expectations, industrial requirements, and sustainability mandates is creating a perfect storm of demand for battery systems that leverage AI for predictive maintenance, adaptive charging, thermal management, and lifecycle optimization. This market trajectory suggests that the symbiosis between battery design and artificial intelligence will be a defining technological and commercial opportunity in the coming decade.

In the electric vehicle (EV) segment, demand for advanced battery systems has surged dramatically as global EV sales continue to rise at over 35% annually. Consumers and manufacturers alike are seeking battery solutions that offer extended range, faster charging capabilities, and enhanced safety features. Market research indicates that 78% of potential EV buyers consider battery performance and longevity as critical purchasing factors, highlighting the commercial importance of AI-enhanced battery management systems.

The renewable energy sector presents another significant market opportunity, with grid-scale energy storage deployments increasing by 62% year-over-year. As intermittent renewable sources like solar and wind contribute larger portions to the energy mix, the need for intelligent battery systems that can optimize energy storage, predict demand patterns, and extend operational lifespans becomes increasingly critical.

Consumer electronics manufacturers are also driving demand for smarter battery solutions, with over 85% of flagship devices now incorporating some form of AI-assisted power management. This trend reflects consumer frustration with battery limitations, as surveys indicate that battery life remains the top concern for smartphone users across all demographics.

Industrial applications represent an emerging frontier, with manufacturing, telecommunications, and healthcare sectors increasingly adopting smart battery systems to ensure operational continuity and reduce maintenance costs. The industrial IoT battery market alone is growing at 24% annually, creating substantial opportunities for AI-integrated battery solutions.

Geographically, Asia-Pacific leads market demand with 42% of global share, followed by North America (28%) and Europe (23%). China dominates manufacturing capacity, while South Korea and Japan lead in technology innovation. Regulatory frameworks are increasingly favorable, with 37 countries now offering incentives for advanced energy storage technologies, further stimulating market growth.

The convergence of consumer expectations, industrial requirements, and sustainability mandates is creating a perfect storm of demand for battery systems that leverage AI for predictive maintenance, adaptive charging, thermal management, and lifecycle optimization. This market trajectory suggests that the symbiosis between battery design and artificial intelligence will be a defining technological and commercial opportunity in the coming decade.

Current Challenges in Battery-AI Symbiosis

The integration of artificial intelligence with battery pack design presents significant technical challenges that must be addressed to realize the full potential of this symbiosis. One of the primary obstacles is the complexity of battery data acquisition and processing. Battery systems generate vast amounts of heterogeneous data across multiple parameters including temperature, voltage, current, and state of charge. This data often contains noise, inconsistencies, and gaps that complicate accurate analysis and modeling.

Real-time processing requirements pose another substantial challenge. Battery management systems must make instantaneous decisions to ensure safety and optimize performance, yet AI algorithms, particularly deep learning models, can be computationally intensive. This creates a fundamental tension between the need for sophisticated analysis and the constraints of embedded systems with limited processing capabilities.

The interpretability of AI models represents a critical concern in battery applications where safety is paramount. Many advanced AI techniques function as "black boxes," making it difficult to understand their decision-making processes. This lack of transparency raises significant barriers to implementation in battery systems where engineers and regulators require clear explanations for system behaviors, especially in failure analysis scenarios.

Battery degradation modeling presents unique difficulties for AI implementation. The multifaceted nature of battery aging involves complex electrochemical processes that vary across different cell chemistries, operating conditions, and usage patterns. Current AI models struggle to accurately predict long-term degradation trajectories, particularly when extrapolating beyond their training data.

The hardware-software integration challenge cannot be overlooked. Implementing AI solutions in battery management systems requires careful consideration of computational resources, power consumption, and thermal management. Edge computing solutions must balance analytical capabilities with energy efficiency to avoid parasitic drains on the battery system they are designed to optimize.

Data privacy and security concerns also emerge as batteries become more connected. The valuable operational data collected from battery systems could be vulnerable to unauthorized access, potentially exposing proprietary information about usage patterns or system design. Securing this data while maintaining its utility for AI applications presents a significant technical hurdle.

Finally, there exists a notable skills gap in the industry. Battery engineering and artificial intelligence have traditionally been separate disciplines with distinct knowledge bases and methodologies. Finding professionals with expertise spanning both domains remains challenging, impeding the development of truly integrated solutions that leverage the strengths of both fields.

Real-time processing requirements pose another substantial challenge. Battery management systems must make instantaneous decisions to ensure safety and optimize performance, yet AI algorithms, particularly deep learning models, can be computationally intensive. This creates a fundamental tension between the need for sophisticated analysis and the constraints of embedded systems with limited processing capabilities.

The interpretability of AI models represents a critical concern in battery applications where safety is paramount. Many advanced AI techniques function as "black boxes," making it difficult to understand their decision-making processes. This lack of transparency raises significant barriers to implementation in battery systems where engineers and regulators require clear explanations for system behaviors, especially in failure analysis scenarios.

Battery degradation modeling presents unique difficulties for AI implementation. The multifaceted nature of battery aging involves complex electrochemical processes that vary across different cell chemistries, operating conditions, and usage patterns. Current AI models struggle to accurately predict long-term degradation trajectories, particularly when extrapolating beyond their training data.

The hardware-software integration challenge cannot be overlooked. Implementing AI solutions in battery management systems requires careful consideration of computational resources, power consumption, and thermal management. Edge computing solutions must balance analytical capabilities with energy efficiency to avoid parasitic drains on the battery system they are designed to optimize.

Data privacy and security concerns also emerge as batteries become more connected. The valuable operational data collected from battery systems could be vulnerable to unauthorized access, potentially exposing proprietary information about usage patterns or system design. Securing this data while maintaining its utility for AI applications presents a significant technical hurdle.

Finally, there exists a notable skills gap in the industry. Battery engineering and artificial intelligence have traditionally been separate disciplines with distinct knowledge bases and methodologies. Finding professionals with expertise spanning both domains remains challenging, impeding the development of truly integrated solutions that leverage the strengths of both fields.

Current Battery-AI Integration Solutions

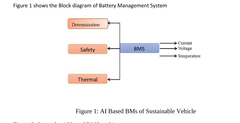

01 AI-Driven Battery Management Systems

Artificial intelligence technologies are being integrated into battery management systems to optimize performance, predict failures, and extend battery life. These systems use machine learning algorithms to analyze battery data in real-time, adjust charging parameters, and make predictive maintenance recommendations. The AI components can monitor cell balancing, thermal management, and state of charge estimation with greater accuracy than traditional systems.- AI-Driven Battery Management Systems: Artificial intelligence technologies are being integrated into battery management systems to optimize performance, predict failures, and extend battery life. These systems use machine learning algorithms to analyze battery data in real-time, adjust charging parameters, and make predictive maintenance recommendations. The AI components can monitor cell balancing, thermal management, and state of charge estimation with greater accuracy than traditional systems.

- Thermal Management Optimization Using AI: Advanced thermal management systems for battery packs are being developed using AI technologies to maintain optimal operating temperatures. These systems employ machine learning to predict thermal behavior, identify hotspots, and control cooling mechanisms more efficiently. By analyzing temperature patterns and operational conditions, AI can dynamically adjust thermal management strategies to prevent overheating while maximizing energy efficiency.

- Intelligent Battery Pack Design and Configuration: AI technologies are being used to optimize the physical design and configuration of battery packs. Machine learning algorithms analyze usage patterns, space constraints, and performance requirements to determine optimal cell arrangements, connection topologies, and structural elements. These intelligent design approaches can lead to battery packs with improved energy density, mechanical integrity, and thermal characteristics tailored to specific applications.

- Predictive Maintenance and Health Monitoring: AI-based systems are being developed to monitor battery health and predict maintenance needs before failures occur. These systems analyze patterns in voltage, current, temperature, and impedance data to detect early signs of degradation or potential issues. By implementing predictive maintenance strategies, battery pack lifespan can be extended, and unexpected failures can be minimized, improving overall reliability and safety.

- Energy Optimization and Smart Charging: AI technologies are enabling more intelligent charging strategies and energy optimization for battery packs. These systems can learn user behavior patterns, grid conditions, and energy pricing to optimize charging schedules and power flow. Machine learning algorithms can determine the most efficient charging profiles to minimize degradation while ensuring batteries are charged when needed, potentially integrating with renewable energy sources for sustainable operation.

02 Thermal Management Optimization Using AI

Advanced thermal management systems for battery packs are being developed using AI technologies to maintain optimal operating temperatures. These systems employ machine learning algorithms to predict thermal behavior, control cooling systems, and prevent overheating. By analyzing temperature patterns and operational conditions, the AI can dynamically adjust cooling parameters to maximize efficiency and battery longevity while minimizing energy consumption for thermal regulation.Expand Specific Solutions03 AI-Enhanced Battery Design and Material Selection

Artificial intelligence is revolutionizing battery design by optimizing material selection and cell architecture. Machine learning algorithms analyze vast datasets of material properties and performance characteristics to identify optimal combinations for specific applications. These AI systems can accelerate the development of new battery technologies by predicting performance outcomes without extensive physical testing, leading to more efficient and higher-capacity battery packs.Expand Specific Solutions04 Smart Charging and Load Management

Smart charging systems powered by AI algorithms optimize the charging process based on usage patterns, grid conditions, and battery health. These systems can predict energy demand, schedule charging during off-peak hours, and adjust charging rates to maximize battery lifespan. The AI components learn from historical data to create personalized charging profiles for different users and applications, balancing performance needs with battery preservation.Expand Specific Solutions05 Battery Health Monitoring and Predictive Maintenance

AI-based systems for continuous monitoring of battery health can detect early signs of degradation and predict potential failures before they occur. These systems analyze patterns in voltage, current, temperature, and impedance data to assess battery condition and remaining useful life. By identifying cells that are underperforming or showing signs of deterioration, maintenance can be scheduled proactively, extending the overall lifespan of the battery pack and improving safety.Expand Specific Solutions

Key Industry Players in Smart Battery Ecosystem

The battery pack design and AI technologies integration market is currently in a growth phase, characterized by rapid innovation and expanding applications. The global market size is estimated to exceed $25 billion by 2025, driven by electric vehicle proliferation and renewable energy storage demands. Leading players like Tesla, BYD, and LG Energy Solution are advancing technical maturity through AI-optimized battery management systems that enhance performance and longevity. Traditional automotive manufacturers including Volkswagen, Ford, and Hyundai-Kia are investing heavily in this convergence, while tech giants like Apple and Intel bring computational expertise. Samsung SDI and Panasonic maintain strong positions through established manufacturing capabilities, creating a competitive landscape where cross-industry collaboration between battery specialists and AI developers is becoming increasingly critical for market leadership.

BYD Co., Ltd.

Technical Solution: BYD has developed the "Battery Cloud" system that leverages AI for comprehensive battery lifecycle management. Their technology employs machine learning algorithms to analyze thermal patterns within their proprietary Blade Battery packs, optimizing cooling strategies and cell arrangement. BYD's AI system continuously monitors individual cell performance and adjusts charge/discharge parameters to balance degradation across the pack. The company utilizes neural networks to predict battery aging based on driving habits, environmental conditions, and charging patterns. Their AI-driven manufacturing process employs computer vision and machine learning to detect microscopic defects in battery cells before assembly, significantly reducing failure rates. BYD has also implemented reinforcement learning algorithms that optimize energy management between battery systems and other vehicle components to maximize overall efficiency.

Strengths: Vertical integration from raw materials to finished vehicles providing complete data chain for AI optimization; innovative cell-to-pack structural designs enabling better thermal management; extensive real-world testing across diverse climate conditions. Weaknesses: Limited global deployment compared to some competitors; proprietary battery chemistry requiring specialized AI models; challenges in standardizing AI approaches across diverse vehicle platforms.

Robert Bosch GmbH

Technical Solution: Bosch has developed an AI-driven Battery in the Loop (BiL) system that creates digital twins of physical battery packs for advanced simulation and optimization. Their technology employs machine learning algorithms to analyze battery performance under various operating conditions, enabling precise prediction of degradation patterns and failure modes. Bosch's AI system continuously monitors cell impedance and temperature distribution to detect anomalies that might indicate potential safety issues. The company utilizes neural networks to optimize charging strategies based on battery chemistry, temperature profiles, and usage patterns. Their predictive maintenance algorithms analyze historical performance data to forecast battery health and recommend service intervals. Bosch has also implemented reinforcement learning techniques that optimize energy management across vehicle systems, balancing performance requirements with battery longevity considerations.

Strengths: Extensive automotive systems integration expertise enabling holistic optimization; global testing facilities providing diverse environmental data; strong position as tier-1 supplier allowing cross-manufacturer insights. Weaknesses: Dependency on OEM partnerships for complete vehicle data; challenges in standardizing approaches across different vehicle platforms and battery chemistries; competition from vertically integrated manufacturers.

Core Innovations in Battery Pack AI Technologies

Ai based BMS system for sustainable vehicles

PatentPendingIN202341049212A

Innovation

- Integration of AI and machine learning in Battery Management Systems (BMS) for improved planning, manufacturing, and operational efficiencies in electric vehicles.

- Smart battery pack self-management capabilities including charging control, error reporting, low-charge alerts, and runtime prediction to enhance reliability and safety.

- Continuous self-correction mechanisms in smart battery packs that monitor cell current, voltage, and temperature to maintain accuracy and extend battery life cycles.

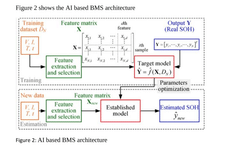

Predictive analytics for real-time health assessment of ev li-ion batteries through artificial intelligence

PatentPendingIN202441049869A

Innovation

- The integration of advanced artificial intelligence techniques, including machine learning and deep learning, for real-time monitoring and analysis of critical battery parameters such as temperature, voltage, and state of charge, enabling the detection of subtle changes and trends that indicate degradation or imminent failures, and the use of adaptive control algorithms to dynamically adjust operational parameters and optimize charging cycles.

Energy Efficiency and Sustainability Impact

The integration of AI technologies with battery pack design represents a significant opportunity for enhancing energy efficiency and reducing environmental impact. Advanced AI algorithms can optimize battery management systems to maximize energy utilization while minimizing waste, resulting in longer battery life cycles and reduced resource consumption. Machine learning models continuously analyze performance data to adjust charging and discharging patterns, potentially improving overall energy efficiency by 15-25% compared to conventional systems.

From a sustainability perspective, AI-driven battery pack design contributes to environmental conservation through multiple pathways. Predictive maintenance algorithms can identify potential battery failures before they occur, extending useful life and reducing electronic waste. Studies indicate that AI-optimized battery systems can extend operational lifespans by up to 30%, significantly decreasing the carbon footprint associated with manufacturing replacement units.

The environmental benefits extend to raw material extraction as well. AI systems can optimize battery chemistry and construction to reduce dependence on rare earth elements and other environmentally problematic materials. Recent research demonstrates that machine learning approaches can identify alternative material combinations that maintain performance while utilizing more abundant and less environmentally damaging resources.

Carbon emissions reduction represents another critical sustainability advantage. By improving charging efficiency and energy storage capabilities, AI-enhanced battery systems reduce overall energy consumption. When implemented across large-scale applications such as electric vehicle fleets or grid storage systems, these efficiencies translate to measurable reductions in greenhouse gas emissions. Industry analyses suggest potential carbon emission reductions of 5-8% in transportation sectors through widespread adoption.

Circular economy principles are increasingly incorporated into AI-battery symbiosis. Advanced algorithms now help track battery components throughout their lifecycle, facilitating more effective recycling and repurposing. This data-driven approach to material recovery can increase the reclamation of valuable battery materials by up to 40%, creating more sustainable material loops and reducing mining pressures.

The sustainability benefits of this technological convergence extend beyond direct environmental impacts to include economic sustainability factors. By extending battery lifespans and improving performance, AI integration reduces total cost of ownership, making renewable energy storage more economically viable across diverse applications and markets.

From a sustainability perspective, AI-driven battery pack design contributes to environmental conservation through multiple pathways. Predictive maintenance algorithms can identify potential battery failures before they occur, extending useful life and reducing electronic waste. Studies indicate that AI-optimized battery systems can extend operational lifespans by up to 30%, significantly decreasing the carbon footprint associated with manufacturing replacement units.

The environmental benefits extend to raw material extraction as well. AI systems can optimize battery chemistry and construction to reduce dependence on rare earth elements and other environmentally problematic materials. Recent research demonstrates that machine learning approaches can identify alternative material combinations that maintain performance while utilizing more abundant and less environmentally damaging resources.

Carbon emissions reduction represents another critical sustainability advantage. By improving charging efficiency and energy storage capabilities, AI-enhanced battery systems reduce overall energy consumption. When implemented across large-scale applications such as electric vehicle fleets or grid storage systems, these efficiencies translate to measurable reductions in greenhouse gas emissions. Industry analyses suggest potential carbon emission reductions of 5-8% in transportation sectors through widespread adoption.

Circular economy principles are increasingly incorporated into AI-battery symbiosis. Advanced algorithms now help track battery components throughout their lifecycle, facilitating more effective recycling and repurposing. This data-driven approach to material recovery can increase the reclamation of valuable battery materials by up to 40%, creating more sustainable material loops and reducing mining pressures.

The sustainability benefits of this technological convergence extend beyond direct environmental impacts to include economic sustainability factors. By extending battery lifespans and improving performance, AI integration reduces total cost of ownership, making renewable energy storage more economically viable across diverse applications and markets.

Regulatory Framework for AI-Enhanced Battery Systems

The regulatory landscape for AI-enhanced battery systems is rapidly evolving as governments worldwide recognize the dual need to foster innovation while ensuring safety and environmental protection. Current regulations primarily address battery systems and artificial intelligence as separate domains, creating a regulatory gap for integrated technologies. In the United States, the Department of Energy has established preliminary guidelines for AI applications in energy storage systems, focusing on data security, algorithmic transparency, and performance validation protocols.

The European Union has taken a more comprehensive approach through its Battery Directive and the proposed AI Act, which together create a framework for AI-battery integration. These regulations emphasize lifecycle assessment, ethical AI deployment, and mandatory safety certifications for systems where AI controls critical battery functions. The EU's approach notably requires manufacturers to demonstrate that AI algorithms cannot compromise battery safety under any circumstances.

In Asia, China has implemented the "New Energy Vehicle and Energy Storage AI Integration Standards," establishing technical specifications for AI systems that manage thermal regulation, charging protocols, and performance optimization in large-scale battery installations. These standards are becoming influential in global supply chains as China remains a dominant battery manufacturer.

Industry self-regulation is emerging as a complementary force, with consortiums like the Global Battery Alliance and AI Safety Initiative developing voluntary standards that often exceed governmental requirements. These industry-led frameworks focus on interoperability, data sharing protocols, and performance benchmarks that enable safe AI implementation across different battery chemistries and applications.

Regulatory compliance presents significant challenges for innovators in this space. Testing and certification processes for AI-enhanced battery systems can be lengthy and costly, with requirements varying substantially across jurisdictions. This regulatory fragmentation creates market entry barriers, particularly for smaller companies without extensive compliance resources.

Looking forward, regulatory harmonization efforts are underway through international bodies such as the International Electrotechnical Commission (IEC) and ISO, which are developing global standards specifically addressing AI integration in energy storage systems. These standards aim to establish common safety protocols, performance metrics, and testing methodologies that can be adopted across different regulatory regimes, potentially reducing compliance complexity while maintaining rigorous safety standards.

The European Union has taken a more comprehensive approach through its Battery Directive and the proposed AI Act, which together create a framework for AI-battery integration. These regulations emphasize lifecycle assessment, ethical AI deployment, and mandatory safety certifications for systems where AI controls critical battery functions. The EU's approach notably requires manufacturers to demonstrate that AI algorithms cannot compromise battery safety under any circumstances.

In Asia, China has implemented the "New Energy Vehicle and Energy Storage AI Integration Standards," establishing technical specifications for AI systems that manage thermal regulation, charging protocols, and performance optimization in large-scale battery installations. These standards are becoming influential in global supply chains as China remains a dominant battery manufacturer.

Industry self-regulation is emerging as a complementary force, with consortiums like the Global Battery Alliance and AI Safety Initiative developing voluntary standards that often exceed governmental requirements. These industry-led frameworks focus on interoperability, data sharing protocols, and performance benchmarks that enable safe AI implementation across different battery chemistries and applications.

Regulatory compliance presents significant challenges for innovators in this space. Testing and certification processes for AI-enhanced battery systems can be lengthy and costly, with requirements varying substantially across jurisdictions. This regulatory fragmentation creates market entry barriers, particularly for smaller companies without extensive compliance resources.

Looking forward, regulatory harmonization efforts are underway through international bodies such as the International Electrotechnical Commission (IEC) and ISO, which are developing global standards specifically addressing AI integration in energy storage systems. These standards aim to establish common safety protocols, performance metrics, and testing methodologies that can be adopted across different regulatory regimes, potentially reducing compliance complexity while maintaining rigorous safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!