Battery Pack Design in Hydrogen and Electric Synergy Systems

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen-Electric Battery Pack Technology Background and Objectives

The integration of hydrogen and electric power systems represents a significant evolution in sustainable energy technology, emerging from decades of separate development in both fields. Since the early 2000s, researchers have explored hybrid systems that leverage the complementary strengths of batteries and hydrogen fuel cells, aiming to overcome the limitations inherent in each technology when used independently.

Battery pack design within these synergistic systems has evolved from simple configurations to sophisticated energy management architectures. Initially, these systems featured basic battery packs primarily serving as power buffers for hydrogen fuel cells. The technological trajectory has since advanced toward intelligent, integrated systems where batteries and hydrogen technologies work in concert to optimize energy efficiency, range, and performance.

The primary objective of modern hydrogen-electric battery pack design is to create a seamless energy ecosystem that maximizes the advantages of both technologies. This includes developing battery packs specifically engineered to complement hydrogen fuel cells' operational characteristics, managing power distribution during various load conditions, and enabling energy recovery through regenerative processes.

Current technological goals focus on addressing several critical challenges: reducing system weight while increasing energy density, improving thermal management across both subsystems, extending battery cycle life in hybrid operations, and developing advanced battery chemistries optimized for hydrogen-electric integration. Additionally, there is significant emphasis on creating intelligent energy management systems that can dynamically allocate power demands between batteries and fuel cells based on real-time conditions.

The evolution of these systems is closely tied to advancements in materials science, particularly in electrode materials, electrolytes, and catalysts that can function efficiently in hybrid environments. Recent breakthroughs in solid-state batteries and high-temperature fuel cells have opened new possibilities for more efficient integration.

Looking forward, the technology roadmap for hydrogen-electric battery packs aims to achieve greater system integration, with reduced component count and simplified architectures. This includes the development of unified cooling systems, shared power electronics, and modular designs that can be scaled across different applications from passenger vehicles to heavy-duty transport and stationary power systems.

The convergence of these technologies represents a paradigm shift in how we conceptualize energy storage and conversion, potentially offering solutions that transcend the traditional boundaries between different energy vectors and storage methodologies.

Battery pack design within these synergistic systems has evolved from simple configurations to sophisticated energy management architectures. Initially, these systems featured basic battery packs primarily serving as power buffers for hydrogen fuel cells. The technological trajectory has since advanced toward intelligent, integrated systems where batteries and hydrogen technologies work in concert to optimize energy efficiency, range, and performance.

The primary objective of modern hydrogen-electric battery pack design is to create a seamless energy ecosystem that maximizes the advantages of both technologies. This includes developing battery packs specifically engineered to complement hydrogen fuel cells' operational characteristics, managing power distribution during various load conditions, and enabling energy recovery through regenerative processes.

Current technological goals focus on addressing several critical challenges: reducing system weight while increasing energy density, improving thermal management across both subsystems, extending battery cycle life in hybrid operations, and developing advanced battery chemistries optimized for hydrogen-electric integration. Additionally, there is significant emphasis on creating intelligent energy management systems that can dynamically allocate power demands between batteries and fuel cells based on real-time conditions.

The evolution of these systems is closely tied to advancements in materials science, particularly in electrode materials, electrolytes, and catalysts that can function efficiently in hybrid environments. Recent breakthroughs in solid-state batteries and high-temperature fuel cells have opened new possibilities for more efficient integration.

Looking forward, the technology roadmap for hydrogen-electric battery packs aims to achieve greater system integration, with reduced component count and simplified architectures. This includes the development of unified cooling systems, shared power electronics, and modular designs that can be scaled across different applications from passenger vehicles to heavy-duty transport and stationary power systems.

The convergence of these technologies represents a paradigm shift in how we conceptualize energy storage and conversion, potentially offering solutions that transcend the traditional boundaries between different energy vectors and storage methodologies.

Market Analysis for Hybrid Energy Storage Systems

The hybrid energy storage market is experiencing significant growth driven by the increasing adoption of renewable energy sources and the need for more efficient energy management systems. The global market for hybrid energy storage systems, which combine battery technologies with hydrogen fuel cells, was valued at approximately $1.2 billion in 2022 and is projected to reach $5.4 billion by 2030, representing a compound annual growth rate of 20.7%. This remarkable growth trajectory is primarily fueled by the automotive sector's transition toward cleaner energy solutions and the industrial sector's increasing demand for reliable backup power systems.

In the automotive segment, the integration of battery packs with hydrogen fuel cells presents a compelling value proposition by addressing the limitations of pure electric vehicles, such as range anxiety and lengthy charging times. Market research indicates that consumers are increasingly receptive to hybrid energy solutions that offer the convenience of quick hydrogen refueling combined with the efficiency of battery-electric propulsion. This consumer sentiment is reflected in the 35% year-over-year increase in sales of hydrogen-electric hybrid vehicles in key markets including Japan, South Korea, and parts of Europe.

The industrial and commercial sectors represent another significant market opportunity for hybrid energy storage systems. Large-scale operations such as data centers, manufacturing facilities, and logistics hubs are increasingly exploring hydrogen-electric hybrid solutions to ensure uninterrupted power supply while reducing their carbon footprint. The market penetration in this segment has grown by 28% since 2020, with particularly strong adoption in regions with ambitious decarbonization targets.

Geographically, Asia-Pacific dominates the market with a 42% share, led by substantial investments in hydrogen infrastructure in Japan, South Korea, and China. Europe follows with a 35% market share, driven by stringent emission regulations and government incentives for clean energy technologies. North America accounts for 18% of the market, with growth accelerating due to recent policy shifts favoring hydrogen technologies.

The competitive landscape is characterized by strategic partnerships between traditional battery manufacturers and hydrogen technology developers. These collaborations aim to create integrated solutions that optimize the strengths of both technologies. Market consolidation is expected to continue as companies seek to establish comprehensive offerings that address the full spectrum of energy storage needs.

Customer segmentation reveals three primary buyer groups: automotive manufacturers seeking differentiated powertrain solutions, industrial operations requiring reliable and sustainable backup power, and utility companies looking to enhance grid stability through advanced energy storage. Each segment presents unique requirements and growth opportunities, with the automotive sector currently showing the highest growth potential at 24% annually.

In the automotive segment, the integration of battery packs with hydrogen fuel cells presents a compelling value proposition by addressing the limitations of pure electric vehicles, such as range anxiety and lengthy charging times. Market research indicates that consumers are increasingly receptive to hybrid energy solutions that offer the convenience of quick hydrogen refueling combined with the efficiency of battery-electric propulsion. This consumer sentiment is reflected in the 35% year-over-year increase in sales of hydrogen-electric hybrid vehicles in key markets including Japan, South Korea, and parts of Europe.

The industrial and commercial sectors represent another significant market opportunity for hybrid energy storage systems. Large-scale operations such as data centers, manufacturing facilities, and logistics hubs are increasingly exploring hydrogen-electric hybrid solutions to ensure uninterrupted power supply while reducing their carbon footprint. The market penetration in this segment has grown by 28% since 2020, with particularly strong adoption in regions with ambitious decarbonization targets.

Geographically, Asia-Pacific dominates the market with a 42% share, led by substantial investments in hydrogen infrastructure in Japan, South Korea, and China. Europe follows with a 35% market share, driven by stringent emission regulations and government incentives for clean energy technologies. North America accounts for 18% of the market, with growth accelerating due to recent policy shifts favoring hydrogen technologies.

The competitive landscape is characterized by strategic partnerships between traditional battery manufacturers and hydrogen technology developers. These collaborations aim to create integrated solutions that optimize the strengths of both technologies. Market consolidation is expected to continue as companies seek to establish comprehensive offerings that address the full spectrum of energy storage needs.

Customer segmentation reveals three primary buyer groups: automotive manufacturers seeking differentiated powertrain solutions, industrial operations requiring reliable and sustainable backup power, and utility companies looking to enhance grid stability through advanced energy storage. Each segment presents unique requirements and growth opportunities, with the automotive sector currently showing the highest growth potential at 24% annually.

Current Challenges in Battery-Hydrogen Integration

The integration of battery systems with hydrogen technologies presents significant technical challenges that must be addressed to realize the full potential of hybrid energy systems. One of the primary obstacles is thermal management, as batteries and hydrogen systems operate under different optimal temperature ranges. Lithium-ion batteries typically perform best between 15-35°C, while hydrogen fuel cells may generate considerable heat during operation, potentially reaching temperatures above 80°C. This thermal disparity creates complex engineering challenges for integrated system design, requiring sophisticated cooling systems that can maintain different temperature zones within a compact space.

Weight distribution and spatial optimization represent another critical challenge. Battery packs are inherently dense and heavy, while hydrogen storage systems require specific configurations to safely contain pressurized hydrogen. When designing vehicles or stationary power systems that incorporate both technologies, engineers must carefully balance weight distribution to maintain proper vehicle dynamics or structural integrity, while also optimizing the limited available space to accommodate two fundamentally different energy storage systems.

Control system integration presents significant complexity due to the different response characteristics of batteries and hydrogen systems. Batteries can respond almost instantaneously to power demands but have limited energy capacity, while hydrogen fuel cells offer higher energy density but typically exhibit slower response times. Developing control algorithms that can effectively manage power flow between these two systems, particularly during transient operations like acceleration or rapid load changes, remains technically challenging.

Safety considerations introduce additional design constraints. Batteries present risks of thermal runaway and fire, while hydrogen systems must address concerns related to gas leakage and flammability. Integrating these technologies requires comprehensive safety systems that can monitor and mitigate risks from both technologies simultaneously, often with competing requirements for ventilation, isolation, and emergency response protocols.

Material compatibility issues further complicate integration efforts. The electrochemical environment of batteries can accelerate corrosion in certain materials, while hydrogen embrittlement can compromise structural components. Engineers must carefully select materials that maintain integrity when exposed to both battery electrolytes and hydrogen environments, often requiring compromise between optimal materials for each system individually.

Lifecycle management and system degradation present long-term operational challenges. Batteries and hydrogen systems typically have different operational lifespans and degradation patterns. Batteries may experience capacity fade over thousands of cycles, while fuel cell membranes may degrade through different mechanisms. Designing integrated systems that account for these different aging profiles while maintaining overall system performance throughout the intended service life requires sophisticated predictive modeling and adaptive control strategies.

Weight distribution and spatial optimization represent another critical challenge. Battery packs are inherently dense and heavy, while hydrogen storage systems require specific configurations to safely contain pressurized hydrogen. When designing vehicles or stationary power systems that incorporate both technologies, engineers must carefully balance weight distribution to maintain proper vehicle dynamics or structural integrity, while also optimizing the limited available space to accommodate two fundamentally different energy storage systems.

Control system integration presents significant complexity due to the different response characteristics of batteries and hydrogen systems. Batteries can respond almost instantaneously to power demands but have limited energy capacity, while hydrogen fuel cells offer higher energy density but typically exhibit slower response times. Developing control algorithms that can effectively manage power flow between these two systems, particularly during transient operations like acceleration or rapid load changes, remains technically challenging.

Safety considerations introduce additional design constraints. Batteries present risks of thermal runaway and fire, while hydrogen systems must address concerns related to gas leakage and flammability. Integrating these technologies requires comprehensive safety systems that can monitor and mitigate risks from both technologies simultaneously, often with competing requirements for ventilation, isolation, and emergency response protocols.

Material compatibility issues further complicate integration efforts. The electrochemical environment of batteries can accelerate corrosion in certain materials, while hydrogen embrittlement can compromise structural components. Engineers must carefully select materials that maintain integrity when exposed to both battery electrolytes and hydrogen environments, often requiring compromise between optimal materials for each system individually.

Lifecycle management and system degradation present long-term operational challenges. Batteries and hydrogen systems typically have different operational lifespans and degradation patterns. Batteries may experience capacity fade over thousands of cycles, while fuel cell membranes may degrade through different mechanisms. Designing integrated systems that account for these different aging profiles while maintaining overall system performance throughout the intended service life requires sophisticated predictive modeling and adaptive control strategies.

Current Battery Pack Solutions for Hydrogen Systems

01 Thermal Management Systems for Battery Packs

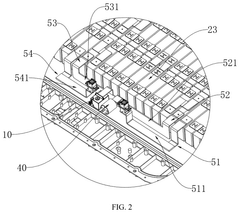

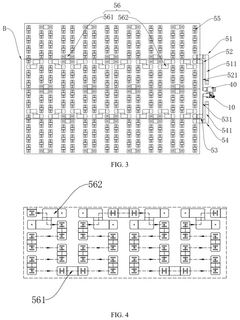

Effective thermal management systems are crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems can include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms that help dissipate heat generated during charging and discharging cycles. Advanced designs incorporate temperature sensors and control algorithms to regulate thermal conditions across the battery pack.- Battery pack thermal management systems: Thermal management is crucial for battery pack design to maintain optimal operating temperatures and prevent overheating. These systems include cooling mechanisms, heat dissipation structures, and temperature monitoring components that work together to ensure battery safety and longevity. Effective thermal management prevents thermal runaway, extends battery life, and maintains consistent performance across various operating conditions.

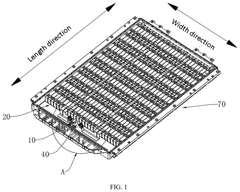

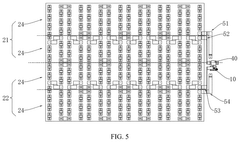

- Battery cell arrangement and connection configurations: The physical arrangement and electrical connection of battery cells within a pack significantly impact its overall performance, safety, and space efficiency. Various configurations include series, parallel, or series-parallel connections to achieve desired voltage and capacity. Innovative cell arrangements can optimize space utilization, improve cooling efficiency, and enhance structural integrity while maintaining electrical performance requirements.

- Battery management systems (BMS) for monitoring and control: Battery management systems are essential components that monitor, control, and protect battery packs. These systems track parameters such as voltage, current, temperature, and state of charge to optimize performance and prevent dangerous conditions. Advanced BMS designs incorporate features like cell balancing, fault detection, and communication interfaces that enable integration with larger systems while ensuring safe operation throughout the battery lifecycle.

- Structural design and mechanical protection: The structural aspects of battery pack design focus on providing mechanical protection, vibration resistance, and impact absorption. These designs incorporate robust housings, shock-absorbing materials, and reinforcement structures to protect cells from physical damage. Considerations include weight optimization, ease of assembly/disassembly for maintenance, and integration methods for various applications while maintaining structural integrity under different environmental conditions.

- Battery pack modular and scalable architectures: Modular battery pack designs allow for scalability, easier maintenance, and customization for different applications. These architectures feature standardized interfaces between modules that can be combined to achieve various capacity and voltage requirements. Modular approaches facilitate easier replacement of faulty components, system upgrades, and adaptation to different space constraints while maintaining consistent performance characteristics across configurations.

02 Structural Design and Mechanical Protection

Battery pack designs incorporate structural elements that provide mechanical protection against physical damage, vibration, and impact. These designs include robust enclosures, shock-absorbing materials, and reinforcement structures that protect the battery cells while maintaining overall pack integrity. The structural components are engineered to balance protection with weight considerations, especially important for applications in electric vehicles and portable electronics.Expand Specific Solutions03 Battery Management Systems (BMS)

Battery Management Systems are integral to modern battery pack designs, monitoring and controlling various parameters such as voltage, current, temperature, and state of charge. These systems help prevent overcharging, over-discharging, and thermal runaway conditions while optimizing battery performance and longevity. Advanced BMS designs incorporate cell balancing techniques, predictive algorithms, and communication interfaces that enable integration with broader power management systems.Expand Specific Solutions04 Cell Arrangement and Interconnection Methods

The arrangement and interconnection of individual battery cells within a pack significantly impact overall performance, safety, and efficiency. Various configurations include series, parallel, or series-parallel arrangements to achieve desired voltage and capacity specifications. Advanced interconnection methods utilize bus bars, flexible circuits, or direct bonding techniques to minimize resistance, improve current distribution, and enhance thermal management while ensuring reliable electrical connections between cells.Expand Specific Solutions05 Safety Features and Failure Mitigation

Modern battery pack designs incorporate multiple safety features to prevent catastrophic failures and mitigate risks. These include pressure relief mechanisms, thermal fuses, current limiters, isolation systems, and fire-resistant materials. Advanced designs implement redundant safety systems, fault detection algorithms, and rapid disconnection mechanisms that can isolate damaged cells or sections to prevent failure propagation throughout the pack.Expand Specific Solutions

Key Industry Players in Hybrid Energy Storage

The battery pack design landscape in hydrogen and electric synergy systems is evolving rapidly, currently in a growth phase with increasing market adoption. The global market is expanding significantly as automotive manufacturers like Hyundai, Kia, and Stellantis integrate hybrid hydrogen-electric solutions. Leading battery technology companies including LG Energy Solution, Samsung SDI, and AESC Japan are advancing technical maturity through innovations in energy density, thermal management, and system integration. Companies like Bosch and Rimac Technology are developing specialized battery management systems that optimize the synergy between hydrogen fuel cells and battery packs. The competitive landscape features established players from traditional automotive sectors collaborating with emerging technology specialists to overcome challenges in weight reduction, safety, and cost-effectiveness for commercial deployment.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a specialized battery pack design for hydrogen-electric hybrid vehicles that features a dual-chemistry approach. Their system combines high-power lithium titanate oxide (LTO) cells for rapid charge/discharge cycles with high-energy nickel-manganese-cobalt (NMC) cells for extended range capability. The battery pack architecture is modular and scalable, allowing for customization based on vehicle size and performance requirements. A distinctive feature is their adaptive thermal management system that uses predictive algorithms to anticipate temperature fluctuations based on driving patterns and environmental conditions. The battery packs incorporate a smart cell balancing system that extends overall battery life by preventing individual cells from overcharging or deep discharging. LG Energy Solution's design also features integrated diagnostics that monitor cell health and predict potential failures before they occur, enhancing system reliability and safety in hybrid hydrogen-electric applications.

Strengths: Dual-chemistry approach optimizes both power and energy requirements; advanced predictive thermal management; sophisticated cell balancing technology; robust diagnostic capabilities. Weaknesses: Higher initial cost due to dual-chemistry design; increased complexity in manufacturing and quality control; requires more sophisticated control algorithms.

Robert Bosch GmbH

Technical Solution: Bosch has developed an integrated battery pack system for hydrogen-electric hybrid applications that focuses on system efficiency and reliability. Their design features a compact, high-voltage battery pack that works in conjunction with hydrogen fuel cells to provide optimal power delivery across various operating conditions. The battery system incorporates Bosch's proprietary cell connection technology that reduces internal resistance and improves overall efficiency. A key innovation is their predictive energy management system that uses route data, traffic information, and topographical details to optimize the power split between battery and hydrogen systems. The battery pack includes a sophisticated thermal management solution with liquid cooling that maintains optimal operating temperatures even under extreme conditions. Bosch's design also features enhanced safety systems including multiple redundant monitoring circuits, isolation detection, and rapid disconnect capabilities in case of collision or system failure. Their battery packs are designed for serviceability, with modular components that can be individually replaced, reducing lifetime maintenance costs.

Strengths: Exceptional system integration capabilities; advanced predictive energy management; robust safety features; designed for serviceability and maintenance. Weaknesses: Less energy-dense compared to some competitors; higher initial system complexity; requires sophisticated vehicle integration.

Core Patents in Hydrogen-Electric Energy Storage

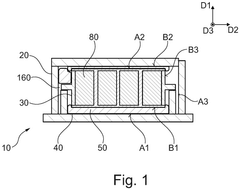

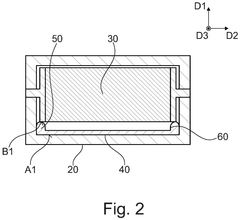

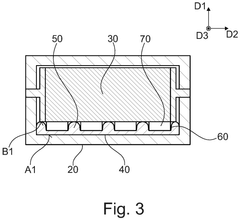

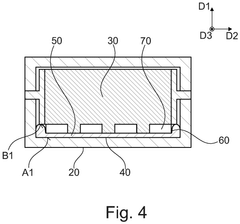

Battery pack with containing member comprising a self-expendable filler material

PatentPendingEP4597713A1

Innovation

- A battery pack design incorporating a self-expandable filler material within a containing member that provides stability and support to battery systems, using a chemical transformation to expand and harden, offering thermal and fire insulation, shock absorption, and ease of replacement without additional fixing, while maintaining structural integrity and reducing noise, vibration, and harshness.

Battery pack and electric apparatus

PatentPendingUS20250219165A1

Innovation

- A battery pack design with a switch device that allows battery cell units to be connected in series or separately, enabling compatibility with multiple charging voltages by controlling the switch device to connect or disconnect the series circuit, and incorporating a power distribution unit for high voltage distribution.

Safety Standards and Certification Requirements

The integration of battery packs in hydrogen and electric synergy systems necessitates adherence to rigorous safety standards and certification requirements. These systems must comply with international standards such as IEC 62619 for secondary lithium-ion cells and batteries for industrial applications, and ISO 6469 for electrically propelled road vehicles. Additionally, UN 38.3 testing requirements for lithium batteries during transportation are mandatory for market access.

For hydrogen components, standards like ISO 19880 for hydrogen fueling stations and ISO 19881/19882 for onboard hydrogen storage must be followed. The European Union's Regulation (EU) 2019/1291 specifically addresses type-approval requirements for hydrogen vehicles, while SAE J2579 provides standards for fuel systems in fuel cell vehicles.

Battery pack designs in these hybrid systems require dual certification paths, addressing both electrical storage and hydrogen safety concerns. This creates a complex regulatory landscape where manufacturers must navigate overlapping requirements from different regulatory bodies. The certification process typically involves third-party testing by organizations like UL, TÜV, or SGS, which verify compliance with thermal runaway protection, electrical isolation, and emergency shutdown capabilities.

Regional variations in certification requirements present significant challenges. While the EU follows ECE R100 for battery electric vehicles and ECE R134 for hydrogen systems, North America relies on FMVSS 305 and NFPA 2 standards. Asian markets, particularly China and Japan, have established their own certification frameworks through GB/T standards and JARI certification processes respectively.

Emerging standards specifically addressing the interface between battery systems and hydrogen components are currently under development by organizations like ISO and IEC. These standards aim to address unique safety concerns in hybrid systems, such as thermal management between components and emergency response protocols for dual-energy storage systems.

Risk assessment methodologies for these hybrid systems must incorporate FMEA (Failure Mode and Effects Analysis) and FTA (Fault Tree Analysis) approaches that consider the interaction between battery packs and hydrogen systems. This includes analysis of potential cascading failures where an incident in one system could trigger failures in the other.

Manufacturers developing battery packs for hydrogen-electric hybrid applications must implement comprehensive safety management systems that address both technologies' requirements while maintaining documentation trails for certification purposes. This often necessitates specialized expertise in both battery and hydrogen safety regulations, creating additional overhead in the development process.

For hydrogen components, standards like ISO 19880 for hydrogen fueling stations and ISO 19881/19882 for onboard hydrogen storage must be followed. The European Union's Regulation (EU) 2019/1291 specifically addresses type-approval requirements for hydrogen vehicles, while SAE J2579 provides standards for fuel systems in fuel cell vehicles.

Battery pack designs in these hybrid systems require dual certification paths, addressing both electrical storage and hydrogen safety concerns. This creates a complex regulatory landscape where manufacturers must navigate overlapping requirements from different regulatory bodies. The certification process typically involves third-party testing by organizations like UL, TÜV, or SGS, which verify compliance with thermal runaway protection, electrical isolation, and emergency shutdown capabilities.

Regional variations in certification requirements present significant challenges. While the EU follows ECE R100 for battery electric vehicles and ECE R134 for hydrogen systems, North America relies on FMVSS 305 and NFPA 2 standards. Asian markets, particularly China and Japan, have established their own certification frameworks through GB/T standards and JARI certification processes respectively.

Emerging standards specifically addressing the interface between battery systems and hydrogen components are currently under development by organizations like ISO and IEC. These standards aim to address unique safety concerns in hybrid systems, such as thermal management between components and emergency response protocols for dual-energy storage systems.

Risk assessment methodologies for these hybrid systems must incorporate FMEA (Failure Mode and Effects Analysis) and FTA (Fault Tree Analysis) approaches that consider the interaction between battery packs and hydrogen systems. This includes analysis of potential cascading failures where an incident in one system could trigger failures in the other.

Manufacturers developing battery packs for hydrogen-electric hybrid applications must implement comprehensive safety management systems that address both technologies' requirements while maintaining documentation trails for certification purposes. This often necessitates specialized expertise in both battery and hydrogen safety regulations, creating additional overhead in the development process.

Environmental Impact and Sustainability Analysis

The integration of battery packs within hydrogen and electric synergy systems presents significant environmental implications that warrant comprehensive analysis. These hybrid systems combine the advantages of both hydrogen fuel cells and electric batteries, potentially offering more sustainable transportation and energy storage solutions compared to conventional single-technology approaches.

Life cycle assessment (LCA) studies indicate that battery-hydrogen hybrid systems can reduce greenhouse gas emissions by 25-40% compared to traditional internal combustion engines, depending on the energy sources used for hydrogen production and battery charging. When renewable energy sources power both components, these systems approach near-zero operational emissions, representing a substantial environmental benefit.

Material sourcing for battery packs remains a critical environmental concern. Lithium-ion batteries typically require cobalt, nickel, and lithium—materials associated with significant mining impacts including habitat destruction, water pollution, and in some regions, human rights concerns. However, the hybrid approach allows for smaller battery packs compared to pure electric vehicles, potentially reducing the overall material footprint by 30-45%.

End-of-life management presents both challenges and opportunities. Current battery recycling technologies recover approximately 50-70% of critical materials, while hydrogen system components have higher recyclability rates for precious metals like platinum. Emerging closed-loop manufacturing systems aim to increase recovery rates to over 90% by 2030, significantly reducing waste and resource depletion.

Water consumption represents a notable environmental factor in these synergy systems. Hydrogen production through electrolysis requires substantial water inputs—approximately 9 liters per kilogram of hydrogen produced. However, when integrated with battery systems that require minimal water during operation, the overall water footprint can be optimized through intelligent energy management systems.

Carbon intensity varies significantly based on system design and energy sources. Green hydrogen production coupled with batteries charged from renewable sources can achieve carbon intensities below 10g CO2e/km, compared to 50-60g CO2e/km for conventional electric vehicles and 120-180g CO2e/km for internal combustion engines.

The environmental resilience of these hybrid systems also merits consideration. By diversifying energy carriers, these systems reduce dependency on single resource streams, potentially decreasing environmental vulnerability to resource scarcity and extraction-related impacts. This resilience factor represents an often overlooked sustainability benefit that extends beyond direct emissions calculations.

Life cycle assessment (LCA) studies indicate that battery-hydrogen hybrid systems can reduce greenhouse gas emissions by 25-40% compared to traditional internal combustion engines, depending on the energy sources used for hydrogen production and battery charging. When renewable energy sources power both components, these systems approach near-zero operational emissions, representing a substantial environmental benefit.

Material sourcing for battery packs remains a critical environmental concern. Lithium-ion batteries typically require cobalt, nickel, and lithium—materials associated with significant mining impacts including habitat destruction, water pollution, and in some regions, human rights concerns. However, the hybrid approach allows for smaller battery packs compared to pure electric vehicles, potentially reducing the overall material footprint by 30-45%.

End-of-life management presents both challenges and opportunities. Current battery recycling technologies recover approximately 50-70% of critical materials, while hydrogen system components have higher recyclability rates for precious metals like platinum. Emerging closed-loop manufacturing systems aim to increase recovery rates to over 90% by 2030, significantly reducing waste and resource depletion.

Water consumption represents a notable environmental factor in these synergy systems. Hydrogen production through electrolysis requires substantial water inputs—approximately 9 liters per kilogram of hydrogen produced. However, when integrated with battery systems that require minimal water during operation, the overall water footprint can be optimized through intelligent energy management systems.

Carbon intensity varies significantly based on system design and energy sources. Green hydrogen production coupled with batteries charged from renewable sources can achieve carbon intensities below 10g CO2e/km, compared to 50-60g CO2e/km for conventional electric vehicles and 120-180g CO2e/km for internal combustion engines.

The environmental resilience of these hybrid systems also merits consideration. By diversifying energy carriers, these systems reduce dependency on single resource streams, potentially decreasing environmental vulnerability to resource scarcity and extraction-related impacts. This resilience factor represents an often overlooked sustainability benefit that extends beyond direct emissions calculations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!