Battery Pack Design Strategies for Renewable Energy Storage

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Renewable Energy Storage Battery Evolution and Objectives

The evolution of battery storage technologies for renewable energy applications has undergone significant transformation over the past decades. Initially dominated by lead-acid batteries in the 1970s and 1980s, the field has progressively shifted toward more advanced chemistries offering higher energy density, longer cycle life, and improved safety characteristics. This evolution has been primarily driven by the intermittent nature of renewable energy sources such as solar and wind, which require efficient storage solutions to ensure grid stability and energy availability.

Lithium-ion technology emerged as a revolutionary advancement in the 1990s, offering substantially higher energy density and longer cycle life compared to traditional battery chemistries. The subsequent decades witnessed continuous improvements in lithium-ion formulations, including the development of lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium nickel cobalt aluminum oxide (NCA) variants, each offering specific advantages for renewable energy applications.

Flow batteries represent another significant technological milestone, particularly for grid-scale storage, offering decoupled power and energy capacity along with exceptional cycle life. Concurrently, sodium-ion and solid-state batteries have emerged as promising next-generation technologies that may address the limitations of current lithium-based systems, particularly regarding resource availability and safety concerns.

The primary objectives of modern battery pack design for renewable energy storage encompass several critical dimensions. First, maximizing energy density remains paramount to reduce physical footprint and installation costs, particularly in space-constrained environments. Second, extending cycle life and calendar life is essential to ensure economic viability over the typical 20-25 year lifespan of renewable energy installations.

Safety considerations have gained increasing prominence, with thermal management systems and advanced battery management systems (BMS) becoming standard components to prevent thermal runaway and ensure operational reliability. Cost reduction represents another fundamental objective, with current industry targets aiming for below $100/kWh at the pack level to achieve grid parity with conventional energy sources.

Sustainability has emerged as a crucial design consideration, encompassing both the environmental impact of materials sourcing and the development of effective recycling pathways. This includes reducing dependence on critical materials like cobalt and developing battery chemistries based on more abundant elements.

The integration capabilities of battery systems with renewable generation and grid infrastructure have become increasingly sophisticated, with objectives now including advanced functionalities such as frequency regulation, peak shaving, and voltage support to enhance grid stability and maximize economic value through multiple revenue streams.

Lithium-ion technology emerged as a revolutionary advancement in the 1990s, offering substantially higher energy density and longer cycle life compared to traditional battery chemistries. The subsequent decades witnessed continuous improvements in lithium-ion formulations, including the development of lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium nickel cobalt aluminum oxide (NCA) variants, each offering specific advantages for renewable energy applications.

Flow batteries represent another significant technological milestone, particularly for grid-scale storage, offering decoupled power and energy capacity along with exceptional cycle life. Concurrently, sodium-ion and solid-state batteries have emerged as promising next-generation technologies that may address the limitations of current lithium-based systems, particularly regarding resource availability and safety concerns.

The primary objectives of modern battery pack design for renewable energy storage encompass several critical dimensions. First, maximizing energy density remains paramount to reduce physical footprint and installation costs, particularly in space-constrained environments. Second, extending cycle life and calendar life is essential to ensure economic viability over the typical 20-25 year lifespan of renewable energy installations.

Safety considerations have gained increasing prominence, with thermal management systems and advanced battery management systems (BMS) becoming standard components to prevent thermal runaway and ensure operational reliability. Cost reduction represents another fundamental objective, with current industry targets aiming for below $100/kWh at the pack level to achieve grid parity with conventional energy sources.

Sustainability has emerged as a crucial design consideration, encompassing both the environmental impact of materials sourcing and the development of effective recycling pathways. This includes reducing dependence on critical materials like cobalt and developing battery chemistries based on more abundant elements.

The integration capabilities of battery systems with renewable generation and grid infrastructure have become increasingly sophisticated, with objectives now including advanced functionalities such as frequency regulation, peak shaving, and voltage support to enhance grid stability and maximize economic value through multiple revenue streams.

Market Analysis for Grid-Scale Battery Storage Systems

The global grid-scale battery storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources into power grids worldwide. As of 2023, the market size has reached approximately $8.5 billion and is projected to grow at a compound annual growth rate (CAGR) of 24% through 2030, potentially reaching $45 billion by the end of the decade. This remarkable expansion is primarily fueled by the inherent intermittency of renewable energy sources like solar and wind, which necessitates effective energy storage solutions to ensure grid stability and reliability.

North America currently leads the market with about 38% share, followed by Europe (27%) and Asia-Pacific (25%), with the latter showing the fastest growth trajectory. China, the United States, Germany, Australia, and South Korea represent the top five markets by deployment volume. The recent Inflation Reduction Act in the US and the European Green Deal have created substantial incentives for grid-scale battery installations, accelerating market development in these regions.

From an application perspective, the market segments into frequency regulation (32%), peak shaving (28%), renewable integration (25%), and other applications (15%). Lithium-ion technologies dominate with approximately 85% market share due to their decreasing costs, improving energy density, and established supply chains. However, flow batteries, sodium-sulfur, and emerging solid-state technologies are gaining traction for longer-duration storage applications.

The competitive landscape features three distinct player categories: traditional energy companies pivoting toward storage (like NextEra Energy and EDF), pure-play battery manufacturers (such as CATL, LG Energy Solution, and Samsung SDI), and technology integrators (including Tesla, Fluence, and Wartsila). Market concentration remains moderate with the top five players controlling approximately 40% of global capacity installations.

Key market drivers include declining battery costs (which have fallen by 89% over the past decade), supportive government policies, grid modernization initiatives, and increasing corporate commitments to renewable energy. Challenges persist in the form of supply chain constraints for critical minerals, interconnection delays, regulatory uncertainties, and competition from alternative storage technologies like pumped hydro and compressed air energy storage.

Customer segments show distinct preferences, with utilities focusing on large-scale installations (typically 50MW+), commercial and industrial users deploying mid-sized systems (1-10MW), and remote/island communities implementing smaller but strategically critical systems. The business models continue to evolve, with battery-as-a-service, capacity contracts, and virtual power plant arrangements gaining popularity alongside traditional ownership models.

North America currently leads the market with about 38% share, followed by Europe (27%) and Asia-Pacific (25%), with the latter showing the fastest growth trajectory. China, the United States, Germany, Australia, and South Korea represent the top five markets by deployment volume. The recent Inflation Reduction Act in the US and the European Green Deal have created substantial incentives for grid-scale battery installations, accelerating market development in these regions.

From an application perspective, the market segments into frequency regulation (32%), peak shaving (28%), renewable integration (25%), and other applications (15%). Lithium-ion technologies dominate with approximately 85% market share due to their decreasing costs, improving energy density, and established supply chains. However, flow batteries, sodium-sulfur, and emerging solid-state technologies are gaining traction for longer-duration storage applications.

The competitive landscape features three distinct player categories: traditional energy companies pivoting toward storage (like NextEra Energy and EDF), pure-play battery manufacturers (such as CATL, LG Energy Solution, and Samsung SDI), and technology integrators (including Tesla, Fluence, and Wartsila). Market concentration remains moderate with the top five players controlling approximately 40% of global capacity installations.

Key market drivers include declining battery costs (which have fallen by 89% over the past decade), supportive government policies, grid modernization initiatives, and increasing corporate commitments to renewable energy. Challenges persist in the form of supply chain constraints for critical minerals, interconnection delays, regulatory uncertainties, and competition from alternative storage technologies like pumped hydro and compressed air energy storage.

Customer segments show distinct preferences, with utilities focusing on large-scale installations (typically 50MW+), commercial and industrial users deploying mid-sized systems (1-10MW), and remote/island communities implementing smaller but strategically critical systems. The business models continue to evolve, with battery-as-a-service, capacity contracts, and virtual power plant arrangements gaining popularity alongside traditional ownership models.

Current Battery Pack Technologies and Limitations

Battery pack technologies for renewable energy storage have evolved significantly, yet still face substantial limitations. Currently, lithium-ion batteries dominate the market due to their relatively high energy density, decreasing costs, and established manufacturing infrastructure. These systems typically integrate multiple cells with battery management systems (BMS) that monitor voltage, current, and temperature while balancing cell performance. Advanced designs incorporate thermal management systems using air or liquid cooling to maintain optimal operating temperatures and extend battery life.

Despite their prevalence, lithium-ion battery packs face several critical limitations. Energy density remains insufficient for many large-scale renewable applications, with current commercial solutions typically delivering 150-250 Wh/kg, far below theoretical maximums. Cycle life degradation presents another significant challenge, with most systems losing 20-30% capacity after 1,000-2,000 cycles, inadequate for long-term renewable energy storage applications requiring 10+ years of operation.

Safety concerns persist as thermal runaway risks necessitate complex and costly management systems. The flammability of conventional electrolytes compounds these issues, particularly in large-scale installations where thermal propagation between cells can lead to catastrophic failures. Additionally, current battery packs suffer from limited operational temperature ranges, typically performing optimally between 15-35°C, with significant capacity and power reductions outside these parameters.

Cost remains a substantial barrier despite recent price declines. Current lithium-ion battery pack costs range from $150-300/kWh, still too expensive for many grid-scale applications where economic viability requires prices below $100/kWh. Resource constraints and supply chain vulnerabilities further complicate matters, with critical materials like cobalt, lithium, and nickel facing potential shortages and geopolitical supply risks.

Recycling infrastructure remains underdeveloped, with current processes recovering only 50-60% of materials economically. This creates end-of-life management challenges for large-scale deployments. Furthermore, existing battery management systems often lack sophisticated predictive capabilities and standardization, limiting interoperability between different manufacturers' components and increasing integration complexity.

Fast-charging capabilities remain limited in current designs, with most systems requiring hours for full recharge. This restricts their ability to capture intermittent renewable energy effectively. Power density limitations also constrain rapid discharge capabilities needed for grid stabilization applications. These technical constraints collectively highlight the need for innovative battery pack design strategies that can overcome these limitations while meeting the demanding requirements of renewable energy storage applications.

Despite their prevalence, lithium-ion battery packs face several critical limitations. Energy density remains insufficient for many large-scale renewable applications, with current commercial solutions typically delivering 150-250 Wh/kg, far below theoretical maximums. Cycle life degradation presents another significant challenge, with most systems losing 20-30% capacity after 1,000-2,000 cycles, inadequate for long-term renewable energy storage applications requiring 10+ years of operation.

Safety concerns persist as thermal runaway risks necessitate complex and costly management systems. The flammability of conventional electrolytes compounds these issues, particularly in large-scale installations where thermal propagation between cells can lead to catastrophic failures. Additionally, current battery packs suffer from limited operational temperature ranges, typically performing optimally between 15-35°C, with significant capacity and power reductions outside these parameters.

Cost remains a substantial barrier despite recent price declines. Current lithium-ion battery pack costs range from $150-300/kWh, still too expensive for many grid-scale applications where economic viability requires prices below $100/kWh. Resource constraints and supply chain vulnerabilities further complicate matters, with critical materials like cobalt, lithium, and nickel facing potential shortages and geopolitical supply risks.

Recycling infrastructure remains underdeveloped, with current processes recovering only 50-60% of materials economically. This creates end-of-life management challenges for large-scale deployments. Furthermore, existing battery management systems often lack sophisticated predictive capabilities and standardization, limiting interoperability between different manufacturers' components and increasing integration complexity.

Fast-charging capabilities remain limited in current designs, with most systems requiring hours for full recharge. This restricts their ability to capture intermittent renewable energy effectively. Power density limitations also constrain rapid discharge capabilities needed for grid stabilization applications. These technical constraints collectively highlight the need for innovative battery pack design strategies that can overcome these limitations while meeting the demanding requirements of renewable energy storage applications.

Contemporary Battery Pack Design Architectures

01 Thermal Management Systems for Battery Packs

Effective thermal management is crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems can include liquid cooling channels, heat sinks, thermal interface materials, and air cooling mechanisms strategically positioned within the battery pack. Advanced thermal management designs help distribute heat evenly, manage temperature gradients, and protect cells during high-discharge operations or extreme environmental conditions.- Thermal Management Systems: Effective thermal management is critical in battery pack design to maintain optimal operating temperatures and prevent overheating. These systems include cooling channels, heat sinks, and thermal interface materials that help dissipate heat generated during charging and discharging cycles. Advanced designs incorporate liquid cooling systems, phase change materials, or air cooling strategies to ensure uniform temperature distribution across cells, extending battery life and improving safety performance.

- Modular and Scalable Architectures: Modular battery pack designs allow for scalability and flexibility in various applications. These architectures feature standardized cell arrangements that can be easily assembled, disassembled, or reconfigured based on power requirements. The modular approach enables efficient manufacturing, simplified maintenance, and easier replacement of individual components without compromising the entire pack. This design strategy also facilitates better space utilization and weight distribution in different vehicle platforms or energy storage systems.

- Battery Management Systems Integration: Advanced battery management systems (BMS) are integrated into pack designs to monitor and control cell performance. These systems include sensors, controllers, and algorithms that track voltage, current, temperature, and state of charge across individual cells. The BMS optimizes charging/discharging processes, performs cell balancing, and implements protective measures against overcharging or deep discharging. Modern designs incorporate wireless communication capabilities and predictive analytics to enhance battery efficiency, reliability, and lifespan.

- Structural Integration and Mechanical Protection: Battery pack designs increasingly focus on structural integration with the vehicle chassis or housing system. This approach includes crash protection features, vibration dampening mechanisms, and reinforced enclosures to shield cells from physical damage. Advanced designs utilize composite materials, honeycomb structures, or sandwich panels that provide both mechanical strength and weight reduction. Some innovations incorporate the battery pack as a load-bearing element, contributing to overall structural rigidity while optimizing space utilization.

- Cell Arrangement and Interconnection Strategies: Innovative cell arrangement and interconnection methods optimize energy density, power output, and pack reliability. These designs include various cell formats (cylindrical, prismatic, or pouch) arranged in series and parallel configurations to achieve desired voltage and capacity specifications. Advanced interconnection technologies utilize flexible bus bars, wire bonding, or laser welding to minimize resistance and heat generation at connection points. Some designs implement redundant connection paths to maintain pack functionality even if individual connections fail.

02 Battery Cell Arrangement and Connection Strategies

The physical arrangement and electrical connection of battery cells significantly impact the overall performance, safety, and efficiency of battery packs. Various configurations include series, parallel, or series-parallel connections to achieve desired voltage and capacity requirements. Strategic cell placement considers factors such as heat distribution, weight balance, space optimization, and vibration resistance. Innovative connection methods like bus bars, flexible circuits, and direct cell-to-cell connections are employed to minimize resistance and maximize energy density.Expand Specific Solutions03 Battery Management System Integration

Battery Management Systems (BMS) are essential components integrated into battery pack designs to monitor and control various parameters. These systems provide cell balancing, state-of-charge estimation, temperature monitoring, and protection against overcharging or deep discharging. Advanced BMS designs incorporate predictive algorithms for battery health monitoring, fault detection, and performance optimization. The integration strategy of BMS components within the battery pack affects overall reliability, maintenance accessibility, and system response time.Expand Specific Solutions04 Mechanical Structure and Housing Design

The mechanical structure and housing of battery packs are designed to provide physical protection, environmental sealing, and structural integrity. Innovative housing materials include lightweight metals, composites, and engineered polymers that offer optimal strength-to-weight ratios. Design considerations include shock and vibration absorption, expansion accommodation, IP-rated sealing against moisture and dust, and crash safety features. Modular designs allow for easier maintenance, replacement, and scalability of battery systems.Expand Specific Solutions05 Safety and Protection Mechanisms

Battery pack designs incorporate multiple layers of safety and protection mechanisms to prevent catastrophic failures. These include physical separation barriers between cells, thermal runaway prevention systems, pressure relief mechanisms, and isolation strategies for damaged cells. Electrical protection features such as fuses, circuit breakers, and isolation contactors protect against short circuits, overcurrent, and overvoltage conditions. Advanced designs also include fire-resistant materials, venting systems, and containment structures to mitigate potential hazards.Expand Specific Solutions

Leading Battery Manufacturers and Energy Storage Providers

The renewable energy storage battery pack design market is currently in a growth phase, with increasing demand driven by the global shift towards sustainable energy solutions. The market size is expanding rapidly, projected to reach significant scale as renewable energy adoption accelerates worldwide. From a technological maturity perspective, the landscape shows varying degrees of advancement. Industry leaders like LG Energy Solution, Samsung SDI, and BYD have established mature lithium-ion battery technologies, while companies such as EnerVenue and Powin are pioneering alternative solutions including metal-hydrogen technology. State Grid Corporation of China and its research institutes are focusing on grid-scale integration, while academic institutions like Tsinghua University and North China Electric Power University contribute fundamental research. The competitive environment is characterized by established players expanding capabilities while newer entrants focus on technological differentiation for specific applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive battery pack design strategy centered around their advanced laminated pouch cell technology. Their renewable energy storage systems feature a modular architecture with standardized battery trays that can be stacked and configured according to capacity requirements, ranging from residential 9.8kWh units to utility-scale multi-MWh installations. The company's battery packs incorporate a sophisticated thermal management system using flat plate heat exchangers with liquid cooling that maintains temperature differentials below 3°C across the pack, significantly extending battery life. LG's proprietary Battery Management System employs predictive analytics and machine learning algorithms to optimize charge/discharge cycles, with demonstrated cycle life improvements of up to 20%. Their latest ESS designs incorporate silicon-carbon composite anodes that increase energy density by approximately 30% compared to conventional graphite anodes. For grid applications, LG has implemented a containerized approach with pre-engineered 2.5MWh units that include integrated fire suppression systems and remote monitoring capabilities.

Strengths: High energy density (up to 260Wh/kg) with NMC chemistry; excellent cycle life exceeding 6,000 cycles at 80% depth of discharge; advanced thermal management enabling operation across wide temperature ranges; comprehensive safety features including multi-layer protection systems. Weaknesses: Higher cost compared to LFP alternatives; thermal runaway risks inherent to NMC chemistry requiring more complex safety systems; greater environmental impact in manufacturing process.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered an innovative battery pack design strategy for renewable energy storage centered on their prismatic cell technology. Their E3 (Excellent, Economic, Environmental) battery system employs a modular architecture with standardized 113kWh battery trays that can be combined to create systems from 500kWh to 4MWh in a single installation. The design features a patented cell-to-module integration approach that reduces inactive materials by approximately 25%, resulting in higher energy density at the pack level. Samsung's thermal management system utilizes phase-change materials combined with forced air cooling to maintain optimal operating temperatures while minimizing parasitic energy losses. Their Battery Management System incorporates real-time impedance tracking and state-of-health algorithms that have demonstrated accuracy within 2% of actual capacity throughout the battery lifecycle. For grid stabilization applications, Samsung has developed a high-power variant capable of 4C discharge rates while maintaining thermal stability. The company's latest ESS designs include integrated power conditioning systems with bi-directional inverters that achieve round-trip efficiency exceeding 95%.

Strengths: Exceptional energy density at system level (over 200Wh/kg); superior cycle life performance with 70% capacity retention after 7,000 cycles; compact footprint with high volumetric efficiency; advanced diagnostic capabilities enabling predictive maintenance. Weaknesses: Premium pricing positioning limits market penetration in cost-sensitive applications; complex manufacturing process requiring precision assembly; moderate performance degradation in extreme temperature environments.

Critical Patents in Battery Management and Thermal Control

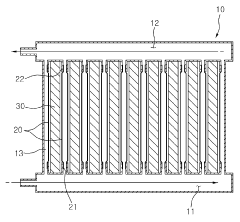

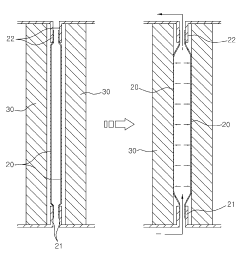

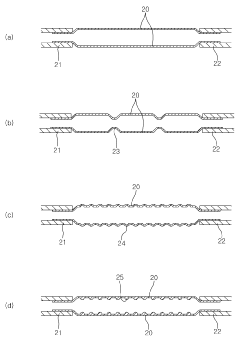

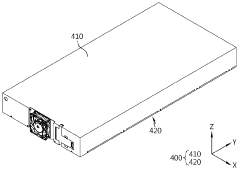

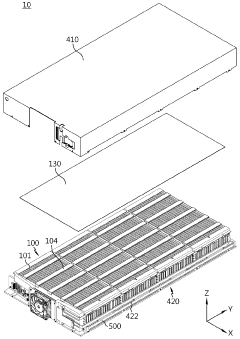

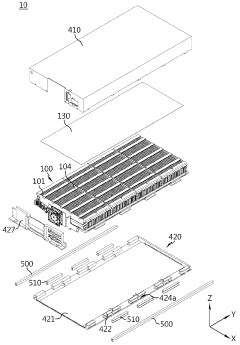

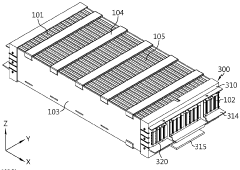

Battery Pack of Energy Storage System

PatentActiveKR1020190107400A

Innovation

- A battery pack design featuring a flow path forming member that expands and contracts with the pressure of a cooling medium to enhance contact with battery cells, improving cooling efficiency while allowing easy installation and replacement of cells.

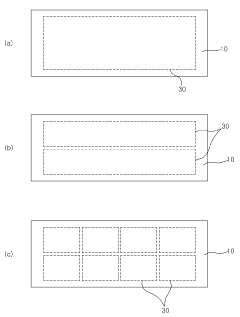

Battery pack and energy storage system comprising same

PatentWO2024136318A1

Innovation

- A battery pack design featuring a plastic injection-molded pack case with a reinforcing member, such as a steel pipe, that provides electrical insulation and structural stability without additional insulating parts, reducing the need for bolts and nuts and minimizing weight.

Environmental Impact and Recycling Considerations

The environmental footprint of battery pack systems for renewable energy storage extends far beyond their operational phase. Life cycle assessments reveal that battery manufacturing processes are energy-intensive and resource-demanding, with lithium-ion batteries typically generating 60-150 kg CO2-equivalent per kWh of capacity during production. These environmental costs must be balanced against the emissions avoided through renewable energy integration over the battery's lifetime.

Material selection significantly influences environmental impact. While lithium, cobalt, and nickel provide high energy density, their extraction creates substantial ecological disruption. Cobalt mining, particularly in the Democratic Republic of Congo, raises serious environmental and ethical concerns. Alternative chemistries such as lithium iron phosphate (LFP) offer reduced environmental impact but with performance trade-offs that designers must carefully evaluate.

Thermal management systems present another environmental consideration. Liquid cooling systems, though efficient, introduce additional materials and potential environmental hazards through coolant leakage or disposal. Passive cooling designs may offer more environmentally sound alternatives despite potential performance limitations in extreme conditions.

End-of-life management represents a critical environmental challenge. Currently, less than 5% of lithium-ion batteries are effectively recycled globally. Advanced recycling technologies are emerging, including hydrometallurgical and direct recycling processes that can recover up to 95% of critical materials. Battery pack designs that facilitate disassembly and material separation can significantly improve recyclability rates and reduce waste.

Second-life applications offer promising pathways to extend environmental benefits. Batteries that retain 70-80% of original capacity after vehicle applications can serve effectively in stationary storage for an additional 5-10 years. Design strategies that anticipate second-life use, such as modular construction and standardized interfaces, maximize this potential while reducing overall environmental impact.

Regulatory frameworks increasingly influence battery design considerations. The European Union's proposed Battery Regulation mandates carbon footprint declarations, minimum recycled content requirements, and extended producer responsibility. Forward-thinking battery pack designs must anticipate these evolving requirements, incorporating environmental considerations from inception rather than as afterthoughts.

Ultimately, optimizing battery pack designs for environmental performance requires holistic assessment across the entire life cycle, balancing immediate performance needs against long-term sustainability objectives. This approach necessitates collaboration across disciplines and stakeholders to develop truly sustainable energy storage solutions.

Material selection significantly influences environmental impact. While lithium, cobalt, and nickel provide high energy density, their extraction creates substantial ecological disruption. Cobalt mining, particularly in the Democratic Republic of Congo, raises serious environmental and ethical concerns. Alternative chemistries such as lithium iron phosphate (LFP) offer reduced environmental impact but with performance trade-offs that designers must carefully evaluate.

Thermal management systems present another environmental consideration. Liquid cooling systems, though efficient, introduce additional materials and potential environmental hazards through coolant leakage or disposal. Passive cooling designs may offer more environmentally sound alternatives despite potential performance limitations in extreme conditions.

End-of-life management represents a critical environmental challenge. Currently, less than 5% of lithium-ion batteries are effectively recycled globally. Advanced recycling technologies are emerging, including hydrometallurgical and direct recycling processes that can recover up to 95% of critical materials. Battery pack designs that facilitate disassembly and material separation can significantly improve recyclability rates and reduce waste.

Second-life applications offer promising pathways to extend environmental benefits. Batteries that retain 70-80% of original capacity after vehicle applications can serve effectively in stationary storage for an additional 5-10 years. Design strategies that anticipate second-life use, such as modular construction and standardized interfaces, maximize this potential while reducing overall environmental impact.

Regulatory frameworks increasingly influence battery design considerations. The European Union's proposed Battery Regulation mandates carbon footprint declarations, minimum recycled content requirements, and extended producer responsibility. Forward-thinking battery pack designs must anticipate these evolving requirements, incorporating environmental considerations from inception rather than as afterthoughts.

Ultimately, optimizing battery pack designs for environmental performance requires holistic assessment across the entire life cycle, balancing immediate performance needs against long-term sustainability objectives. This approach necessitates collaboration across disciplines and stakeholders to develop truly sustainable energy storage solutions.

Regulatory Framework for Large-Scale Energy Storage Systems

The regulatory landscape for large-scale energy storage systems has evolved significantly in response to the growing integration of renewable energy sources and battery storage technologies. In the United States, the Federal Energy Regulatory Commission (FERC) has implemented Order 841, which requires regional transmission organizations and independent system operators to establish market rules that recognize the physical and operational characteristics of electric storage resources. This landmark regulation has opened electricity markets to energy storage participation, creating new revenue streams for battery pack developers.

The European Union has established the Clean Energy Package, which includes specific provisions for energy storage systems. Directive 2019/944 explicitly recognizes storage as a distinct asset class in the electricity market, preventing double taxation and network charges. These regulations have significantly influenced battery pack design strategies, as manufacturers must ensure compliance with these frameworks while optimizing performance.

Safety standards represent another critical regulatory component. UL 9540 in the United States and IEC 62619 internationally establish requirements for the safe design and construction of battery energy storage systems. These standards mandate specific thermal management systems, fire suppression mechanisms, and battery management systems that directly impact pack architecture and component selection.

Grid interconnection requirements further shape battery pack design. IEEE 1547-2018 provides standards for interconnecting distributed energy resources with electric power systems, specifying voltage regulation capabilities, frequency response, and ride-through requirements during grid disturbances. Battery pack designers must incorporate sophisticated power electronics and control systems to meet these technical specifications.

Environmental regulations also influence battery pack development strategies. The EU Battery Directive and similar regulations in other regions establish requirements for battery recycling, material recovery, and end-of-life management. These considerations are increasingly driving design decisions toward modular architectures that facilitate disassembly and material recovery.

Permitting processes for large-scale energy storage systems vary significantly across jurisdictions, creating additional complexity for battery pack designers. In some regions, streamlined permitting pathways have been established for standardized battery configurations that meet pre-approved safety criteria, incentivizing manufacturers to align their designs with these specifications.

As renewable energy penetration increases, regulatory frameworks continue to evolve, with emerging requirements for grid services such as frequency regulation, voltage support, and capacity reserves. Battery pack designs must incorporate the flexibility to provide these services while maintaining compliance with an increasingly complex regulatory landscape.

The European Union has established the Clean Energy Package, which includes specific provisions for energy storage systems. Directive 2019/944 explicitly recognizes storage as a distinct asset class in the electricity market, preventing double taxation and network charges. These regulations have significantly influenced battery pack design strategies, as manufacturers must ensure compliance with these frameworks while optimizing performance.

Safety standards represent another critical regulatory component. UL 9540 in the United States and IEC 62619 internationally establish requirements for the safe design and construction of battery energy storage systems. These standards mandate specific thermal management systems, fire suppression mechanisms, and battery management systems that directly impact pack architecture and component selection.

Grid interconnection requirements further shape battery pack design. IEEE 1547-2018 provides standards for interconnecting distributed energy resources with electric power systems, specifying voltage regulation capabilities, frequency response, and ride-through requirements during grid disturbances. Battery pack designers must incorporate sophisticated power electronics and control systems to meet these technical specifications.

Environmental regulations also influence battery pack development strategies. The EU Battery Directive and similar regulations in other regions establish requirements for battery recycling, material recovery, and end-of-life management. These considerations are increasingly driving design decisions toward modular architectures that facilitate disassembly and material recovery.

Permitting processes for large-scale energy storage systems vary significantly across jurisdictions, creating additional complexity for battery pack designers. In some regions, streamlined permitting pathways have been established for standardized battery configurations that meet pre-approved safety criteria, incentivizing manufacturers to align their designs with these specifications.

As renewable energy penetration increases, regulatory frameworks continue to evolve, with emerging requirements for grid services such as frequency regulation, voltage support, and capacity reserves. Battery pack designs must incorporate the flexibility to provide these services while maintaining compliance with an increasingly complex regulatory landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!