Battery Pack Design Optimization for Load Balancing

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Pack Evolution and Optimization Goals

Battery pack technology has undergone significant evolution since its inception in the early 1990s. Initially, battery packs were simple assemblies of cells with minimal management systems, primarily used in portable electronics. The early 2000s marked a transition toward more sophisticated designs as electric vehicles (EVs) began entering mainstream markets, demanding higher energy density, improved safety features, and longer lifespans.

The evolution accelerated dramatically between 2010-2020, with the emergence of advanced battery management systems (BMS) that incorporated rudimentary load balancing techniques. These systems primarily focused on preventing overcharging and maintaining basic cell equilibrium rather than optimizing overall pack performance. The industry's focus remained largely on increasing energy density rather than addressing the fundamental challenges of load distribution.

Recent technological advancements have shifted attention toward sophisticated load balancing as a critical factor in battery pack performance. Modern battery packs now incorporate complex thermal management systems, advanced cell monitoring capabilities, and dynamic load distribution algorithms. This evolution reflects growing recognition that uneven load distribution significantly impacts battery degradation rates, operational efficiency, and overall lifespan.

The primary optimization goals for battery pack design now center on achieving uniform load distribution across all cells while maintaining optimal operational parameters. Key objectives include minimizing temperature gradients within the pack, equalizing state-of-charge across cells, reducing parasitic losses, and extending overall cycle life. These goals directly address the challenges of capacity fade and performance degradation that have historically limited battery technology applications.

Industry benchmarks now target less than 5% variation in load distribution across cells, temperature differentials below 3°C throughout the pack, and state-of-charge balancing within 2% across all cells. These parameters represent significant improvements over previous generation designs where variations of 15-20% were common, resulting in premature pack failure and reduced energy efficiency.

The technological trajectory points toward increasingly integrated approaches that combine hardware innovations with sophisticated software algorithms. Future optimization goals include real-time adaptive load balancing that responds to changing operational conditions, predictive degradation modeling to anticipate cell failures, and self-healing architectures that can reconfigure power pathways to maintain performance despite individual cell degradation.

As electrification expands beyond consumer vehicles into commercial transportation, grid storage, and industrial applications, the optimization of load balancing in battery packs has become a critical enabler for broader adoption of battery technology across multiple sectors.

The evolution accelerated dramatically between 2010-2020, with the emergence of advanced battery management systems (BMS) that incorporated rudimentary load balancing techniques. These systems primarily focused on preventing overcharging and maintaining basic cell equilibrium rather than optimizing overall pack performance. The industry's focus remained largely on increasing energy density rather than addressing the fundamental challenges of load distribution.

Recent technological advancements have shifted attention toward sophisticated load balancing as a critical factor in battery pack performance. Modern battery packs now incorporate complex thermal management systems, advanced cell monitoring capabilities, and dynamic load distribution algorithms. This evolution reflects growing recognition that uneven load distribution significantly impacts battery degradation rates, operational efficiency, and overall lifespan.

The primary optimization goals for battery pack design now center on achieving uniform load distribution across all cells while maintaining optimal operational parameters. Key objectives include minimizing temperature gradients within the pack, equalizing state-of-charge across cells, reducing parasitic losses, and extending overall cycle life. These goals directly address the challenges of capacity fade and performance degradation that have historically limited battery technology applications.

Industry benchmarks now target less than 5% variation in load distribution across cells, temperature differentials below 3°C throughout the pack, and state-of-charge balancing within 2% across all cells. These parameters represent significant improvements over previous generation designs where variations of 15-20% were common, resulting in premature pack failure and reduced energy efficiency.

The technological trajectory points toward increasingly integrated approaches that combine hardware innovations with sophisticated software algorithms. Future optimization goals include real-time adaptive load balancing that responds to changing operational conditions, predictive degradation modeling to anticipate cell failures, and self-healing architectures that can reconfigure power pathways to maintain performance despite individual cell degradation.

As electrification expands beyond consumer vehicles into commercial transportation, grid storage, and industrial applications, the optimization of load balancing in battery packs has become a critical enabler for broader adoption of battery technology across multiple sectors.

Market Demand Analysis for Balanced Battery Systems

The global market for balanced battery systems has witnessed substantial growth in recent years, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. As of 2023, the market size for battery management systems with load balancing capabilities reached approximately $8.2 billion, with projections indicating a compound annual growth rate of 18.3% through 2030.

Electric vehicle manufacturers represent the largest demand segment, accounting for nearly 42% of the total market. This dominance stems from the critical need for optimized battery performance in EVs, where imbalanced cells can significantly reduce range, efficiency, and battery lifespan. Tesla, BYD, and Volkswagen have been particularly vocal about their requirements for advanced load balancing technologies that can manage increasingly larger battery packs while minimizing thermal issues.

The renewable energy storage sector constitutes the fastest-growing segment, with a 24.7% annual growth rate. Grid-scale energy storage installations and residential solar-plus-storage systems both require sophisticated load balancing to maximize energy density, cycle life, and safety. Industry reports indicate that balanced battery systems can extend storage system lifespans by up to 40% compared to systems with basic battery management.

Consumer electronics manufacturers are increasingly demanding miniaturized load balancing solutions as devices become more power-intensive while maintaining compact form factors. Apple, Samsung, and other major manufacturers have published technical requirements specifying the need for battery management systems that can balance multiple cells in limited spaces while generating minimal heat.

Geographic analysis reveals that Asia-Pacific dominates the market with a 48% share, led by China's massive investments in electric mobility and energy storage. North America follows at 27%, with Europe at 21%. However, Europe shows the highest growth trajectory due to aggressive renewable energy targets and EV adoption policies.

Key market drivers include increasingly stringent safety regulations, particularly following high-profile battery failure incidents. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have both updated their standards to emphasize the importance of cell balancing in multi-cell battery systems.

Cost sensitivity varies significantly by application segment. While automotive manufacturers prioritize performance and reliability over cost, consumer electronics manufacturers identify cost as their primary consideration. This market segmentation has created distinct technology paths, with premium solutions featuring active balancing for high-performance applications and passive balancing solutions dominating cost-sensitive segments.

Electric vehicle manufacturers represent the largest demand segment, accounting for nearly 42% of the total market. This dominance stems from the critical need for optimized battery performance in EVs, where imbalanced cells can significantly reduce range, efficiency, and battery lifespan. Tesla, BYD, and Volkswagen have been particularly vocal about their requirements for advanced load balancing technologies that can manage increasingly larger battery packs while minimizing thermal issues.

The renewable energy storage sector constitutes the fastest-growing segment, with a 24.7% annual growth rate. Grid-scale energy storage installations and residential solar-plus-storage systems both require sophisticated load balancing to maximize energy density, cycle life, and safety. Industry reports indicate that balanced battery systems can extend storage system lifespans by up to 40% compared to systems with basic battery management.

Consumer electronics manufacturers are increasingly demanding miniaturized load balancing solutions as devices become more power-intensive while maintaining compact form factors. Apple, Samsung, and other major manufacturers have published technical requirements specifying the need for battery management systems that can balance multiple cells in limited spaces while generating minimal heat.

Geographic analysis reveals that Asia-Pacific dominates the market with a 48% share, led by China's massive investments in electric mobility and energy storage. North America follows at 27%, with Europe at 21%. However, Europe shows the highest growth trajectory due to aggressive renewable energy targets and EV adoption policies.

Key market drivers include increasingly stringent safety regulations, particularly following high-profile battery failure incidents. The International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have both updated their standards to emphasize the importance of cell balancing in multi-cell battery systems.

Cost sensitivity varies significantly by application segment. While automotive manufacturers prioritize performance and reliability over cost, consumer electronics manufacturers identify cost as their primary consideration. This market segmentation has created distinct technology paths, with premium solutions featuring active balancing for high-performance applications and passive balancing solutions dominating cost-sensitive segments.

Current Load Balancing Technologies and Challenges

Load balancing in battery pack design represents one of the most critical challenges in modern energy storage systems. Current technologies primarily focus on equalizing the state of charge (SOC) across multiple cells to prevent overcharging, deep discharging, and thermal runaway. The predominant load balancing methods can be categorized into passive and active approaches, each with distinct advantages and limitations.

Passive balancing systems utilize resistors to dissipate excess energy from cells with higher charge levels, effectively "burning off" the excess energy as heat. While cost-effective and simple to implement, these systems suffer from significant energy inefficiency, with conversion losses often exceeding 20%. Additionally, the heat generated during balancing can accelerate battery degradation and potentially create thermal management challenges in densely packed battery arrays.

Active balancing technologies represent a more sophisticated approach, employing DC-DC converters, switched capacitors, or transformer-based systems to transfer energy between cells rather than dissipating it. These systems achieve efficiency rates of 85-95%, significantly improving overall battery pack performance. However, they introduce greater complexity, higher component costs, and increased control system requirements, creating implementation barriers particularly for cost-sensitive applications.

A significant technical challenge in current load balancing systems is the response time limitation. Most commercial systems operate at relatively slow balancing rates (typically 50-200mA), making them inadequate for high-dynamic applications where load profiles change rapidly, such as in electric vehicles during acceleration and regenerative braking cycles.

Sensing accuracy presents another major hurdle, as precise cell voltage and temperature measurements are prerequisites for effective balancing. Current systems typically achieve voltage measurement accuracy of ±5mV, which may be insufficient for detecting subtle imbalances in newer high-energy-density chemistries where the voltage curves are increasingly flat.

Integration complexity remains problematic, particularly as battery packs grow in size and complexity. Modern electric vehicle battery packs containing thousands of cells require sophisticated balancing architectures that can effectively manage cell-to-cell variations without introducing excessive parasitic loads or control overhead.

Thermal management during balancing operations continues to challenge designers, as temperature gradients across the pack can both cause and result from imbalances. Current cooling systems often struggle to maintain uniform temperatures during aggressive balancing operations, creating a feedback loop that can exacerbate existing imbalances.

Passive balancing systems utilize resistors to dissipate excess energy from cells with higher charge levels, effectively "burning off" the excess energy as heat. While cost-effective and simple to implement, these systems suffer from significant energy inefficiency, with conversion losses often exceeding 20%. Additionally, the heat generated during balancing can accelerate battery degradation and potentially create thermal management challenges in densely packed battery arrays.

Active balancing technologies represent a more sophisticated approach, employing DC-DC converters, switched capacitors, or transformer-based systems to transfer energy between cells rather than dissipating it. These systems achieve efficiency rates of 85-95%, significantly improving overall battery pack performance. However, they introduce greater complexity, higher component costs, and increased control system requirements, creating implementation barriers particularly for cost-sensitive applications.

A significant technical challenge in current load balancing systems is the response time limitation. Most commercial systems operate at relatively slow balancing rates (typically 50-200mA), making them inadequate for high-dynamic applications where load profiles change rapidly, such as in electric vehicles during acceleration and regenerative braking cycles.

Sensing accuracy presents another major hurdle, as precise cell voltage and temperature measurements are prerequisites for effective balancing. Current systems typically achieve voltage measurement accuracy of ±5mV, which may be insufficient for detecting subtle imbalances in newer high-energy-density chemistries where the voltage curves are increasingly flat.

Integration complexity remains problematic, particularly as battery packs grow in size and complexity. Modern electric vehicle battery packs containing thousands of cells require sophisticated balancing architectures that can effectively manage cell-to-cell variations without introducing excessive parasitic loads or control overhead.

Thermal management during balancing operations continues to challenge designers, as temperature gradients across the pack can both cause and result from imbalances. Current cooling systems often struggle to maintain uniform temperatures during aggressive balancing operations, creating a feedback loop that can exacerbate existing imbalances.

Existing Load Balancing Design Solutions

01 Active cell balancing techniques

Active cell balancing techniques involve transferring energy from higher-charged cells to lower-charged cells within a battery pack. This approach uses electronic circuits such as switched capacitors, inductors, or DC-DC converters to actively redistribute energy, maximizing the usable capacity of the battery pack and extending its overall lifespan. Active balancing is particularly effective for large battery packs where cell imbalances can significantly impact performance and safety.- Active cell balancing techniques: Active cell balancing techniques involve transferring energy from higher-charged cells to lower-charged cells within a battery pack. This approach uses electronic circuits such as DC-DC converters, switched capacitors, or transformers to redistribute energy efficiently. Active balancing improves overall battery pack efficiency, extends battery life, and maximizes available capacity by ensuring all cells operate at similar charge levels.

- Passive cell balancing methods: Passive balancing methods dissipate excess energy from higher-charged cells as heat through resistors until all cells reach the same voltage level. While simpler and less expensive than active balancing, this approach wastes energy but effectively prevents overcharging of individual cells. Passive balancing is commonly implemented using bypass resistors that activate when cell voltages exceed predetermined thresholds.

- Battery management systems for load balancing: Battery management systems (BMS) monitor and control the charging and discharging processes of battery packs to maintain balanced cell states. These systems incorporate sensors to measure voltage, current, and temperature of individual cells, and use algorithms to determine optimal balancing strategies. Advanced BMS solutions may include predictive modeling to anticipate imbalances and implement preventive measures before issues occur.

- Thermal management in battery balancing: Thermal management is crucial for effective battery balancing as temperature differences between cells can lead to charge imbalances. Systems that incorporate thermal management alongside electrical balancing ensure more uniform performance across the battery pack. These solutions may include cooling systems, heat distribution mechanisms, and temperature-based control algorithms that adjust balancing operations based on thermal conditions.

- Intelligent charging algorithms for load balancing: Intelligent charging algorithms optimize the charging process to maintain balance across battery cells. These algorithms adjust charging parameters based on the state of individual cells, employing techniques such as variable current distribution, pulse charging, and multi-stage charging profiles. Machine learning and adaptive control methods can further enhance these algorithms by learning from battery behavior patterns and adjusting balancing strategies accordingly.

02 Passive cell balancing methods

Passive balancing methods equalize cell voltages by dissipating excess energy from higher-charged cells through resistors as heat. This approach is simpler and less expensive than active balancing but results in energy loss. Passive balancing systems typically use bypass resistors connected in parallel with each cell, activated when cell voltage exceeds a predetermined threshold. While less efficient than active methods, passive balancing is reliable and widely used in applications where cost and simplicity are prioritized over maximum energy efficiency.Expand Specific Solutions03 Battery management systems for load balancing

Battery management systems (BMS) incorporate sophisticated monitoring and control algorithms to manage cell balancing in real-time. These systems continuously monitor individual cell voltages, temperatures, and states of charge to detect imbalances and implement appropriate balancing strategies. Advanced BMS solutions may employ machine learning algorithms to predict cell behavior and optimize balancing operations based on usage patterns. The integration of BMS with load balancing functionality ensures optimal battery performance, safety, and longevity across various operating conditions.Expand Specific Solutions04 Thermal management in battery balancing

Thermal management is crucial for effective battery pack load balancing, as temperature variations between cells can lead to performance disparities and accelerated degradation. Integrated cooling systems help maintain uniform temperature distribution across the battery pack, reducing the need for balancing interventions. Some advanced systems combine thermal management with cell balancing algorithms to address both electrical and thermal imbalances simultaneously. This comprehensive approach ensures more uniform cell aging and improved overall battery pack reliability and efficiency.Expand Specific Solutions05 State of charge estimation for balanced operation

Accurate state of charge (SOC) estimation is essential for effective battery pack load balancing. Advanced algorithms use voltage measurements, current integration, impedance tracking, and temperature compensation to determine the precise charge level of each cell. These estimations enable more targeted balancing interventions, focusing resources on cells that need adjustment while avoiding unnecessary balancing operations on cells that are already well-matched. Improved SOC estimation techniques contribute to more efficient balancing strategies and better overall battery pack performance.Expand Specific Solutions

Key Industry Players in Battery Pack Technology

Battery Pack Design Optimization for Load Balancing is evolving in a rapidly maturing market, currently transitioning from early adoption to mainstream implementation. The global battery management system market is projected to exceed $12 billion by 2025, growing at approximately 19% CAGR. Major players like LG Energy Solution, Samsung SDI, BYD, and Panasonic lead technological innovation with advanced load balancing solutions. These companies are investing heavily in R&D to address thermal management challenges and extend battery life. Emerging competitors such as A123 Systems and SK Innovation are focusing on specialized applications, while tech giants like Apple are integrating proprietary battery management systems into their ecosystem. The technology is approaching maturity with standardization efforts underway, though innovations in AI-driven predictive balancing represent the next frontier.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed an advanced Battery Management System (BMS) for load balancing that incorporates cell-to-cell balancing technology. Their solution uses active balancing circuits that can transfer energy from higher-charged cells to lower-charged cells rather than dissipating excess energy as heat. The system employs proprietary algorithms that continuously monitor individual cell voltages, temperatures, and internal resistance to optimize charge distribution across the entire pack. Their latest innovation includes predictive analytics that anticipates cell degradation patterns and proactively adjusts balancing strategies to extend overall pack life[1]. The company has implemented wireless BMS technology that reduces wiring complexity while improving diagnostic capabilities and thermal management integration[3]. Their battery packs feature modular designs with standardized interfaces that allow for easier maintenance and replacement of individual modules without compromising the entire pack's integrity.

Strengths: Superior energy efficiency through active balancing rather than passive resistance-based methods; comprehensive cell monitoring with predictive analytics; wireless communication reducing physical vulnerabilities. Weaknesses: Higher initial system cost compared to passive balancing solutions; increased complexity requiring more sophisticated control systems; potential single point of failure in centralized management architecture.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered a multi-layered approach to battery pack load balancing through their "Smart Balancing Technology." This system combines both passive and active balancing methods, with intelligent switching between modes based on operational conditions. Their technology incorporates dedicated balancing ICs for each module that communicate with a master controller, enabling both module-level and cell-level balancing strategies[2]. Samsung's solution features proprietary algorithms that analyze historical cell performance data to create adaptive balancing profiles for different usage scenarios. The company has implemented a thermal gradient compensation system that accounts for temperature variations across the pack when determining optimal balancing strategies. Their latest innovation includes a "pre-emptive balancing" feature that initiates balancing operations based on predicted load patterns rather than waiting for voltage differences to emerge[4]. Samsung SDI also utilizes machine learning algorithms to continuously improve balancing efficiency based on actual usage patterns.

Strengths: Hybrid balancing approach maximizes efficiency while managing costs; sophisticated predictive algorithms reduce balancing frequency; excellent thermal management integration. Weaknesses: Complex system architecture requires significant computational resources; higher component count increases potential failure points; system optimization requires substantial data collection periods.

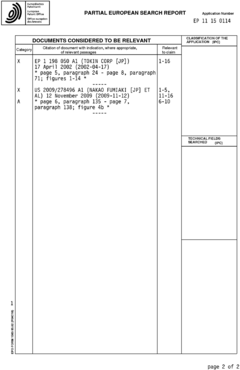

Critical Patents in Battery Pack Balancing Techniques

Method for balancing of high voltage battery pack

PatentActiveEP2227850A2

Innovation

- A cell balancing method that measures and uses electromotive force instead of terminal voltage, with specific threshold times and current states to exclude errors from IR and polarization voltage, and computes and balances based on total charge amounts to ensure accurate balancing.

Balancing system for a battery pack

PatentInactiveEP2372866A3

Innovation

- A multi-stage balancing system utilizing transformers and switches to actively balance unbalanced cells and modules within the battery pack by transferring energy between cells and modules, ensuring faster and more efficient balancing through a combination of flyback transformers, analog front-end devices, and pulse width modulation.

Thermal Management Integration Strategies

Thermal management integration represents a critical aspect of battery pack design optimization for load balancing. Effective thermal management systems must be seamlessly integrated with electrical load balancing mechanisms to ensure optimal battery performance and longevity. The integration strategy begins with a comprehensive thermal modeling approach that accounts for heat generation during various charging and discharging cycles, particularly focusing on high-current operations where thermal imbalances are most pronounced.

Advanced thermal management integration strategies employ multi-layer approaches combining active and passive cooling systems. Liquid cooling channels strategically positioned between cell groups have demonstrated superior performance in high-density battery packs, reducing temperature gradients by up to 60% compared to traditional air cooling methods. These systems can be dynamically controlled based on real-time temperature monitoring, adjusting coolant flow rates in response to detected thermal hotspots.

Integration of phase change materials (PCMs) within the battery structure represents another innovative approach. These materials absorb excess heat during high-load operations and release it during idle periods, effectively dampening temperature fluctuations. Recent developments in PCM technology have yielded compounds with thermal conductivity enhancements of 200-300% when compared to conventional materials, significantly improving heat distribution throughout the pack.

Thermal-electrical co-optimization algorithms constitute a sophisticated integration strategy gaining prominence in advanced battery management systems. These algorithms simultaneously balance electrical load distribution and thermal management resources, making dynamic adjustments based on operational conditions. Machine learning approaches have demonstrated particular promise in this domain, with neural network models achieving 15-20% improvements in thermal uniformity while maintaining optimal electrical performance.

Physical design integration strategies focus on structural elements that serve dual purposes. Heat-dissipating bus bars, thermally conductive yet electrically insulating materials between cells, and strategically positioned thermal bridges all contribute to passive thermal management while supporting electrical connectivity requirements. These design elements must be carefully integrated during the early stages of battery pack development to ensure optimal performance.

Sensor integration represents another crucial aspect of thermal management strategies. Distributed temperature sensing networks embedded throughout the battery pack provide real-time thermal mapping capabilities, enabling precise control of cooling systems and load balancing mechanisms. Advanced fiber optic sensing technologies offer advantages in terms of electromagnetic interference immunity and high spatial resolution, though integration challenges related to durability and connection points remain.

Advanced thermal management integration strategies employ multi-layer approaches combining active and passive cooling systems. Liquid cooling channels strategically positioned between cell groups have demonstrated superior performance in high-density battery packs, reducing temperature gradients by up to 60% compared to traditional air cooling methods. These systems can be dynamically controlled based on real-time temperature monitoring, adjusting coolant flow rates in response to detected thermal hotspots.

Integration of phase change materials (PCMs) within the battery structure represents another innovative approach. These materials absorb excess heat during high-load operations and release it during idle periods, effectively dampening temperature fluctuations. Recent developments in PCM technology have yielded compounds with thermal conductivity enhancements of 200-300% when compared to conventional materials, significantly improving heat distribution throughout the pack.

Thermal-electrical co-optimization algorithms constitute a sophisticated integration strategy gaining prominence in advanced battery management systems. These algorithms simultaneously balance electrical load distribution and thermal management resources, making dynamic adjustments based on operational conditions. Machine learning approaches have demonstrated particular promise in this domain, with neural network models achieving 15-20% improvements in thermal uniformity while maintaining optimal electrical performance.

Physical design integration strategies focus on structural elements that serve dual purposes. Heat-dissipating bus bars, thermally conductive yet electrically insulating materials between cells, and strategically positioned thermal bridges all contribute to passive thermal management while supporting electrical connectivity requirements. These design elements must be carefully integrated during the early stages of battery pack development to ensure optimal performance.

Sensor integration represents another crucial aspect of thermal management strategies. Distributed temperature sensing networks embedded throughout the battery pack provide real-time thermal mapping capabilities, enabling precise control of cooling systems and load balancing mechanisms. Advanced fiber optic sensing technologies offer advantages in terms of electromagnetic interference immunity and high spatial resolution, though integration challenges related to durability and connection points remain.

Safety Standards and Regulatory Compliance

Battery pack safety standards and regulatory compliance represent a critical framework that manufacturers must navigate when optimizing load balancing systems. The International Electrotechnical Commission (IEC) has established several key standards, including IEC 62133 for secondary cells and batteries and IEC 61508 for functional safety of electrical/electronic systems. These standards define specific requirements for thermal management, electrical isolation, and protection against overcharging—all directly impacting load balancing design parameters.

In the United States, UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries, with particular emphasis on cell balancing mechanisms. The National Fire Protection Association (NFPA) has also published NFPA 855, which addresses installation of energy storage systems and includes provisions relevant to battery management systems that perform load balancing functions.

European regulations, particularly UN/ECE-R100 for automotive applications, mandate specific performance criteria for voltage management and thermal runaway prevention. These regulations require sophisticated load balancing algorithms that can maintain cell voltages within safe operating windows while optimizing overall pack performance. The European Battery Directive (2006/66/EC) further imposes requirements on battery recycling and hazardous material content that influence design choices.

For electric vehicle applications, ISO 26262 (Road Vehicles – Functional Safety) classifies battery management systems as safety-critical components, requiring fault-tolerant load balancing architectures. This standard necessitates redundancy in monitoring circuits and fail-safe mechanisms that must be incorporated into the optimization algorithms.

Emerging regulations in China, including GB/T 31467 and GB/T 31485, are increasingly influential in global battery design practices. These standards establish stringent requirements for cell consistency and balance management, often exceeding international benchmarks in certain parameters.

Compliance testing protocols typically include cycle life testing under various load balancing strategies, thermal shock testing to verify system stability during rapid temperature changes, and electromagnetic compatibility testing to ensure load balancing circuits do not interfere with other vehicle systems. These tests must be documented in technical files that demonstrate conformity with applicable standards.

Regulatory trends indicate movement toward more stringent requirements for real-time monitoring and predictive balancing capabilities, with particular emphasis on thermal management during fast-charging scenarios. Future standards are expected to address advanced load balancing techniques such as active cell balancing with energy recovery systems.

In the United States, UL 1642 and UL 2054 provide comprehensive safety requirements for lithium batteries, with particular emphasis on cell balancing mechanisms. The National Fire Protection Association (NFPA) has also published NFPA 855, which addresses installation of energy storage systems and includes provisions relevant to battery management systems that perform load balancing functions.

European regulations, particularly UN/ECE-R100 for automotive applications, mandate specific performance criteria for voltage management and thermal runaway prevention. These regulations require sophisticated load balancing algorithms that can maintain cell voltages within safe operating windows while optimizing overall pack performance. The European Battery Directive (2006/66/EC) further imposes requirements on battery recycling and hazardous material content that influence design choices.

For electric vehicle applications, ISO 26262 (Road Vehicles – Functional Safety) classifies battery management systems as safety-critical components, requiring fault-tolerant load balancing architectures. This standard necessitates redundancy in monitoring circuits and fail-safe mechanisms that must be incorporated into the optimization algorithms.

Emerging regulations in China, including GB/T 31467 and GB/T 31485, are increasingly influential in global battery design practices. These standards establish stringent requirements for cell consistency and balance management, often exceeding international benchmarks in certain parameters.

Compliance testing protocols typically include cycle life testing under various load balancing strategies, thermal shock testing to verify system stability during rapid temperature changes, and electromagnetic compatibility testing to ensure load balancing circuits do not interfere with other vehicle systems. These tests must be documented in technical files that demonstrate conformity with applicable standards.

Regulatory trends indicate movement toward more stringent requirements for real-time monitoring and predictive balancing capabilities, with particular emphasis on thermal management during fast-charging scenarios. Future standards are expected to address advanced load balancing techniques such as active cell balancing with energy recovery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!