Exploring Battery Pack Design for Military Application Agility

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Military Battery Evolution and Objectives

The evolution of military battery technology has undergone significant transformation since the early 20th century, progressing from basic lead-acid configurations to today's sophisticated lithium-based systems. During World War II, military forces primarily relied on rudimentary battery solutions with limited energy density and operational lifespan. The Cold War era witnessed substantial investments in battery research, driven by the increasing electrification of military equipment and the need for reliable power sources in remote deployment scenarios.

The 1990s marked a pivotal shift with the introduction of lithium-ion technology to military applications, offering unprecedented energy density advantages. This technological leap enabled the development of more compact, lightweight power solutions for field operations. By the early 2000s, military-specific battery standards began emerging, establishing rigorous performance benchmarks for durability, reliability, and safety under extreme conditions.

Recent military conflicts in diverse environmental conditions have highlighted critical limitations in existing battery technologies, particularly regarding thermal management, rapid charging capabilities, and resilience against ballistic impacts. These operational challenges have accelerated research into next-generation battery solutions specifically engineered for tactical environments.

The primary objectives for modern military battery pack design center around five key parameters: enhanced energy density to reduce the carried load of infantry units; improved operational temperature range for deployment in extreme environments; increased cycle life to minimize field replacements; enhanced safety features to withstand combat conditions; and modular architectures enabling rapid adaptation to diverse mission requirements.

Current military doctrine increasingly emphasizes energy independence and tactical mobility, driving requirements for battery systems that can operate effectively across the full spectrum of military operations. The integration of renewable charging capabilities with traditional battery systems has become a strategic priority, particularly for forward operating bases and special operations units operating beyond conventional supply lines.

Looking forward, military battery technology aims to achieve a 50% reduction in weight while doubling energy capacity by 2030, enabling extended mission durations without compromising mobility. Concurrently, there is growing emphasis on developing battery systems capable of withstanding electromagnetic pulse (EMP) threats and cyber attacks, reflecting the evolving nature of modern warfare. The ultimate goal remains creating power solutions that enhance warfighter effectiveness while minimizing logistical burdens across the operational spectrum.

The 1990s marked a pivotal shift with the introduction of lithium-ion technology to military applications, offering unprecedented energy density advantages. This technological leap enabled the development of more compact, lightweight power solutions for field operations. By the early 2000s, military-specific battery standards began emerging, establishing rigorous performance benchmarks for durability, reliability, and safety under extreme conditions.

Recent military conflicts in diverse environmental conditions have highlighted critical limitations in existing battery technologies, particularly regarding thermal management, rapid charging capabilities, and resilience against ballistic impacts. These operational challenges have accelerated research into next-generation battery solutions specifically engineered for tactical environments.

The primary objectives for modern military battery pack design center around five key parameters: enhanced energy density to reduce the carried load of infantry units; improved operational temperature range for deployment in extreme environments; increased cycle life to minimize field replacements; enhanced safety features to withstand combat conditions; and modular architectures enabling rapid adaptation to diverse mission requirements.

Current military doctrine increasingly emphasizes energy independence and tactical mobility, driving requirements for battery systems that can operate effectively across the full spectrum of military operations. The integration of renewable charging capabilities with traditional battery systems has become a strategic priority, particularly for forward operating bases and special operations units operating beyond conventional supply lines.

Looking forward, military battery technology aims to achieve a 50% reduction in weight while doubling energy capacity by 2030, enabling extended mission durations without compromising mobility. Concurrently, there is growing emphasis on developing battery systems capable of withstanding electromagnetic pulse (EMP) threats and cyber attacks, reflecting the evolving nature of modern warfare. The ultimate goal remains creating power solutions that enhance warfighter effectiveness while minimizing logistical burdens across the operational spectrum.

Market Analysis for Tactical Power Solutions

The tactical power solutions market for military applications is experiencing significant growth driven by increasing defense modernization programs worldwide. Current market valuation stands at approximately 5.2 billion USD with projections indicating a compound annual growth rate of 6.8% through 2030. This expansion is primarily fueled by the rising demand for portable, reliable, and efficient power sources for military personnel and equipment in field operations.

Military organizations globally are shifting toward lighter, more efficient power solutions to enhance soldier mobility and operational effectiveness. The average soldier carries between 15-30 pounds of battery weight during extended missions, creating substantial demand for weight reduction without compromising power capacity. Market research indicates that solutions offering at least 30% weight reduction while maintaining current power outputs could capture significant market share.

Regional analysis shows North America dominating the market with approximately 38% share, followed by Europe (27%), Asia-Pacific (22%), and rest of the world (13%). The United States Department of Defense alone allocates over 1.7 billion USD annually for portable power solutions research and procurement, representing a substantial market opportunity for innovative battery pack designs.

Key customer segments include ground forces (42%), special operations (28%), aviation support (17%), and naval applications (13%). Each segment presents unique requirements regarding power density, operational temperature ranges, and durability specifications. Special operations forces in particular demand ultra-lightweight solutions capable of operating in extreme environmental conditions, with procurement budgets showing 12% annual increases for specialized tactical power equipment.

Market trends indicate growing preference for hybrid power solutions that combine traditional battery technologies with emerging energy harvesting capabilities. Military procurement cycles are increasingly prioritizing solutions that offer backward compatibility with existing systems while providing pathways for future technology integration. Additionally, there is rising demand for smart battery management systems that provide real-time diagnostics and predictive maintenance capabilities.

Competitive analysis reveals a fragmented market with several specialized players rather than domination by major defense contractors. This creates significant opportunity for innovative market entrants with specialized expertise in battery technology. Recent military procurement patterns show increasing openness to commercial off-the-shelf technologies adapted for military use, reducing traditional barriers to market entry for companies with proven commercial battery innovations.

Military organizations globally are shifting toward lighter, more efficient power solutions to enhance soldier mobility and operational effectiveness. The average soldier carries between 15-30 pounds of battery weight during extended missions, creating substantial demand for weight reduction without compromising power capacity. Market research indicates that solutions offering at least 30% weight reduction while maintaining current power outputs could capture significant market share.

Regional analysis shows North America dominating the market with approximately 38% share, followed by Europe (27%), Asia-Pacific (22%), and rest of the world (13%). The United States Department of Defense alone allocates over 1.7 billion USD annually for portable power solutions research and procurement, representing a substantial market opportunity for innovative battery pack designs.

Key customer segments include ground forces (42%), special operations (28%), aviation support (17%), and naval applications (13%). Each segment presents unique requirements regarding power density, operational temperature ranges, and durability specifications. Special operations forces in particular demand ultra-lightweight solutions capable of operating in extreme environmental conditions, with procurement budgets showing 12% annual increases for specialized tactical power equipment.

Market trends indicate growing preference for hybrid power solutions that combine traditional battery technologies with emerging energy harvesting capabilities. Military procurement cycles are increasingly prioritizing solutions that offer backward compatibility with existing systems while providing pathways for future technology integration. Additionally, there is rising demand for smart battery management systems that provide real-time diagnostics and predictive maintenance capabilities.

Competitive analysis reveals a fragmented market with several specialized players rather than domination by major defense contractors. This creates significant opportunity for innovative market entrants with specialized expertise in battery technology. Recent military procurement patterns show increasing openness to commercial off-the-shelf technologies adapted for military use, reducing traditional barriers to market entry for companies with proven commercial battery innovations.

Current Challenges in Military Battery Technology

Military battery technology faces significant challenges in meeting the evolving demands of modern warfare. The increasing electrification of military equipment and the growing reliance on portable electronic devices have placed unprecedented demands on power sources. Traditional battery technologies struggle to balance the critical requirements of energy density, power output, operational durability, and safety in extreme environments.

Weight constraints represent one of the most pressing challenges, as soldiers already carry substantial loads during operations. Current military battery packs often contribute significantly to this burden, with some systems adding 15-20 pounds to a soldier's equipment. This weight limitation directly impacts mobility and operational effectiveness in the field, creating a critical need for lighter power solutions without compromising performance.

Thermal management presents another major hurdle, particularly in extreme environments. Military operations frequently occur in temperature ranges from -40°C to +60°C, conditions that severely degrade battery performance. Conventional lithium-ion technologies experience significant capacity reduction at temperature extremes, with some systems losing up to 80% of their rated capacity in cold environments. Additionally, thermal runaway risks increase in hot conditions, creating potential safety hazards during critical missions.

Durability requirements for military applications far exceed commercial standards. Batteries must withstand severe mechanical shocks, vibrations, and impacts that occur during transport and combat situations. Current ruggedization approaches often involve protective casings that add substantial weight and volume, creating a challenging design trade-off between protection and portability.

Logistical challenges further complicate military battery deployment. The diversity of equipment requiring power sources has led to a proliferation of battery types and charging systems. This "battery burden" creates significant supply chain complexities and increases the logistical footprint of military operations. Studies indicate that some forward operating bases dedicate up to 20% of supply missions solely to battery resupply.

Rapid charging capabilities remain insufficient for operational needs. Current military battery systems typically require 3-8 hours for a full charge, creating significant downtime between missions. This limitation becomes particularly problematic during extended operations where access to charging infrastructure is limited or compromised.

Security concerns also present unique challenges for military battery technology. Batteries must be designed to prevent unauthorized access to stored energy and data, while also incorporating fail-safe mechanisms to prevent exploitation if captured. These security requirements add complexity to battery management systems and often conflict with goals for simplicity and reliability.

Weight constraints represent one of the most pressing challenges, as soldiers already carry substantial loads during operations. Current military battery packs often contribute significantly to this burden, with some systems adding 15-20 pounds to a soldier's equipment. This weight limitation directly impacts mobility and operational effectiveness in the field, creating a critical need for lighter power solutions without compromising performance.

Thermal management presents another major hurdle, particularly in extreme environments. Military operations frequently occur in temperature ranges from -40°C to +60°C, conditions that severely degrade battery performance. Conventional lithium-ion technologies experience significant capacity reduction at temperature extremes, with some systems losing up to 80% of their rated capacity in cold environments. Additionally, thermal runaway risks increase in hot conditions, creating potential safety hazards during critical missions.

Durability requirements for military applications far exceed commercial standards. Batteries must withstand severe mechanical shocks, vibrations, and impacts that occur during transport and combat situations. Current ruggedization approaches often involve protective casings that add substantial weight and volume, creating a challenging design trade-off between protection and portability.

Logistical challenges further complicate military battery deployment. The diversity of equipment requiring power sources has led to a proliferation of battery types and charging systems. This "battery burden" creates significant supply chain complexities and increases the logistical footprint of military operations. Studies indicate that some forward operating bases dedicate up to 20% of supply missions solely to battery resupply.

Rapid charging capabilities remain insufficient for operational needs. Current military battery systems typically require 3-8 hours for a full charge, creating significant downtime between missions. This limitation becomes particularly problematic during extended operations where access to charging infrastructure is limited or compromised.

Security concerns also present unique challenges for military battery technology. Batteries must be designed to prevent unauthorized access to stored energy and data, while also incorporating fail-safe mechanisms to prevent exploitation if captured. These security requirements add complexity to battery management systems and often conflict with goals for simplicity and reliability.

Current Battery Pack Design Approaches

01 Modular battery pack design for flexibility

Modular battery pack designs allow for greater flexibility and adaptability in various applications. These designs feature interchangeable components that can be easily reconfigured or replaced, enabling quick adjustments to capacity, voltage, or form factor. Modular approaches facilitate easier maintenance, upgrades, and customization to meet changing requirements without redesigning the entire system.- Modular battery pack design for flexibility: Modular battery pack designs allow for greater flexibility and adaptability in various applications. These designs feature interchangeable components that can be easily assembled or reconfigured based on specific power requirements. The modular approach enables quick adjustments to battery capacity, voltage, and form factor, enhancing design agility and reducing development time for new applications.

- Scalable battery management systems: Scalable battery management systems provide the ability to monitor and control battery packs of varying sizes and configurations. These systems incorporate flexible control architectures that can adapt to different battery chemistries, cell counts, and power requirements. By implementing scalable management solutions, battery pack designs can be quickly modified to meet changing specifications while maintaining optimal performance and safety.

- Rapid prototyping and manufacturing techniques: Advanced manufacturing techniques enable faster development cycles for battery pack designs. These include 3D printing of battery housings, automated assembly processes, and standardized connection interfaces. Rapid prototyping allows for quick iteration and validation of design concepts, significantly reducing the time from concept to production and enabling more agile responses to market demands.

- Adaptive thermal management solutions: Adaptive thermal management systems improve battery pack design agility by accommodating various operating conditions and power profiles. These solutions incorporate adjustable cooling channels, smart temperature sensors, and dynamic control algorithms that can be reconfigured based on specific application requirements. Flexible thermal management enables battery packs to be quickly optimized for different environments without complete redesign.

- Software-defined battery configurations: Software-defined battery configurations allow for dynamic adjustment of battery pack characteristics through programmable control systems. These designs incorporate intelligent power management algorithms that can reconfigure electrical pathways, adjust charging parameters, and optimize energy distribution based on usage patterns. The software-centric approach enables rapid adaptation to new requirements without physical modifications to the battery pack.

02 Adaptive battery management systems

Advanced battery management systems that can adapt to changing conditions improve battery pack agility. These systems incorporate intelligent algorithms to monitor and optimize battery performance in real-time, adjusting charging parameters, load distribution, and thermal management based on usage patterns and environmental conditions. This adaptive approach extends battery life while maintaining performance across various operating scenarios.Expand Specific Solutions03 Rapid reconfiguration technologies

Technologies enabling rapid reconfiguration of battery packs enhance design agility. These include quick-connect interfaces, standardized form factors, and hot-swappable components that allow for fast adaptation to different power requirements or physical constraints. Such technologies support efficient production changes, field upgrades, and application-specific customization without extensive downtime or engineering resources.Expand Specific Solutions04 Scalable battery architecture

Scalable battery architectures provide the foundation for agile battery pack design. These architectures incorporate standardized cell arrangements and connection methods that can be easily scaled up or down to meet different energy and power requirements. The scalability enables manufacturers to efficiently develop multiple product variants from a common platform, reducing development time and engineering costs while maintaining consistent performance characteristics.Expand Specific Solutions05 Digital twin and simulation tools

Digital twin technology and advanced simulation tools accelerate battery pack design iterations. These virtual modeling approaches enable engineers to rapidly test design changes, predict performance, and identify potential issues before physical prototyping. By simulating various operating conditions and failure modes, designers can quickly optimize battery configurations for specific applications, reducing development cycles and increasing design agility.Expand Specific Solutions

Key Industry Players in Military Power Systems

The military battery pack design market is currently in a growth phase, with increasing demand for agile, lightweight, and high-performance power solutions. The market size is expanding rapidly due to defense modernization programs worldwide, estimated to reach several billion dollars by 2030. Technologically, the field shows varying maturity levels, with established players like LG Energy Solution, Samsung SDI, and Panasonic Energy leading in conventional lithium-ion solutions. Companies like BYD, CATL, and SK On are advancing high-density energy storage technologies, while Toyota and Honda focus on ruggedized designs. Military-specific innovations are emerging from collaborations between defense contractors like Rolls-Royce and battery specialists. The competitive landscape is characterized by a blend of commercial battery giants adapting consumer technologies and specialized firms developing military-specific solutions with enhanced durability and security features.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced military-grade battery pack designs featuring modular architecture that allows for rapid reconfiguration based on mission requirements. Their technology incorporates high-energy density lithium-ion cells with specialized thermal management systems designed to operate in extreme temperature environments (-40°C to +60°C). The company's military battery packs utilize proprietary Battery Management Systems (BMS) with enhanced safety protocols including thermal runaway prevention and ballistic protection features. Their designs incorporate quick-connect interfaces for field replacement and maintenance, reducing downtime in tactical situations. LG Energy Solution's military battery solutions also feature smart power management algorithms that optimize energy usage based on mission profiles and environmental conditions, extending operational range while maintaining performance.

Strengths: Superior energy density-to-weight ratio compared to competitors; advanced thermal management for extreme environments; field-serviceable design. Weaknesses: Higher initial cost compared to conventional solutions; proprietary BMS may limit interoperability with some military systems.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has engineered military-specific battery pack solutions featuring their ruggedized prismatic cell technology optimized for high-stress environments. Their military battery architecture employs a distributed power management system that maintains operational capability even when portions of the pack are damaged, critical for combat situations. Samsung's designs incorporate advanced composite materials for the battery enclosure that provide superior ballistic protection while minimizing weight penalties. Their military battery packs feature intelligent power distribution systems that can prioritize critical systems during emergency operations. Samsung SDI has also developed rapid charging capabilities specifically for forward operating bases, allowing for 80% charge in under 30 minutes while maintaining cell integrity and operational lifespan. The company's military battery solutions include built-in diagnostic systems that provide real-time performance data and predictive maintenance alerts.

Strengths: Exceptional durability in high-vibration and impact environments; distributed architecture provides redundancy; advanced diagnostic capabilities. Weaknesses: Slightly lower energy density compared to some competitors; more complex maintenance requirements due to sophisticated management systems.

Critical Patents in Military-Grade Energy Storage

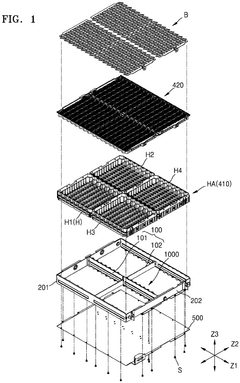

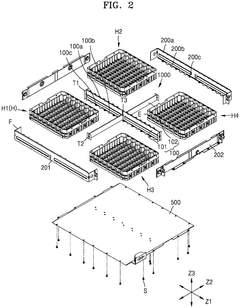

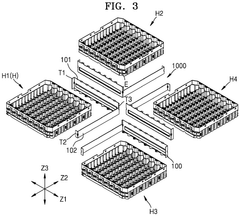

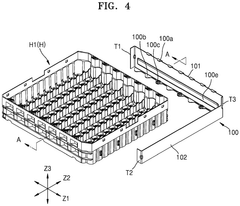

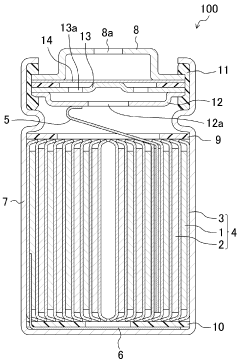

Battery pack

PatentPendingEP4439756A2

Innovation

- A battery pack design featuring a sub-holder assembly with inner and outer plates that securely couple to prevent movement, using upper and lower locking protrusions and nut members to stabilize the sub-holders, and a cooling plate to enhance structural integrity.

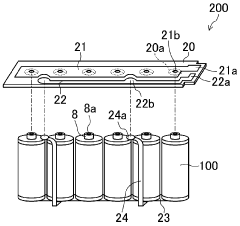

Battery pack

PatentWO2011104792A1

Innovation

- The design incorporates two types of battery modules with different minimum widths, where one is arranged in parallel and the other in series, allowing for increased flexibility in mounting and ensuring current supply even if individual cells fail, with safety features like exhaust ducts for gas discharge.

Ruggedization Standards and Compliance Requirements

Military battery pack designs must adhere to stringent ruggedization standards to ensure operational reliability in extreme conditions. The MIL-STD-810 serves as the cornerstone framework, detailing environmental testing procedures for equipment durability against temperature extremes (-40°C to +85°C), shock resistance (up to 75G), vibration tolerance, and humidity exposure (up to 100% RH). These parameters establish the minimum performance thresholds for military-grade battery systems.

Beyond MIL-STD-810, battery packs for military applications must comply with MIL-STD-461 for electromagnetic compatibility, ensuring they neither emit disruptive electromagnetic interference nor succumb to external electromagnetic fields. This standard is particularly critical for battery systems integrated with sensitive communication equipment or deployed in electromagnetically contested environments.

Safety certification requirements present another compliance dimension, with UN38.3 mandating rigorous testing protocols for lithium-based batteries during transportation. These tests include altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge assessments. Additionally, IEC 62133 certification addresses safety aspects during normal operation and reasonably foreseeable misuse.

Military-specific ingress protection standards, typically requiring IP67 or IP68 ratings, demand complete dust resistance and water immersion protection. These ratings ensure operational integrity in desert environments, during river crossings, or in maritime operations. For specialized applications, additional standards such as MIL-STD-1275 for electrical power systems in military vehicles may apply, regulating voltage spikes, surges, and ripple characteristics.

Compliance verification processes involve comprehensive documentation and third-party testing by certified laboratories. The Defense Logistics Agency (DLA) and similar international bodies often maintain Qualified Products Lists (QPL) for battery systems meeting military specifications. Manufacturers must navigate these certification pathways, which typically involve prototype testing, design validation, and production quality assurance measures.

Recent trends indicate a shift toward harmonized international standards, with NATO STANAG requirements gaining prominence for interoperability among allied forces. The AECTP-500 standard specifically addresses electromagnetic environmental effects for NATO military applications, complementing traditional national standards while facilitating multinational operations and procurement efficiency.

Beyond MIL-STD-810, battery packs for military applications must comply with MIL-STD-461 for electromagnetic compatibility, ensuring they neither emit disruptive electromagnetic interference nor succumb to external electromagnetic fields. This standard is particularly critical for battery systems integrated with sensitive communication equipment or deployed in electromagnetically contested environments.

Safety certification requirements present another compliance dimension, with UN38.3 mandating rigorous testing protocols for lithium-based batteries during transportation. These tests include altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge assessments. Additionally, IEC 62133 certification addresses safety aspects during normal operation and reasonably foreseeable misuse.

Military-specific ingress protection standards, typically requiring IP67 or IP68 ratings, demand complete dust resistance and water immersion protection. These ratings ensure operational integrity in desert environments, during river crossings, or in maritime operations. For specialized applications, additional standards such as MIL-STD-1275 for electrical power systems in military vehicles may apply, regulating voltage spikes, surges, and ripple characteristics.

Compliance verification processes involve comprehensive documentation and third-party testing by certified laboratories. The Defense Logistics Agency (DLA) and similar international bodies often maintain Qualified Products Lists (QPL) for battery systems meeting military specifications. Manufacturers must navigate these certification pathways, which typically involve prototype testing, design validation, and production quality assurance measures.

Recent trends indicate a shift toward harmonized international standards, with NATO STANAG requirements gaining prominence for interoperability among allied forces. The AECTP-500 standard specifically addresses electromagnetic environmental effects for NATO military applications, complementing traditional national standards while facilitating multinational operations and procurement efficiency.

Field Performance Metrics and Testing Protocols

Field performance metrics and testing protocols for military battery packs require rigorous standards that exceed commercial applications due to extreme operational environments. The primary metrics include energy density (Wh/kg), which typically ranges from 100-200 Wh/kg for military-grade lithium-ion systems, significantly higher than lead-acid alternatives at 30-40 Wh/kg. Power density (W/kg) measurements are equally critical, with military specifications demanding 300-500 W/kg to support high-drain applications like communications equipment and weapon systems.

Temperature performance testing represents a cornerstone of military battery evaluation, with protocols requiring functionality across extreme ranges (-40°C to +71°C) compared to commercial standards (-20°C to +60°C). Military testing protocols implement MIL-STD-810H methodologies, particularly Method 501.7 for high temperature and Method 502.7 for low temperature performance, with discharge capacity retention at temperature extremes serving as a key performance indicator.

Vibration and shock resistance testing follows MIL-STD-810H Methods 514.8 and 516.8 respectively, with battery packs required to maintain at least 80% capacity after exposure to 5-500 Hz vibration profiles and shock impacts of 40G. These protocols simulate transportation conditions and battlefield impacts that commercial batteries rarely encounter.

Cycle life testing for military applications extends beyond standard protocols, requiring 80% capacity retention after 500-1000 cycles under variable discharge rates and environmental conditions. This contrasts with commercial testing that typically evaluates consistent discharge patterns in controlled environments.

Electromagnetic interference (EMI) testing per MIL-STD-461G ensures battery management systems do not interfere with sensitive communications equipment, while ballistic protection testing evaluates resistance to projectile penetration and subsequent thermal events. The latter has no commercial equivalent but is essential for battlefield survivability.

Field testing protocols incorporate mission profile testing, where batteries undergo discharge patterns that simulate actual operational scenarios rather than laboratory conditions. This includes variable load profiles that mimic communications equipment usage patterns, surveillance system power draws, and weapon system activation sequences.

Accelerated aging protocols expose battery packs to combinations of environmental stressors simultaneously rather than sequentially, providing more realistic predictions of field performance degradation. Data collection during these tests utilizes embedded sensors that monitor cell-level performance metrics, enabling predictive maintenance algorithms to forecast remaining useful life under battlefield conditions.

Temperature performance testing represents a cornerstone of military battery evaluation, with protocols requiring functionality across extreme ranges (-40°C to +71°C) compared to commercial standards (-20°C to +60°C). Military testing protocols implement MIL-STD-810H methodologies, particularly Method 501.7 for high temperature and Method 502.7 for low temperature performance, with discharge capacity retention at temperature extremes serving as a key performance indicator.

Vibration and shock resistance testing follows MIL-STD-810H Methods 514.8 and 516.8 respectively, with battery packs required to maintain at least 80% capacity after exposure to 5-500 Hz vibration profiles and shock impacts of 40G. These protocols simulate transportation conditions and battlefield impacts that commercial batteries rarely encounter.

Cycle life testing for military applications extends beyond standard protocols, requiring 80% capacity retention after 500-1000 cycles under variable discharge rates and environmental conditions. This contrasts with commercial testing that typically evaluates consistent discharge patterns in controlled environments.

Electromagnetic interference (EMI) testing per MIL-STD-461G ensures battery management systems do not interfere with sensitive communications equipment, while ballistic protection testing evaluates resistance to projectile penetration and subsequent thermal events. The latter has no commercial equivalent but is essential for battlefield survivability.

Field testing protocols incorporate mission profile testing, where batteries undergo discharge patterns that simulate actual operational scenarios rather than laboratory conditions. This includes variable load profiles that mimic communications equipment usage patterns, surveillance system power draws, and weapon system activation sequences.

Accelerated aging protocols expose battery packs to combinations of environmental stressors simultaneously rather than sequentially, providing more realistic predictions of field performance degradation. Data collection during these tests utilizes embedded sensors that monitor cell-level performance metrics, enabling predictive maintenance algorithms to forecast remaining useful life under battlefield conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!