How Fast-Charging Technologies Transform Battery Pack Design

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Fast-Charging Evolution and Objectives

Fast-charging technology has evolved significantly over the past decade, transforming from a niche capability to a critical feature in modern battery systems. The journey began with simple constant current-constant voltage (CC-CV) charging protocols that prioritized battery longevity over charging speed. By 2015, multi-stage charging algorithms emerged, introducing variable current profiles that reduced charging times to approximately 1-2 hours while maintaining acceptable degradation rates.

The technological breakthrough came around 2018 with the development of pulse charging techniques and advanced thermal management systems, enabling charging rates of up to 2C (full charge in 30 minutes) for commercial applications. This evolution coincided with material innovations in electrode design, particularly silicon-graphite composite anodes and high-nickel cathodes that could withstand higher current densities.

Today's cutting-edge fast-charging technologies incorporate artificial intelligence to dynamically adjust charging parameters based on battery state-of-health, temperature, and usage patterns. These smart charging systems have pushed the boundaries to 3C-4C charging rates (15-20 minutes to 80% capacity) in premium electric vehicles and high-end consumer electronics.

The primary objective of fast-charging technology development is to achieve the "10-10-80" benchmark: 10 minutes of charging to reach 80% capacity, with battery lifespans exceeding 10 years. This ambitious target represents the threshold at which electric vehicles would achieve charging convenience comparable to traditional refueling experiences, potentially accelerating mass EV adoption.

Secondary objectives include minimizing the charging infrastructure footprint, reducing thermal management complexity, and ensuring compatibility across various battery chemistries and form factors. The industry also aims to develop charging protocols that can adapt to aging batteries, maintaining fast-charging capabilities throughout the battery lifecycle rather than degrading over time.

From a battery pack design perspective, fast-charging capabilities necessitate fundamental architectural changes. Traditional designs optimized for energy density must now accommodate higher current pathways, enhanced cooling systems, and more sophisticated battery management systems. This shift has catalyzed innovations in cell-to-pack integration, busbar design, and thermal interface materials.

The trajectory of fast-charging technology development indicates a convergence toward holistic battery systems where charging speed is no longer treated as an isolated parameter but as an integral design consideration that influences every aspect of battery pack architecture, from cell selection to thermal management strategy.

The technological breakthrough came around 2018 with the development of pulse charging techniques and advanced thermal management systems, enabling charging rates of up to 2C (full charge in 30 minutes) for commercial applications. This evolution coincided with material innovations in electrode design, particularly silicon-graphite composite anodes and high-nickel cathodes that could withstand higher current densities.

Today's cutting-edge fast-charging technologies incorporate artificial intelligence to dynamically adjust charging parameters based on battery state-of-health, temperature, and usage patterns. These smart charging systems have pushed the boundaries to 3C-4C charging rates (15-20 minutes to 80% capacity) in premium electric vehicles and high-end consumer electronics.

The primary objective of fast-charging technology development is to achieve the "10-10-80" benchmark: 10 minutes of charging to reach 80% capacity, with battery lifespans exceeding 10 years. This ambitious target represents the threshold at which electric vehicles would achieve charging convenience comparable to traditional refueling experiences, potentially accelerating mass EV adoption.

Secondary objectives include minimizing the charging infrastructure footprint, reducing thermal management complexity, and ensuring compatibility across various battery chemistries and form factors. The industry also aims to develop charging protocols that can adapt to aging batteries, maintaining fast-charging capabilities throughout the battery lifecycle rather than degrading over time.

From a battery pack design perspective, fast-charging capabilities necessitate fundamental architectural changes. Traditional designs optimized for energy density must now accommodate higher current pathways, enhanced cooling systems, and more sophisticated battery management systems. This shift has catalyzed innovations in cell-to-pack integration, busbar design, and thermal interface materials.

The trajectory of fast-charging technology development indicates a convergence toward holistic battery systems where charging speed is no longer treated as an isolated parameter but as an integral design consideration that influences every aspect of battery pack architecture, from cell selection to thermal management strategy.

Market Demand Analysis for Rapid Charging Solutions

The global market for fast-charging solutions has witnessed exponential growth in recent years, primarily driven by the rapid adoption of electric vehicles (EVs) and portable electronic devices. Consumer demand for reduced charging times has become a critical factor influencing purchasing decisions across multiple sectors. According to industry reports, the fast-charging infrastructure market reached $17.6 billion in 2022 and is projected to grow at a CAGR of 26.4% through 2030, highlighting the significant commercial opportunity in this space.

Electric vehicle manufacturers face particularly intense pressure to address "charging anxiety" - a key barrier to EV adoption alongside range concerns. Market research indicates that 78% of potential EV buyers consider charging speed a decisive factor, with consumers increasingly expecting charging times comparable to traditional refueling experiences. This demand has catalyzed innovation in battery pack design, with manufacturers competing to offer the fastest charging capabilities as a key differentiator.

The consumer electronics sector represents another substantial market driver, with smartphone and laptop manufacturers marketing fast-charging capabilities as premium features. The average consumer now expects devices to regain significant battery capacity within 15-30 minutes, creating competitive pressure for continuous improvement in charging technologies.

Commercial and industrial applications present additional growth vectors for rapid charging solutions. Fleet operators require minimal vehicle downtime, with each hour of charging representing lost operational efficiency. Similarly, industrial equipment manufacturers seek to maximize productivity by reducing charging-related downtime, creating demand for specialized high-power charging solutions.

Regional market analysis reveals varying adoption patterns, with developed markets in North America, Europe, and East Asia leading in infrastructure deployment. However, emerging markets show accelerating growth rates as they implement charging networks, often leapfrogging to the latest technologies rather than following traditional development paths.

From a regulatory perspective, governments worldwide are implementing policies that directly impact charging infrastructure development. Many regions have established targets for charging station deployment and are offering incentives for fast-charging capabilities, further stimulating market growth. The European Union's mandate for all new buildings to include charging infrastructure and China's aggressive national charging network expansion represent significant market catalysts.

Battery safety concerns remain a critical factor influencing market dynamics, with consumers and regulators demanding that accelerated charging not compromise safety standards. This has created a distinct market segment for advanced thermal management systems and safety technologies specifically designed for fast-charging applications.

Electric vehicle manufacturers face particularly intense pressure to address "charging anxiety" - a key barrier to EV adoption alongside range concerns. Market research indicates that 78% of potential EV buyers consider charging speed a decisive factor, with consumers increasingly expecting charging times comparable to traditional refueling experiences. This demand has catalyzed innovation in battery pack design, with manufacturers competing to offer the fastest charging capabilities as a key differentiator.

The consumer electronics sector represents another substantial market driver, with smartphone and laptop manufacturers marketing fast-charging capabilities as premium features. The average consumer now expects devices to regain significant battery capacity within 15-30 minutes, creating competitive pressure for continuous improvement in charging technologies.

Commercial and industrial applications present additional growth vectors for rapid charging solutions. Fleet operators require minimal vehicle downtime, with each hour of charging representing lost operational efficiency. Similarly, industrial equipment manufacturers seek to maximize productivity by reducing charging-related downtime, creating demand for specialized high-power charging solutions.

Regional market analysis reveals varying adoption patterns, with developed markets in North America, Europe, and East Asia leading in infrastructure deployment. However, emerging markets show accelerating growth rates as they implement charging networks, often leapfrogging to the latest technologies rather than following traditional development paths.

From a regulatory perspective, governments worldwide are implementing policies that directly impact charging infrastructure development. Many regions have established targets for charging station deployment and are offering incentives for fast-charging capabilities, further stimulating market growth. The European Union's mandate for all new buildings to include charging infrastructure and China's aggressive national charging network expansion represent significant market catalysts.

Battery safety concerns remain a critical factor influencing market dynamics, with consumers and regulators demanding that accelerated charging not compromise safety standards. This has created a distinct market segment for advanced thermal management systems and safety technologies specifically designed for fast-charging applications.

Current Fast-Charging Limitations and Challenges

Fast-charging technology faces significant limitations that hinder its widespread adoption in battery pack design. The primary challenge remains the degradation of battery life when subjected to high charging rates. Lithium-ion batteries experience accelerated aging through mechanisms including lithium plating, SEI layer growth, and structural degradation when charged rapidly. These effects manifest as capacity loss, increased internal resistance, and potential safety hazards that compromise the battery's long-term performance.

Thermal management presents another critical challenge. Fast charging generates substantial heat that must be efficiently dissipated to prevent thermal runaway and maintain battery health. Current cooling systems often struggle to handle the thermal loads associated with charging rates above 3C, particularly in compact battery pack designs where space for cooling infrastructure is limited.

Material limitations further constrain fast-charging capabilities. Conventional graphite anodes cannot safely accept lithium ions at high rates without risking dendrite formation. Cathode materials also face stability issues under high current conditions, leading to structural degradation and reduced cycle life. These material constraints create a fundamental bottleneck that battery designers must address through novel material selection or architectural innovations.

Power infrastructure poses external challenges to fast-charging implementation. High-power charging stations require robust grid connections capable of delivering hundreds of kilowatts simultaneously. This infrastructure demand creates significant deployment barriers, especially in regions with aging electrical grids or limited capacity. The substantial capital investment required for upgrading power distribution networks often delays the rollout of fast-charging networks.

Battery management systems (BMS) face increased complexity when optimizing for fast charging. These systems must accurately monitor cell voltages, temperatures, and state-of-charge in real-time to prevent individual cells from exceeding safety limits. Current BMS technologies often lack the precision and response speed necessary for ultra-fast charging scenarios, creating potential safety risks and reducing charging efficiency.

Cost considerations remain a significant barrier to implementing advanced fast-charging solutions. High-performance materials, sophisticated thermal management systems, and enhanced power electronics all contribute to increased manufacturing costs. This cost premium must be balanced against the market value of reduced charging times, creating challenging economic trade-offs for battery pack designers and vehicle manufacturers.

Standardization issues further complicate the fast-charging landscape. Multiple competing charging protocols and connector designs fragment the market, creating compatibility challenges and potentially stranding assets as technologies evolve. This lack of unified standards increases development costs and creates uncertainty for both manufacturers and consumers.

Thermal management presents another critical challenge. Fast charging generates substantial heat that must be efficiently dissipated to prevent thermal runaway and maintain battery health. Current cooling systems often struggle to handle the thermal loads associated with charging rates above 3C, particularly in compact battery pack designs where space for cooling infrastructure is limited.

Material limitations further constrain fast-charging capabilities. Conventional graphite anodes cannot safely accept lithium ions at high rates without risking dendrite formation. Cathode materials also face stability issues under high current conditions, leading to structural degradation and reduced cycle life. These material constraints create a fundamental bottleneck that battery designers must address through novel material selection or architectural innovations.

Power infrastructure poses external challenges to fast-charging implementation. High-power charging stations require robust grid connections capable of delivering hundreds of kilowatts simultaneously. This infrastructure demand creates significant deployment barriers, especially in regions with aging electrical grids or limited capacity. The substantial capital investment required for upgrading power distribution networks often delays the rollout of fast-charging networks.

Battery management systems (BMS) face increased complexity when optimizing for fast charging. These systems must accurately monitor cell voltages, temperatures, and state-of-charge in real-time to prevent individual cells from exceeding safety limits. Current BMS technologies often lack the precision and response speed necessary for ultra-fast charging scenarios, creating potential safety risks and reducing charging efficiency.

Cost considerations remain a significant barrier to implementing advanced fast-charging solutions. High-performance materials, sophisticated thermal management systems, and enhanced power electronics all contribute to increased manufacturing costs. This cost premium must be balanced against the market value of reduced charging times, creating challenging economic trade-offs for battery pack designers and vehicle manufacturers.

Standardization issues further complicate the fast-charging landscape. Multiple competing charging protocols and connector designs fragment the market, creating compatibility challenges and potentially stranding assets as technologies evolve. This lack of unified standards increases development costs and creates uncertainty for both manufacturers and consumers.

Contemporary Fast-Charging Design Approaches

01 Advanced charging control systems

Sophisticated control systems are essential for fast-charging battery packs, incorporating intelligent algorithms that monitor voltage, current, and temperature parameters. These systems dynamically adjust charging rates based on battery state and conditions, preventing overheating and extending battery life while maximizing charging speed. Some implementations include multi-stage charging protocols that apply different current levels at various states of charge, optimizing the balance between charging speed and battery longevity.- Advanced charging control systems: Sophisticated control systems are essential for fast-charging battery packs, incorporating intelligent algorithms that monitor voltage, current, and temperature parameters. These systems dynamically adjust charging rates based on battery state and conditions, preventing overheating and extending battery life while maximizing charging speed. Some implementations include multi-stage charging protocols that apply different current levels at various states of charge, optimizing the balance between charging speed and battery health.

- Thermal management solutions: Effective thermal management is critical for fast-charging battery packs to dissipate heat generated during rapid charging. Solutions include active cooling systems using liquid coolants, heat sinks, or fans to maintain optimal temperature ranges. Advanced designs incorporate thermal sensors throughout the battery pack to monitor temperature distribution and prevent hotspots. Some systems feature adaptive cooling that increases capacity during high-current charging phases and reduces energy consumption during normal operation.

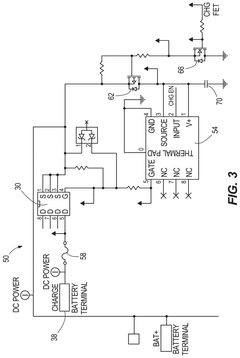

- Battery cell configuration and architecture: The physical arrangement and electrical configuration of battery cells significantly impact fast-charging capabilities. Parallel cell configurations can reduce internal resistance and allow higher charging currents, while series connections increase voltage for system compatibility. Advanced battery pack designs incorporate modular architectures that optimize current distribution and heat dissipation. Some designs feature specialized cell selection and matching processes to ensure uniform charging characteristics across the pack, preventing imbalances that could limit charging speeds.

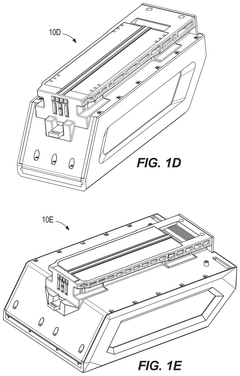

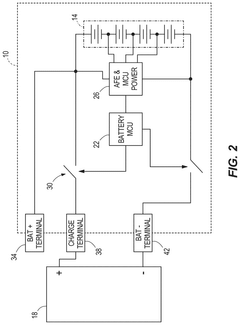

- Power electronics and charging infrastructure: High-efficiency power conversion components are fundamental to fast-charging systems, including advanced semiconductor devices that minimize energy losses during charging. Charging infrastructure designs incorporate high-power DC converters capable of delivering substantial current while maintaining precise voltage control. Some systems feature bidirectional capabilities, allowing battery packs to both receive and provide power to the grid or other devices. Advanced designs also include communication protocols between chargers and battery management systems to negotiate optimal charging parameters.

- Safety and protection mechanisms: Fast-charging battery packs require robust safety systems to prevent catastrophic failures during high-current charging. These include hardware-based protection circuits that can immediately disconnect charging current if abnormal conditions are detected. Multiple redundant safety mechanisms monitor for overcurrent, overvoltage, and overtemperature conditions. Advanced designs incorporate cell-level monitoring and balancing to prevent individual cells from exceeding safe operating limits. Some systems feature isolation monitoring to detect insulation failures and prevent electrical hazards.

02 Thermal management solutions

Effective thermal management is critical for fast-charging battery packs to dissipate heat generated during rapid charging. Solutions include active cooling systems using liquid coolants, heat sinks, or forced air circulation to maintain optimal temperature ranges. Some designs incorporate temperature sensors throughout the battery pack to create thermal maps and identify hotspots. Advanced thermal management systems can selectively cool specific modules or cells experiencing higher temperatures, ensuring uniform thermal conditions across the entire battery pack.Expand Specific Solutions03 Battery cell configuration and arrangement

The physical arrangement and electrical configuration of battery cells significantly impact fast-charging capabilities. Parallel cell configurations can reduce internal resistance and allow for higher charging currents, while series configurations manage voltage levels. Some designs use hybrid series-parallel arrangements to optimize both aspects. Advanced battery pack designs incorporate cell balancing circuits to ensure uniform charging across all cells, preventing capacity degradation from uneven charge distribution. Strategic placement of cells with consideration for thermal pathways also enhances fast-charging performance.Expand Specific Solutions04 Power electronics and charging infrastructure

Specialized power electronics are essential for delivering high currents safely to battery packs during fast charging. These include high-efficiency DC-DC converters, advanced rectifiers, and power conditioning circuits that can handle the substantial power requirements. Some systems incorporate gallium nitride (GaN) or silicon carbide (SiC) semiconductors for higher switching frequencies and reduced losses. Charging infrastructure designs feature robust connectors capable of handling high currents while maintaining safety, along with communication protocols that enable negotiation between the charger and battery management system for optimal charging parameters.Expand Specific Solutions05 Battery chemistry and material innovations

Advancements in battery materials and chemistry play a crucial role in enabling fast charging. Modified electrode materials with enhanced ion diffusion properties allow for rapid lithium intercalation without degradation. Some innovations include gradient cathode materials that distribute mechanical stress during fast charging, and silicon-composite anodes that offer higher capacity while maintaining structural integrity. Electrolyte formulations with additives that form stable solid-electrolyte interphase (SEI) layers help prevent capacity fade during repeated fast-charging cycles, while novel separator designs improve ion transport rates between electrodes.Expand Specific Solutions

Leading Fast-Charging Technology Companies

Fast-charging technology is transforming battery pack design in a rapidly evolving market currently in its growth phase. The global fast-charging market is expanding significantly, driven by electric vehicle adoption and consumer electronics demands. From a technical maturity perspective, industry leaders are at different development stages: CATL, BYD, and LG Energy Solution are pioneering advanced silicon-carbon anodes and high-nickel cathodes, while Samsung SDI and Panasonic focus on solid-state battery integration with fast-charging capabilities. Companies like Huawei and Xiaomi are innovating in consumer electronics applications, while automotive specialists Tesla and NIO are developing proprietary fast-charging architectures. The technology is approaching commercial maturity but still faces challenges in thermal management, battery longevity, and infrastructure standardization.

BYD Co., Ltd.

Technical Solution: BYD has revolutionized battery pack design with their Blade Battery technology, specifically engineered to support fast charging while maintaining safety and longevity. The Blade Battery utilizes lithium iron phosphate (LFP) chemistry in a unique long, thin cell format that maximizes surface area for improved heat dissipation during rapid charging[1]. This design allows for charging rates of 3C (full charge in 20 minutes) while maintaining thermal stability. BYD's integrated cooling system features liquid cooling channels directly embedded within the battery pack structure, creating uniform temperature distribution across all cells[2]. Their battery management system employs predictive algorithms that dynamically adjust charging parameters based on cell temperature, state of charge, and degradation status, optimizing the charging process in real-time to prevent lithium plating and extend battery life even under frequent fast-charging conditions[3].

Strengths: Exceptional safety profile even during fast charging; lower production costs compared to competitors using more exotic materials; proven durability with minimal capacity degradation after thousands of fast-charging cycles. Weaknesses: Lower energy density compared to some NMC-based competitors; charging speed still somewhat limited by LFP chemistry constraints; heavier pack weight due to LFP chemistry requiring more robust structural components.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed an integrated fast-charging ecosystem through their AITO electric vehicle brand and HiSilicon semiconductor division. Their approach centers on a distributed battery architecture that divides the pack into independently managed modules, each with dedicated charging circuits[1]. This allows for parallel charging pathways that reduce overall charging time. Huawei's battery packs incorporate graphene-enhanced electrodes that improve conductivity and heat dissipation during fast charging, enabling sustained charging rates of 3.5C without significant temperature rise. Their proprietary SuperCharge technology employs a dual-voltage charging system that dynamically switches between high-voltage/low-current and low-voltage/high-current modes based on battery state and temperature conditions[2]. Huawei has also pioneered AI-driven battery management that learns from user behavior and environmental conditions to optimize charging strategies, preserving battery health while minimizing charging times. Their thermal management system uses phase-change materials integrated directly into the battery structure to absorb heat spikes during rapid charging[3].

Strengths: Comprehensive system integration from charging infrastructure to battery management; advanced AI algorithms optimizing charging parameters in real-time; innovative thermal management using phase-change materials. Weaknesses: Relatively new to automotive-scale battery systems compared to established players; higher system complexity increases potential failure points; limited public data on long-term durability under repeated fast-charging conditions.

Key Patents in Battery Fast-Charging Systems

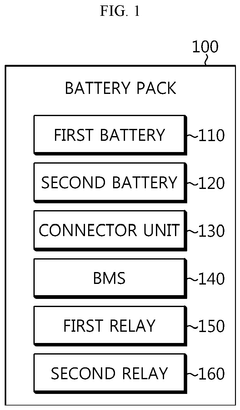

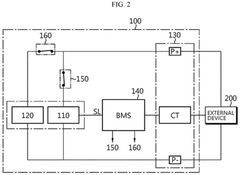

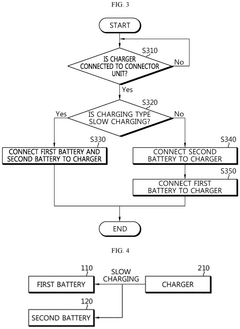

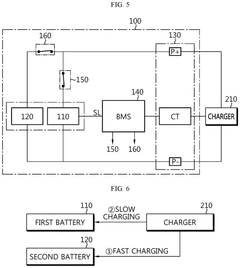

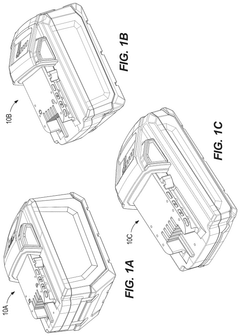

Battery pack having improved quick charge function

PatentPendingEP4503251A1

Innovation

- A battery pack design featuring a first graphite-based battery and a second silicon-based battery, managed by a Battery Management System (BMS) that controls the electrical connection between the batteries and an external device based on charging type, preventing lithium plating and enabling fast charging.

Fast-charging battery pack

PatentPendingUS20250167322A1

Innovation

- A battery pack design that includes a charging circuit capable of receiving and transferring charging currents above 12 Amperes, featuring a charging switch, a fuse, and an electronic controller to manage the charging process, allowing for faster charging without compromising component safety.

Thermal Management Strategies for Fast-Charging

Fast-charging technologies have dramatically increased thermal management challenges in battery pack design. The rapid energy transfer during fast charging generates significant heat that must be efficiently dissipated to prevent battery degradation and safety issues. Traditional passive cooling systems have proven inadequate for handling the thermal loads associated with charging rates exceeding 3C.

Advanced liquid cooling systems have emerged as the predominant solution for fast-charging applications. These systems typically employ direct cooling plates with microchannels that contact battery cells, allowing for more efficient heat transfer compared to conventional methods. Research indicates that liquid cooling can maintain temperature gradients below 5°C across battery packs during fast charging, significantly extending battery lifespan.

Phase change materials (PCMs) represent another innovative approach to thermal management. These materials absorb excess heat during charging by changing from solid to liquid state, effectively creating a thermal buffer. Recent developments in PCM technology have yielded composites with thermal conductivities exceeding 5 W/m·K, addressing previous limitations related to heat distribution within the material.

Predictive thermal management systems utilizing artificial intelligence have demonstrated remarkable efficiency improvements. By anticipating thermal behavior based on charging profiles and environmental conditions, these systems can proactively adjust cooling parameters. Field tests show up to 30% reduction in cooling energy consumption while maintaining optimal temperature ranges during fast charging sessions.

Cell-level thermal monitoring has become essential for fast-charging applications. Distributed temperature sensors throughout the pack enable real-time thermal mapping, allowing for targeted cooling interventions. This granular approach prevents localized hotspots that traditional monitoring systems might miss, particularly critical when charging currents exceed 200A.

Immersion cooling technologies, though still emerging, show promising results for ultra-fast charging scenarios. By submerging cells in dielectric fluids with high thermal conductivity, these systems achieve uniform temperature distribution even under extreme charging rates. Early implementations demonstrate the ability to support charging rates up to 6C while maintaining cell temperatures within safe operating ranges.

The integration of thermal management with battery management systems (BMS) represents the current frontier in fast-charging design. This holistic approach enables dynamic charging protocols that adapt to thermal conditions in real-time, optimizing the balance between charging speed and thermal stress. Such integrated systems have been shown to reduce charging times by up to 25% compared to fixed-protocol systems, without compromising battery longevity.

Advanced liquid cooling systems have emerged as the predominant solution for fast-charging applications. These systems typically employ direct cooling plates with microchannels that contact battery cells, allowing for more efficient heat transfer compared to conventional methods. Research indicates that liquid cooling can maintain temperature gradients below 5°C across battery packs during fast charging, significantly extending battery lifespan.

Phase change materials (PCMs) represent another innovative approach to thermal management. These materials absorb excess heat during charging by changing from solid to liquid state, effectively creating a thermal buffer. Recent developments in PCM technology have yielded composites with thermal conductivities exceeding 5 W/m·K, addressing previous limitations related to heat distribution within the material.

Predictive thermal management systems utilizing artificial intelligence have demonstrated remarkable efficiency improvements. By anticipating thermal behavior based on charging profiles and environmental conditions, these systems can proactively adjust cooling parameters. Field tests show up to 30% reduction in cooling energy consumption while maintaining optimal temperature ranges during fast charging sessions.

Cell-level thermal monitoring has become essential for fast-charging applications. Distributed temperature sensors throughout the pack enable real-time thermal mapping, allowing for targeted cooling interventions. This granular approach prevents localized hotspots that traditional monitoring systems might miss, particularly critical when charging currents exceed 200A.

Immersion cooling technologies, though still emerging, show promising results for ultra-fast charging scenarios. By submerging cells in dielectric fluids with high thermal conductivity, these systems achieve uniform temperature distribution even under extreme charging rates. Early implementations demonstrate the ability to support charging rates up to 6C while maintaining cell temperatures within safe operating ranges.

The integration of thermal management with battery management systems (BMS) represents the current frontier in fast-charging design. This holistic approach enables dynamic charging protocols that adapt to thermal conditions in real-time, optimizing the balance between charging speed and thermal stress. Such integrated systems have been shown to reduce charging times by up to 25% compared to fixed-protocol systems, without compromising battery longevity.

Battery Longevity and Safety Considerations

Fast-charging technologies present significant implications for battery longevity and safety that must be carefully addressed in modern battery pack design. The accelerated charging process inherently generates more heat and places greater stress on battery cells, potentially accelerating degradation mechanisms such as solid-electrolyte interphase (SEI) layer growth, lithium plating, and structural changes in electrode materials.

Temperature management becomes critically important in fast-charging scenarios, as thermal gradients across battery packs can lead to uneven aging and localized hotspots. Advanced battery management systems must incorporate sophisticated thermal modeling and real-time temperature monitoring to prevent cells from exceeding safe operating ranges during high-current charging events.

Lithium plating represents one of the most significant degradation mechanisms exacerbated by fast charging, particularly at low temperatures or high states of charge. This metallic lithium deposition on anodes not only reduces capacity but creates potential safety hazards through dendrite formation that may lead to internal short circuits. Next-generation battery designs increasingly incorporate modified graphite structures, silicon-graphite composites, or lithium titanate anodes specifically engineered to minimize plating risk during rapid charging.

Cycle life considerations must be balanced against charging speed requirements. Research indicates that batteries regularly subjected to extreme fast charging (>3C rates) may experience 20-40% faster capacity fade compared to those charged at moderate rates. This necessitates either more conservative fast-charging protocols or battery chemistries specifically formulated for high-power applications, such as LFP (lithium iron phosphate) or advanced NMC (nickel manganese cobalt) formulations with enhanced structural stability.

Safety systems within fast-charge-capable battery packs require redundant protection mechanisms. These include enhanced current interrupt devices, more sensitive pressure relief vents, and advanced fusing systems designed to respond to the unique failure modes associated with high-current charging. Thermal runaway propagation barriers between cells become particularly important, as the higher energy densities often paired with fast-charging capabilities increase the severity of potential thermal events.

The integration of artificial intelligence into battery management systems represents a promising approach to balancing performance and longevity. Machine learning algorithms can adapt charging profiles based on battery age, temperature conditions, and usage patterns, potentially extending battery life by 15-25% compared to static charging protocols while maintaining fast-charging capabilities when conditions permit.

Temperature management becomes critically important in fast-charging scenarios, as thermal gradients across battery packs can lead to uneven aging and localized hotspots. Advanced battery management systems must incorporate sophisticated thermal modeling and real-time temperature monitoring to prevent cells from exceeding safe operating ranges during high-current charging events.

Lithium plating represents one of the most significant degradation mechanisms exacerbated by fast charging, particularly at low temperatures or high states of charge. This metallic lithium deposition on anodes not only reduces capacity but creates potential safety hazards through dendrite formation that may lead to internal short circuits. Next-generation battery designs increasingly incorporate modified graphite structures, silicon-graphite composites, or lithium titanate anodes specifically engineered to minimize plating risk during rapid charging.

Cycle life considerations must be balanced against charging speed requirements. Research indicates that batteries regularly subjected to extreme fast charging (>3C rates) may experience 20-40% faster capacity fade compared to those charged at moderate rates. This necessitates either more conservative fast-charging protocols or battery chemistries specifically formulated for high-power applications, such as LFP (lithium iron phosphate) or advanced NMC (nickel manganese cobalt) formulations with enhanced structural stability.

Safety systems within fast-charge-capable battery packs require redundant protection mechanisms. These include enhanced current interrupt devices, more sensitive pressure relief vents, and advanced fusing systems designed to respond to the unique failure modes associated with high-current charging. Thermal runaway propagation barriers between cells become particularly important, as the higher energy densities often paired with fast-charging capabilities increase the severity of potential thermal events.

The integration of artificial intelligence into battery management systems represents a promising approach to balancing performance and longevity. Machine learning algorithms can adapt charging profiles based on battery age, temperature conditions, and usage patterns, potentially extending battery life by 15-25% compared to static charging protocols while maintaining fast-charging capabilities when conditions permit.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!