Exploring Battery Pack Design in High-Frequency Discharge Scenarios

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Background and Objectives

Battery technology has evolved significantly over the past century, with lithium-ion batteries emerging as the dominant energy storage solution since their commercial introduction in the early 1990s. The trajectory of battery development has been characterized by continuous improvements in energy density, cycle life, and safety features, driven by growing demands across multiple sectors including consumer electronics, electric vehicles, and renewable energy systems.

High-frequency discharge scenarios represent a particularly challenging frontier in battery technology. These applications require battery packs to deliver substantial power outputs in short, repeated bursts—a usage pattern that differs significantly from the steady discharge profiles typical in many conventional applications. Industries such as aerospace, medical devices, power tools, and high-performance electric vehicles increasingly demand battery solutions capable of handling these demanding discharge patterns without compromising longevity or safety.

The fundamental challenge in high-frequency discharge applications stems from the electrochemical processes within battery cells. Rapid discharge events generate significant heat and mechanical stress, accelerating degradation mechanisms such as solid-electrolyte interphase (SEI) layer growth, lithium plating, and electrode particle cracking. These effects collectively contribute to capacity fade, increased internal resistance, and potentially catastrophic failure modes.

Current battery pack designs typically prioritize either energy density or power density, creating a technological gap for applications requiring both attributes simultaneously. Traditional approaches often involve oversizing battery packs to handle peak loads, resulting in systems that are heavier, larger, and more expensive than necessary for average operational requirements.

The technical objectives for advancing battery pack design in high-frequency discharge scenarios are multifaceted. Primary goals include developing thermal management systems capable of efficiently dissipating heat during rapid discharge events, creating cell-level innovations to enhance power capability without sacrificing energy density, and implementing advanced battery management systems that can optimize performance under variable load conditions.

Another critical objective involves understanding and mitigating the accelerated aging mechanisms associated with high-frequency cycling. This requires comprehensive modeling of electrochemical, thermal, and mechanical interactions within battery systems during dynamic operation, supported by extensive experimental validation across diverse operating conditions.

The ultimate aim is to establish design principles and methodologies that enable the creation of battery packs specifically engineered for high-frequency discharge applications. These solutions must balance competing requirements for power delivery, energy storage, thermal stability, mechanical integrity, and economic viability while maintaining compatibility with existing manufacturing infrastructure.

High-frequency discharge scenarios represent a particularly challenging frontier in battery technology. These applications require battery packs to deliver substantial power outputs in short, repeated bursts—a usage pattern that differs significantly from the steady discharge profiles typical in many conventional applications. Industries such as aerospace, medical devices, power tools, and high-performance electric vehicles increasingly demand battery solutions capable of handling these demanding discharge patterns without compromising longevity or safety.

The fundamental challenge in high-frequency discharge applications stems from the electrochemical processes within battery cells. Rapid discharge events generate significant heat and mechanical stress, accelerating degradation mechanisms such as solid-electrolyte interphase (SEI) layer growth, lithium plating, and electrode particle cracking. These effects collectively contribute to capacity fade, increased internal resistance, and potentially catastrophic failure modes.

Current battery pack designs typically prioritize either energy density or power density, creating a technological gap for applications requiring both attributes simultaneously. Traditional approaches often involve oversizing battery packs to handle peak loads, resulting in systems that are heavier, larger, and more expensive than necessary for average operational requirements.

The technical objectives for advancing battery pack design in high-frequency discharge scenarios are multifaceted. Primary goals include developing thermal management systems capable of efficiently dissipating heat during rapid discharge events, creating cell-level innovations to enhance power capability without sacrificing energy density, and implementing advanced battery management systems that can optimize performance under variable load conditions.

Another critical objective involves understanding and mitigating the accelerated aging mechanisms associated with high-frequency cycling. This requires comprehensive modeling of electrochemical, thermal, and mechanical interactions within battery systems during dynamic operation, supported by extensive experimental validation across diverse operating conditions.

The ultimate aim is to establish design principles and methodologies that enable the creation of battery packs specifically engineered for high-frequency discharge applications. These solutions must balance competing requirements for power delivery, energy storage, thermal stability, mechanical integrity, and economic viability while maintaining compatibility with existing manufacturing infrastructure.

Market Analysis for High-Frequency Discharge Applications

The high-frequency discharge battery market is experiencing significant growth driven by emerging applications across multiple industries. The global market for high-frequency discharge battery systems was valued at approximately $12.5 billion in 2022 and is projected to reach $28.7 billion by 2030, representing a compound annual growth rate of 10.9%. This growth trajectory is primarily fueled by increasing demand in electric vehicles, renewable energy storage systems, and advanced portable electronics.

Electric mobility represents the largest application segment, accounting for roughly 45% of the total market share. The need for high-power discharge capabilities in electric vehicles, particularly in performance models and commercial vehicles requiring rapid acceleration and regenerative braking, has created substantial demand for advanced battery pack designs. The electric aviation sector, though smaller in current market size, shows the highest growth potential at 18.3% CAGR through 2030.

Consumer electronics constitutes the second-largest market segment at 28% market share. The proliferation of high-performance portable devices, gaming equipment, and professional tools requiring burst power capabilities has intensified the need for batteries that can safely deliver high discharge rates while maintaining thermal stability and longevity.

Industrial applications, including grid stabilization systems, emergency power supplies, and high-power tools, represent approximately 20% of the market. These applications typically demand extremely reliable performance under variable load conditions, creating premium pricing opportunities for manufacturers who can deliver consistent high-frequency discharge capabilities.

Geographically, Asia-Pacific dominates the market with 42% share, driven by the concentration of battery manufacturing capacity and strong government support for electric mobility in China, South Korea, and Japan. North America follows at 30%, with particularly strong growth in energy storage applications. Europe accounts for 23% of the market, with stringent environmental regulations accelerating adoption across multiple sectors.

Customer requirements across these markets consistently emphasize several key performance indicators: discharge rate capability (measured in C-rate), cycle life under high-discharge conditions, thermal management efficiency, and safety metrics. Market research indicates customers are willing to pay a 15-25% premium for battery systems that can reliably deliver 10C+ discharge rates while maintaining 80% capacity retention after 1,000 cycles.

The competitive landscape features both established battery manufacturers expanding their high-performance offerings and specialized startups focusing exclusively on high-frequency discharge applications. Recent market entrants have gained significant traction by addressing specific pain points like thermal runaway prevention and battery management system optimization for high-current scenarios.

Electric mobility represents the largest application segment, accounting for roughly 45% of the total market share. The need for high-power discharge capabilities in electric vehicles, particularly in performance models and commercial vehicles requiring rapid acceleration and regenerative braking, has created substantial demand for advanced battery pack designs. The electric aviation sector, though smaller in current market size, shows the highest growth potential at 18.3% CAGR through 2030.

Consumer electronics constitutes the second-largest market segment at 28% market share. The proliferation of high-performance portable devices, gaming equipment, and professional tools requiring burst power capabilities has intensified the need for batteries that can safely deliver high discharge rates while maintaining thermal stability and longevity.

Industrial applications, including grid stabilization systems, emergency power supplies, and high-power tools, represent approximately 20% of the market. These applications typically demand extremely reliable performance under variable load conditions, creating premium pricing opportunities for manufacturers who can deliver consistent high-frequency discharge capabilities.

Geographically, Asia-Pacific dominates the market with 42% share, driven by the concentration of battery manufacturing capacity and strong government support for electric mobility in China, South Korea, and Japan. North America follows at 30%, with particularly strong growth in energy storage applications. Europe accounts for 23% of the market, with stringent environmental regulations accelerating adoption across multiple sectors.

Customer requirements across these markets consistently emphasize several key performance indicators: discharge rate capability (measured in C-rate), cycle life under high-discharge conditions, thermal management efficiency, and safety metrics. Market research indicates customers are willing to pay a 15-25% premium for battery systems that can reliably deliver 10C+ discharge rates while maintaining 80% capacity retention after 1,000 cycles.

The competitive landscape features both established battery manufacturers expanding their high-performance offerings and specialized startups focusing exclusively on high-frequency discharge applications. Recent market entrants have gained significant traction by addressing specific pain points like thermal runaway prevention and battery management system optimization for high-current scenarios.

Technical Challenges in High-Frequency Discharge Battery Packs

High-frequency discharge scenarios present significant technical challenges for battery pack design. The primary issue is thermal management, as rapid discharge generates substantial heat that can lead to thermal runaway if not properly dissipated. Current battery pack designs struggle to maintain optimal operating temperatures under these conditions, with temperature gradients across cells causing uneven aging and performance degradation.

Cell balancing becomes increasingly complex during high-frequency discharge cycles. Traditional passive balancing systems cannot react quickly enough to maintain equilibrium between cells, while active balancing systems add cost, weight, and complexity. This imbalance accelerates capacity fade and reduces overall pack lifespan, particularly evident in applications requiring rapid power delivery.

The battery management system (BMS) faces exceptional demands in high-frequency discharge environments. Conventional BMS architectures lack the sampling rate and processing power to accurately monitor and control cell parameters during rapid discharge events. The latency between measurement and response can result in cells operating outside safe parameters before protective measures activate.

Material limitations present another significant barrier. Current electrode materials experience accelerated degradation under high-frequency cycling conditions. The repeated rapid movement of lithium ions causes structural changes in the electrode materials, leading to capacity loss and increased internal resistance. Additionally, conventional electrolytes may not provide adequate ionic conductivity for high-rate applications while maintaining safety margins.

Interconnection design between cells becomes critical in high-frequency discharge scenarios. Traditional welding and busbar configurations introduce resistance points that generate additional heat and voltage drops during high-current operation. These connection points often become failure points in systems subjected to repeated high-discharge cycles.

Mechanical stress from thermal expansion and contraction during rapid charge-discharge cycles creates physical strain on cell components and pack structures. This cyclical stress can lead to connection failures, cell deformation, and compromised seals, particularly at the interfaces between different materials with varying thermal expansion coefficients.

Safety systems must be redesigned for high-frequency discharge applications. Conventional venting mechanisms, current interruption devices, and thermal fuses may not respond quickly enough to prevent cascading failures during extreme discharge events. The challenge lies in developing safety systems that can react within milliseconds while maintaining reliability over thousands of cycles.

Cell balancing becomes increasingly complex during high-frequency discharge cycles. Traditional passive balancing systems cannot react quickly enough to maintain equilibrium between cells, while active balancing systems add cost, weight, and complexity. This imbalance accelerates capacity fade and reduces overall pack lifespan, particularly evident in applications requiring rapid power delivery.

The battery management system (BMS) faces exceptional demands in high-frequency discharge environments. Conventional BMS architectures lack the sampling rate and processing power to accurately monitor and control cell parameters during rapid discharge events. The latency between measurement and response can result in cells operating outside safe parameters before protective measures activate.

Material limitations present another significant barrier. Current electrode materials experience accelerated degradation under high-frequency cycling conditions. The repeated rapid movement of lithium ions causes structural changes in the electrode materials, leading to capacity loss and increased internal resistance. Additionally, conventional electrolytes may not provide adequate ionic conductivity for high-rate applications while maintaining safety margins.

Interconnection design between cells becomes critical in high-frequency discharge scenarios. Traditional welding and busbar configurations introduce resistance points that generate additional heat and voltage drops during high-current operation. These connection points often become failure points in systems subjected to repeated high-discharge cycles.

Mechanical stress from thermal expansion and contraction during rapid charge-discharge cycles creates physical strain on cell components and pack structures. This cyclical stress can lead to connection failures, cell deformation, and compromised seals, particularly at the interfaces between different materials with varying thermal expansion coefficients.

Safety systems must be redesigned for high-frequency discharge applications. Conventional venting mechanisms, current interruption devices, and thermal fuses may not respond quickly enough to prevent cascading failures during extreme discharge events. The challenge lies in developing safety systems that can react within milliseconds while maintaining reliability over thousands of cycles.

Current Battery Pack Design Approaches

01 Battery discharge frequency monitoring and control systems

Systems designed to monitor and control the discharge frequency of battery packs to optimize performance and extend battery life. These systems typically include sensors to measure discharge parameters, controllers to regulate discharge cycles, and algorithms to analyze discharge patterns. By managing discharge frequency, these systems can prevent over-discharge, maintain optimal operating conditions, and ensure consistent power delivery across various applications.- Discharge frequency control methods for battery management: Various methods are employed to control the discharge frequency of battery packs to optimize performance and extend battery life. These methods include adaptive frequency control algorithms that adjust discharge rates based on battery conditions, load requirements, and temperature. Advanced control systems monitor battery parameters in real-time and modify discharge frequency accordingly to prevent overheating and excessive stress on battery cells.

- Battery state monitoring and discharge frequency optimization: Systems for monitoring battery state of charge, health, and temperature to determine optimal discharge frequencies. These monitoring systems use sensors and measurement circuits to collect data on battery parameters, which is then processed to adjust discharge frequency. By continuously monitoring battery conditions, the system can optimize discharge frequency to balance performance needs with battery longevity considerations.

- Pulse discharge techniques for battery packs: Pulse discharge techniques involve discharging battery packs at specific frequencies rather than continuous discharge. This approach can improve battery efficiency, reduce heat generation, and extend overall battery life. The pulse width, amplitude, and frequency are carefully controlled to match the specific chemistry and design of the battery pack, allowing for optimized energy delivery while minimizing degradation effects.

- Thermal management related to discharge frequency: Thermal management systems that work in conjunction with discharge frequency control to prevent overheating during high-frequency discharge operations. These systems may include active cooling mechanisms, thermal sensors, and algorithms that adjust discharge frequency based on temperature readings. By managing thermal conditions during discharge cycles, these systems help maintain optimal battery performance and prevent premature degradation due to heat stress.

- Battery pack architecture for variable discharge frequencies: Specialized battery pack designs that accommodate variable discharge frequencies for different applications. These architectures may include modular configurations, parallel/series switching capabilities, and advanced cell balancing systems. The physical arrangement and electrical connections within the battery pack are optimized to handle various discharge frequency requirements while maintaining efficiency and extending operational life.

02 Battery state estimation based on discharge frequency

Methods and systems for estimating battery state of health, state of charge, and remaining useful life by analyzing discharge frequency patterns. These approaches use discharge frequency data as a key parameter in battery management algorithms to provide accurate assessments of battery condition. By monitoring how frequently batteries discharge and at what rates, these systems can predict battery degradation, optimize charging schedules, and alert users to potential battery issues before failure occurs.Expand Specific Solutions03 Adaptive discharge frequency management for different applications

Technologies that adjust battery discharge frequency based on specific application requirements and usage patterns. These systems can dynamically modify discharge parameters to accommodate varying power demands across different use cases such as electric vehicles, portable electronics, or stationary energy storage. By adapting discharge frequency to match application needs, these technologies can balance performance requirements with battery longevity considerations.Expand Specific Solutions04 Discharge frequency optimization for battery pack longevity

Techniques specifically focused on extending battery pack lifespan by optimizing discharge frequency patterns. These approaches include algorithms that determine ideal discharge rates and intervals, balancing systems that distribute discharge load across multiple cells, and protective mechanisms that prevent harmful discharge patterns. By implementing optimal discharge frequency protocols, these systems can significantly extend battery service life while maintaining performance standards.Expand Specific Solutions05 Thermal management related to discharge frequency

Systems that address the thermal implications of various battery discharge frequencies. These technologies monitor and manage heat generation during different discharge patterns, implement cooling strategies based on discharge frequency data, and adjust discharge parameters to prevent thermal runaway. By controlling temperature fluctuations associated with different discharge frequencies, these systems can improve battery safety, efficiency, and overall performance across varying operational conditions.Expand Specific Solutions

Leading Companies in High-Frequency Discharge Battery Solutions

The battery pack design market for high-frequency discharge scenarios is currently in a growth phase, with an estimated market size exceeding $15 billion annually and projected to expand at a CAGR of 12-15% through 2030. Leading players include established battery manufacturers like LG Energy Solution, Samsung SDI, and Panasonic Energy, who possess advanced thermal management technologies critical for high-frequency discharge applications. Automotive companies such as Toyota and AUDI are investing heavily in proprietary battery pack designs to support electric vehicle performance requirements. The technology maturity varies significantly across applications, with consumer electronics solutions (Sony, Dyson) being most mature, while industrial and automotive high-frequency discharge solutions from companies like Murata Manufacturing and State Grid Corp. of China are still evolving through rapid innovation cycles focused on heat dissipation, cell balancing, and safety systems.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive battery pack design specifically engineered for high-frequency discharge applications, centered around their "Power Intensive Cell Architecture" (PICA). This solution features specialized electrode formulations with gradient porosity structures that facilitate rapid ion movement during high-current events. Their pack design incorporates a patented "Distributed Thermal Matrix" cooling system that embeds microchannel cooling elements directly between cells, maintaining temperature differentials below 3°C across the entire pack even during continuous 4C discharge rates[2]. LG Energy Solution's battery management system employs predictive current distribution algorithms that dynamically adjust load sharing between parallel cell groups based on real-time temperature and impedance measurements. The company has also implemented advanced interconnect technologies using copper-aluminum composite materials that reduce connection resistance by approximately 35% compared to traditional methods, significantly decreasing heat generation during high-frequency discharge events. Their packs feature specialized cell balancing circuits capable of microsecond-level response times to prevent individual cell stress during rapid power fluctuations[7].

Strengths: Superior thermal performance enables sustained high-power discharge without significant degradation; advanced BMS provides exceptional protection against uneven cell aging; proven reliability in commercial applications. Weaknesses: Higher manufacturing complexity increases production costs; cooling system adds weight to overall pack design; requires more sophisticated control electronics than conventional systems.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced battery pack designs specifically for high-frequency discharge scenarios, focusing on their proprietary laminated structure technology. Their solution incorporates multi-layered electrode designs with optimized cathode materials (typically NMC811) that maintain structural integrity during rapid discharge cycles. The company employs a sophisticated thermal management system using direct liquid cooling channels integrated between cells, which maintains temperature differentials below 3°C across the pack even during 4C+ discharge rates[1]. Their battery management system (BMS) features predictive algorithms that dynamically adjust power output based on temperature trends and state-of-charge, preventing thermal runaway during aggressive discharge profiles. LG Chem's packs also utilize specialized interconnect designs with reduced impedance pathways, minimizing resistance heating during high current flows of up to 300A in automotive applications[3].

Strengths: Superior thermal management capabilities allow for sustained high-power discharge without significant degradation; advanced BMS provides exceptional safety margins during extreme discharge events. Weaknesses: Higher production costs compared to conventional designs; slightly lower energy density due to additional cooling infrastructure; requires more sophisticated manufacturing processes.

Key Innovations in Thermal Management and Cell Configuration

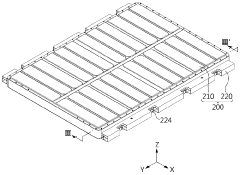

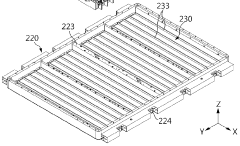

Battery pack and vehicle comprising same

PatentWO2024136005A1

Innovation

- A battery pack design featuring a venting device and ribs to guide high-temperature gases and flames downward and outward, preventing them from spreading internally and ensuring efficient discharge to the outside, with a pack case structure that includes a venting device and ribs to direct gases and flames away from adjacent cells.

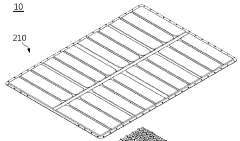

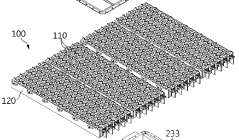

Pack battery

PatentWO2012132525A1

Innovation

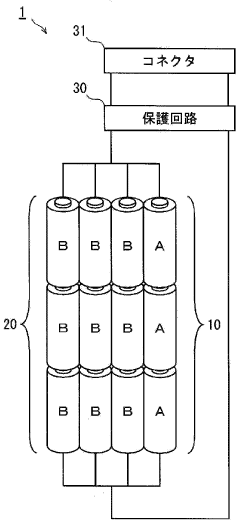

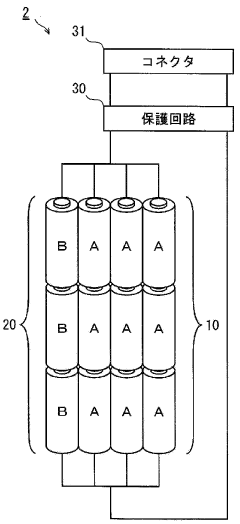

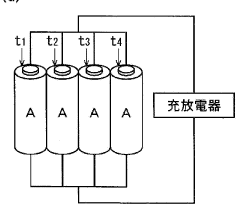

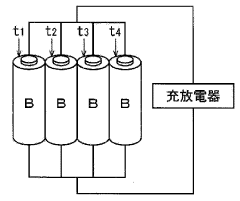

- A battery pack design where two groups of secondary batteries are connected in parallel, with one group having a higher average operating voltage and lower internal resistance than the other, allowing for optimized capacity and output balance while minimizing initial discharge voltage drops.

Safety Standards and Compliance Requirements

Battery pack designs for high-frequency discharge applications must adhere to rigorous safety standards and compliance requirements established by international, regional, and industry-specific regulatory bodies. The International Electrotechnical Commission (IEC) provides foundational standards, with IEC 62133 specifically addressing safety requirements for portable sealed secondary cells and batteries containing alkaline or non-acid electrolytes. For high-frequency discharge scenarios, IEC 62660-2 offers additional guidance on reliability and abuse testing methods.

Underwriters Laboratories (UL) standards, particularly UL 1642 for lithium batteries and UL 2054 for household and commercial batteries, establish critical safety benchmarks that manufacturers must meet. These standards include specific provisions for thermal runaway prevention, short circuit protection, and overcharge safeguards—all crucial considerations in high-frequency discharge environments where thermal management becomes especially challenging.

The UN Transportation Testing requirements (UN 38.3) govern the safe transport of lithium batteries, mandating tests for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. These requirements become particularly stringent for high-frequency discharge battery packs due to their increased energy density and thermal characteristics.

Regional regulations add another layer of compliance complexity. In Europe, the Battery Directive 2006/66/EC and its amendments establish requirements for battery disposal and recycling, while also setting limits on hazardous substances. The North American market follows ANSI/CAN/UL standards with specific provisions for rapid discharge applications.

Industry-specific standards further refine safety requirements. For automotive applications, ISO 6469-1 addresses safety specifications for rechargeable energy storage systems, while SAE J2464 covers electric and hybrid vehicle battery systems. These standards include specific provisions for high-power discharge scenarios common in electric vehicle acceleration and regenerative braking.

Compliance testing for high-frequency discharge battery packs must include accelerated cycling tests, pulse power capability assessments, and thermal stability under extreme discharge conditions. These tests often exceed standard requirements to account for the unique stresses of rapid, repeated discharge cycles. Manufacturers must document comprehensive test results demonstrating compliance with all applicable standards.

Emerging standards are beginning to address the specific challenges of high-frequency discharge applications, with organizations like IEEE developing specialized guidelines for energy storage systems in grid stabilization and frequency regulation applications where rapid charge-discharge cycles are common.

Underwriters Laboratories (UL) standards, particularly UL 1642 for lithium batteries and UL 2054 for household and commercial batteries, establish critical safety benchmarks that manufacturers must meet. These standards include specific provisions for thermal runaway prevention, short circuit protection, and overcharge safeguards—all crucial considerations in high-frequency discharge environments where thermal management becomes especially challenging.

The UN Transportation Testing requirements (UN 38.3) govern the safe transport of lithium batteries, mandating tests for altitude simulation, thermal cycling, vibration, shock, external short circuit, impact, overcharge, and forced discharge. These requirements become particularly stringent for high-frequency discharge battery packs due to their increased energy density and thermal characteristics.

Regional regulations add another layer of compliance complexity. In Europe, the Battery Directive 2006/66/EC and its amendments establish requirements for battery disposal and recycling, while also setting limits on hazardous substances. The North American market follows ANSI/CAN/UL standards with specific provisions for rapid discharge applications.

Industry-specific standards further refine safety requirements. For automotive applications, ISO 6469-1 addresses safety specifications for rechargeable energy storage systems, while SAE J2464 covers electric and hybrid vehicle battery systems. These standards include specific provisions for high-power discharge scenarios common in electric vehicle acceleration and regenerative braking.

Compliance testing for high-frequency discharge battery packs must include accelerated cycling tests, pulse power capability assessments, and thermal stability under extreme discharge conditions. These tests often exceed standard requirements to account for the unique stresses of rapid, repeated discharge cycles. Manufacturers must document comprehensive test results demonstrating compliance with all applicable standards.

Emerging standards are beginning to address the specific challenges of high-frequency discharge applications, with organizations like IEEE developing specialized guidelines for energy storage systems in grid stabilization and frequency regulation applications where rapid charge-discharge cycles are common.

Environmental Impact and Sustainability Considerations

The environmental impact of battery pack designs for high-frequency discharge applications extends far beyond operational efficiency. Battery manufacturing processes involve resource-intensive extraction of raw materials including lithium, cobalt, nickel, and manganese, which contribute significantly to carbon emissions and ecological disruption. High-frequency discharge scenarios typically demand more robust battery constructions, potentially increasing the material footprint per unit of energy storage capacity.

Lifecycle assessment studies indicate that batteries designed for high-frequency discharge often experience accelerated degradation, shortening their useful lifespan and exacerbating disposal challenges. This accelerated replacement cycle compounds environmental concerns, as each new battery manufactured represents additional resource consumption and manufacturing emissions. Recent research suggests that optimizing thermal management systems specifically for high-frequency discharge applications can extend battery life by 30-45%, substantially reducing lifetime environmental impact.

Recycling infrastructure for advanced battery technologies remains underdeveloped globally, with recovery rates for critical materials like cobalt and lithium typically below 50%. High-frequency discharge battery packs often incorporate specialized materials and complex cooling systems that can further complicate end-of-life processing. Designing for disassembly and material recovery becomes particularly important in these applications to mitigate environmental harm.

Water consumption presents another significant environmental consideration, with estimates suggesting production of each kilowatt-hour of battery capacity requires between 7-15 cubic meters of water. High-frequency discharge batteries with enhanced cooling requirements may increase this water footprint during both manufacturing and operation phases. Innovations in dry electrode manufacturing techniques show promise for reducing water requirements by up to 80% while maintaining performance characteristics necessary for high-discharge applications.

Carbon footprint reduction strategies for high-frequency discharge battery packs increasingly focus on supply chain optimization and manufacturing efficiency. Localized production reduces transportation emissions, while renewable energy integration in manufacturing facilities can decrease embedded carbon by 35-60%. Several leading manufacturers have implemented carbon-neutral production roadmaps specifically for high-performance battery lines, recognizing the growing market demand for environmentally responsible energy storage solutions.

Regulatory frameworks worldwide are evolving to address battery sustainability, with the European Union's proposed Battery Regulation establishing comprehensive requirements for carbon footprint declarations, minimum recycled content, and extended producer responsibility. These regulations will likely impose additional design constraints on high-frequency discharge applications, necessitating proactive environmental considerations in current research and development efforts.

Lifecycle assessment studies indicate that batteries designed for high-frequency discharge often experience accelerated degradation, shortening their useful lifespan and exacerbating disposal challenges. This accelerated replacement cycle compounds environmental concerns, as each new battery manufactured represents additional resource consumption and manufacturing emissions. Recent research suggests that optimizing thermal management systems specifically for high-frequency discharge applications can extend battery life by 30-45%, substantially reducing lifetime environmental impact.

Recycling infrastructure for advanced battery technologies remains underdeveloped globally, with recovery rates for critical materials like cobalt and lithium typically below 50%. High-frequency discharge battery packs often incorporate specialized materials and complex cooling systems that can further complicate end-of-life processing. Designing for disassembly and material recovery becomes particularly important in these applications to mitigate environmental harm.

Water consumption presents another significant environmental consideration, with estimates suggesting production of each kilowatt-hour of battery capacity requires between 7-15 cubic meters of water. High-frequency discharge batteries with enhanced cooling requirements may increase this water footprint during both manufacturing and operation phases. Innovations in dry electrode manufacturing techniques show promise for reducing water requirements by up to 80% while maintaining performance characteristics necessary for high-discharge applications.

Carbon footprint reduction strategies for high-frequency discharge battery packs increasingly focus on supply chain optimization and manufacturing efficiency. Localized production reduces transportation emissions, while renewable energy integration in manufacturing facilities can decrease embedded carbon by 35-60%. Several leading manufacturers have implemented carbon-neutral production roadmaps specifically for high-performance battery lines, recognizing the growing market demand for environmentally responsible energy storage solutions.

Regulatory frameworks worldwide are evolving to address battery sustainability, with the European Union's proposed Battery Regulation establishing comprehensive requirements for carbon footprint declarations, minimum recycled content, and extended producer responsibility. These regulations will likely impose additional design constraints on high-frequency discharge applications, necessitating proactive environmental considerations in current research and development efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!