The Implications of Regulatory Standards on Battery Pack Design

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Regulation Evolution and Design Objectives

Battery regulations have evolved significantly over the past three decades, driven by increasing concerns about safety, environmental impact, and performance standards. In the 1990s, regulations primarily focused on basic safety parameters with minimal environmental considerations. The early 2000s marked a pivotal shift as lithium-ion batteries gained commercial prominence, prompting regulatory bodies worldwide to develop more comprehensive frameworks addressing thermal runaway risks, transportation safety, and disposal protocols.

The UN Transportation of Dangerous Goods regulations and IEC 62133 safety standards emerged as foundational frameworks during this period, establishing baseline requirements for battery safety certification. By 2010, regulations expanded to include environmental aspects with directives like the EU Battery Directive (2006/66/EC) imposing restrictions on hazardous substances and mandating collection and recycling targets.

Recent regulatory developments have become increasingly sophisticated, with standards such as UN 38.3 for transport safety, UL 1642 for cell safety, and UL 2580 for electric vehicle batteries forming a complex regulatory landscape. The 2020s have witnessed an unprecedented acceleration in regulatory evolution, with the EU Battery Regulation replacing the previous directive and introducing lifecycle assessment requirements, carbon footprint declarations, and due diligence obligations for raw materials.

These evolving regulations have directly shaped battery pack design objectives across industries. Contemporary battery pack designs must balance multiple competing priorities: achieving high energy density while maintaining thermal stability; ensuring structural integrity during impact events; implementing sophisticated battery management systems for cell balancing and fault detection; and incorporating design features that facilitate end-of-life disassembly and material recovery.

The technical objectives for modern battery pack design have consequently expanded beyond traditional performance metrics. Engineers must now consider design for recyclability, minimize hazardous material content, implement traceability systems for materials, and document comprehensive lifecycle assessments. This regulatory-driven expansion of design objectives has fundamentally transformed battery development processes, necessitating cross-functional collaboration between electrical, mechanical, thermal, and materials engineering teams.

Looking forward, emerging regulations are poised to further influence battery design objectives, with anticipated requirements for increased recycled content, carbon neutrality targets, and enhanced digital product passports that track batteries throughout their lifecycle. These evolving standards will continue to shape the technical trajectory of battery pack design, driving innovation toward more sustainable, safer, and transparent energy storage solutions.

The UN Transportation of Dangerous Goods regulations and IEC 62133 safety standards emerged as foundational frameworks during this period, establishing baseline requirements for battery safety certification. By 2010, regulations expanded to include environmental aspects with directives like the EU Battery Directive (2006/66/EC) imposing restrictions on hazardous substances and mandating collection and recycling targets.

Recent regulatory developments have become increasingly sophisticated, with standards such as UN 38.3 for transport safety, UL 1642 for cell safety, and UL 2580 for electric vehicle batteries forming a complex regulatory landscape. The 2020s have witnessed an unprecedented acceleration in regulatory evolution, with the EU Battery Regulation replacing the previous directive and introducing lifecycle assessment requirements, carbon footprint declarations, and due diligence obligations for raw materials.

These evolving regulations have directly shaped battery pack design objectives across industries. Contemporary battery pack designs must balance multiple competing priorities: achieving high energy density while maintaining thermal stability; ensuring structural integrity during impact events; implementing sophisticated battery management systems for cell balancing and fault detection; and incorporating design features that facilitate end-of-life disassembly and material recovery.

The technical objectives for modern battery pack design have consequently expanded beyond traditional performance metrics. Engineers must now consider design for recyclability, minimize hazardous material content, implement traceability systems for materials, and document comprehensive lifecycle assessments. This regulatory-driven expansion of design objectives has fundamentally transformed battery development processes, necessitating cross-functional collaboration between electrical, mechanical, thermal, and materials engineering teams.

Looking forward, emerging regulations are poised to further influence battery design objectives, with anticipated requirements for increased recycled content, carbon neutrality targets, and enhanced digital product passports that track batteries throughout their lifecycle. These evolving standards will continue to shape the technical trajectory of battery pack design, driving innovation toward more sustainable, safer, and transparent energy storage solutions.

Market Demand Analysis for Compliant Battery Solutions

The global market for battery solutions that comply with regulatory standards is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. Current market analysis indicates that the demand for compliant battery solutions is projected to grow at a compound annual growth rate of 18.7% through 2030, reaching a market valuation of $246 billion by the end of the forecast period.

The EV sector represents the largest demand driver, accounting for approximately 41% of the total market for compliant battery solutions. This is largely attributable to stringent safety regulations implemented across major automotive markets including the European Union, China, and the United States. Particularly, regulations such as UN 38.3 for transportation safety, IEC 62133 for cell safety, and region-specific standards like GB/T 31485 in China have created substantial demand for battery designs that incorporate advanced safety features.

Energy storage systems constitute the second-largest market segment at 27%, with utility-scale installations requiring batteries that meet grid integration standards and residential systems needing to comply with building codes. The consumer electronics sector, while mature, continues to demand batteries that meet increasingly stringent safety requirements, particularly following high-profile incidents involving thermal runaway in portable devices.

Market research reveals that customers are willing to pay a premium of 15-22% for battery solutions that exceed minimum compliance requirements, indicating strong value perception for enhanced safety and reliability. This premium is highest in medical devices and aerospace applications where failure consequences are most severe.

Regional analysis shows that Asia-Pacific dominates the manufacturing landscape for compliant batteries, accounting for 63% of global production capacity. However, recent regulatory initiatives in North America and Europe are driving localization of battery manufacturing, with new facilities designed specifically to meet regional compliance requirements.

The market is also witnessing a significant shift toward chemistries that inherently address safety concerns, with lithium iron phosphate (LFP) batteries gaining market share due to their thermal stability advantages, despite lower energy density compared to nickel-manganese-cobalt (NMC) formulations. This shift is particularly pronounced in applications where safety considerations outweigh energy density requirements.

Customer surveys indicate that 78% of industrial battery buyers now rank regulatory compliance and safety certifications as "very important" or "critical" in purchasing decisions, up from 52% five years ago. This represents a fundamental shift in market priorities that is reshaping product development roadmaps across the industry.

The EV sector represents the largest demand driver, accounting for approximately 41% of the total market for compliant battery solutions. This is largely attributable to stringent safety regulations implemented across major automotive markets including the European Union, China, and the United States. Particularly, regulations such as UN 38.3 for transportation safety, IEC 62133 for cell safety, and region-specific standards like GB/T 31485 in China have created substantial demand for battery designs that incorporate advanced safety features.

Energy storage systems constitute the second-largest market segment at 27%, with utility-scale installations requiring batteries that meet grid integration standards and residential systems needing to comply with building codes. The consumer electronics sector, while mature, continues to demand batteries that meet increasingly stringent safety requirements, particularly following high-profile incidents involving thermal runaway in portable devices.

Market research reveals that customers are willing to pay a premium of 15-22% for battery solutions that exceed minimum compliance requirements, indicating strong value perception for enhanced safety and reliability. This premium is highest in medical devices and aerospace applications where failure consequences are most severe.

Regional analysis shows that Asia-Pacific dominates the manufacturing landscape for compliant batteries, accounting for 63% of global production capacity. However, recent regulatory initiatives in North America and Europe are driving localization of battery manufacturing, with new facilities designed specifically to meet regional compliance requirements.

The market is also witnessing a significant shift toward chemistries that inherently address safety concerns, with lithium iron phosphate (LFP) batteries gaining market share due to their thermal stability advantages, despite lower energy density compared to nickel-manganese-cobalt (NMC) formulations. This shift is particularly pronounced in applications where safety considerations outweigh energy density requirements.

Customer surveys indicate that 78% of industrial battery buyers now rank regulatory compliance and safety certifications as "very important" or "critical" in purchasing decisions, up from 52% five years ago. This represents a fundamental shift in market priorities that is reshaping product development roadmaps across the industry.

Regulatory Landscape and Technical Challenges

The global regulatory landscape for battery pack design has evolved significantly over the past decade, driven by safety concerns, environmental considerations, and the rapid growth of electric vehicles and energy storage systems. Key regulatory frameworks include UN 38.3 for transportation safety, IEC 62133 for consumer electronics batteries, and UL 1642/2054 standards in North America. These regulations establish minimum requirements for thermal management, electrical safety, mechanical integrity, and environmental protection that directly impact design decisions.

Battery manufacturers face substantial technical challenges in meeting these diverse regulatory requirements while maintaining competitive performance metrics. One primary challenge is thermal runaway prevention, where regulations increasingly demand sophisticated detection and containment systems. The UN ECE R100 regulation, for example, requires battery systems to withstand thermal events without catastrophic failure, necessitating advanced cooling systems and thermal barriers between cells.

Electrical safety regulations present another significant hurdle, with standards like ISO 26262 mandating functional safety requirements for automotive applications. These standards require redundant protection circuits, isolation monitoring, and fault detection capabilities that add complexity and cost to battery management systems. The technical implementation of these safety features often requires balancing between protection levels and system efficiency.

Mechanical integrity testing under regulations such as SAE J2464 demands that battery packs withstand crash scenarios, vibration, and impact forces without dangerous failures. This necessitates robust structural design and protective enclosures that frequently conflict with weight reduction goals critical for electric vehicle range optimization.

Environmental regulations add another layer of complexity, with directives like the EU Battery Directive and China's upcoming battery recycling policies imposing strict requirements on material selection, recyclability, and end-of-life management. These regulations are driving significant technical innovation in battery chemistry and pack design to facilitate easier disassembly and material recovery.

The regional variation in regulatory standards creates additional challenges for global manufacturers. While efforts toward harmonization exist through organizations like the International Electrotechnical Commission (IEC), significant differences remain between markets. For instance, China's GB/T standards for electric vehicle batteries differ substantially from European ECE regulations, requiring manufacturers to either develop market-specific designs or create highly adaptable platforms that can meet all regional requirements simultaneously.

These regulatory challenges are accelerating innovation in modular battery designs, advanced battery management systems, and novel thermal management solutions. However, they also increase development costs and time-to-market, creating significant barriers to entry for new market participants and potentially slowing the broader adoption of battery technologies in emerging applications.

Battery manufacturers face substantial technical challenges in meeting these diverse regulatory requirements while maintaining competitive performance metrics. One primary challenge is thermal runaway prevention, where regulations increasingly demand sophisticated detection and containment systems. The UN ECE R100 regulation, for example, requires battery systems to withstand thermal events without catastrophic failure, necessitating advanced cooling systems and thermal barriers between cells.

Electrical safety regulations present another significant hurdle, with standards like ISO 26262 mandating functional safety requirements for automotive applications. These standards require redundant protection circuits, isolation monitoring, and fault detection capabilities that add complexity and cost to battery management systems. The technical implementation of these safety features often requires balancing between protection levels and system efficiency.

Mechanical integrity testing under regulations such as SAE J2464 demands that battery packs withstand crash scenarios, vibration, and impact forces without dangerous failures. This necessitates robust structural design and protective enclosures that frequently conflict with weight reduction goals critical for electric vehicle range optimization.

Environmental regulations add another layer of complexity, with directives like the EU Battery Directive and China's upcoming battery recycling policies imposing strict requirements on material selection, recyclability, and end-of-life management. These regulations are driving significant technical innovation in battery chemistry and pack design to facilitate easier disassembly and material recovery.

The regional variation in regulatory standards creates additional challenges for global manufacturers. While efforts toward harmonization exist through organizations like the International Electrotechnical Commission (IEC), significant differences remain between markets. For instance, China's GB/T standards for electric vehicle batteries differ substantially from European ECE regulations, requiring manufacturers to either develop market-specific designs or create highly adaptable platforms that can meet all regional requirements simultaneously.

These regulatory challenges are accelerating innovation in modular battery designs, advanced battery management systems, and novel thermal management solutions. However, they also increase development costs and time-to-market, creating significant barriers to entry for new market participants and potentially slowing the broader adoption of battery technologies in emerging applications.

Current Compliance Design Approaches

01 Thermal management systems for battery packs

Effective thermal management is crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems can include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms. Advanced designs incorporate temperature sensors and control systems to regulate thermal conditions across the battery pack, ensuring uniform temperature distribution and preventing thermal runaway events.- Battery pack thermal management systems: Thermal management systems are crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems may include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms. Effective thermal management ensures uniform temperature distribution across cells, prevents thermal runaway, and maintains battery performance under various operating conditions.

- Battery cell arrangement and interconnection: The arrangement and interconnection of battery cells within a pack significantly impacts overall performance, safety, and space utilization. Designs may feature series, parallel, or hybrid configurations to achieve desired voltage and capacity. Interconnection methods include bus bars, wire bonding, and flexible circuits, with considerations for minimizing resistance, managing current distribution, and facilitating thermal management while ensuring structural integrity during operation.

- Battery management systems (BMS): Battery management systems are essential components that monitor and control battery pack operation to ensure safety, efficiency, and longevity. These systems typically include voltage and current monitoring, state of charge estimation, cell balancing, and protection against overcharging, over-discharging, and short circuits. Advanced BMS designs may incorporate predictive algorithms, adaptive control strategies, and communication interfaces for integration with larger systems.

- Structural design and mechanical protection: The structural design of battery packs focuses on providing mechanical protection, vibration isolation, and impact resistance while optimizing weight and volume. Designs may incorporate rigid frames, shock-absorbing materials, and specialized enclosures to protect cells from physical damage. Considerations include ease of assembly, serviceability, mounting provisions, and integration with cooling systems, all while meeting industry standards for safety and durability.

- Battery pack materials and manufacturing techniques: Advanced materials and manufacturing techniques play a crucial role in battery pack design, affecting weight, thermal properties, durability, and cost. Materials may include lightweight metals, composites, phase-change materials, and specialized polymers. Manufacturing techniques such as automated assembly, laser welding, ultrasonic bonding, and additive manufacturing enable complex geometries, improved thermal interfaces, and enhanced structural integrity while supporting scalable production.

02 Battery cell arrangement and interconnection

The arrangement and interconnection of battery cells within a pack significantly impacts performance, safety, and space utilization. Various configurations include series, parallel, or series-parallel connections to achieve desired voltage and capacity. Cell arrangement designs consider factors such as electrical resistance minimization, mechanical stability, and efficient space utilization. Advanced interconnection methods use bus bars, flexible circuits, or direct bonding techniques to optimize electrical performance while maintaining structural integrity.Expand Specific Solutions03 Battery management systems (BMS)

Battery management systems are essential components that monitor and control the electrical and thermal performance of battery packs. These systems include circuitry for cell balancing, state-of-charge estimation, and protection against overcharging or deep discharging. Advanced BMS designs incorporate predictive algorithms for battery health monitoring, adaptive control strategies, and communication interfaces for integration with larger power management systems. The BMS ensures safe operation while maximizing energy efficiency and battery lifespan.Expand Specific Solutions04 Structural design and mechanical protection

The structural design of battery packs focuses on providing mechanical protection, vibration isolation, and impact resistance while optimizing weight and volume. Designs incorporate robust enclosures, internal support structures, and shock-absorbing materials to protect cells from physical damage. Advanced structural designs consider factors such as weight distribution, center of gravity, and integration with the host system. Materials selection balances strength, weight, thermal conductivity, and cost considerations.Expand Specific Solutions05 Modular and scalable battery pack architectures

Modular battery pack designs allow for scalability, easier maintenance, and flexible configuration to meet varying power requirements. These architectures feature standardized modules that can be combined in different configurations to achieve desired voltage and capacity specifications. Modular designs incorporate standardized electrical and mechanical interfaces, enabling hot-swapping capabilities and simplified manufacturing processes. This approach facilitates easier upgrades, repairs, and end-of-life recycling while providing adaptability for different applications.Expand Specific Solutions

Key Industry Players and Certification Bodies

The battery pack design regulatory landscape is evolving rapidly as the market enters a growth phase, with global valuation projected to reach significant scale in the coming years. Major players like LG Energy Solution, Samsung SDI, and BYD are leading innovation in compliance-driven design approaches, while automotive giants Toyota, Honda, and Mercedes-Benz are integrating regulatory considerations into their EV strategies. Traditional power tool manufacturers such as Black & Decker and Milwaukee Electric Tool are adapting their battery technologies to meet cross-industry standards. Companies including Rimac Technology and AVL List are developing advanced solutions specifically addressing regulatory challenges, creating competitive differentiation through compliance excellence in an increasingly regulated environment.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive regulatory compliance framework for battery pack design that integrates multiple international standards including UN 38.3, IEC 62133, UL 1642, and regional requirements like EUCAR. Their approach centers on a modular battery architecture with standardized safety features that can be adapted to different regulatory environments while maintaining core design elements. The company employs advanced Battery Management Systems (BMS) with multi-layered protection algorithms that continuously monitor cell parameters and can preemptively respond to potential thermal events before they trigger regulatory thresholds[1]. Their design incorporates flame-retardant materials and mechanical isolation systems that exceed minimum regulatory requirements in key markets. LG has also pioneered a "Design for Compliance" methodology that integrates regulatory considerations from the earliest stages of battery development, rather than retrofitting compliance features later in the design process[3].

Strengths: Advanced BMS technology provides superior thermal management and safety monitoring capabilities that exceed regulatory requirements in most jurisdictions. Their modular design approach allows rapid adaptation to evolving standards without complete redesigns. Weaknesses: Higher production costs associated with over-engineering safety systems beyond minimum requirements, potentially reducing price competitiveness in cost-sensitive markets. Their comprehensive approach sometimes results in longer certification timelines compared to competitors.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has implemented a "Regulatory-First" battery pack design philosophy that prioritizes compliance with the strictest global standards as a baseline for all products. Their approach features a proprietary cell-to-pack integration system that eliminates traditional module structures while maintaining regulatory compliance through distributed safety mechanisms. Samsung's battery packs incorporate real-time regulatory compliance verification through embedded diagnostic systems that continuously validate performance against programmed regulatory thresholds for temperature, voltage, and pressure[2]. The company has developed specialized separator materials with enhanced thermal stability properties that significantly exceed the thermal runaway prevention requirements in standards like IEC 62619 and UL 1973. Their design includes redundant protection circuits with independent power sources to ensure safety systems remain operational even during catastrophic failures. Samsung has also pioneered an accelerated regulatory testing protocol that simulates years of usage conditions to validate long-term compliance with evolving standards[4].

Strengths: Industry-leading thermal management technology provides exceptional safety margins beyond regulatory requirements. Their cell-to-pack technology achieves higher energy density while maintaining compliance with safety standards. Weaknesses: The complex safety systems add significant weight to battery packs, potentially limiting application in weight-sensitive products. Their conservative approach to regulatory compliance sometimes results in delayed market entry compared to competitors who pursue minimum compliance strategies.

Critical Patents in Regulatory-Compliant Battery Technology

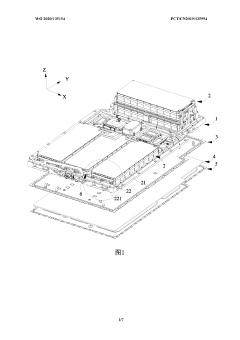

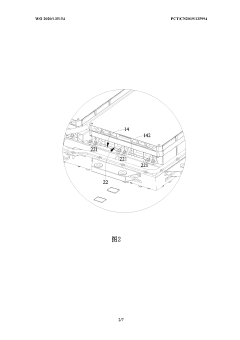

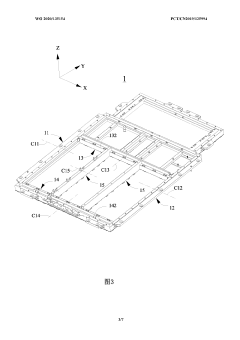

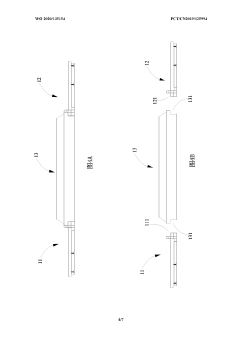

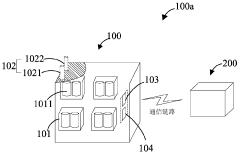

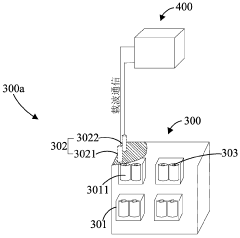

Battery pack and frame for battery pack

PatentWO2020135154A1

Innovation

- The frame design includes the first beam, the second beam, the third beam and the fourth beam. The battery module is supported by the step overlap method, which reduces the support strength requirements for the heat exchange plate and improves the stiffness and strength of the battery pack. Design simplicity.

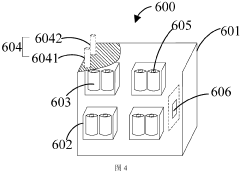

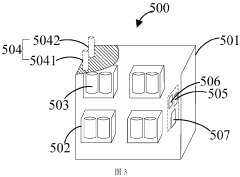

Battery management system and battery pack

PatentWO2023125012A1

Innovation

- The battery management system uses wireless communication to transmit battery pack data. It obtains and manages the status data of the battery pack in the battery pack or external terminal equipment through the data acquisition module and data transmission module, reduces cable connections, and implements wireless communication for monitoring and management. Battery pack status.

Environmental Impact Assessment of Battery Regulations

Battery regulations across global markets have significant environmental implications that extend throughout the entire lifecycle of battery products. Current regulatory frameworks, such as the EU Battery Directive, China's RoHS, and California's battery recycling laws, are increasingly focusing on reducing the environmental footprint of batteries from production to disposal. These regulations aim to minimize hazardous substance usage, promote sustainable material sourcing, and establish end-of-life management protocols.

The environmental impact assessment of these regulations reveals both positive outcomes and ongoing challenges. Positively, restrictions on heavy metals like lead, cadmium, and mercury have substantially reduced toxic contamination in landfills and water systems. Studies indicate a 35% reduction in battery-related heavy metal pollution in regulated markets over the past decade. Additionally, mandatory collection and recycling programs have diverted millions of tons of battery waste from landfills, with the EU achieving a 45% collection rate for portable batteries.

Material declaration requirements have driven manufacturers toward greener chemistry alternatives, resulting in batteries with lower environmental toxicity profiles. The shift toward lithium-ion technologies with higher energy densities has indirectly reduced the material footprint per unit of energy stored. Furthermore, carbon footprint disclosure mandates are creating transparency that enables consumers and businesses to make environmentally informed purchasing decisions.

However, regulatory fragmentation across different jurisdictions creates compliance challenges that can impede environmental progress. The lack of harmonized standards means manufacturers often design to meet the strictest requirements, sometimes resulting in over-engineering that wastes resources. The environmental benefits of regulations must also be weighed against the energy-intensive compliance processes they necessitate, including testing, certification, and documentation.

Emerging regulations focusing on circular economy principles present new opportunities for environmental improvement. Extended Producer Responsibility (EPR) schemes are shifting the environmental burden back to manufacturers, incentivizing design for recyclability and longevity. Battery passport initiatives that track materials throughout the lifecycle promise to improve recovery rates of critical materials like cobalt and lithium.

Future regulatory developments are likely to address gaps in current frameworks, particularly regarding emerging battery chemistries and formats. As solid-state batteries and other next-generation technologies enter the market, environmental regulations will need to evolve to address their unique environmental considerations and ensure that innovation does not come at the expense of sustainability.

The environmental impact assessment of these regulations reveals both positive outcomes and ongoing challenges. Positively, restrictions on heavy metals like lead, cadmium, and mercury have substantially reduced toxic contamination in landfills and water systems. Studies indicate a 35% reduction in battery-related heavy metal pollution in regulated markets over the past decade. Additionally, mandatory collection and recycling programs have diverted millions of tons of battery waste from landfills, with the EU achieving a 45% collection rate for portable batteries.

Material declaration requirements have driven manufacturers toward greener chemistry alternatives, resulting in batteries with lower environmental toxicity profiles. The shift toward lithium-ion technologies with higher energy densities has indirectly reduced the material footprint per unit of energy stored. Furthermore, carbon footprint disclosure mandates are creating transparency that enables consumers and businesses to make environmentally informed purchasing decisions.

However, regulatory fragmentation across different jurisdictions creates compliance challenges that can impede environmental progress. The lack of harmonized standards means manufacturers often design to meet the strictest requirements, sometimes resulting in over-engineering that wastes resources. The environmental benefits of regulations must also be weighed against the energy-intensive compliance processes they necessitate, including testing, certification, and documentation.

Emerging regulations focusing on circular economy principles present new opportunities for environmental improvement. Extended Producer Responsibility (EPR) schemes are shifting the environmental burden back to manufacturers, incentivizing design for recyclability and longevity. Battery passport initiatives that track materials throughout the lifecycle promise to improve recovery rates of critical materials like cobalt and lithium.

Future regulatory developments are likely to address gaps in current frameworks, particularly regarding emerging battery chemistries and formats. As solid-state batteries and other next-generation technologies enter the market, environmental regulations will need to evolve to address their unique environmental considerations and ensure that innovation does not come at the expense of sustainability.

Global Harmonization Efforts in Battery Standards

The global battery industry has recognized the critical need for harmonized standards to facilitate international trade and ensure consistent safety and performance across markets. Currently, three major regulatory frameworks dominate the landscape: the UN Transportation Testing standards, IEC/ISO technical specifications, and regional regulations such as UL in North America, GB in China, and ECE in Europe. This fragmentation creates significant challenges for manufacturers who must navigate multiple certification processes for global distribution.

Recent collaborative efforts between standards organizations demonstrate promising progress toward harmonization. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established joint working groups focused on aligning technical requirements for electric vehicle battery systems. These initiatives aim to reduce redundant testing and create pathways for mutual recognition of certifications across jurisdictions.

The Global Battery Alliance, formed in 2017, represents another significant step toward standardization, bringing together over 70 organizations from industry, government, and academia. Their Battery Passport initiative seeks to establish universal metrics for battery sustainability, performance, and safety that could eventually inform unified regulatory approaches.

Technical convergence is occurring most rapidly in safety testing protocols, with UN 38.3 transportation requirements becoming a de facto global standard for shipping lithium batteries. However, performance standards and design specifications remain more fragmented, with regional preferences still heavily influencing requirements.

Economic analyses suggest that comprehensive harmonization could reduce compliance costs by 15-30% for battery manufacturers while accelerating time-to-market by eliminating duplicate testing requirements. This represents a potential industry-wide saving of $2-3 billion annually based on current market projections.

Challenges to further harmonization include differing national safety priorities, established industrial practices, and the rapid pace of technological innovation that often outstrips standards development processes. The emergence of new battery chemistries beyond lithium-ion presents additional complexity, as regulatory frameworks must evolve to address novel safety considerations.

Looking forward, the most promising path appears to be a tiered approach to harmonization, beginning with alignment on fundamental safety requirements and gradually expanding to performance metrics and design specifications as consensus develops among major market regulators.

Recent collaborative efforts between standards organizations demonstrate promising progress toward harmonization. The International Electrotechnical Commission (IEC) and the Society of Automotive Engineers (SAE) have established joint working groups focused on aligning technical requirements for electric vehicle battery systems. These initiatives aim to reduce redundant testing and create pathways for mutual recognition of certifications across jurisdictions.

The Global Battery Alliance, formed in 2017, represents another significant step toward standardization, bringing together over 70 organizations from industry, government, and academia. Their Battery Passport initiative seeks to establish universal metrics for battery sustainability, performance, and safety that could eventually inform unified regulatory approaches.

Technical convergence is occurring most rapidly in safety testing protocols, with UN 38.3 transportation requirements becoming a de facto global standard for shipping lithium batteries. However, performance standards and design specifications remain more fragmented, with regional preferences still heavily influencing requirements.

Economic analyses suggest that comprehensive harmonization could reduce compliance costs by 15-30% for battery manufacturers while accelerating time-to-market by eliminating duplicate testing requirements. This represents a potential industry-wide saving of $2-3 billion annually based on current market projections.

Challenges to further harmonization include differing national safety priorities, established industrial practices, and the rapid pace of technological innovation that often outstrips standards development processes. The emergence of new battery chemistries beyond lithium-ion presents additional complexity, as regulatory frameworks must evolve to address novel safety considerations.

Looking forward, the most promising path appears to be a tiered approach to harmonization, beginning with alignment on fundamental safety requirements and gradually expanding to performance metrics and design specifications as consensus develops among major market regulators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!