Exploring Nanotechnology in Future Battery Pack Design

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nanotechnology Battery Evolution and Objectives

Nanotechnology has revolutionized battery technology over the past three decades, transforming from theoretical concepts to practical applications that address fundamental limitations in energy storage systems. The evolution began in the early 1990s with initial explorations of nanomaterials for electrode applications, progressing through significant breakthroughs in the 2000s with carbon nanotubes and graphene implementations. This technological progression has consistently aimed to overcome the traditional constraints of conventional batteries: limited energy density, slow charging capabilities, and relatively short cycle life.

The current trajectory of nanotechnology in battery development focuses on enhancing four critical parameters: energy density, power density, cycle life, and safety. Nanomaterials offer unique advantages through their high surface-to-volume ratio, enabling faster ion transport and more efficient electrochemical reactions. This fundamental property has driven research toward nano-structured electrodes, solid-state electrolytes with nanoscale interfaces, and advanced separator technologies incorporating nanomaterials.

Market demands for electric vehicles, portable electronics, and renewable energy storage have accelerated nanotechnology battery research, creating clear objectives for the field. Primary among these is achieving energy densities exceeding 500 Wh/kg at the cell level while maintaining safety and stability—a threshold considered necessary for next-generation applications. Secondary objectives include developing fast-charging capabilities (80% charge in under 15 minutes) and extending cycle life beyond 2,000 complete cycles without significant degradation.

The integration of nanotechnology into battery pack design represents a multi-disciplinary approach combining materials science, electrochemistry, and thermal engineering. Recent advancements in silicon nanowire anodes, lithium-sulfur batteries with nanostructured sulfur hosts, and solid-state electrolytes with engineered nanoscale interfaces demonstrate the field's innovative potential. These developments suggest a convergence toward "3D battery architectures" that optimize ion transport pathways at the nanoscale.

Looking forward, the field aims to develop commercially viable manufacturing processes for nanomaterial-enhanced batteries, addressing scalability challenges that have historically limited industrial adoption. The ultimate objective is creating battery systems that simultaneously optimize energy density, power capability, safety, and longevity—parameters that have traditionally involved trade-offs. Nanotechnology offers a promising path to transcend these limitations through precise structural control at the molecular level, potentially enabling the next generation of energy storage solutions that power everything from consumer electronics to electric transportation and grid-scale storage systems.

The current trajectory of nanotechnology in battery development focuses on enhancing four critical parameters: energy density, power density, cycle life, and safety. Nanomaterials offer unique advantages through their high surface-to-volume ratio, enabling faster ion transport and more efficient electrochemical reactions. This fundamental property has driven research toward nano-structured electrodes, solid-state electrolytes with nanoscale interfaces, and advanced separator technologies incorporating nanomaterials.

Market demands for electric vehicles, portable electronics, and renewable energy storage have accelerated nanotechnology battery research, creating clear objectives for the field. Primary among these is achieving energy densities exceeding 500 Wh/kg at the cell level while maintaining safety and stability—a threshold considered necessary for next-generation applications. Secondary objectives include developing fast-charging capabilities (80% charge in under 15 minutes) and extending cycle life beyond 2,000 complete cycles without significant degradation.

The integration of nanotechnology into battery pack design represents a multi-disciplinary approach combining materials science, electrochemistry, and thermal engineering. Recent advancements in silicon nanowire anodes, lithium-sulfur batteries with nanostructured sulfur hosts, and solid-state electrolytes with engineered nanoscale interfaces demonstrate the field's innovative potential. These developments suggest a convergence toward "3D battery architectures" that optimize ion transport pathways at the nanoscale.

Looking forward, the field aims to develop commercially viable manufacturing processes for nanomaterial-enhanced batteries, addressing scalability challenges that have historically limited industrial adoption. The ultimate objective is creating battery systems that simultaneously optimize energy density, power capability, safety, and longevity—parameters that have traditionally involved trade-offs. Nanotechnology offers a promising path to transcend these limitations through precise structural control at the molecular level, potentially enabling the next generation of energy storage solutions that power everything from consumer electronics to electric transportation and grid-scale storage systems.

Market Analysis for Nano-Enhanced Battery Solutions

The global market for nano-enhanced battery solutions is experiencing unprecedented growth, driven by increasing demand for high-performance energy storage systems across multiple industries. Current market valuations place the nano-enhanced battery sector at approximately $5.2 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 24.7% through 2030, potentially reaching $24.6 billion by the end of the decade.

Consumer electronics continues to dominate market share, accounting for 42% of nano-enhanced battery applications. This segment's demand is primarily fueled by the need for longer-lasting, faster-charging batteries in smartphones, laptops, and wearable devices. Manufacturers like Samsung and Apple have already begun incorporating nanomaterial-enhanced batteries in their premium product lines, reporting up to 30% improvements in battery life.

The electric vehicle (EV) sector represents the fastest-growing application segment, with a projected CAGR of 32.3% through 2028. Major automotive manufacturers including Tesla, BYD, and Volkswagen are investing heavily in nanotechnology research for battery pack design, seeking solutions that address range anxiety, charging speed, and battery longevity concerns that continue to limit widespread EV adoption.

Geographically, Asia-Pacific leads the market with 48% share, driven by robust manufacturing capabilities in China, South Korea, and Japan. North America follows at 27%, with significant growth potential due to increasing government initiatives supporting clean energy technologies and domestic battery production.

Consumer demand patterns clearly indicate preference shifts toward devices with extended battery life, with 78% of smartphone users citing battery performance as a critical purchasing factor. Similarly, EV market surveys show that 65% of potential buyers consider battery range and charging time as their primary concerns when evaluating electric vehicles.

Key market drivers include stringent environmental regulations promoting clean energy solutions, increasing R&D investments in battery technologies, and growing consumer awareness regarding sustainable energy storage options. The push toward carbon neutrality across major economies has created favorable market conditions for advanced battery technologies that offer improved efficiency and reduced environmental impact.

Market challenges include high initial production costs, with nano-enhanced batteries currently commanding a 40-60% premium over conventional lithium-ion batteries. Supply chain vulnerabilities for critical raw materials and technical challenges in scaling production also present significant barriers to market expansion. However, ongoing technological advancements and economies of scale are expected to gradually reduce these cost differentials over the next five years.

Consumer electronics continues to dominate market share, accounting for 42% of nano-enhanced battery applications. This segment's demand is primarily fueled by the need for longer-lasting, faster-charging batteries in smartphones, laptops, and wearable devices. Manufacturers like Samsung and Apple have already begun incorporating nanomaterial-enhanced batteries in their premium product lines, reporting up to 30% improvements in battery life.

The electric vehicle (EV) sector represents the fastest-growing application segment, with a projected CAGR of 32.3% through 2028. Major automotive manufacturers including Tesla, BYD, and Volkswagen are investing heavily in nanotechnology research for battery pack design, seeking solutions that address range anxiety, charging speed, and battery longevity concerns that continue to limit widespread EV adoption.

Geographically, Asia-Pacific leads the market with 48% share, driven by robust manufacturing capabilities in China, South Korea, and Japan. North America follows at 27%, with significant growth potential due to increasing government initiatives supporting clean energy technologies and domestic battery production.

Consumer demand patterns clearly indicate preference shifts toward devices with extended battery life, with 78% of smartphone users citing battery performance as a critical purchasing factor. Similarly, EV market surveys show that 65% of potential buyers consider battery range and charging time as their primary concerns when evaluating electric vehicles.

Key market drivers include stringent environmental regulations promoting clean energy solutions, increasing R&D investments in battery technologies, and growing consumer awareness regarding sustainable energy storage options. The push toward carbon neutrality across major economies has created favorable market conditions for advanced battery technologies that offer improved efficiency and reduced environmental impact.

Market challenges include high initial production costs, with nano-enhanced batteries currently commanding a 40-60% premium over conventional lithium-ion batteries. Supply chain vulnerabilities for critical raw materials and technical challenges in scaling production also present significant barriers to market expansion. However, ongoing technological advancements and economies of scale are expected to gradually reduce these cost differentials over the next five years.

Global Nanotechnology Battery Research Status and Barriers

Nanotechnology in battery research has witnessed significant advancements globally, yet faces substantial technical and commercial barriers. Current research is concentrated in North America, East Asia, and Europe, with China, the United States, and South Korea leading patent applications. These regions have established comprehensive research ecosystems connecting academic institutions, government laboratories, and private enterprises, creating effective innovation pipelines.

The primary technical barriers in nanomaterial battery development include scalability challenges, where laboratory-scale successes often fail to translate to mass production. Manufacturing processes for nanomaterials require precise control over particle size, morphology, and distribution—parameters that become increasingly difficult to maintain at industrial scales. This scalability gap represents one of the most significant obstacles to commercial implementation.

Stability and safety concerns constitute another major barrier. Nanomaterials can exhibit unexpected behaviors at interfaces, potentially leading to accelerated degradation or safety risks. The high surface area of nanomaterials, while beneficial for electrochemical performance, can increase reactivity with electrolytes, causing unwanted side reactions that compromise long-term stability and safety profiles of battery systems.

Cost factors remain prohibitive for widespread adoption. Current synthesis methods for high-quality nanomaterials often involve expensive precursors, energy-intensive processes, or complex equipment. The precision required for nanomaterial production significantly increases manufacturing costs compared to conventional battery materials, creating a substantial economic barrier to market entry.

Characterization and quality control present unique challenges at the nanoscale. Existing analytical techniques struggle to provide real-time, in-line monitoring of nanomaterial properties during production. This limitation hampers quality assurance processes essential for consistent battery performance and reliability.

Regulatory uncertainties further complicate commercialization efforts. The novel properties of nanomaterials have raised questions about potential environmental and health impacts, leading to evolving regulatory frameworks across different regions. This regulatory landscape creates additional compliance burdens and market entry barriers for nanotechnology-enhanced battery products.

Knowledge gaps in fundamental understanding persist despite extensive research. The complex interactions between nanomaterials and other battery components are not fully characterized, particularly regarding long-term performance and degradation mechanisms. These knowledge gaps impede rational design approaches and slow the optimization process for nanotechnology-enhanced battery systems.

Bridging these barriers requires coordinated efforts across the research ecosystem, including development of scalable synthesis methods, standardized characterization protocols, and comprehensive safety assessment frameworks specifically tailored to nanomaterial applications in battery technologies.

The primary technical barriers in nanomaterial battery development include scalability challenges, where laboratory-scale successes often fail to translate to mass production. Manufacturing processes for nanomaterials require precise control over particle size, morphology, and distribution—parameters that become increasingly difficult to maintain at industrial scales. This scalability gap represents one of the most significant obstacles to commercial implementation.

Stability and safety concerns constitute another major barrier. Nanomaterials can exhibit unexpected behaviors at interfaces, potentially leading to accelerated degradation or safety risks. The high surface area of nanomaterials, while beneficial for electrochemical performance, can increase reactivity with electrolytes, causing unwanted side reactions that compromise long-term stability and safety profiles of battery systems.

Cost factors remain prohibitive for widespread adoption. Current synthesis methods for high-quality nanomaterials often involve expensive precursors, energy-intensive processes, or complex equipment. The precision required for nanomaterial production significantly increases manufacturing costs compared to conventional battery materials, creating a substantial economic barrier to market entry.

Characterization and quality control present unique challenges at the nanoscale. Existing analytical techniques struggle to provide real-time, in-line monitoring of nanomaterial properties during production. This limitation hampers quality assurance processes essential for consistent battery performance and reliability.

Regulatory uncertainties further complicate commercialization efforts. The novel properties of nanomaterials have raised questions about potential environmental and health impacts, leading to evolving regulatory frameworks across different regions. This regulatory landscape creates additional compliance burdens and market entry barriers for nanotechnology-enhanced battery products.

Knowledge gaps in fundamental understanding persist despite extensive research. The complex interactions between nanomaterials and other battery components are not fully characterized, particularly regarding long-term performance and degradation mechanisms. These knowledge gaps impede rational design approaches and slow the optimization process for nanotechnology-enhanced battery systems.

Bridging these barriers requires coordinated efforts across the research ecosystem, including development of scalable synthesis methods, standardized characterization protocols, and comprehensive safety assessment frameworks specifically tailored to nanomaterial applications in battery technologies.

Current Nanomaterial Applications in Battery Pack Design

01 Nanomaterials for electrode enhancement

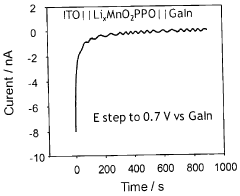

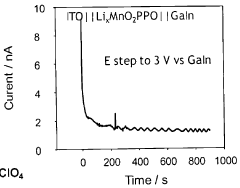

Nanotechnology enables the development of advanced electrode materials with increased surface area and improved electrochemical properties. Nanomaterials such as carbon nanotubes, graphene, and nanoparticles can be incorporated into battery electrodes to enhance energy density, power output, and cycling stability. These nanoscale structures facilitate faster ion transport and electron transfer, resulting in batteries with higher capacity and improved performance.- Nanomaterials for electrode enhancement: Nanotechnology enables the development of advanced electrode materials with increased surface area and improved electrochemical properties. Nanomaterials such as carbon nanotubes, graphene, and nanoparticles can be incorporated into battery electrodes to enhance energy density, power density, and cycling stability. These nanomaterials facilitate faster ion transport and electron transfer, resulting in batteries with higher capacity and better performance.

- Nanostructured thermal management systems: Battery packs incorporating nanotechnology-based thermal management systems can achieve more efficient heat dissipation and temperature control. Nanofluids, nanocomposite heat sinks, and phase change materials with nanoparticles help maintain optimal operating temperatures throughout the battery pack. These advanced thermal management solutions prevent hotspots, reduce thermal runaway risks, and extend battery life while allowing for more compact and efficient battery pack designs.

- Nano-enhanced battery management systems: Battery management systems utilizing nanosensors and nanoelectronics provide more precise monitoring and control of battery packs. These systems incorporate nanotechnology-based sensors for real-time measurement of temperature, voltage, current, and chemical composition at the nanoscale. The enhanced data collection and processing capabilities enable more accurate state-of-charge estimation, predictive maintenance, and adaptive control strategies, resulting in improved safety and performance of battery packs.

- Nanocoatings for battery protection and safety: Protective nanocoatings applied to battery components enhance safety and durability of battery packs. These nanoscale coatings provide improved resistance to moisture, chemicals, and mechanical stress while maintaining electrical conductivity where needed. Some nanocoatings also offer self-healing properties or fire-retardant characteristics, reducing the risk of thermal runaway and improving overall battery pack safety and longevity in various operating conditions.

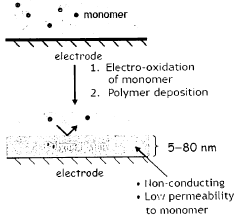

- Nano-engineered solid-state electrolytes: Nanotechnology enables the development of advanced solid-state electrolytes with improved ionic conductivity and mechanical properties. These nano-engineered materials facilitate faster ion transport while preventing dendrite formation, addressing key challenges in solid-state battery design. The integration of nanostructured solid electrolytes allows for safer, more energy-dense battery packs with reduced risk of leakage and thermal runaway, making them suitable for demanding applications including electric vehicles and grid storage.

02 Nanostructured thermal management systems

Nanotechnology-based thermal management solutions address heat dissipation challenges in battery packs. Nanofluids, nanocomposite materials, and nano-engineered heat sinks can be integrated into battery pack designs to efficiently transfer and distribute heat. These systems help maintain optimal operating temperatures, prevent thermal runaway, and extend battery life while enabling higher charging and discharging rates without compromising safety.Expand Specific Solutions03 Nano-enhanced battery management systems

Battery management systems incorporating nanosensors and nanoelectronics provide more precise monitoring and control of battery pack performance. These systems utilize nanoscale components to accurately measure temperature, voltage, and current at the cell level. The enhanced data collection and processing capabilities enable optimized charging protocols, improved state-of-charge estimation, and early detection of potential failure modes, resulting in safer and more efficient battery operation.Expand Specific Solutions04 Nanocoatings for battery protection

Protective nanocoatings can be applied to battery components to enhance durability and safety. These nanometer-thick layers provide barriers against moisture, oxygen, and contaminants while improving mechanical stability. Specialized nanocoatings can also offer self-healing properties, flame retardancy, and enhanced electrical insulation. The implementation of these coatings extends battery lifespan, improves safety characteristics, and enables operation in more demanding environments.Expand Specific Solutions05 Nano-engineered structural components

Nanotechnology enables the development of lightweight yet strong structural components for battery packs. Nanocomposites combining polymers with nanomaterials like carbon nanotubes or nanoclays create housing and support structures with superior mechanical properties and reduced weight. These materials can also incorporate functionalities such as electromagnetic shielding, vibration dampening, and impact resistance, contributing to overall battery pack performance and safety while reducing vehicle weight.Expand Specific Solutions

Leading Companies and Research Institutions in Battery Nanotechnology

The nanotechnology battery pack market is in a growth phase, characterized by significant R&D investments and emerging commercial applications. The global market is projected to expand rapidly as demand for high-performance energy storage solutions increases across automotive, consumer electronics, and renewable energy sectors. Technologically, the field remains in early-to-mid maturity, with companies like Samsung SDI, Apple, and Amprius Technologies leading commercial development while academic institutions such as MIT, Cornell University, and Fudan University drive fundamental research breakthroughs. Major industrial players including FMC Corp and Murata Manufacturing are scaling manufacturing capabilities, while specialized innovators like Nanocomp Technologies and Ensor Inc. focus on novel nanomaterial approaches. The competitive landscape features strategic partnerships between research institutions and commercial entities to accelerate technology transfer and market adoption.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered several breakthrough nanotechnologies for next-generation battery pack design through its research laboratories. Their work includes the development of self-assembling battery materials that leverage block copolymers to create precisely ordered nanostructures for improved ion transport. MIT researchers have created novel electrode architectures using templated synthesis methods to produce three-dimensional nanostructured electrodes with optimized porosity for enhanced power density. Their solid-state battery research incorporates nanoscale engineering of ceramic-polymer composite electrolytes to achieve both high ionic conductivity and mechanical stability. MIT has also developed advanced in situ characterization techniques that enable real-time observation of nanoscale processes occurring within batteries during operation, providing crucial insights for optimizing battery designs. Their recent work on strain-engineering of cathode materials at the nanoscale has demonstrated significant improvements in cycle life by accommodating structural changes during lithiation/delithiation processes[7][8]. MIT's battery research frequently transitions to commercial applications through startup companies and industry partnerships.

Strengths: Cutting-edge fundamental research capabilities; multidisciplinary approach combining materials science, chemistry, and mechanical engineering; strong industry partnerships for technology transfer; access to advanced characterization facilities. Weaknesses: Focus on early-stage research rather than manufacturing scale-up; technologies often require significant further development before commercialization; intellectual property sometimes distributed across multiple entities.

Amprius Technologies, Inc.

Technical Solution: Amprius has pioneered silicon nanowire anode technology for next-generation battery packs. Their proprietary Si-Nanowire platform replaces conventional graphite anodes with 100% silicon nanowires, enabling significantly higher energy density (up to 450 Wh/kg and 1,150 Wh/L) compared to traditional lithium-ion batteries[1]. The silicon nanowire structure allows for efficient lithium-ion insertion and extraction while accommodating the substantial volume changes silicon undergoes during charge-discharge cycles. Their manufacturing process involves direct growth of silicon nanowires on current collectors, creating a three-dimensional architecture that maximizes active material utilization while maintaining structural integrity. Amprius has successfully commercialized this technology for applications requiring high energy density, including aerospace and electric vehicles, with demonstrated cycle life exceeding 500 cycles with minimal capacity degradation[2].

Strengths: Industry-leading energy density (450 Wh/kg); silicon nanowire structure solves expansion issues that plagued earlier silicon anodes; scalable manufacturing process; proven commercial applications. Weaknesses: Higher production costs compared to conventional lithium-ion batteries; limited large-scale manufacturing capacity; requires specialized manufacturing equipment and processes.

Key Patents and Breakthroughs in Battery Nanomaterials

Three-dimensional battery architectures and methods of making same

PatentWO2011014312A1

Innovation

- The development of ultraporous nanoarchitectures with bicontinuous pore and solid networks allows for the design of three-dimensional battery architectures on the nanoscale, featuring a sol-gel-derived scaffold with a continuous mesoporous network, where all active components are tricontinuous, enabling rapid diffusional flux and high surface area, with polymer films serving as separators and conformal coatings enhancing charge transport.

Carbon nanotube-coated silicon/metal composite particle, preparation method thereof, and anode for secondary battery and secondary battery using the same

PatentInactiveUS20100092868A1

Innovation

- A carbon nanotube-coated silicon/metal composite particle is developed, where a metal catalyst aids in the growth of carbon nanotubes on the surface of silicon particles, enhancing electrical conductivity and mechanical stability while preventing SEI membrane formation and electrolyte reactivity, achieved through a method involving heat treatment in a mixed gas atmosphere.

Environmental Impact and Sustainability of Nanobatteries

The integration of nanotechnology into battery design presents significant environmental implications that must be carefully evaluated. Nanomaterials offer potential sustainability advantages through improved energy density and extended battery lifecycles, potentially reducing the overall environmental footprint of energy storage systems. When nanobatteries achieve longer operational lifespans, fewer replacement units are required, directly decreasing manufacturing resource demands and associated waste generation.

Nanomaterials enable more efficient resource utilization through precise material engineering at the atomic scale. This optimization allows for reduced quantities of rare earth elements and critical materials in battery production, addressing supply chain vulnerabilities and extraction-related environmental degradation. Additionally, nanobatteries typically demonstrate enhanced energy efficiency during charging and discharging cycles, contributing to reduced energy consumption throughout their operational lifetime.

However, the environmental benefits must be weighed against potential risks. Nanomaterial production often involves energy-intensive processes and specialized manufacturing techniques that may offset some sustainability gains. The novel properties of engineered nanomaterials raise concerns regarding their environmental fate and behavior, particularly regarding potential toxicity to aquatic ecosystems and soil microbiota if improperly disposed of or released during manufacturing.

End-of-life management presents both challenges and opportunities. The complex composition of nanobatteries may complicate traditional recycling processes, requiring development of specialized recovery techniques. Conversely, nanotechnology may enable more efficient recycling methods through targeted material separation and recovery, potentially increasing the percentage of materials that can be reclaimed from spent batteries.

Life cycle assessment (LCA) studies indicate that nanobatteries' environmental impact varies significantly based on manufacturing processes, material selection, and end-of-life management. Current research suggests that while production-phase impacts may be higher for nanobatteries, these can be offset by operational efficiency gains and extended service life when properly designed.

Regulatory frameworks are evolving to address nanomaterial-specific environmental considerations, with organizations like the EPA and EU implementing guidelines for nanomaterial handling and disposal. Industry stakeholders are increasingly adopting green chemistry principles in nanobattery development, focusing on benign-by-design approaches that minimize hazardous materials and consider environmental impacts throughout the product lifecycle.

Future sustainability improvements will likely emerge from bio-inspired nanomaterials, water-based manufacturing processes, and closed-loop production systems that maximize material recovery and reuse. The environmental viability of nanobatteries ultimately depends on holistic design approaches that consider impacts across the entire product lifecycle, from raw material extraction through end-of-life management.

Nanomaterials enable more efficient resource utilization through precise material engineering at the atomic scale. This optimization allows for reduced quantities of rare earth elements and critical materials in battery production, addressing supply chain vulnerabilities and extraction-related environmental degradation. Additionally, nanobatteries typically demonstrate enhanced energy efficiency during charging and discharging cycles, contributing to reduced energy consumption throughout their operational lifetime.

However, the environmental benefits must be weighed against potential risks. Nanomaterial production often involves energy-intensive processes and specialized manufacturing techniques that may offset some sustainability gains. The novel properties of engineered nanomaterials raise concerns regarding their environmental fate and behavior, particularly regarding potential toxicity to aquatic ecosystems and soil microbiota if improperly disposed of or released during manufacturing.

End-of-life management presents both challenges and opportunities. The complex composition of nanobatteries may complicate traditional recycling processes, requiring development of specialized recovery techniques. Conversely, nanotechnology may enable more efficient recycling methods through targeted material separation and recovery, potentially increasing the percentage of materials that can be reclaimed from spent batteries.

Life cycle assessment (LCA) studies indicate that nanobatteries' environmental impact varies significantly based on manufacturing processes, material selection, and end-of-life management. Current research suggests that while production-phase impacts may be higher for nanobatteries, these can be offset by operational efficiency gains and extended service life when properly designed.

Regulatory frameworks are evolving to address nanomaterial-specific environmental considerations, with organizations like the EPA and EU implementing guidelines for nanomaterial handling and disposal. Industry stakeholders are increasingly adopting green chemistry principles in nanobattery development, focusing on benign-by-design approaches that minimize hazardous materials and consider environmental impacts throughout the product lifecycle.

Future sustainability improvements will likely emerge from bio-inspired nanomaterials, water-based manufacturing processes, and closed-loop production systems that maximize material recovery and reuse. The environmental viability of nanobatteries ultimately depends on holistic design approaches that consider impacts across the entire product lifecycle, from raw material extraction through end-of-life management.

Safety Standards and Regulatory Framework for Nanotechnology in Batteries

The regulatory landscape for nanotechnology in battery applications is evolving rapidly as the technology advances toward commercial implementation. Currently, there exists a patchwork of regulations across different jurisdictions, with no unified global framework specifically addressing nanomaterials in energy storage systems. In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily through the Toxic Substances Control Act (TSCA), requiring manufacturers to submit premanufacture notices for new chemical substances, including nanomaterials used in battery production.

The European Union has implemented more stringent measures through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which requires registration of nanomaterials exceeding one ton per year. Additionally, the EU's Battery Directive is being updated to incorporate specific provisions for nanomaterials, focusing on end-of-life management and recycling considerations unique to nano-enhanced batteries.

International standards organizations are actively developing frameworks to address the unique safety challenges posed by nanotechnology in batteries. The International Organization for Standardization (ISO) Technical Committee 229 has published several standards for nanotechnology, including ISO/TR 12885:2018, which provides health and safety practices in occupational settings relevant to nanotechnology manufacturing. Similarly, the International Electrotechnical Commission (IEC) has established Technical Committee 113 to develop standards for electrical and electronic products using nanomaterials.

Safety testing protocols for nano-enhanced batteries are becoming increasingly sophisticated. These include specialized thermal runaway tests, mechanical integrity assessments under extreme conditions, and leachability studies to evaluate potential nanoparticle release during normal operation and failure modes. The National Institute for Occupational Safety and Health (NIOSH) has established recommended exposure limits for certain engineered nanomaterials commonly used in battery applications, such as carbon nanotubes and metal oxide nanoparticles.

Risk assessment methodologies are being refined to address the unique properties of nanomaterials in battery systems. These methodologies incorporate considerations of particle size, surface chemistry, agglomeration behavior, and potential for bioaccumulation. The Organization for Economic Cooperation and Development (OECD) Working Party on Manufactured Nanomaterials has developed standardized testing approaches specifically for evaluating the environmental and health impacts of nanomaterials throughout their lifecycle.

Emerging regulatory trends indicate a shift toward lifecycle-based approaches that consider nanomaterial risks from raw material extraction through manufacturing, use, and disposal phases. This holistic perspective is particularly relevant for battery applications, where end-of-life management presents unique challenges for nanomaterial containment and recovery. Industry stakeholders are increasingly adopting voluntary stewardship programs to demonstrate responsible management practices while formal regulations continue to develop.

The European Union has implemented more stringent measures through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which requires registration of nanomaterials exceeding one ton per year. Additionally, the EU's Battery Directive is being updated to incorporate specific provisions for nanomaterials, focusing on end-of-life management and recycling considerations unique to nano-enhanced batteries.

International standards organizations are actively developing frameworks to address the unique safety challenges posed by nanotechnology in batteries. The International Organization for Standardization (ISO) Technical Committee 229 has published several standards for nanotechnology, including ISO/TR 12885:2018, which provides health and safety practices in occupational settings relevant to nanotechnology manufacturing. Similarly, the International Electrotechnical Commission (IEC) has established Technical Committee 113 to develop standards for electrical and electronic products using nanomaterials.

Safety testing protocols for nano-enhanced batteries are becoming increasingly sophisticated. These include specialized thermal runaway tests, mechanical integrity assessments under extreme conditions, and leachability studies to evaluate potential nanoparticle release during normal operation and failure modes. The National Institute for Occupational Safety and Health (NIOSH) has established recommended exposure limits for certain engineered nanomaterials commonly used in battery applications, such as carbon nanotubes and metal oxide nanoparticles.

Risk assessment methodologies are being refined to address the unique properties of nanomaterials in battery systems. These methodologies incorporate considerations of particle size, surface chemistry, agglomeration behavior, and potential for bioaccumulation. The Organization for Economic Cooperation and Development (OECD) Working Party on Manufactured Nanomaterials has developed standardized testing approaches specifically for evaluating the environmental and health impacts of nanomaterials throughout their lifecycle.

Emerging regulatory trends indicate a shift toward lifecycle-based approaches that consider nanomaterial risks from raw material extraction through manufacturing, use, and disposal phases. This holistic perspective is particularly relevant for battery applications, where end-of-life management presents unique challenges for nanomaterial containment and recovery. Industry stakeholders are increasingly adopting voluntary stewardship programs to demonstrate responsible management practices while formal regulations continue to develop.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!