Comparative Study of Lithium-Ion vs Solid-State Battery Pack Designs

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Objectives

Battery technology has undergone significant evolution since the commercialization of lithium-ion batteries by Sony in 1991. The initial lithium-ion cells offered energy densities of approximately 200 Wh/kg, representing a substantial improvement over previous nickel-cadmium and lead-acid technologies. Over the subsequent three decades, incremental improvements in electrode materials, electrolytes, and manufacturing processes have pushed lithium-ion energy densities to approximately 300 Wh/kg in modern commercial cells, with laboratory prototypes reaching up to 400 Wh/kg.

Despite these advances, lithium-ion technology is approaching its theoretical limits. Safety concerns related to flammable liquid electrolytes, dendrite formation risks, and limited energy density potential have driven research toward alternative battery chemistries. Solid-state battery technology emerged as a promising successor, with development efforts accelerating significantly since 2010, led by pioneering work from institutions like Toyota Research Institute and QuantumScape.

The evolution trajectory indicates a clear shift from optimizing existing lithium-ion designs toward fundamentally new architectures. This transition is motivated by automotive industry demands for batteries with higher energy density (>400 Wh/kg), faster charging capabilities (80% charge in <15 minutes), improved safety profiles, and extended cycle life (>1,000 cycles at 80% capacity retention).

Current solid-state battery research focuses on three primary objectives: developing stable solid electrolytes with ionic conductivity comparable to liquid systems, creating manufacturing processes suitable for mass production, and designing battery pack architectures that maximize the inherent advantages of solid-state technology while addressing thermal management challenges.

The comparative analysis of lithium-ion versus solid-state battery pack designs must consider both cell-level performance characteristics and system-level integration requirements. At the cell level, solid-state designs promise 50-100% higher energy density, substantially improved safety through elimination of flammable components, and potentially longer cycle life. At the pack level, the analysis must address thermal management strategies, mechanical stress accommodation, and electronic control systems optimized for each technology's unique characteristics.

The technical objectives for next-generation battery packs include achieving volumetric energy densities exceeding 1,000 Wh/L at the pack level, reducing manufacturing costs below $100/kWh, ensuring operational stability across temperature ranges from -30°C to 60°C, and developing modular architectures that facilitate both vehicle integration and second-life applications in stationary storage systems.

Despite these advances, lithium-ion technology is approaching its theoretical limits. Safety concerns related to flammable liquid electrolytes, dendrite formation risks, and limited energy density potential have driven research toward alternative battery chemistries. Solid-state battery technology emerged as a promising successor, with development efforts accelerating significantly since 2010, led by pioneering work from institutions like Toyota Research Institute and QuantumScape.

The evolution trajectory indicates a clear shift from optimizing existing lithium-ion designs toward fundamentally new architectures. This transition is motivated by automotive industry demands for batteries with higher energy density (>400 Wh/kg), faster charging capabilities (80% charge in <15 minutes), improved safety profiles, and extended cycle life (>1,000 cycles at 80% capacity retention).

Current solid-state battery research focuses on three primary objectives: developing stable solid electrolytes with ionic conductivity comparable to liquid systems, creating manufacturing processes suitable for mass production, and designing battery pack architectures that maximize the inherent advantages of solid-state technology while addressing thermal management challenges.

The comparative analysis of lithium-ion versus solid-state battery pack designs must consider both cell-level performance characteristics and system-level integration requirements. At the cell level, solid-state designs promise 50-100% higher energy density, substantially improved safety through elimination of flammable components, and potentially longer cycle life. At the pack level, the analysis must address thermal management strategies, mechanical stress accommodation, and electronic control systems optimized for each technology's unique characteristics.

The technical objectives for next-generation battery packs include achieving volumetric energy densities exceeding 1,000 Wh/L at the pack level, reducing manufacturing costs below $100/kWh, ensuring operational stability across temperature ranges from -30°C to 60°C, and developing modular architectures that facilitate both vehicle integration and second-life applications in stationary storage systems.

Market Demand Analysis for Advanced Battery Solutions

The global battery market is experiencing unprecedented growth driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the advanced battery market will reach $240 billion by 2027, with a compound annual growth rate exceeding 18% from 2022. This accelerated growth reflects the urgent need for battery technologies that overcome the limitations of traditional lithium-ion solutions.

Consumer demand for EVs continues to surge, with global sales increasing by 55% in 2022 compared to the previous year. This growth trajectory creates substantial pressure for batteries with higher energy density, faster charging capabilities, and improved safety profiles. Market research indicates that consumers consistently rank driving range anxiety and charging time as the top barriers to EV adoption, directly correlating to battery performance limitations.

The renewable energy sector presents another significant market driver, with grid-scale storage installations growing by 160% in 2022. Utility companies increasingly require battery solutions with longer cycle life, improved thermal stability, and reduced maintenance requirements. This segment values total cost of ownership over initial acquisition costs, creating opportunities for advanced battery technologies with superior longevity characteristics.

Safety concerns represent a critical market demand factor, particularly following high-profile thermal runaway incidents in consumer electronics and EVs. Insurance data shows claims related to battery fires increased by 35% between 2020 and 2022, intensifying regulatory scrutiny and consumer awareness. This has accelerated demand for inherently safer battery chemistries and designs, particularly in densely populated urban environments and sensitive applications like aviation.

Supply chain resilience has emerged as a strategic priority following recent disruptions. Market analysis reveals 78% of battery manufacturers experienced significant material shortages in the past three years. This vulnerability has stimulated interest in battery technologies utilizing more abundant and geographically distributed materials, reducing dependence on constrained supply chains and volatile commodity markets.

The sustainability profile of battery technologies increasingly influences purchasing decisions across market segments. Life cycle assessment studies demonstrate growing consumer willingness to pay premium prices for products with demonstrably lower environmental impacts. This trend is particularly pronounced in European and North American markets, where regulatory frameworks increasingly incorporate carbon footprint considerations into product standards and incentive structures.

Commercial fleet operators represent a rapidly expanding market segment with specific performance requirements. These customers prioritize total cost per mile metrics, creating demand for battery solutions optimized for high utilization rates, rapid charging capabilities, and predictable degradation profiles. This segment is projected to grow at 24% annually through 2026, outpacing the broader EV market.

Consumer demand for EVs continues to surge, with global sales increasing by 55% in 2022 compared to the previous year. This growth trajectory creates substantial pressure for batteries with higher energy density, faster charging capabilities, and improved safety profiles. Market research indicates that consumers consistently rank driving range anxiety and charging time as the top barriers to EV adoption, directly correlating to battery performance limitations.

The renewable energy sector presents another significant market driver, with grid-scale storage installations growing by 160% in 2022. Utility companies increasingly require battery solutions with longer cycle life, improved thermal stability, and reduced maintenance requirements. This segment values total cost of ownership over initial acquisition costs, creating opportunities for advanced battery technologies with superior longevity characteristics.

Safety concerns represent a critical market demand factor, particularly following high-profile thermal runaway incidents in consumer electronics and EVs. Insurance data shows claims related to battery fires increased by 35% between 2020 and 2022, intensifying regulatory scrutiny and consumer awareness. This has accelerated demand for inherently safer battery chemistries and designs, particularly in densely populated urban environments and sensitive applications like aviation.

Supply chain resilience has emerged as a strategic priority following recent disruptions. Market analysis reveals 78% of battery manufacturers experienced significant material shortages in the past three years. This vulnerability has stimulated interest in battery technologies utilizing more abundant and geographically distributed materials, reducing dependence on constrained supply chains and volatile commodity markets.

The sustainability profile of battery technologies increasingly influences purchasing decisions across market segments. Life cycle assessment studies demonstrate growing consumer willingness to pay premium prices for products with demonstrably lower environmental impacts. This trend is particularly pronounced in European and North American markets, where regulatory frameworks increasingly incorporate carbon footprint considerations into product standards and incentive structures.

Commercial fleet operators represent a rapidly expanding market segment with specific performance requirements. These customers prioritize total cost per mile metrics, creating demand for battery solutions optimized for high utilization rates, rapid charging capabilities, and predictable degradation profiles. This segment is projected to grow at 24% annually through 2026, outpacing the broader EV market.

Current Challenges in Battery Pack Design

Battery pack design faces significant challenges in both lithium-ion and solid-state technologies. Thermal management remains one of the most critical issues for lithium-ion battery packs, as these systems generate substantial heat during charging and discharging cycles. Inadequate thermal management can lead to thermal runaway, resulting in catastrophic failures and safety hazards. Current cooling systems add considerable weight and complexity to pack designs, reducing overall energy density.

Energy density optimization presents another major challenge. While lithium-ion technology has improved significantly, it approaches theoretical limits. Pack designers must balance the trade-off between maximizing energy capacity and maintaining structural integrity, often sacrificing one for the other. This challenge becomes particularly evident in applications requiring both high energy density and mechanical robustness, such as electric vehicles.

Safety concerns persist despite years of development. Lithium-ion packs remain vulnerable to internal short circuits, overcharging, and physical damage. Current protection mechanisms include sophisticated battery management systems (BMS), thermal fuses, and reinforced enclosures, all of which add complexity, weight, and cost to the final design.

For emerging solid-state battery pack designs, manufacturing scalability represents a formidable obstacle. Current production methods remain largely laboratory-focused, with significant challenges in scaling to commercial volumes. The precision required for solid electrolyte layers and interfaces exceeds capabilities of existing mass production equipment.

Interface stability between solid electrolytes and electrodes creates persistent performance issues in solid-state designs. Contact resistance at these interfaces leads to capacity degradation over time, limiting cycle life and practical implementation. Research shows that mechanical stress during cycling can create microcracks at these interfaces, further exacerbating the problem.

Cost factors significantly impact both technologies. Lithium-ion pack designs face increasing material costs, particularly for cobalt and nickel. Solid-state alternatives currently require expensive manufacturing processes and specialized materials, making them prohibitively expensive for mass-market applications. Industry analysis indicates solid-state pack costs remain 5-8 times higher than conventional designs.

Standardization gaps affect both technologies but particularly impact solid-state development. Without established design standards, manufacturers pursue proprietary approaches, creating fragmentation that slows industry-wide adoption and increases development costs. This lack of standardization extends to testing protocols, safety certifications, and component specifications.

Recycling and end-of-life considerations present growing challenges as battery production volumes increase. Current pack designs often prioritize performance over recyclability, making disassembly and material recovery difficult and expensive. This challenge will intensify as first-generation electric vehicle batteries reach end-of-life in coming years.

Energy density optimization presents another major challenge. While lithium-ion technology has improved significantly, it approaches theoretical limits. Pack designers must balance the trade-off between maximizing energy capacity and maintaining structural integrity, often sacrificing one for the other. This challenge becomes particularly evident in applications requiring both high energy density and mechanical robustness, such as electric vehicles.

Safety concerns persist despite years of development. Lithium-ion packs remain vulnerable to internal short circuits, overcharging, and physical damage. Current protection mechanisms include sophisticated battery management systems (BMS), thermal fuses, and reinforced enclosures, all of which add complexity, weight, and cost to the final design.

For emerging solid-state battery pack designs, manufacturing scalability represents a formidable obstacle. Current production methods remain largely laboratory-focused, with significant challenges in scaling to commercial volumes. The precision required for solid electrolyte layers and interfaces exceeds capabilities of existing mass production equipment.

Interface stability between solid electrolytes and electrodes creates persistent performance issues in solid-state designs. Contact resistance at these interfaces leads to capacity degradation over time, limiting cycle life and practical implementation. Research shows that mechanical stress during cycling can create microcracks at these interfaces, further exacerbating the problem.

Cost factors significantly impact both technologies. Lithium-ion pack designs face increasing material costs, particularly for cobalt and nickel. Solid-state alternatives currently require expensive manufacturing processes and specialized materials, making them prohibitively expensive for mass-market applications. Industry analysis indicates solid-state pack costs remain 5-8 times higher than conventional designs.

Standardization gaps affect both technologies but particularly impact solid-state development. Without established design standards, manufacturers pursue proprietary approaches, creating fragmentation that slows industry-wide adoption and increases development costs. This lack of standardization extends to testing protocols, safety certifications, and component specifications.

Recycling and end-of-life considerations present growing challenges as battery production volumes increase. Current pack designs often prioritize performance over recyclability, making disassembly and material recovery difficult and expensive. This challenge will intensify as first-generation electric vehicle batteries reach end-of-life in coming years.

Comparative Analysis of Li-ion vs Solid-State Architectures

01 Structural design differences between lithium-ion and solid-state battery packs

Solid-state battery packs feature a fundamentally different architecture compared to traditional lithium-ion batteries, eliminating the need for liquid electrolytes. This structural difference allows for more compact designs, improved energy density, and enhanced safety features. Solid-state designs typically incorporate specialized housing configurations to accommodate the solid electrolyte while maintaining proper thermal management and mechanical stability.- Structural design differences between lithium-ion and solid-state battery packs: Solid-state battery packs feature a fundamentally different architecture compared to traditional lithium-ion batteries, eliminating the need for liquid electrolytes. This structural difference allows for more compact designs, improved energy density, and enhanced safety features. Solid-state designs typically incorporate specialized housing configurations to accommodate the solid electrolyte while maintaining proper pressure distribution and thermal management across the cells.

- Thermal management systems comparison: Thermal management approaches differ significantly between lithium-ion and solid-state battery packs. Lithium-ion batteries typically require more extensive cooling systems to prevent thermal runaway, while solid-state batteries demonstrate improved thermal stability. Advanced thermal management solutions for solid-state batteries focus on maintaining optimal operating temperatures for ion conductivity rather than heat dissipation. These systems may incorporate novel materials and configurations to address the unique thermal characteristics of solid electrolytes.

- Safety features and protection mechanisms: Solid-state battery packs offer inherent safety advantages over lithium-ion designs due to the elimination of flammable liquid electrolytes. However, they require different protection mechanisms to address unique failure modes. Safety features in solid-state designs focus on preventing mechanical stress and maintaining electrolyte integrity, while lithium-ion batteries emphasize thermal runaway prevention and gas venting. Both technologies incorporate various sensors and control systems, but with different parameters monitored and different intervention strategies.

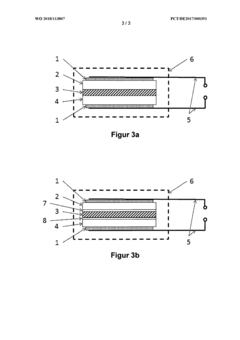

- Cell-to-pack integration approaches: The integration of cells into complete battery packs follows different methodologies for lithium-ion versus solid-state technologies. Solid-state designs often enable more direct cell-to-pack approaches with fewer intermediate components, potentially eliminating module-level structures. This integration difference affects how electrical connections are established, how mechanical support is provided, and how the overall pack is assembled and serviced. Novel interconnection technologies are being developed specifically for solid-state cell integration to maximize the benefits of their unique properties.

- Energy density and form factor optimization: Solid-state battery packs enable different form factor possibilities compared to lithium-ion designs, allowing for more flexible integration into various applications. The higher theoretical energy density of solid-state technology permits more compact designs or extended range within the same volume constraints. Pack designs for solid-state batteries are being optimized to take advantage of the technology's unique characteristics, including the potential for bipolar stacking and reduced need for separation between cells, resulting in higher volumetric efficiency.

02 Thermal management systems comparison

Thermal management approaches differ significantly between lithium-ion and solid-state battery packs. Solid-state batteries generally produce less heat during operation and have reduced thermal runaway risks, allowing for simplified cooling systems. However, they require specialized thermal management solutions to maintain optimal operating temperatures for the solid electrolyte. Lithium-ion batteries typically need more robust cooling systems to prevent overheating and ensure safe operation under high discharge rates.Expand Specific Solutions03 Safety features and protection mechanisms

Solid-state battery packs offer inherent safety advantages over lithium-ion designs due to the elimination of flammable liquid electrolytes. This fundamental difference influences the design of protection circuits, cell isolation methods, and overall pack architecture. Solid-state designs can reduce or eliminate certain safety components required in lithium-ion packs, while potentially requiring new protection mechanisms specific to solid electrolyte characteristics and failure modes.Expand Specific Solutions04 Cell-to-pack integration approaches

The integration of cells into complete battery packs follows different methodologies between lithium-ion and solid-state technologies. Solid-state batteries enable novel cell-to-pack designs that can increase energy density at the pack level by reducing structural components. These integration approaches affect how cells are electrically connected, physically arranged, and mechanically supported within the pack housing, with solid-state designs potentially allowing for more efficient space utilization and simplified manufacturing processes.Expand Specific Solutions05 Electrode and interface design considerations

The electrode-electrolyte interfaces in solid-state and lithium-ion battery packs present distinct design challenges. Solid-state batteries require specialized electrode designs to ensure proper contact with the solid electrolyte and manage interfacial resistance. This affects how electrodes are manufactured, positioned, and connected within the cell and pack structure. The different interface characteristics influence pack design decisions related to pressure application, expansion accommodation, and long-term performance stability.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The lithium-ion vs solid-state battery pack design landscape is currently in a transitional phase, with the market for lithium-ion batteries well-established ($45+ billion) while solid-state technology remains in early commercialization stages. Major automotive players like GM, Ford, and Honda are actively investing in both technologies, while specialized battery manufacturers including LG Energy Solution, Panasonic, and CATL (Dongguan Amperex) dominate lithium-ion production. Research institutions such as University of California and Michigan State University are advancing solid-state technology alongside innovative companies like Wildcat Discovery Technologies and Microvast. The competitive landscape shows established players protecting lithium-ion market share while simultaneously developing solid-state capabilities, with Asian manufacturers currently holding technological leadership positions.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive battery pack design strategy that integrates both lithium-ion and solid-state technologies. Their Ultium battery platform represents their current lithium-ion solution with a unique modular architecture allowing for horizontal or vertical stacking of battery cells. For solid-state development, GM has partnered with Solid Energy Systems to develop silicon-dominant anode technology as a bridge toward full solid-state implementation. Their approach focuses on a gradual transition strategy, incorporating solid-state elements into existing lithium-ion frameworks before full adoption. GM's battery pack designs emphasize thermal management systems that can be adapted for both technologies, with particular attention to the different cooling requirements of solid-state cells which generate less heat during operation but require more precise temperature control.

Strengths: Established manufacturing infrastructure for lithium-ion technology; strong partnerships for solid-state development; modular design approach allows for flexible implementation. Weaknesses: Currently behind some competitors in full solid-state implementation; transition strategy may delay realization of all solid-state benefits; significant capital investment required for manufacturing transition.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed dual-track battery pack designs addressing both lithium-ion and solid-state technologies. Their current lithium-ion packs utilize high-nickel cathode chemistry (over 80% nickel content) with silicon-graphite composite anodes, achieving energy densities of 260-270 Wh/kg. For solid-state technology, LG has developed prototype packs using sulfide-based solid electrolytes with lithium metal anodes, demonstrating energy densities exceeding 400 Wh/kg in laboratory settings. Their comparative pack designs feature innovative safety mechanisms tailored to each technology: lithium-ion packs incorporate advanced thermal propagation prevention systems with intumescent materials, while solid-state designs leverage the inherent safety of non-flammable electrolytes to reduce pack complexity and weight. LG's manufacturing approach includes pilot production lines capable of producing both technologies, with specialized equipment for handling the pressure-sensitive assembly requirements of solid-state cells.

Strengths: Industry-leading energy density in both technologies; established global manufacturing capacity; strong materials science expertise in electrolyte development. Weaknesses: Solid-state manufacturing processes still not fully scaled; higher production costs for solid-state technology; thermal management systems for solid-state packs still being optimized for extreme conditions.

Critical Patents and Technical Innovations

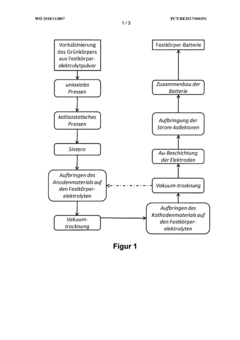

Lithium ion solid-state battery and method for producing the same

PatentWO2018113807A1

Innovation

- A method for producing lithium-ion solid-state batteries where a dense, sintered solid electrolyte is used as a mechanical support, with electrodes applied on both sides, utilizing a mixture of phosphate compounds like lithium vanadium phosphate and lithium aluminum titanium phosphate, and nanostructuring to enhance structural integrity and ion conductivity.

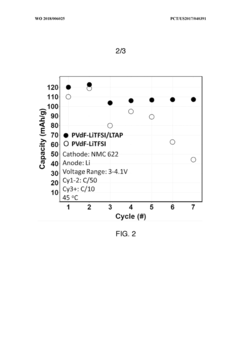

Electrode compositions for solid-state batteries

PatentWO2018006025A1

Innovation

- A cathode composition using a polymer, such as polyvinylene difluoride (PVdF), combined with an inorganic ion-conducting material like lithium titanate phosphate (LTAP) and a lithium salt, which enhances lithium ion conductivity and mitigates interfacial impedance, allowing for improved energy density and cycle life.

Safety and Thermal Management Considerations

Safety considerations represent a critical differentiator between lithium-ion and solid-state battery pack designs. Conventional lithium-ion batteries face inherent safety challenges due to their flammable liquid electrolytes, which can lead to thermal runaway events when subjected to physical damage, overcharging, or manufacturing defects. These incidents typically progress through a cascade of exothermic reactions, potentially resulting in fires or explosions that are difficult to suppress once initiated.

Solid-state batteries offer significant safety advantages by eliminating flammable liquid components. Their solid electrolytes substantially reduce fire risks and enhance structural integrity under mechanical stress. Testing data indicates that solid-state designs can withstand penetration tests, extreme temperature conditions, and overcharging scenarios that would trigger catastrophic failures in conventional lithium-ion cells.

Thermal management systems differ substantially between these technologies. Lithium-ion battery packs require sophisticated cooling architectures—typically liquid cooling circuits or forced air systems—to maintain optimal operating temperatures between 15-35°C. These systems add considerable weight, complexity, and parasitic energy consumption to the overall pack design. Current industry standards mandate temperature gradients below 5°C across cells to prevent premature degradation and safety incidents.

Solid-state batteries demonstrate superior thermal stability, potentially simplifying thermal management requirements. Their wider operating temperature range (-20°C to 60°C) and reduced heat generation during charge/discharge cycles may allow for passive cooling strategies in certain applications. However, challenges remain in managing temperature distribution during fast-charging operations, where localized heating can still occur at electrode interfaces.

Regulatory frameworks increasingly recognize these differences, with transportation safety standards evolving to accommodate solid-state technology's improved safety profile. The UN 38.3 testing protocol and IEC 62660 standards are being adapted to address the unique characteristics of solid-state designs, potentially allowing for less restrictive shipping classifications and simplified battery management systems.

Cost implications of these safety differences are substantial. While lithium-ion battery packs require approximately 8-12% of total pack cost for thermal management systems, preliminary data suggests solid-state designs might reduce this to 3-5%, representing significant savings in high-volume production scenarios. Additionally, simplified safety systems could reduce pack weight by 5-8%, indirectly improving vehicle efficiency and range.

Solid-state batteries offer significant safety advantages by eliminating flammable liquid components. Their solid electrolytes substantially reduce fire risks and enhance structural integrity under mechanical stress. Testing data indicates that solid-state designs can withstand penetration tests, extreme temperature conditions, and overcharging scenarios that would trigger catastrophic failures in conventional lithium-ion cells.

Thermal management systems differ substantially between these technologies. Lithium-ion battery packs require sophisticated cooling architectures—typically liquid cooling circuits or forced air systems—to maintain optimal operating temperatures between 15-35°C. These systems add considerable weight, complexity, and parasitic energy consumption to the overall pack design. Current industry standards mandate temperature gradients below 5°C across cells to prevent premature degradation and safety incidents.

Solid-state batteries demonstrate superior thermal stability, potentially simplifying thermal management requirements. Their wider operating temperature range (-20°C to 60°C) and reduced heat generation during charge/discharge cycles may allow for passive cooling strategies in certain applications. However, challenges remain in managing temperature distribution during fast-charging operations, where localized heating can still occur at electrode interfaces.

Regulatory frameworks increasingly recognize these differences, with transportation safety standards evolving to accommodate solid-state technology's improved safety profile. The UN 38.3 testing protocol and IEC 62660 standards are being adapted to address the unique characteristics of solid-state designs, potentially allowing for less restrictive shipping classifications and simplified battery management systems.

Cost implications of these safety differences are substantial. While lithium-ion battery packs require approximately 8-12% of total pack cost for thermal management systems, preliminary data suggests solid-state designs might reduce this to 3-5%, representing significant savings in high-volume production scenarios. Additionally, simplified safety systems could reduce pack weight by 5-8%, indirectly improving vehicle efficiency and range.

Environmental Impact and Sustainability Assessment

The environmental impact of battery technologies extends far beyond their operational efficiency, encompassing their entire lifecycle from raw material extraction to end-of-life disposal. Lithium-ion batteries, while revolutionizing portable electronics and electric vehicles, present significant environmental challenges. The mining of lithium, cobalt, and nickel involves substantial land disruption, water consumption, and potential contamination of local ecosystems. Additionally, the energy-intensive manufacturing process contributes to carbon emissions, particularly when powered by fossil fuels.

Solid-state batteries offer promising environmental advantages over their lithium-ion counterparts. The elimination of liquid electrolytes reduces fire risks and toxic leakage potential, making them inherently safer for both users and the environment. Furthermore, many solid-state designs aim to reduce or eliminate cobalt usage, addressing ethical concerns related to mining practices in regions like the Democratic Republic of Congo.

From a lifecycle perspective, solid-state batteries demonstrate superior sustainability metrics. Their potentially longer lifespan—estimated at 2-3 times that of conventional lithium-ion batteries—translates to fewer replacement cycles and reduced manufacturing demands over time. This extended durability directly correlates with decreased resource extraction and waste generation throughout the product lifecycle.

Recycling capabilities represent another critical sustainability factor. Current lithium-ion recycling processes recover only 50-60% of materials, with complex separation requirements due to liquid electrolytes and multiple material types. Solid-state designs may facilitate more efficient recycling through simplified construction and reduced material complexity, though large-scale recycling infrastructure remains underdeveloped for both technologies.

Carbon footprint analysis reveals that manufacturing accounts for approximately 70% of lifetime emissions for both battery types. However, solid-state batteries' longer operational lifespan effectively amortizes these production emissions over more usage cycles, resulting in lower environmental impact per kilowatt-hour delivered throughout their service life.

Water usage presents a significant environmental concern, particularly for lithium extraction from salt flats in water-stressed regions like Chile's Atacama Desert. Solid-state technologies utilizing alternative materials or requiring less water-intensive processing could substantially reduce hydrological impacts, though comprehensive comparative data remains limited as commercial-scale production is still emerging.

Solid-state batteries offer promising environmental advantages over their lithium-ion counterparts. The elimination of liquid electrolytes reduces fire risks and toxic leakage potential, making them inherently safer for both users and the environment. Furthermore, many solid-state designs aim to reduce or eliminate cobalt usage, addressing ethical concerns related to mining practices in regions like the Democratic Republic of Congo.

From a lifecycle perspective, solid-state batteries demonstrate superior sustainability metrics. Their potentially longer lifespan—estimated at 2-3 times that of conventional lithium-ion batteries—translates to fewer replacement cycles and reduced manufacturing demands over time. This extended durability directly correlates with decreased resource extraction and waste generation throughout the product lifecycle.

Recycling capabilities represent another critical sustainability factor. Current lithium-ion recycling processes recover only 50-60% of materials, with complex separation requirements due to liquid electrolytes and multiple material types. Solid-state designs may facilitate more efficient recycling through simplified construction and reduced material complexity, though large-scale recycling infrastructure remains underdeveloped for both technologies.

Carbon footprint analysis reveals that manufacturing accounts for approximately 70% of lifetime emissions for both battery types. However, solid-state batteries' longer operational lifespan effectively amortizes these production emissions over more usage cycles, resulting in lower environmental impact per kilowatt-hour delivered throughout their service life.

Water usage presents a significant environmental concern, particularly for lithium extraction from salt flats in water-stressed regions like Chile's Atacama Desert. Solid-state technologies utilizing alternative materials or requiring less water-intensive processing could substantially reduce hydrological impacts, though comprehensive comparative data remains limited as commercial-scale production is still emerging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!