The Role of Battery Pack Design in Offshore Energy Solutions

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Offshore Battery Evolution and Objectives

The evolution of battery technology for offshore applications has undergone significant transformation over the past two decades, shifting from basic lead-acid systems to sophisticated lithium-ion configurations specifically engineered for harsh marine environments. Early offshore battery implementations primarily served as emergency backup power, with limited capacity and reliability under extreme conditions. The technological progression accelerated around 2010 when the offshore energy sector began exploring more sustainable operational models.

The current generation of offshore battery systems represents a convergence of multiple technological advancements, including enhanced energy density, improved thermal management, and sophisticated battery management systems capable of withstanding saltwater exposure and extreme temperature fluctuations. These developments have expanded the functional role of batteries from mere backup systems to critical components in hybrid power solutions for offshore platforms, vessels, and renewable energy installations.

A key milestone in this evolution was the introduction of containerized battery systems around 2015, which provided modular, scalable energy storage solutions specifically designed for offshore deployment. These systems incorporated advanced safety features including fire suppression, explosion-proof casings, and remote monitoring capabilities essential for unmanned operations in remote marine locations.

The primary objectives driving offshore battery pack design center on four critical parameters: maximizing energy density to reduce spatial footprint on space-constrained platforms; enhancing durability against corrosion, vibration, and temperature extremes; improving safety protocols to mitigate thermal runaway risks in isolated environments; and extending operational lifespan to justify the significant capital investment required for offshore installations.

Looking forward, the technical trajectory aims to develop battery systems capable of supporting the complete electrification of offshore operations, particularly as the industry transitions toward renewable energy integration. This includes developing battery configurations that can efficiently store energy from offshore wind farms during peak production periods and discharge during low-wind conditions, thereby stabilizing power supply to critical operations.

The ultimate objective is to create battery systems that enable offshore facilities to operate with minimal reliance on fossil fuels, significantly reducing carbon emissions while maintaining operational reliability. This transition necessitates battery designs that can deliver both high-power output for equipment operation and long-duration storage capacity for sustained energy provision during extended periods of renewable resource variability.

The current generation of offshore battery systems represents a convergence of multiple technological advancements, including enhanced energy density, improved thermal management, and sophisticated battery management systems capable of withstanding saltwater exposure and extreme temperature fluctuations. These developments have expanded the functional role of batteries from mere backup systems to critical components in hybrid power solutions for offshore platforms, vessels, and renewable energy installations.

A key milestone in this evolution was the introduction of containerized battery systems around 2015, which provided modular, scalable energy storage solutions specifically designed for offshore deployment. These systems incorporated advanced safety features including fire suppression, explosion-proof casings, and remote monitoring capabilities essential for unmanned operations in remote marine locations.

The primary objectives driving offshore battery pack design center on four critical parameters: maximizing energy density to reduce spatial footprint on space-constrained platforms; enhancing durability against corrosion, vibration, and temperature extremes; improving safety protocols to mitigate thermal runaway risks in isolated environments; and extending operational lifespan to justify the significant capital investment required for offshore installations.

Looking forward, the technical trajectory aims to develop battery systems capable of supporting the complete electrification of offshore operations, particularly as the industry transitions toward renewable energy integration. This includes developing battery configurations that can efficiently store energy from offshore wind farms during peak production periods and discharge during low-wind conditions, thereby stabilizing power supply to critical operations.

The ultimate objective is to create battery systems that enable offshore facilities to operate with minimal reliance on fossil fuels, significantly reducing carbon emissions while maintaining operational reliability. This transition necessitates battery designs that can deliver both high-power output for equipment operation and long-duration storage capacity for sustained energy provision during extended periods of renewable resource variability.

Market Analysis for Maritime Energy Storage Systems

The maritime energy storage market is experiencing significant growth, driven by increasing electrification of vessels and offshore platforms. Current market valuations place the global maritime battery market at approximately 250 million USD in 2023, with projections indicating a compound annual growth rate of 18-20% through 2030. This growth trajectory is supported by stringent environmental regulations, particularly IMO 2023 and European Green Deal initiatives, which mandate substantial reductions in maritime carbon emissions.

Demand for maritime energy storage systems is segmented across several vessel categories. Commercial vessels, including ferries and offshore supply vessels, currently represent the largest market share at roughly 40%. Cruise ships and passenger vessels follow at 25%, with specialized offshore platforms accounting for 20%. Military and research vessels comprise the remaining 15% of market demand. Geographically, Northern Europe leads adoption with approximately 35% market share, followed by East Asia at 28%, North America at 22%, and other regions collectively representing 15%.

Key market drivers include regulatory pressure, operational cost optimization, and increasing renewable energy integration in maritime operations. Battery systems enable hybrid propulsion configurations that can reduce fuel consumption by 15-30% depending on vessel type and operational profile. Additionally, the ability to operate in emission-controlled areas without penalties provides significant economic advantages for operators.

Market challenges primarily revolve around initial capital expenditure, which remains 30-40% higher than conventional systems. Safety concerns regarding battery thermal management in marine environments and limited charging infrastructure in many ports also constrain market expansion. The weight and space requirements of battery systems present design challenges, particularly for retrofitting existing vessels.

Customer requirements are evolving toward higher energy density solutions, with current market demands averaging 200-300 Wh/kg, representing a 40% increase from five years ago. Cycle life expectations have similarly increased, with customers now expecting 3,000-5,000 cycles under maritime conditions. Fast charging capabilities and integration with vessel management systems have become standard requirements rather than premium features.

The competitive landscape features established marine technology providers expanding into energy storage, alongside specialized battery manufacturers developing maritime-specific solutions. Price sensitivity varies by segment, with commercial operators prioritizing total cost of ownership while specialized applications focus more on performance and reliability metrics. Current pricing trends indicate a gradual decline of 8-12% annually in per-kWh costs, though this is partially offset by increasing system complexity and safety requirements.

Demand for maritime energy storage systems is segmented across several vessel categories. Commercial vessels, including ferries and offshore supply vessels, currently represent the largest market share at roughly 40%. Cruise ships and passenger vessels follow at 25%, with specialized offshore platforms accounting for 20%. Military and research vessels comprise the remaining 15% of market demand. Geographically, Northern Europe leads adoption with approximately 35% market share, followed by East Asia at 28%, North America at 22%, and other regions collectively representing 15%.

Key market drivers include regulatory pressure, operational cost optimization, and increasing renewable energy integration in maritime operations. Battery systems enable hybrid propulsion configurations that can reduce fuel consumption by 15-30% depending on vessel type and operational profile. Additionally, the ability to operate in emission-controlled areas without penalties provides significant economic advantages for operators.

Market challenges primarily revolve around initial capital expenditure, which remains 30-40% higher than conventional systems. Safety concerns regarding battery thermal management in marine environments and limited charging infrastructure in many ports also constrain market expansion. The weight and space requirements of battery systems present design challenges, particularly for retrofitting existing vessels.

Customer requirements are evolving toward higher energy density solutions, with current market demands averaging 200-300 Wh/kg, representing a 40% increase from five years ago. Cycle life expectations have similarly increased, with customers now expecting 3,000-5,000 cycles under maritime conditions. Fast charging capabilities and integration with vessel management systems have become standard requirements rather than premium features.

The competitive landscape features established marine technology providers expanding into energy storage, alongside specialized battery manufacturers developing maritime-specific solutions. Price sensitivity varies by segment, with commercial operators prioritizing total cost of ownership while specialized applications focus more on performance and reliability metrics. Current pricing trends indicate a gradual decline of 8-12% annually in per-kWh costs, though this is partially offset by increasing system complexity and safety requirements.

Current Challenges in Offshore Battery Pack Technology

Offshore battery pack technology faces significant challenges due to the harsh marine environment and unique operational requirements. The corrosive nature of saltwater and high humidity levels accelerate degradation of battery components, requiring specialized protective measures beyond those used in land-based applications. Material selection becomes critical, with advanced corrosion-resistant alloys and marine-grade enclosures necessary to ensure longevity in these conditions.

Temperature management presents another major hurdle. Offshore installations experience extreme temperature fluctuations that can severely impact battery performance and lifespan. Conventional cooling systems often prove inadequate when faced with the combination of internal heat generation and external environmental factors. Engineers must develop sophisticated thermal management systems that can operate reliably despite space constraints and limited maintenance access.

Safety concerns are magnified in offshore environments where evacuation options are limited and emergency response is complicated by location. Battery thermal runaway events pose particularly severe risks, necessitating redundant safety systems and advanced fire suppression technologies specifically designed for marine applications. These systems must function autonomously and maintain reliability despite prolonged exposure to harsh conditions.

Weight and space optimization create additional engineering challenges. Offshore platforms and vessels have strict weight limitations and space constraints, requiring battery packs with higher energy density than their land-based counterparts. This drives the need for advanced cell chemistries and innovative structural designs that maximize energy storage while minimizing footprint.

Maintenance logistics represent a significant operational challenge. The remote nature of offshore installations makes regular maintenance difficult and costly. Battery systems must be designed with extended service intervals and remote monitoring capabilities to reduce the frequency of physical inspections. When maintenance is required, modular designs that facilitate rapid component replacement become essential.

Regulatory compliance adds another layer of complexity. Maritime regulations impose strict requirements on electrical systems used offshore, with standards varying across jurisdictions. Battery systems must meet these diverse requirements while also addressing classification society rules that govern marine equipment certification. This regulatory landscape continues to evolve as battery technology advances, creating a moving target for compliance efforts.

Integration with existing offshore power systems presents technical hurdles related to power quality, grid stability, and energy management. Battery systems must accommodate variable renewable inputs while providing stable power output under challenging conditions. Advanced battery management systems with sophisticated control algorithms are required to optimize performance and extend operational life in these demanding applications.

Temperature management presents another major hurdle. Offshore installations experience extreme temperature fluctuations that can severely impact battery performance and lifespan. Conventional cooling systems often prove inadequate when faced with the combination of internal heat generation and external environmental factors. Engineers must develop sophisticated thermal management systems that can operate reliably despite space constraints and limited maintenance access.

Safety concerns are magnified in offshore environments where evacuation options are limited and emergency response is complicated by location. Battery thermal runaway events pose particularly severe risks, necessitating redundant safety systems and advanced fire suppression technologies specifically designed for marine applications. These systems must function autonomously and maintain reliability despite prolonged exposure to harsh conditions.

Weight and space optimization create additional engineering challenges. Offshore platforms and vessels have strict weight limitations and space constraints, requiring battery packs with higher energy density than their land-based counterparts. This drives the need for advanced cell chemistries and innovative structural designs that maximize energy storage while minimizing footprint.

Maintenance logistics represent a significant operational challenge. The remote nature of offshore installations makes regular maintenance difficult and costly. Battery systems must be designed with extended service intervals and remote monitoring capabilities to reduce the frequency of physical inspections. When maintenance is required, modular designs that facilitate rapid component replacement become essential.

Regulatory compliance adds another layer of complexity. Maritime regulations impose strict requirements on electrical systems used offshore, with standards varying across jurisdictions. Battery systems must meet these diverse requirements while also addressing classification society rules that govern marine equipment certification. This regulatory landscape continues to evolve as battery technology advances, creating a moving target for compliance efforts.

Integration with existing offshore power systems presents technical hurdles related to power quality, grid stability, and energy management. Battery systems must accommodate variable renewable inputs while providing stable power output under challenging conditions. Advanced battery management systems with sophisticated control algorithms are required to optimize performance and extend operational life in these demanding applications.

Contemporary Battery Pack Solutions for Offshore Applications

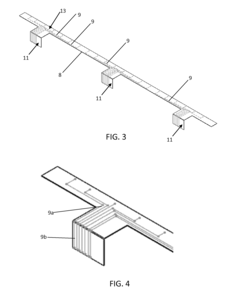

01 Thermal Management Systems for Battery Packs

Effective thermal management systems are crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems may include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms. Advanced designs incorporate temperature sensors and control algorithms to regulate thermal conditions across the battery pack, ensuring uniform temperature distribution and preventing thermal runaway events.- Thermal Management Systems for Battery Packs: Effective thermal management systems are crucial for battery pack design to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems may include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms that help dissipate heat generated during charging and discharging cycles. Advanced designs incorporate temperature sensors and control algorithms to regulate thermal conditions across the battery pack.

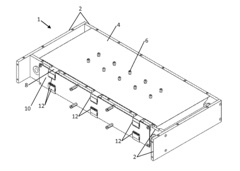

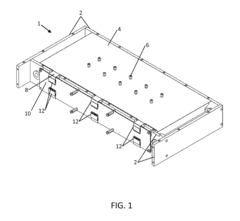

- Structural Design and Mechanical Protection: Battery pack structural design focuses on providing mechanical protection while optimizing space utilization and weight distribution. This includes robust housing materials, shock absorption features, and reinforcement structures to protect cells from physical damage. Designs must account for vibration resistance, impact protection, and structural integrity while maintaining accessibility for maintenance and replacement. Advanced designs incorporate modular approaches that allow for flexible configuration and easier servicing.

- Battery Management Systems (BMS): Battery Management Systems are essential components that monitor and control the electrical performance of battery packs. These systems regulate charging and discharging processes, perform cell balancing to ensure uniform performance across all cells, and implement safety protocols to prevent overcharging, over-discharging, and short circuits. Advanced BMS designs incorporate predictive analytics for battery health monitoring, state-of-charge estimation, and fault detection algorithms.

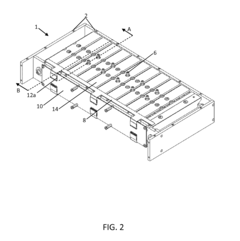

- Cell Configuration and Interconnection Methods: The arrangement and interconnection of individual battery cells significantly impact the overall performance of battery packs. Various configurations include series, parallel, or series-parallel arrangements to achieve desired voltage and capacity specifications. Advanced interconnection methods utilize bus bars, flexible circuits, or direct bonding techniques to minimize resistance and improve current distribution. Designs must consider thermal expansion, vibration effects, and maintenance accessibility while optimizing electrical performance.

- Safety Features and Failure Mitigation: Safety features are paramount in battery pack design to prevent catastrophic failures and mitigate risks. These include isolation mechanisms, pressure relief valves, thermal fuses, and fire-resistant materials. Advanced designs incorporate redundant safety systems, fault isolation capabilities, and early warning detection for potential failure modes. Compartmentalization strategies help contain failures to prevent propagation throughout the pack, while monitoring systems continuously assess safety parameters during operation.

02 Battery Cell Arrangement and Connection Configurations

The arrangement and connection of battery cells within a pack significantly impacts performance, safety, and energy density. Various configurations include series, parallel, or series-parallel connections to achieve desired voltage and capacity. Cell arrangement considerations include space optimization, weight distribution, and accessibility for maintenance. Advanced designs feature modular architectures that allow for easier replacement of individual cells or modules while maintaining structural integrity of the overall pack.Expand Specific Solutions03 Battery Management Systems (BMS)

Battery Management Systems are essential components that monitor and control the electrical performance of battery packs. These systems manage cell balancing, state of charge estimation, and protection against over-charging or over-discharging. Advanced BMS designs incorporate predictive algorithms for battery health monitoring, fault detection, and performance optimization. They may also include communication interfaces for data exchange with external systems and remote monitoring capabilities.Expand Specific Solutions04 Structural Design and Mechanical Protection

The structural design of battery packs focuses on providing mechanical protection while optimizing weight and volume. This includes robust enclosures, shock absorption systems, and reinforcement structures to protect cells from physical damage. Designs must account for expansion and contraction during thermal cycling, vibration resistance, and crash safety. Advanced materials such as composite structures and engineered polymers are used to achieve lightweight yet durable battery pack housings.Expand Specific Solutions05 Integration of Safety Features

Safety features are critical components in battery pack design to prevent catastrophic failures. These include pressure relief mechanisms, thermal fuses, current limiters, and isolation systems. Advanced designs incorporate multiple redundant safety systems, including gas venting channels, flame-retardant materials, and electrical isolation barriers. Some designs feature compartmentalization to contain potential failures within limited sections of the pack, preventing propagation of thermal events.Expand Specific Solutions

Leading Manufacturers and Industry Competitors

The offshore energy solutions market is witnessing significant growth in battery pack design innovation, currently transitioning from early adoption to growth phase. The market is projected to expand substantially due to increasing renewable energy integration and maritime electrification demands. Leading players like LG Energy Solution, Samsung SDI, and Panasonic Energy are driving technological advancement with mature lithium-ion solutions, while emerging competitors such as Huawei Digital Power and China Shipbuilding Power Engineering Institute are developing specialized marine applications. Traditional energy companies like Halliburton and GE Energy Power Conversion are leveraging their offshore expertise to enter this space. Academic institutions including Northwestern Polytechnical University and Harbin Engineering University are contributing significant research to address unique challenges of marine environments, particularly in thermal management and saltwater resistance.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed specialized marine battery systems featuring prismatic lithium-ion cells with advanced thermal management systems specifically designed for offshore applications. Their marine battery packs incorporate multi-layer safety mechanisms including cell-to-pack (CTP) technology that eliminates module housing, increasing energy density by up to 20%. The company's battery management system (BMS) employs predictive analytics to monitor cell health in harsh marine environments, with IP68-rated enclosures ensuring protection against saltwater intrusion. Their offshore battery solutions include active cooling systems that maintain optimal operating temperatures between 15-35°C even during peak load conditions, extending battery life by up to 40% compared to conventional designs. LG's marine battery packs also feature redundant power distribution architecture and isolation systems that prevent cascading failures in offshore installations.

Strengths: Superior energy density through CTP technology; advanced thermal management optimized for marine conditions; comprehensive safety systems with maritime certifications. Weaknesses: Higher initial cost compared to conventional solutions; requires specialized installation expertise; thermal management systems add complexity to maintenance procedures.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has engineered robust battery pack designs specifically for offshore energy applications, featuring their proprietary cylindrical cell technology with enhanced structural integrity against vibration and shock. Their marine battery systems incorporate specialized electrolyte formulations that maintain performance stability in fluctuating temperature environments typical of offshore operations. The company's battery packs employ a modular architecture that allows for hot-swapping capabilities in marine installations, minimizing downtime during maintenance. Panasonic's offshore battery solutions include advanced thermal propagation prevention with physical cell separation barriers and phase-change materials that absorb excess heat during extreme conditions. Their battery management system incorporates maritime-specific algorithms that account for wave motion patterns when balancing cells and predicting state-of-health, extending operational life by up to 30% in offshore deployments compared to land-based applications.

Strengths: Exceptional vibration and shock resistance ideal for rough sea conditions; proven reliability in extreme maritime environments; modular design facilitating maintenance in remote locations. Weaknesses: Lower energy density compared to some prismatic cell competitors; more complex cooling requirements for cylindrical cells; higher weight-to-energy ratio affecting installation flexibility.

Key Innovations in Marine-Grade Battery Systems

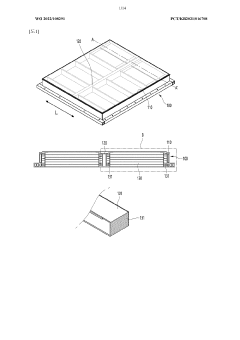

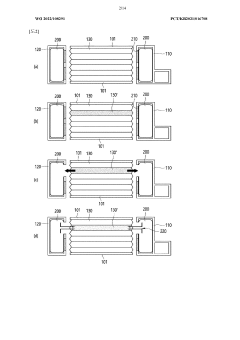

Battery pack including structure for suppressing thermal diffusion

PatentWO2022108291A1

Innovation

- A battery pack design that incorporates a water tank and a sealing member with a low melting point, allowing coolant to be injected through a through hole to quickly cool ignited battery cells, thereby preventing thermal runaway and reducing the risk of flame spread, while minimizing weight and cost.

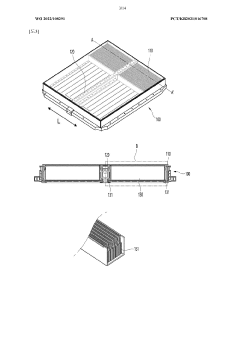

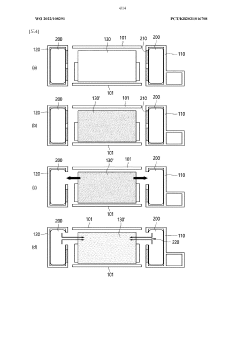

Battery pack design for integrating and monitoring multiple single battery cells

PatentInactiveUS20140329124A1

Innovation

- A battery packaging apparatus with integrated spring contacts and a planar conduction medium that uses flexible PCBs with traces and compression fasteners to ensure consistent electrical and thermal coupling between cells, eliminating the need for additional wires and reducing manufacturing costs.

Environmental Impact and Sustainability Considerations

Battery pack design for offshore energy solutions carries significant environmental implications that must be carefully considered throughout the entire lifecycle. The harsh marine environment presents unique challenges for sustainable battery implementation, requiring specialized materials and designs that can withstand saltwater exposure while minimizing ecological impact. Current offshore battery systems often utilize lithium-ion technology, which raises concerns regarding resource extraction, particularly for materials like lithium, cobalt, and nickel that have documented environmental and social impacts in mining regions.

The manufacturing process of marine-grade battery packs consumes substantial energy and resources, contributing to the carbon footprint before deployment. However, when properly designed, these battery systems can enable greater integration of renewable energy sources in offshore operations, potentially offsetting their production emissions through operational benefits. Advanced battery management systems that optimize charging cycles and extend battery lifespan are crucial for maximizing this positive environmental impact ratio.

End-of-life considerations represent another critical environmental dimension. The marine environment accelerates certain degradation processes, potentially shortening operational lifespans compared to land-based applications. Developing effective recycling pathways specifically for offshore battery components remains challenging due to their specialized construction and exposure to corrosive elements. Current recycling rates for marine battery materials lag behind those of conventional applications, creating an opportunity for innovation in circular economy approaches.

Water quality protection must be prioritized in battery pack design, with robust containment systems preventing electrolyte leakage even under extreme conditions. Recent advancements in bio-based electrolytes and environmentally benign battery chemistries show promise for reducing potential marine contamination risks, though these technologies require further development for offshore durability requirements.

Carbon footprint analysis reveals that offshore battery installations can achieve carbon payback periods of 1-3 years depending on application and renewable integration levels. This favorable sustainability profile is driving increased adoption in offshore wind platforms and remote marine operations. However, comprehensive lifecycle assessments must account for the energy-intensive maintenance operations often required in offshore environments.

Regulatory frameworks governing environmental aspects of offshore battery installations continue to evolve, with international maritime organizations establishing increasingly stringent standards for emissions, material selection, and decommissioning protocols. Forward-thinking battery pack designs must anticipate these regulatory trends while balancing performance requirements with environmental responsibility.

The manufacturing process of marine-grade battery packs consumes substantial energy and resources, contributing to the carbon footprint before deployment. However, when properly designed, these battery systems can enable greater integration of renewable energy sources in offshore operations, potentially offsetting their production emissions through operational benefits. Advanced battery management systems that optimize charging cycles and extend battery lifespan are crucial for maximizing this positive environmental impact ratio.

End-of-life considerations represent another critical environmental dimension. The marine environment accelerates certain degradation processes, potentially shortening operational lifespans compared to land-based applications. Developing effective recycling pathways specifically for offshore battery components remains challenging due to their specialized construction and exposure to corrosive elements. Current recycling rates for marine battery materials lag behind those of conventional applications, creating an opportunity for innovation in circular economy approaches.

Water quality protection must be prioritized in battery pack design, with robust containment systems preventing electrolyte leakage even under extreme conditions. Recent advancements in bio-based electrolytes and environmentally benign battery chemistries show promise for reducing potential marine contamination risks, though these technologies require further development for offshore durability requirements.

Carbon footprint analysis reveals that offshore battery installations can achieve carbon payback periods of 1-3 years depending on application and renewable integration levels. This favorable sustainability profile is driving increased adoption in offshore wind platforms and remote marine operations. However, comprehensive lifecycle assessments must account for the energy-intensive maintenance operations often required in offshore environments.

Regulatory frameworks governing environmental aspects of offshore battery installations continue to evolve, with international maritime organizations establishing increasingly stringent standards for emissions, material selection, and decommissioning protocols. Forward-thinking battery pack designs must anticipate these regulatory trends while balancing performance requirements with environmental responsibility.

Regulatory Compliance for Maritime Battery Installations

Maritime battery installations are subject to stringent regulatory frameworks designed to ensure safety, reliability, and environmental protection in the challenging offshore environment. The International Maritime Organization (IMO) serves as the primary global regulatory body, establishing the Safety of Life at Sea (SOLAS) convention which includes specific provisions for electrical installations aboard vessels. These regulations have been progressively updated to address the unique challenges posed by large-scale battery systems deployed in marine environments.

Classification societies such as DNV GL, Lloyd's Register, and the American Bureau of Shipping have developed comprehensive standards specifically addressing maritime battery installations. DNV GL's class notation "Battery Power" and its corresponding rules provide detailed technical requirements for the design, installation, and operation of battery systems on vessels. These requirements cover thermal management, fire safety systems, ventilation, and battery management systems that are critical for offshore applications.

The International Electrotechnical Commission (IEC) has established the IEC 62619 and IEC 62281 standards, which specify safety requirements for lithium-ion batteries in marine applications. These standards address cell design, testing protocols, and safety mechanisms that battery manufacturers must adhere to when developing systems for offshore energy solutions.

National maritime authorities impose additional regulatory requirements that vary by jurisdiction. The United States Coast Guard (USCG) and the European Maritime Safety Agency (EMSA) have established region-specific regulations that battery pack designers must navigate when developing offshore energy solutions. These often include requirements for redundancy systems, emergency power capabilities, and specific certification processes.

Compliance with hazardous area classifications is particularly relevant for offshore installations. The IEC 60079 series of standards defines requirements for equipment used in explosive atmospheres, which may apply to battery installations on certain types of offshore vessels and platforms. Battery enclosures may need to meet specific ingress protection (IP) ratings and explosion-proof certifications depending on their installation location.

Environmental regulations also significantly impact battery pack design for offshore applications. The International Convention for the Prevention of Pollution from Ships (MARPOL) includes provisions that influence battery system design, particularly regarding potential leakage containment and end-of-life disposal considerations. The European Union's Ship Recycling Regulation and Battery Directive further impose requirements on battery composition and recyclability.

Emerging regulations around greenhouse gas emissions, such as the IMO's strategy to reduce carbon intensity of international shipping, are driving increased adoption of battery systems while simultaneously shaping their design requirements. Battery pack designers must demonstrate compliance with these evolving regulatory frameworks through extensive documentation, third-party verification, and ongoing certification maintenance.

Classification societies such as DNV GL, Lloyd's Register, and the American Bureau of Shipping have developed comprehensive standards specifically addressing maritime battery installations. DNV GL's class notation "Battery Power" and its corresponding rules provide detailed technical requirements for the design, installation, and operation of battery systems on vessels. These requirements cover thermal management, fire safety systems, ventilation, and battery management systems that are critical for offshore applications.

The International Electrotechnical Commission (IEC) has established the IEC 62619 and IEC 62281 standards, which specify safety requirements for lithium-ion batteries in marine applications. These standards address cell design, testing protocols, and safety mechanisms that battery manufacturers must adhere to when developing systems for offshore energy solutions.

National maritime authorities impose additional regulatory requirements that vary by jurisdiction. The United States Coast Guard (USCG) and the European Maritime Safety Agency (EMSA) have established region-specific regulations that battery pack designers must navigate when developing offshore energy solutions. These often include requirements for redundancy systems, emergency power capabilities, and specific certification processes.

Compliance with hazardous area classifications is particularly relevant for offshore installations. The IEC 60079 series of standards defines requirements for equipment used in explosive atmospheres, which may apply to battery installations on certain types of offshore vessels and platforms. Battery enclosures may need to meet specific ingress protection (IP) ratings and explosion-proof certifications depending on their installation location.

Environmental regulations also significantly impact battery pack design for offshore applications. The International Convention for the Prevention of Pollution from Ships (MARPOL) includes provisions that influence battery system design, particularly regarding potential leakage containment and end-of-life disposal considerations. The European Union's Ship Recycling Regulation and Battery Directive further impose requirements on battery composition and recyclability.

Emerging regulations around greenhouse gas emissions, such as the IMO's strategy to reduce carbon intensity of international shipping, are driving increased adoption of battery systems while simultaneously shaping their design requirements. Battery pack designers must demonstrate compliance with these evolving regulatory frameworks through extensive documentation, third-party verification, and ongoing certification maintenance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!