How Structural Innovations in Cathodes Affect Battery Pack Design

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cathode Structural Innovation Background and Objectives

Cathode structural innovation has evolved significantly over the past three decades, transitioning from simple layered structures to complex engineered materials that fundamentally alter battery performance characteristics. The journey began with lithium cobalt oxide (LiCoO₂) cathodes in the early 1990s, which provided the foundation for modern lithium-ion batteries but suffered from structural instability during deep cycling and thermal events. This limitation drove research toward more stable structures, including spinel (LiMn₂O₄) and olivine (LiFePO₄) configurations that offered improved safety at the expense of energy density.

The technical evolution accelerated in the 2010s with the development of nickel-rich layered oxides (NMC/NCA) that balanced energy density with reasonable stability. These materials represented a critical advancement but still faced challenges with structural degradation during extended cycling. Recent innovations have focused on concentration gradients, core-shell structures, and dopant engineering to mitigate these issues while maintaining high energy density.

Current research objectives center on developing cathode structures that can simultaneously address multiple performance parameters that directly impact battery pack design. Primary goals include achieving volumetric energy densities exceeding 800 Wh/L at the cell level while maintaining structural integrity beyond 1,000 cycles, enabling fast charging capabilities without compromising safety, and reducing reliance on critical materials like cobalt.

The technical trajectory is now moving toward single-crystal cathodes that minimize particle cracking during cycling, disordered rock-salt structures that offer higher lithium mobility, and lithium-rich materials that can store more energy through both cationic and anionic redox processes. These structural innovations directly influence battery pack design by altering thermal management requirements, cell-to-cell balancing strategies, and overall pack architecture.

A significant objective is developing cathode structures that enable "cell-to-pack" integration, where structural improvements at the material level translate to simplified pack designs with fewer components and higher energy density. This includes cathodes with inherent thermal stability that reduce cooling system requirements and materials with higher voltage stability that simplify battery management systems.

The field is also exploring how advanced manufacturing techniques like 3D printing and precise particle engineering can create cathode structures with tailored porosity and ion transport channels, potentially enabling new form factors at the pack level that were previously impossible with conventional cathode materials.

The technical evolution accelerated in the 2010s with the development of nickel-rich layered oxides (NMC/NCA) that balanced energy density with reasonable stability. These materials represented a critical advancement but still faced challenges with structural degradation during extended cycling. Recent innovations have focused on concentration gradients, core-shell structures, and dopant engineering to mitigate these issues while maintaining high energy density.

Current research objectives center on developing cathode structures that can simultaneously address multiple performance parameters that directly impact battery pack design. Primary goals include achieving volumetric energy densities exceeding 800 Wh/L at the cell level while maintaining structural integrity beyond 1,000 cycles, enabling fast charging capabilities without compromising safety, and reducing reliance on critical materials like cobalt.

The technical trajectory is now moving toward single-crystal cathodes that minimize particle cracking during cycling, disordered rock-salt structures that offer higher lithium mobility, and lithium-rich materials that can store more energy through both cationic and anionic redox processes. These structural innovations directly influence battery pack design by altering thermal management requirements, cell-to-cell balancing strategies, and overall pack architecture.

A significant objective is developing cathode structures that enable "cell-to-pack" integration, where structural improvements at the material level translate to simplified pack designs with fewer components and higher energy density. This includes cathodes with inherent thermal stability that reduce cooling system requirements and materials with higher voltage stability that simplify battery management systems.

The field is also exploring how advanced manufacturing techniques like 3D printing and precise particle engineering can create cathode structures with tailored porosity and ion transport channels, potentially enabling new form factors at the pack level that were previously impossible with conventional cathode materials.

Market Analysis for Advanced Battery Technologies

The global advanced battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and renewable energy storage systems. Current market valuations place the advanced battery sector at approximately $92 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 18.7% through 2030, potentially reaching $279 billion by decade's end. This remarkable trajectory is fundamentally linked to structural innovations in cathode materials, which directly influence battery pack design and performance metrics.

Consumer demand patterns reveal increasing expectations for EV batteries that deliver longer ranges, faster charging capabilities, and enhanced safety profiles. Market research indicates that consumers now consider 300+ miles of range as a baseline expectation for new EV models, representing a significant shift from just five years ago when 200 miles was considered adequate. This evolving demand landscape has intensified competition among battery manufacturers to develop cathode structures that maximize energy density while maintaining thermal stability.

Regional market analysis shows Asia-Pacific continuing its dominance in advanced battery production, controlling approximately 75% of global manufacturing capacity. However, significant investments in North America and Europe are rapidly changing this landscape, with both regions expected to double their market share by 2028. These investments are specifically targeting next-generation cathode technologies, including high-nickel NMC formulations and novel silicon-composite structures.

The commercial battery segment demonstrates clear price sensitivity to cathode innovations. Historical data shows that advancements in cathode structure have contributed to approximately 38% of the overall cost reduction in lithium-ion batteries over the past decade. Market forecasts suggest that emerging single-crystal and gradient cathode technologies could drive costs below $80/kWh by 2025, finally achieving price parity with internal combustion vehicles without subsidies.

Industry adoption patterns indicate that automotive OEMs are increasingly developing proprietary battery pack designs optimized around specific cathode chemistries. This vertical integration trend is reshaping traditional supply chain relationships, with an estimated 62% of major automotive manufacturers now maintaining in-house battery engineering capabilities focused on cathode-specific pack optimization.

The regulatory landscape further influences market dynamics, with several jurisdictions implementing carbon intensity metrics that indirectly favor certain cathode structures. The EU Battery Directive and similar frameworks in California are creating market premiums for low-carbon cathode production methods, influencing investment flows toward more sustainable manufacturing processes for advanced cathode materials.

Consumer demand patterns reveal increasing expectations for EV batteries that deliver longer ranges, faster charging capabilities, and enhanced safety profiles. Market research indicates that consumers now consider 300+ miles of range as a baseline expectation for new EV models, representing a significant shift from just five years ago when 200 miles was considered adequate. This evolving demand landscape has intensified competition among battery manufacturers to develop cathode structures that maximize energy density while maintaining thermal stability.

Regional market analysis shows Asia-Pacific continuing its dominance in advanced battery production, controlling approximately 75% of global manufacturing capacity. However, significant investments in North America and Europe are rapidly changing this landscape, with both regions expected to double their market share by 2028. These investments are specifically targeting next-generation cathode technologies, including high-nickel NMC formulations and novel silicon-composite structures.

The commercial battery segment demonstrates clear price sensitivity to cathode innovations. Historical data shows that advancements in cathode structure have contributed to approximately 38% of the overall cost reduction in lithium-ion batteries over the past decade. Market forecasts suggest that emerging single-crystal and gradient cathode technologies could drive costs below $80/kWh by 2025, finally achieving price parity with internal combustion vehicles without subsidies.

Industry adoption patterns indicate that automotive OEMs are increasingly developing proprietary battery pack designs optimized around specific cathode chemistries. This vertical integration trend is reshaping traditional supply chain relationships, with an estimated 62% of major automotive manufacturers now maintaining in-house battery engineering capabilities focused on cathode-specific pack optimization.

The regulatory landscape further influences market dynamics, with several jurisdictions implementing carbon intensity metrics that indirectly favor certain cathode structures. The EU Battery Directive and similar frameworks in California are creating market premiums for low-carbon cathode production methods, influencing investment flows toward more sustainable manufacturing processes for advanced cathode materials.

Current Cathode Technology Landscape and Challenges

The current cathode technology landscape is dominated by several key chemistries, each with distinct performance characteristics. Lithium-ion batteries utilizing lithium cobalt oxide (LCO) cathodes remain prevalent in consumer electronics due to their high energy density, while lithium nickel manganese cobalt oxide (NMC) and lithium nickel cobalt aluminum oxide (NCA) have gained significant traction in electric vehicle applications. Lithium iron phosphate (LFP) cathodes have resurged in popularity due to their enhanced safety profile and reduced dependency on critical raw materials, despite lower energy density.

A major challenge facing cathode development is the inherent trade-off between energy density, power capability, cycle life, and safety. High-nickel content cathodes (NMC811, NCA) offer superior energy density but suffer from accelerated degradation and thermal stability concerns. This necessitates more complex battery management systems and thermal control mechanisms at the pack level, directly influencing overall design complexity and cost.

Material supply chain constraints represent another significant challenge, particularly regarding cobalt and nickel. Price volatility and ethical sourcing concerns for these materials have accelerated research into alternative cathode chemistries. This shift has profound implications for battery pack design, as emerging cathodes often present different voltage profiles, thermal characteristics, and mechanical properties.

Structural stability during cycling remains a critical technical hurdle. Volume expansion and contraction during lithiation/delithiation processes lead to mechanical stress that can propagate from the cathode particle level to cell and pack structural integrity. Advanced cathode designs incorporating concentration gradients, core-shell structures, and dopants aim to mitigate these issues but introduce manufacturing complexity that must be balanced against performance gains.

The geographical distribution of cathode technology development shows concentration in East Asia, particularly Japan, South Korea, and China, which collectively control approximately 85% of cathode manufacturing capacity. European and North American entities are rapidly investing to reduce this dependency, creating a more diversified but potentially fragmented technology landscape.

Recent innovations in single-crystal cathodes and disordered rock-salt structures represent promising directions for addressing current limitations. These novel structures demonstrate improved structural stability during cycling but require reconsideration of pack-level thermal management due to different heat generation profiles. Additionally, solid-state battery initiatives are driving development of cathode materials compatible with solid electrolytes, potentially enabling simplified pack designs with reduced cooling requirements and safety systems.

A major challenge facing cathode development is the inherent trade-off between energy density, power capability, cycle life, and safety. High-nickel content cathodes (NMC811, NCA) offer superior energy density but suffer from accelerated degradation and thermal stability concerns. This necessitates more complex battery management systems and thermal control mechanisms at the pack level, directly influencing overall design complexity and cost.

Material supply chain constraints represent another significant challenge, particularly regarding cobalt and nickel. Price volatility and ethical sourcing concerns for these materials have accelerated research into alternative cathode chemistries. This shift has profound implications for battery pack design, as emerging cathodes often present different voltage profiles, thermal characteristics, and mechanical properties.

Structural stability during cycling remains a critical technical hurdle. Volume expansion and contraction during lithiation/delithiation processes lead to mechanical stress that can propagate from the cathode particle level to cell and pack structural integrity. Advanced cathode designs incorporating concentration gradients, core-shell structures, and dopants aim to mitigate these issues but introduce manufacturing complexity that must be balanced against performance gains.

The geographical distribution of cathode technology development shows concentration in East Asia, particularly Japan, South Korea, and China, which collectively control approximately 85% of cathode manufacturing capacity. European and North American entities are rapidly investing to reduce this dependency, creating a more diversified but potentially fragmented technology landscape.

Recent innovations in single-crystal cathodes and disordered rock-salt structures represent promising directions for addressing current limitations. These novel structures demonstrate improved structural stability during cycling but require reconsideration of pack-level thermal management due to different heat generation profiles. Additionally, solid-state battery initiatives are driving development of cathode materials compatible with solid electrolytes, potentially enabling simplified pack designs with reduced cooling requirements and safety systems.

Contemporary Battery Pack Design Solutions

01 Nanostructured cathode materials

Nanostructured cathode materials offer improved electrochemical performance through enhanced surface area and shortened ion diffusion paths. These structures include nanoparticles, nanowires, and nanotubes that can be engineered to optimize lithium-ion storage capacity and cycling stability. The nanoscale architecture allows for better accommodation of volume changes during charge/discharge cycles and facilitates faster ion transport, resulting in batteries with higher energy density and power output.- Nanostructured cathode materials: Nanostructured cathode materials offer enhanced electrochemical performance due to their high surface area and shortened ion diffusion paths. These structures include nanoparticles, nanowires, and nanotubes that can improve battery capacity, cycling stability, and rate capability. The nanoscale architecture allows for better accommodation of volume changes during charging/discharging cycles and facilitates faster lithium-ion transport, resulting in improved battery performance.

- Hierarchical porous cathode structures: Hierarchical porous structures in cathode materials combine macro, meso, and micropores to optimize ion transport and electrode kinetics. These multi-level porous architectures provide efficient pathways for electrolyte penetration while maintaining structural integrity. The interconnected pore network enhances lithium-ion accessibility to active sites, reduces diffusion limitations, and accommodates volume changes during cycling, leading to improved capacity retention and rate performance in batteries.

- Core-shell and gradient cathode structures: Core-shell and concentration gradient structures in cathode materials provide a protective outer layer while maintaining a high-capacity core. This design approach mitigates surface-related degradation mechanisms while preserving the electrochemical performance of the interior material. The shell or gradient layer can be engineered to enhance structural stability, prevent unwanted side reactions with the electrolyte, and improve the overall cycling stability and safety of lithium-ion batteries.

- 3D structured cathode architectures: Three-dimensional cathode architectures offer enhanced electronic conductivity and mechanical stability compared to traditional planar designs. These structures include 3D current collectors, vertically aligned arrays, and interconnected networks that provide direct pathways for electron transport while accommodating volume changes during cycling. The increased surface area and optimized ion/electron transport pathways in 3D structures lead to improved energy density, power capability, and cycling performance in batteries.

- Composite and doped cathode materials: Composite and doped cathode materials combine different components to achieve synergistic effects and enhanced properties. These materials often incorporate conductive additives, protective coatings, or dopant elements to improve electronic conductivity, structural stability, and electrochemical performance. Strategic doping and formation of composites can mitigate common degradation mechanisms, enhance rate capability, and extend the cycle life of battery cathodes while maintaining high energy density.

02 Hierarchical porous cathode structures

Hierarchical porous structures in battery cathodes incorporate multi-level porosity (macro, meso, and micro pores) to enhance electrolyte penetration and ion transport. These architectures provide both high surface area for electrochemical reactions and efficient pathways for ion movement. The controlled porosity helps mitigate volume expansion during cycling while maintaining structural integrity, leading to improved capacity retention and cycle life of the battery.Expand Specific Solutions03 Core-shell and gradient cathode designs

Core-shell and concentration gradient structures for battery cathodes feature compositionally different regions within individual particles. The core typically provides high capacity while the shell or gradient layer enhances stability and protects against electrolyte degradation. This design approach minimizes surface reactivity with the electrolyte while maintaining high energy density from the core material. Such structures effectively address the trade-off between capacity and cycling stability in high-energy cathode materials.Expand Specific Solutions04 Single-crystal cathode architectures

Single-crystal cathode materials eliminate grain boundaries present in polycrystalline structures, reducing impedance and enhancing structural stability during cycling. These architectures minimize internal defects that can lead to crack formation and particle degradation during repeated charge-discharge cycles. The oriented crystal structure facilitates more efficient ion transport pathways and reduces side reactions with the electrolyte, resulting in improved capacity retention and longer battery lifespan.Expand Specific Solutions05 Composite and doped cathode structures

Composite and doped cathode structures incorporate secondary materials or dopant elements to enhance the properties of the primary active material. These designs can include carbon coatings, metal oxide additives, or elemental dopants that improve electronic conductivity, structural stability, and thermal properties. The strategic integration of these components creates synergistic effects that address multiple performance limitations simultaneously, resulting in cathodes with enhanced rate capability, cycling stability, and safety characteristics.Expand Specific Solutions

Leading Battery Manufacturers and Research Institutions

The structural innovations in cathode technology are reshaping battery pack design within a rapidly evolving market. Currently in the growth phase, the global advanced battery market is expanding significantly, driven by electric vehicle adoption and renewable energy integration. Key players like LG Energy Solution, Samsung SDI, and CATL (Ningde Amperex Technology) are leading technological advancements, focusing on high-energy density cathode materials and structural optimizations. Western companies including Apple and Automotive Cells Company are investing heavily in proprietary cathode designs, while research institutions like Carnegie Mellon University and Zhejiang University are pioneering next-generation cathode architectures. The competitive landscape shows Asian manufacturers maintaining production dominance while North American and European entities focus on innovation to reduce dependency on established supply chains.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered structural innovations in cathode materials through their "NCMA" (Nickel, Cobalt, Manganese, Aluminum) technology, which incorporates aluminum into traditional NCM cathodes to enhance structural stability. Their battery pack designs leverage these advanced cathodes with silicon-carbon composite anodes to achieve energy densities exceeding 700 Wh/L. The company has developed a proprietary "stacking and folding" electrode assembly method that optimizes the spatial arrangement of cathode materials within cells, allowing for more efficient heat dissipation and improved energy density. Their battery pack architecture incorporates direct cell-to-pack technology, eliminating module housings and reducing weight by approximately 10-15%. LG Energy Solution has also implemented advanced thermal management systems specifically designed to address the unique thermal characteristics of their high-nickel cathode materials, using phase-change materials integrated directly into the battery pack structure.

Strengths: Superior energy density (700+ Wh/L) with excellent thermal stability; reduced cobalt content lowers costs and supply chain risks; direct cell-to-pack design increases volumetric efficiency. Weaknesses: High-nickel cathodes still face calendar aging challenges; manufacturing complexity of NCMA cathodes requires sophisticated quality control; thermal management systems add weight and complexity to overall pack design.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed "PRiMX" cathode technology featuring a unique multi-concentration gradient (MCG) structure that creates a protective shell around each cathode particle. This innovation allows for higher nickel content (over 90%) in the core while maintaining structural stability through a manganese-rich outer layer. Their battery pack designs incorporate these advanced cathodes in a modular architecture with "Z-stacking" technology that optimizes the spatial arrangement of cells. Samsung's Gen5 battery system integrates these cathode innovations with silicon-composite anodes to achieve energy densities approaching 800 Wh/L at the cell level. The company has pioneered a dual-cooling plate design specifically engineered to address the thermal characteristics of their high-nickel cathodes, with cooling elements positioned both below and above cell layers. This approach has demonstrated temperature gradient reductions of up to 40% compared to conventional single-plate cooling systems, directly addressing one of the key limitations of advanced cathode materials.

Strengths: Exceptional energy density with superior thermal management; gradient cathode structure provides excellent cycle life (2000+ cycles to 80% capacity); modular design allows for flexible pack configurations. Weaknesses: Complex manufacturing process for gradient cathodes increases production costs; higher nickel content creates potential supply chain vulnerabilities; cooling system adds weight and complexity to overall pack design.

Key Patents in Cathode Structural Engineering

Durable and high-performance lithium ion batteries with nanostructured cathode materials

PatentPendingIN202341068059A

Innovation

- The development of nanostructured cathode materials leveraging unique properties at the nanoscale, such as increased surface area and quantum effects, is achieved through innovative synthesis methods like sol-gel processes, 3D architectures, carbon coatings, block copolymer self-assembly, hybrid composites, and surface modifying agents, ensuring enhanced performance and stability.

Cathode and method for producing same

PatentWO2023041122A1

Innovation

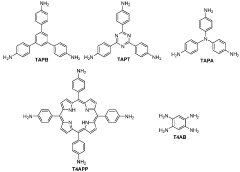

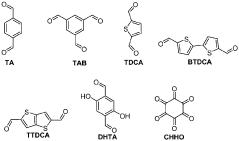

- A cathode comprising a polymer structure formed from alternating imine-linked monomers with aromatic or heteroaromatic cores and bridges, combined with lithium sulfide or sulfur particles and carbon additives, which are processed to create a stable and durable cathode material through a method involving overcoating, reaction, drying, and optional heat treatment.

Thermal Management Implications of Novel Cathode Structures

The thermal management of battery packs represents a critical engineering challenge that directly impacts performance, safety, and longevity. Novel cathode structures are fundamentally altering the thermal landscape within lithium-ion batteries, necessitating innovative approaches to heat dissipation and temperature control at the pack level.

High-energy density cathode materials, such as nickel-rich NMC (Nickel Manganese Cobalt) and NCA (Nickel Cobalt Aluminum), generate significantly different thermal profiles compared to traditional LFP (Lithium Iron Phosphate) cathodes. These advanced structures can produce more localized heat during charging and discharging cycles, particularly at high C-rates, creating thermal hotspots that conventional cooling systems may struggle to address effectively.

Structural innovations like single-crystal cathodes demonstrate improved thermal stability over polycrystalline alternatives, reducing the risk of thermal runaway events. However, their higher energy density concentrates heat generation, requiring more sophisticated thermal management solutions. Similarly, concentration-gradient cathodes, with their variable composition from core to surface, exhibit complex thermal behaviors that demand precise temperature monitoring and control mechanisms.

The integration of silicon-doped and dopant-modified cathodes further complicates thermal management requirements. These materials often feature enhanced conductivity profiles but may generate heat more rapidly during high-power operations. Consequently, battery pack designs must incorporate targeted cooling strategies that address these specific thermal characteristics rather than relying on uniform cooling approaches.

Advanced cooling architectures are emerging in response to these challenges, including direct liquid cooling systems that make contact with individual cells rather than merely cooling the pack exterior. Immersion cooling technologies, where cells are submerged in dielectric fluids, show particular promise for managing the thermal implications of high-energy cathode structures by providing uniform temperature distribution across the entire cell surface.

Phase-change materials (PCMs) integrated into battery packs offer another solution pathway, absorbing excess heat during intensive operation and releasing it during idle periods. This passive approach can complement active cooling systems and is particularly valuable for managing the thermal spikes associated with rapid charging of batteries utilizing advanced cathode structures.

The thermal management system must also adapt to the changing thermal conductivity properties of novel cathode materials throughout their lifecycle. As cathode structures evolve during repeated charge-discharge cycles, their thermal characteristics shift, requiring intelligent thermal management systems capable of adjusting cooling parameters based on battery age and condition.

High-energy density cathode materials, such as nickel-rich NMC (Nickel Manganese Cobalt) and NCA (Nickel Cobalt Aluminum), generate significantly different thermal profiles compared to traditional LFP (Lithium Iron Phosphate) cathodes. These advanced structures can produce more localized heat during charging and discharging cycles, particularly at high C-rates, creating thermal hotspots that conventional cooling systems may struggle to address effectively.

Structural innovations like single-crystal cathodes demonstrate improved thermal stability over polycrystalline alternatives, reducing the risk of thermal runaway events. However, their higher energy density concentrates heat generation, requiring more sophisticated thermal management solutions. Similarly, concentration-gradient cathodes, with their variable composition from core to surface, exhibit complex thermal behaviors that demand precise temperature monitoring and control mechanisms.

The integration of silicon-doped and dopant-modified cathodes further complicates thermal management requirements. These materials often feature enhanced conductivity profiles but may generate heat more rapidly during high-power operations. Consequently, battery pack designs must incorporate targeted cooling strategies that address these specific thermal characteristics rather than relying on uniform cooling approaches.

Advanced cooling architectures are emerging in response to these challenges, including direct liquid cooling systems that make contact with individual cells rather than merely cooling the pack exterior. Immersion cooling technologies, where cells are submerged in dielectric fluids, show particular promise for managing the thermal implications of high-energy cathode structures by providing uniform temperature distribution across the entire cell surface.

Phase-change materials (PCMs) integrated into battery packs offer another solution pathway, absorbing excess heat during intensive operation and releasing it during idle periods. This passive approach can complement active cooling systems and is particularly valuable for managing the thermal spikes associated with rapid charging of batteries utilizing advanced cathode structures.

The thermal management system must also adapt to the changing thermal conductivity properties of novel cathode materials throughout their lifecycle. As cathode structures evolve during repeated charge-discharge cycles, their thermal characteristics shift, requiring intelligent thermal management systems capable of adjusting cooling parameters based on battery age and condition.

Sustainability and Recycling Considerations for Advanced Cathodes

The sustainability implications of advanced cathode materials have become increasingly critical as battery technology evolves to meet growing energy storage demands. Structural innovations in cathodes directly impact the environmental footprint of battery systems throughout their lifecycle. The shift toward nickel-rich NMC and NCA cathodes, while beneficial for energy density, presents significant sustainability challenges due to the use of critical raw materials including cobalt, nickel, and lithium.

Recycling considerations must be integrated into cathode design from the earliest development stages. Current cathode structures, particularly those with complex layered compositions, often complicate end-of-life processing. The physical binding of active materials with polymers and the intricate integration of cathodes within cell structures create barriers to efficient material recovery. Advanced cathodes utilizing novel dopants or coatings may further complicate separation processes.

Material recovery efficiency varies significantly across cathode chemistries. While LFP cathodes contain fewer critical materials, their lower economic value has historically reduced recycling incentives. Conversely, cobalt-rich cathodes present higher recovery value but require more sophisticated recycling technologies. Emerging direct recycling methods that preserve cathode crystal structures show promise for reducing energy consumption in the recycling process, but remain technically challenging for mixed waste streams.

Design for disassembly represents a crucial frontier in sustainable cathode development. Structural innovations that facilitate easier separation of cathode materials from current collectors and other cell components could dramatically improve recycling economics. Some manufacturers have begun exploring water-soluble binders and mechanical fastening systems that eliminate the need for energy-intensive thermal or chemical separation processes.

The carbon footprint of cathode production remains substantial, with high-temperature calcination processes contributing significantly to manufacturing emissions. Structural innovations that enable lower-temperature synthesis or aqueous processing could substantially reduce embodied energy. Additionally, cathode designs that extend cycle life through improved structural stability during charge-discharge cycles effectively amortize manufacturing impacts over longer service periods.

Closed-loop systems for cathode materials represent the ultimate sustainability goal. Several battery manufacturers have established partnerships with recycling firms to develop processes specifically tailored to their cathode formulations. These collaborations are increasingly influencing structural design decisions, with some companies standardizing cathode compositions to optimize both performance and recyclability.

Recycling considerations must be integrated into cathode design from the earliest development stages. Current cathode structures, particularly those with complex layered compositions, often complicate end-of-life processing. The physical binding of active materials with polymers and the intricate integration of cathodes within cell structures create barriers to efficient material recovery. Advanced cathodes utilizing novel dopants or coatings may further complicate separation processes.

Material recovery efficiency varies significantly across cathode chemistries. While LFP cathodes contain fewer critical materials, their lower economic value has historically reduced recycling incentives. Conversely, cobalt-rich cathodes present higher recovery value but require more sophisticated recycling technologies. Emerging direct recycling methods that preserve cathode crystal structures show promise for reducing energy consumption in the recycling process, but remain technically challenging for mixed waste streams.

Design for disassembly represents a crucial frontier in sustainable cathode development. Structural innovations that facilitate easier separation of cathode materials from current collectors and other cell components could dramatically improve recycling economics. Some manufacturers have begun exploring water-soluble binders and mechanical fastening systems that eliminate the need for energy-intensive thermal or chemical separation processes.

The carbon footprint of cathode production remains substantial, with high-temperature calcination processes contributing significantly to manufacturing emissions. Structural innovations that enable lower-temperature synthesis or aqueous processing could substantially reduce embodied energy. Additionally, cathode designs that extend cycle life through improved structural stability during charge-discharge cycles effectively amortize manufacturing impacts over longer service periods.

Closed-loop systems for cathode materials represent the ultimate sustainability goal. Several battery manufacturers have established partnerships with recycling firms to develop processes specifically tailored to their cathode formulations. These collaborations are increasingly influencing structural design decisions, with some companies standardizing cathode compositions to optimize both performance and recyclability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!