Battery Pack Design Solutions for Urban Mobility Challenges

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Urban Mobility Battery Evolution and Objectives

The evolution of urban mobility has undergone significant transformation over the past decade, driven by increasing urbanization, environmental concerns, and technological advancements. Battery technology has emerged as a critical enabler for sustainable urban transportation solutions, transitioning from traditional lead-acid batteries to advanced lithium-ion chemistries and beyond. This evolution reflects the growing demand for cleaner, more efficient transportation options in densely populated urban centers.

The historical trajectory of battery development for urban mobility applications reveals a consistent push toward higher energy density, improved safety, and extended cycle life. Early electric mobility solutions were hampered by limited range and long charging times, making them impractical for widespread adoption. However, breakthroughs in battery chemistry and management systems have progressively addressed these limitations, enabling the current generation of electric scooters, bikes, and compact vehicles that are transforming urban transportation landscapes.

Current urban mobility challenges present unique requirements for battery pack design. Unlike conventional automotive applications, urban mobility solutions demand batteries that balance compact form factors with sufficient energy capacity, while maintaining stringent safety standards for operation in densely populated environments. Weight optimization becomes particularly crucial, as it directly impacts vehicle efficiency and user experience, especially for micromobility applications.

The technical objectives for next-generation urban mobility battery packs center around several key parameters: volumetric and gravimetric energy density improvements of 30-50% over current solutions; fast-charging capabilities enabling 80% capacity in under 15 minutes; cycle life extensions to 2000+ complete cycles; and enhanced thermal management for operation across diverse urban climates. Additionally, these objectives must be achieved while maintaining or reducing production costs to enable mass-market adoption.

Environmental considerations are increasingly shaping battery development objectives, with sustainability becoming a core design principle rather than an afterthought. This includes the development of battery chemistries with reduced reliance on scarce materials, improved recyclability, and lower carbon footprints across the entire lifecycle. The industry is progressively moving toward circular economy models where battery components can be effectively recovered and repurposed.

The convergence of these technical and environmental objectives is expected to drive innovation in urban mobility battery solutions over the next decade, with particular emphasis on modular designs that can be adapted to various vehicle types and usage patterns. This adaptability will be crucial for addressing the diverse transportation needs of modern urban environments while supporting broader sustainability goals.

The historical trajectory of battery development for urban mobility applications reveals a consistent push toward higher energy density, improved safety, and extended cycle life. Early electric mobility solutions were hampered by limited range and long charging times, making them impractical for widespread adoption. However, breakthroughs in battery chemistry and management systems have progressively addressed these limitations, enabling the current generation of electric scooters, bikes, and compact vehicles that are transforming urban transportation landscapes.

Current urban mobility challenges present unique requirements for battery pack design. Unlike conventional automotive applications, urban mobility solutions demand batteries that balance compact form factors with sufficient energy capacity, while maintaining stringent safety standards for operation in densely populated environments. Weight optimization becomes particularly crucial, as it directly impacts vehicle efficiency and user experience, especially for micromobility applications.

The technical objectives for next-generation urban mobility battery packs center around several key parameters: volumetric and gravimetric energy density improvements of 30-50% over current solutions; fast-charging capabilities enabling 80% capacity in under 15 minutes; cycle life extensions to 2000+ complete cycles; and enhanced thermal management for operation across diverse urban climates. Additionally, these objectives must be achieved while maintaining or reducing production costs to enable mass-market adoption.

Environmental considerations are increasingly shaping battery development objectives, with sustainability becoming a core design principle rather than an afterthought. This includes the development of battery chemistries with reduced reliance on scarce materials, improved recyclability, and lower carbon footprints across the entire lifecycle. The industry is progressively moving toward circular economy models where battery components can be effectively recovered and repurposed.

The convergence of these technical and environmental objectives is expected to drive innovation in urban mobility battery solutions over the next decade, with particular emphasis on modular designs that can be adapted to various vehicle types and usage patterns. This adaptability will be crucial for addressing the diverse transportation needs of modern urban environments while supporting broader sustainability goals.

Market Analysis for Urban Mobility Battery Solutions

The urban mobility battery solutions market is experiencing unprecedented growth, driven by the global shift towards sustainable transportation and the increasing adoption of electric vehicles (EVs) in urban environments. Current market valuations indicate that the urban mobility battery sector reached approximately 15 billion USD in 2022, with projections suggesting a compound annual growth rate of 24% through 2030. This remarkable expansion is primarily fueled by stringent emission regulations in major metropolitan areas, rising consumer awareness about environmental sustainability, and significant improvements in battery technology.

Consumer demand patterns reveal distinct preferences across different urban mobility segments. Micro-mobility solutions, including e-bikes and e-scooters, are witnessing the fastest adoption rates in densely populated urban centers, with battery requirements focusing on lightweight, replaceable power sources. The passenger EV segment demands high-energy density batteries with fast-charging capabilities to address range anxiety concerns. Commercial urban logistics vehicles prioritize durability and operational longevity, with total cost of ownership becoming a critical decision factor.

Regional market analysis shows varying adoption rates and preferences. European cities lead in comprehensive urban mobility electrification, supported by progressive policies and well-developed charging infrastructure. Asian markets, particularly China, dominate in terms of volume, with massive deployment of electric two-wheelers and buses. North American urban centers are experiencing accelerated growth in premium electric passenger vehicles and fleet electrification initiatives.

Key market drivers include battery cost reduction trajectories, with prices falling by approximately 85% over the past decade. This trend is expected to continue, albeit at a slower pace, making electric mobility increasingly cost-competitive with internal combustion alternatives. Infrastructure development, particularly charging networks, remains a critical enabler for market expansion, with significant investments being directed toward fast-charging solutions and battery swapping stations in urban environments.

Consumer behavior analysis indicates that urban dwellers increasingly prioritize environmental impact and operational costs when making mobility choices. This shift is particularly pronounced among younger demographics and in cities with robust environmental policies. Fleet operators are increasingly adopting total cost of ownership models that favor electric solutions for urban operations.

Market barriers persist, including concerns about battery longevity in intensive urban use cases, recycling infrastructure limitations, and raw material supply constraints. The urban mobility battery market is also characterized by intense competition, with traditional automotive suppliers, specialized battery manufacturers, and technology startups all vying for market share through differentiated value propositions.

Consumer demand patterns reveal distinct preferences across different urban mobility segments. Micro-mobility solutions, including e-bikes and e-scooters, are witnessing the fastest adoption rates in densely populated urban centers, with battery requirements focusing on lightweight, replaceable power sources. The passenger EV segment demands high-energy density batteries with fast-charging capabilities to address range anxiety concerns. Commercial urban logistics vehicles prioritize durability and operational longevity, with total cost of ownership becoming a critical decision factor.

Regional market analysis shows varying adoption rates and preferences. European cities lead in comprehensive urban mobility electrification, supported by progressive policies and well-developed charging infrastructure. Asian markets, particularly China, dominate in terms of volume, with massive deployment of electric two-wheelers and buses. North American urban centers are experiencing accelerated growth in premium electric passenger vehicles and fleet electrification initiatives.

Key market drivers include battery cost reduction trajectories, with prices falling by approximately 85% over the past decade. This trend is expected to continue, albeit at a slower pace, making electric mobility increasingly cost-competitive with internal combustion alternatives. Infrastructure development, particularly charging networks, remains a critical enabler for market expansion, with significant investments being directed toward fast-charging solutions and battery swapping stations in urban environments.

Consumer behavior analysis indicates that urban dwellers increasingly prioritize environmental impact and operational costs when making mobility choices. This shift is particularly pronounced among younger demographics and in cities with robust environmental policies. Fleet operators are increasingly adopting total cost of ownership models that favor electric solutions for urban operations.

Market barriers persist, including concerns about battery longevity in intensive urban use cases, recycling infrastructure limitations, and raw material supply constraints. The urban mobility battery market is also characterized by intense competition, with traditional automotive suppliers, specialized battery manufacturers, and technology startups all vying for market share through differentiated value propositions.

Battery Pack Design Challenges and Constraints

Battery pack design for urban mobility applications faces multifaceted challenges that significantly impact performance, safety, and commercial viability. The primary constraint revolves around energy density optimization within limited spatial dimensions. Urban vehicles, particularly compact electric cars, scooters, and bikes, demand high energy capacity while maintaining minimal weight and volume profiles. This spatial limitation forces engineers to make critical trade-offs between range capabilities and physical design parameters.

Thermal management represents another fundamental challenge, especially in urban environments where stop-and-go traffic patterns generate irregular heat profiles. Battery cells operating outside optimal temperature ranges (typically 15-35°C) experience accelerated degradation and reduced efficiency. Urban mobility applications often lack the luxury of extensive cooling systems due to weight and space constraints, necessitating innovative passive cooling solutions or highly efficient active systems.

Safety considerations impose rigorous design constraints, particularly given the proximity of battery systems to passengers in compact urban vehicles. Protection against thermal runaway, physical damage from road debris, and moisture ingress requires robust mechanical designs and sophisticated battery management systems (BMS). These safety features inevitably add weight and complexity, working against the primary goals of lightweight, compact designs.

Cost optimization presents a significant challenge as urban mobility solutions typically target price-sensitive market segments. The battery pack often represents 30-40% of the total vehicle cost, creating pressure to reduce expenses while maintaining performance and safety standards. This economic constraint frequently limits material selection and manufacturing processes, pushing designers toward standardized rather than optimized solutions.

Durability requirements add another layer of complexity, as urban mobility batteries must withstand harsh operating conditions including vibration, temperature fluctuations, and exposure to environmental elements. The typical design target of 1,000+ charge cycles under these conditions necessitates robust mechanical structures and sophisticated cell balancing systems that further complicate the design process.

Regulatory compliance adds additional constraints, with different regions implementing varying standards for battery safety, electromagnetic compatibility, and end-of-life recycling. These regulations often require extensive testing and certification processes that extend development timelines and increase costs, particularly challenging for innovative designs that may not fit neatly into existing regulatory frameworks.

Manufacturing scalability represents the final major constraint, as battery pack designs must be amenable to mass production techniques to achieve commercial viability. This often limits design freedom, pushing engineers toward modular approaches and standardized components rather than fully customized solutions optimized for specific applications.

Thermal management represents another fundamental challenge, especially in urban environments where stop-and-go traffic patterns generate irregular heat profiles. Battery cells operating outside optimal temperature ranges (typically 15-35°C) experience accelerated degradation and reduced efficiency. Urban mobility applications often lack the luxury of extensive cooling systems due to weight and space constraints, necessitating innovative passive cooling solutions or highly efficient active systems.

Safety considerations impose rigorous design constraints, particularly given the proximity of battery systems to passengers in compact urban vehicles. Protection against thermal runaway, physical damage from road debris, and moisture ingress requires robust mechanical designs and sophisticated battery management systems (BMS). These safety features inevitably add weight and complexity, working against the primary goals of lightweight, compact designs.

Cost optimization presents a significant challenge as urban mobility solutions typically target price-sensitive market segments. The battery pack often represents 30-40% of the total vehicle cost, creating pressure to reduce expenses while maintaining performance and safety standards. This economic constraint frequently limits material selection and manufacturing processes, pushing designers toward standardized rather than optimized solutions.

Durability requirements add another layer of complexity, as urban mobility batteries must withstand harsh operating conditions including vibration, temperature fluctuations, and exposure to environmental elements. The typical design target of 1,000+ charge cycles under these conditions necessitates robust mechanical structures and sophisticated cell balancing systems that further complicate the design process.

Regulatory compliance adds additional constraints, with different regions implementing varying standards for battery safety, electromagnetic compatibility, and end-of-life recycling. These regulations often require extensive testing and certification processes that extend development timelines and increase costs, particularly challenging for innovative designs that may not fit neatly into existing regulatory frameworks.

Manufacturing scalability represents the final major constraint, as battery pack designs must be amenable to mass production techniques to achieve commercial viability. This often limits design freedom, pushing engineers toward modular approaches and standardized components rather than fully customized solutions optimized for specific applications.

Current Battery Pack Architectures for Urban Mobility

01 Battery pack thermal management systems

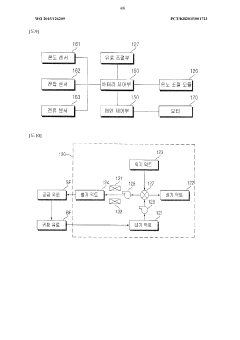

Thermal management systems for battery packs are designed to maintain optimal operating temperatures, prevent overheating, and ensure safety during charging and discharging cycles. These systems may include cooling channels, heat sinks, thermal interface materials, and temperature sensors that work together to dissipate heat efficiently. Advanced thermal management solutions help extend battery life, improve performance, and prevent thermal runaway conditions in high-power applications.- Battery pack thermal management systems: Thermal management systems for battery packs are designed to maintain optimal operating temperatures, prevent overheating, and ensure safety during charging and discharging cycles. These systems may include cooling channels, heat sinks, thermal interface materials, and temperature sensors that work together to dissipate heat efficiently. Advanced thermal management solutions help extend battery life, improve performance, and prevent thermal runaway conditions in high-power applications.

- Battery pack protection and safety mechanisms: Protection circuits and safety mechanisms are integrated into battery packs to prevent damage from overcharging, over-discharging, short circuits, and other electrical faults. These systems may include battery management systems (BMS), fuses, circuit breakers, and isolation mechanisms that monitor cell voltages and currents. Safety features can automatically disconnect power when abnormal conditions are detected, helping to prevent catastrophic failures and ensuring user safety.

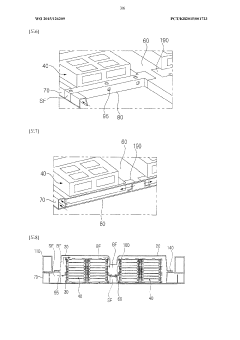

- Battery pack structural design and housing: Structural designs for battery packs focus on mechanical integrity, weight reduction, and space optimization while providing adequate protection for battery cells. Housing materials and configurations are selected to withstand physical impacts, vibration, and environmental conditions. Modular designs allow for easier maintenance and replacement of components, while specialized enclosures may incorporate features for specific applications such as automotive, portable electronics, or industrial equipment.

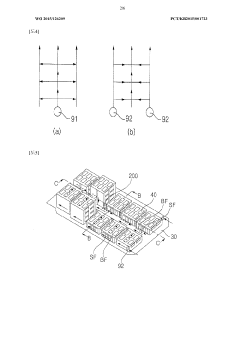

- Battery cell arrangement and interconnection methods: Cell arrangement and interconnection methods within battery packs determine electrical characteristics and overall performance. Various configurations of cells in series and parallel connections achieve desired voltage and capacity specifications. Advanced interconnection techniques minimize resistance, improve current distribution, and enhance thermal performance. Busbar designs, welding methods, and flexible connectors are employed to create reliable electrical paths between cells while accommodating thermal expansion and contraction.

- Battery management systems and charging control: Battery management systems (BMS) monitor and control the charging and discharging processes of battery packs to optimize performance and extend operational life. These systems incorporate sophisticated algorithms for cell balancing, state-of-charge estimation, and health monitoring. Advanced BMS solutions may include wireless connectivity for remote diagnostics, predictive maintenance capabilities, and adaptive charging profiles that adjust based on usage patterns and environmental conditions.

02 Battery pack charging and power management

Charging and power management systems for battery packs incorporate sophisticated control circuits that regulate current flow, voltage levels, and charging profiles. These systems often include battery management systems (BMS) that monitor individual cell performance, balance charge distribution, and implement protection mechanisms against overcharging or deep discharging. Advanced power management features enable efficient energy utilization, fast charging capabilities, and integration with various power sources.Expand Specific Solutions03 Battery pack structural design and assembly

Structural designs for battery packs focus on mechanical integrity, space optimization, and ease of assembly/disassembly. These designs incorporate features such as modular cell arrangements, robust housing materials, vibration dampening systems, and secure electrical connections. Advanced structural solutions address challenges related to weight reduction, impact resistance, and integration with host devices or vehicles, while ensuring proper cell alignment and connection reliability.Expand Specific Solutions04 Battery cell configuration and interconnection

Battery cell configuration and interconnection technologies focus on optimizing the electrical and physical arrangement of cells within a pack. These include series and parallel connections to achieve desired voltage and capacity specifications, bus bar designs for current distribution, and cell balancing circuits. Advanced interconnection methods address challenges related to resistance minimization, thermal expansion management, and fault tolerance, while enabling scalable and flexible battery pack architectures.Expand Specific Solutions05 Battery pack safety and protection mechanisms

Safety and protection mechanisms for battery packs include hardware and software solutions designed to prevent hazardous conditions. These systems incorporate overcurrent protection, short-circuit prevention, temperature monitoring, pressure relief valves, and isolation mechanisms. Advanced safety features may include fire-retardant materials, explosion-proof enclosures, and intelligent diagnostic systems that can detect and respond to abnormal operating conditions before they become dangerous.Expand Specific Solutions

Leading Battery Pack Manufacturers and Innovators

The urban mobility battery pack design market is in a growth phase, with increasing demand driven by electrification trends. The market is expanding rapidly, projected to reach significant scale as cities worldwide adopt electric transportation solutions. Technologically, the landscape shows varying maturity levels, with established players like LG Energy Solution, Samsung SDI, and Panasonic leading with advanced lithium-ion technologies. Automotive manufacturers including Toyota, Mercedes-Benz, and BYD are integrating vertical battery development capabilities. Emerging companies like Xerotech are introducing innovative modular platforms, while traditional players such as Hyundai-Kia and Nissan are accelerating their battery technology investments. Chinese manufacturers are gaining market share through cost-effective solutions, creating a competitive environment where technological differentiation and energy density improvements remain key competitive factors.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed the "Urban Mobility Power Pack" (UMPP) specifically designed to address the unique challenges of city transportation. Their solution utilizes a combination of high-energy and high-power cells in a single pack, dynamically allocating power demands between them based on driving conditions[8]. The battery pack architecture features a patented "Laminated Multi-Layer" design that reduces internal resistance and improves thermal performance during the frequent acceleration and regenerative braking cycles typical in urban environments. LG's battery management system incorporates machine learning algorithms that adapt to individual driving patterns and optimize power delivery accordingly, extending range by up to 15% in urban settings. For addressing space constraints in compact urban vehicles, LG has developed a flexible "Tetris" configuration system that allows battery modules to be arranged in multiple orientations while maintaining structural integrity. Their latest generation incorporates nickel-rich cathodes (NCM 811) with silicon-graphite composite anodes, achieving energy densities exceeding 700 Wh/L while maintaining the cycle life requirements for urban mobility applications[9]. The packs also feature enhanced fast-charging capabilities optimized for urban charging infrastructure.

Strengths: Industry-leading energy density; sophisticated thermal management system optimized for urban heat island effects; advanced BMS with predictive analytics. Weaknesses: Higher cost compared to LFP alternatives; thermal management system adds complexity and weight; some historical safety concerns with high-nickel cathode formulations.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI's "Urban Mobility Battery Solution" centers around their Gen5 battery technology featuring high-nickel NCA chemistry optimized for the demands of urban transportation. Their battery packs employ a modular "building block" architecture that allows for flexible configuration across different vehicle platforms while maintaining manufacturing standardization[10]. Samsung's battery management system incorporates predictive analytics that anticipate power demands based on route information, traffic patterns, and historical usage data. For addressing the thermal challenges of urban environments, Samsung has developed a dual-phase cooling system that combines active liquid cooling for high-demand situations with passive cooling for normal operation, optimizing energy efficiency. Their battery packs feature a proprietary cell balancing technology that extends pack life by up to 25% in the challenging charge-discharge patterns of urban mobility. Samsung's latest urban mobility packs incorporate their "Z-folding" technology for electrode manufacturing, which increases energy density while improving mechanical stability during the vibration and shock conditions of urban roads[11]. The system also features bidirectional charging capabilities, enabling vehicle-to-grid integration for urban energy management.

Strengths: Excellent energy density-to-weight ratio; sophisticated manufacturing processes with high quality control; advanced thermal management system designed specifically for urban heat challenges. Weaknesses: Higher cost per kWh than some competitors; thermal management system adds complexity; relatively new to automotive-scale battery production compared to some competitors.

Key Patents in Urban Mobility Battery Design

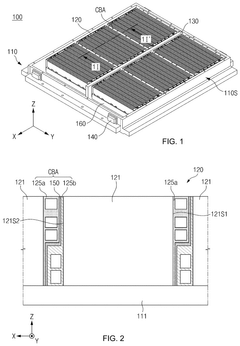

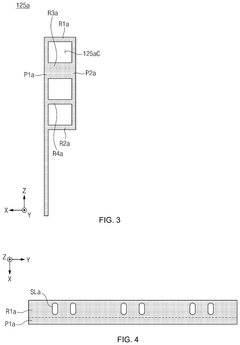

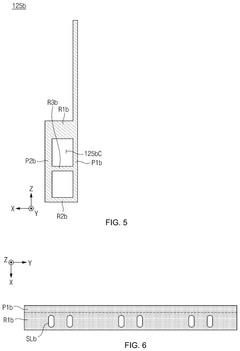

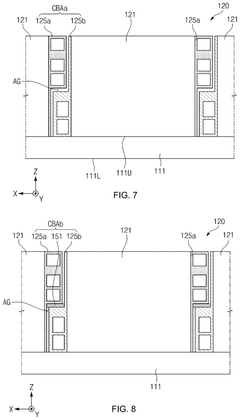

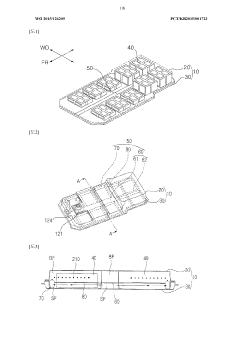

Battery Pack

PatentPendingUS20250233257A1

Innovation

- A battery pack design featuring a housing with first and second battery assemblies, each comprising a cell stack and cross-beams with complementary shapes and thin plates and ribs, along with a heat insulator and air gaps to enhance energy density and thermal insulation.

Battery pack

PatentWO2015126209A1

Innovation

- A battery pack design featuring a frame that partitions space for air flow, includes a center frame, cross frame, and side frame to form suction and injection ports, and uses a flow path control unit to reuse cooled or heated air, thereby maintaining temperature, reducing energy consumption, enhancing rigidity, and minimizing size.

Sustainability and Recycling Considerations

The sustainability aspects of battery pack design for urban mobility solutions have become increasingly critical as electric vehicle adoption accelerates. Current lithium-ion battery production involves significant environmental impacts, including resource extraction challenges, energy-intensive manufacturing processes, and potential ecological damage. Designing battery packs with sustainability as a core principle requires adopting a comprehensive lifecycle approach that considers environmental impacts from raw material sourcing through end-of-life management.

Material selection represents a fundamental sustainability consideration, with manufacturers increasingly exploring alternatives to rare earth elements and conflict minerals. Cobalt substitution has gained particular attention, with nickel-manganese-cobalt (NMC) cathodes evolving toward lower cobalt formulations (NMC 811) and lithium iron phosphate (LFP) batteries offering cobalt-free alternatives with improved sustainability profiles despite lower energy density.

Manufacturing optimization presents another critical sustainability dimension. Advanced production techniques that reduce energy consumption, minimize waste, and limit harmful emissions are being implemented across the battery supply chain. Localized production facilities powered by renewable energy sources significantly reduce the carbon footprint associated with battery manufacturing and transportation.

Design for disassembly has emerged as an essential principle in sustainable battery pack engineering. Modular architectures that facilitate easy component separation, standardized connection systems, and accessible configurations dramatically improve repairability and recyclability. These design approaches extend battery lifecycles through simplified maintenance and component replacement while enabling more efficient material recovery at end-of-life.

Battery second-life applications represent a promising sustainability pathway, with urban mobility batteries potentially serving in stationary energy storage applications after their vehicular utility diminishes. These second-life deployments can extend useful battery life by 5-10 years, significantly improving lifecycle sustainability metrics while supporting renewable energy integration and grid stability.

Recycling infrastructure development remains crucial for closing the battery material loop. Advanced hydrometallurgical and direct recycling processes now achieve recovery rates exceeding 95% for critical materials like lithium, cobalt, and nickel. However, economic viability challenges persist, necessitating policy support, industry collaboration, and continued technological innovation to establish robust recycling ecosystems that can process increasing battery volumes.

Regulatory frameworks increasingly influence battery sustainability practices, with legislation like the European Battery Directive establishing extended producer responsibility requirements, recycled content mandates, and carbon footprint disclosure obligations. These regulatory developments are driving proactive sustainability initiatives throughout the battery value chain, accelerating the transition toward truly circular battery systems for urban mobility applications.

Material selection represents a fundamental sustainability consideration, with manufacturers increasingly exploring alternatives to rare earth elements and conflict minerals. Cobalt substitution has gained particular attention, with nickel-manganese-cobalt (NMC) cathodes evolving toward lower cobalt formulations (NMC 811) and lithium iron phosphate (LFP) batteries offering cobalt-free alternatives with improved sustainability profiles despite lower energy density.

Manufacturing optimization presents another critical sustainability dimension. Advanced production techniques that reduce energy consumption, minimize waste, and limit harmful emissions are being implemented across the battery supply chain. Localized production facilities powered by renewable energy sources significantly reduce the carbon footprint associated with battery manufacturing and transportation.

Design for disassembly has emerged as an essential principle in sustainable battery pack engineering. Modular architectures that facilitate easy component separation, standardized connection systems, and accessible configurations dramatically improve repairability and recyclability. These design approaches extend battery lifecycles through simplified maintenance and component replacement while enabling more efficient material recovery at end-of-life.

Battery second-life applications represent a promising sustainability pathway, with urban mobility batteries potentially serving in stationary energy storage applications after their vehicular utility diminishes. These second-life deployments can extend useful battery life by 5-10 years, significantly improving lifecycle sustainability metrics while supporting renewable energy integration and grid stability.

Recycling infrastructure development remains crucial for closing the battery material loop. Advanced hydrometallurgical and direct recycling processes now achieve recovery rates exceeding 95% for critical materials like lithium, cobalt, and nickel. However, economic viability challenges persist, necessitating policy support, industry collaboration, and continued technological innovation to establish robust recycling ecosystems that can process increasing battery volumes.

Regulatory frameworks increasingly influence battery sustainability practices, with legislation like the European Battery Directive establishing extended producer responsibility requirements, recycled content mandates, and carbon footprint disclosure obligations. These regulatory developments are driving proactive sustainability initiatives throughout the battery value chain, accelerating the transition toward truly circular battery systems for urban mobility applications.

Safety Standards and Regulatory Compliance

The regulatory landscape for battery pack design in urban mobility applications has evolved significantly in response to safety incidents and technological advancements. Key international standards include UN 38.3 for transport safety, IEC 62133 for secondary cells and batteries, and ISO 12405 specifically for electric vehicle battery systems. These standards establish baseline requirements for thermal management, electrical safety, mechanical integrity, and emergency response protocols.

In the United States, UL 2271 for light electric vehicle batteries and UL 2580 for electric vehicle batteries represent critical certification requirements. The National Fire Protection Association (NFPA) has also developed standards addressing battery fire risks in urban environments. The European Union enforces compliance with ECE R100 for electric power train safety and the Battery Directive (2006/66/EC) which addresses environmental concerns alongside safety requirements.

Emerging markets like China have established their own regulatory frameworks, with GB/T 31467 and GB/T 31485 setting stringent requirements for battery safety performance. These standards often exceed international baselines, particularly regarding thermal runaway prevention and battery management system capabilities.

Regulatory compliance presents significant challenges for urban mobility battery pack designers. Testing protocols frequently require destructive testing of production-equivalent units, increasing development costs. Certification timelines can extend development cycles by 3-6 months, creating market entry barriers for innovative solutions. Additionally, regional variations in standards necessitate market-specific design modifications.

Recent regulatory trends indicate a shift toward more stringent thermal propagation requirements, with authorities increasingly demanding that single-cell failures remain contained without cascading through the entire pack. Second-life applications for urban mobility batteries face additional regulatory hurdles, as standards for repurposed battery systems remain under development in most jurisdictions.

Compliance strategies for battery pack designers should include early engagement with certification bodies, modular design approaches that facilitate regional adaptations, and comprehensive battery management systems with advanced diagnostic capabilities. Forward-looking companies are implementing design safety margins that anticipate regulatory evolution, particularly regarding thermal management and cell isolation technologies.

The regulatory landscape continues to evolve rapidly, with standards bodies working to address emerging technologies like solid-state batteries and ultra-fast charging systems. Successful urban mobility battery pack designs must balance innovation with compliance across an increasingly complex global regulatory environment.

In the United States, UL 2271 for light electric vehicle batteries and UL 2580 for electric vehicle batteries represent critical certification requirements. The National Fire Protection Association (NFPA) has also developed standards addressing battery fire risks in urban environments. The European Union enforces compliance with ECE R100 for electric power train safety and the Battery Directive (2006/66/EC) which addresses environmental concerns alongside safety requirements.

Emerging markets like China have established their own regulatory frameworks, with GB/T 31467 and GB/T 31485 setting stringent requirements for battery safety performance. These standards often exceed international baselines, particularly regarding thermal runaway prevention and battery management system capabilities.

Regulatory compliance presents significant challenges for urban mobility battery pack designers. Testing protocols frequently require destructive testing of production-equivalent units, increasing development costs. Certification timelines can extend development cycles by 3-6 months, creating market entry barriers for innovative solutions. Additionally, regional variations in standards necessitate market-specific design modifications.

Recent regulatory trends indicate a shift toward more stringent thermal propagation requirements, with authorities increasingly demanding that single-cell failures remain contained without cascading through the entire pack. Second-life applications for urban mobility batteries face additional regulatory hurdles, as standards for repurposed battery systems remain under development in most jurisdictions.

Compliance strategies for battery pack designers should include early engagement with certification bodies, modular design approaches that facilitate regional adaptations, and comprehensive battery management systems with advanced diagnostic capabilities. Forward-looking companies are implementing design safety margins that anticipate regulatory evolution, particularly regarding thermal management and cell isolation technologies.

The regulatory landscape continues to evolve rapidly, with standards bodies working to address emerging technologies like solid-state batteries and ultra-fast charging systems. Successful urban mobility battery pack designs must balance innovation with compliance across an increasingly complex global regulatory environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!