Exploring Battery Pack Design for Consumer Electronics

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Technology Evolution and Design Objectives

Battery technology has undergone significant evolution since the introduction of the first practical battery by Alessandro Volta in 1800. The journey from primitive zinc-copper cells to today's advanced lithium-ion configurations represents over two centuries of continuous innovation driven by increasing energy demands. The 1990s marked a pivotal moment with Sony's commercialization of lithium-ion batteries, revolutionizing portable electronics and establishing the foundation for modern consumer device power solutions.

In recent years, battery technology has accelerated dramatically, with energy density improvements averaging 5-8% annually. This progression has enabled the miniaturization of consumer electronics while simultaneously extending device operational times. Contemporary battery pack design must balance multiple competing factors: energy density, safety parameters, thermal management, form factor constraints, and increasingly, sustainability considerations.

The consumer electronics landscape presents unique challenges for battery pack design. Devices continue to demand higher power in increasingly compact form factors, creating fundamental engineering tensions. Smartphones, wearables, and portable computing devices each present distinct usage patterns requiring tailored power delivery profiles. Additionally, rapid charging capabilities have become a market differentiator, necessitating sophisticated battery management systems to prevent degradation while meeting consumer expectations.

Current design objectives focus on several key metrics: maximizing energy density (currently averaging 250-300 Wh/kg for premium devices), extending cycle life beyond 1,000 complete charge-discharge cycles, reducing charging times to under 30 minutes for 80% capacity, and maintaining safe operation across diverse environmental conditions. These objectives must be achieved while adhering to stringent international safety standards including IEC 62133 and UL 1642.

The trajectory of battery technology suggests several emerging design priorities. Flexible and structural batteries that conform to device geometries rather than dictating them represent a significant frontier. Similarly, solid-state electrolyte technologies promise to address safety concerns while potentially increasing energy density by 20-50%. Sustainable design incorporating recyclable materials and reduced cobalt dependency aligns with both regulatory trends and consumer preferences.

For consumer electronics manufacturers, battery pack design has evolved from a purely technical consideration to a strategic product differentiator. The ability to optimize power delivery, physical integration, and user experience through advanced battery solutions directly impacts market positioning. This evolution necessitates cross-functional collaboration between materials scientists, electrical engineers, thermal specialists, and industrial designers to create holistic power solutions.

In recent years, battery technology has accelerated dramatically, with energy density improvements averaging 5-8% annually. This progression has enabled the miniaturization of consumer electronics while simultaneously extending device operational times. Contemporary battery pack design must balance multiple competing factors: energy density, safety parameters, thermal management, form factor constraints, and increasingly, sustainability considerations.

The consumer electronics landscape presents unique challenges for battery pack design. Devices continue to demand higher power in increasingly compact form factors, creating fundamental engineering tensions. Smartphones, wearables, and portable computing devices each present distinct usage patterns requiring tailored power delivery profiles. Additionally, rapid charging capabilities have become a market differentiator, necessitating sophisticated battery management systems to prevent degradation while meeting consumer expectations.

Current design objectives focus on several key metrics: maximizing energy density (currently averaging 250-300 Wh/kg for premium devices), extending cycle life beyond 1,000 complete charge-discharge cycles, reducing charging times to under 30 minutes for 80% capacity, and maintaining safe operation across diverse environmental conditions. These objectives must be achieved while adhering to stringent international safety standards including IEC 62133 and UL 1642.

The trajectory of battery technology suggests several emerging design priorities. Flexible and structural batteries that conform to device geometries rather than dictating them represent a significant frontier. Similarly, solid-state electrolyte technologies promise to address safety concerns while potentially increasing energy density by 20-50%. Sustainable design incorporating recyclable materials and reduced cobalt dependency aligns with both regulatory trends and consumer preferences.

For consumer electronics manufacturers, battery pack design has evolved from a purely technical consideration to a strategic product differentiator. The ability to optimize power delivery, physical integration, and user experience through advanced battery solutions directly impacts market positioning. This evolution necessitates cross-functional collaboration between materials scientists, electrical engineers, thermal specialists, and industrial designers to create holistic power solutions.

Consumer Electronics Market Battery Requirements

The consumer electronics market demands increasingly sophisticated battery solutions that balance multiple competing requirements. Modern devices require batteries that deliver high energy density to support extended usage periods between charges, with smartphones typically needing 3000-5000mAh capacity while maintaining slim form factors. Power density has become equally critical as rapid charging capabilities (supporting 25W to 65W+ charging speeds) are now standard consumer expectations across premium device categories.

Safety remains paramount in battery design, particularly following high-profile incidents involving thermal runaway. This has driven stringent regulatory requirements including IEC 62133, UL 2054, and UN 38.3 transportation standards that manufacturers must meet. These standards necessitate multiple protection mechanisms within battery packs, including overcharge protection, thermal management systems, and short-circuit prevention.

Form factor flexibility presents significant engineering challenges as devices continue to shrink while adding functionality. Batteries for wearable devices must conform to curved surfaces and ultra-thin profiles (often under 3mm), while foldable devices require batteries that can either flex or be segmented across hinged sections. This has accelerated development of non-traditional battery geometries beyond standard prismatic and cylindrical cells.

Longevity requirements have intensified with consumers expecting devices to maintain 80% of original capacity after 500-1000 charge cycles. This expectation conflicts with the trend toward faster charging, which typically accelerates battery degradation. Environmental considerations have also gained prominence, with regulations like the EU Battery Directive mandating minimum recycled content and design for disassembly.

Cost sensitivity varies significantly by device category. While premium smartphone manufacturers can absorb battery costs of $15-30 per unit, mass-market devices and IoT applications require solutions under $5. This cost pressure must be balanced against performance requirements, creating a complex optimization challenge for battery designers.

Intelligence features represent an emerging requirement, with smart battery management systems that can adapt charging patterns based on user behavior, ambient conditions, and battery health. These systems require integrated sensors, microcontrollers, and communication interfaces that add complexity to battery pack design but deliver significant improvements in overall battery lifespan and user experience.

Safety remains paramount in battery design, particularly following high-profile incidents involving thermal runaway. This has driven stringent regulatory requirements including IEC 62133, UL 2054, and UN 38.3 transportation standards that manufacturers must meet. These standards necessitate multiple protection mechanisms within battery packs, including overcharge protection, thermal management systems, and short-circuit prevention.

Form factor flexibility presents significant engineering challenges as devices continue to shrink while adding functionality. Batteries for wearable devices must conform to curved surfaces and ultra-thin profiles (often under 3mm), while foldable devices require batteries that can either flex or be segmented across hinged sections. This has accelerated development of non-traditional battery geometries beyond standard prismatic and cylindrical cells.

Longevity requirements have intensified with consumers expecting devices to maintain 80% of original capacity after 500-1000 charge cycles. This expectation conflicts with the trend toward faster charging, which typically accelerates battery degradation. Environmental considerations have also gained prominence, with regulations like the EU Battery Directive mandating minimum recycled content and design for disassembly.

Cost sensitivity varies significantly by device category. While premium smartphone manufacturers can absorb battery costs of $15-30 per unit, mass-market devices and IoT applications require solutions under $5. This cost pressure must be balanced against performance requirements, creating a complex optimization challenge for battery designers.

Intelligence features represent an emerging requirement, with smart battery management systems that can adapt charging patterns based on user behavior, ambient conditions, and battery health. These systems require integrated sensors, microcontrollers, and communication interfaces that add complexity to battery pack design but deliver significant improvements in overall battery lifespan and user experience.

Current Battery Pack Challenges and Constraints

Battery pack design for consumer electronics faces significant technical challenges that constrain innovation and performance optimization. The energy density limitations of current battery technologies represent a primary obstacle, with lithium-ion batteries reaching theoretical limits around 250-300 Wh/kg. This ceiling restricts the ability to create longer-lasting devices without increasing battery size and weight, forcing difficult trade-offs between device functionality and form factor.

Thermal management presents another critical challenge, as consumer electronics batteries generate considerable heat during charging and discharging cycles. Inadequate thermal solutions can lead to performance degradation, reduced battery lifespan, and safety risks including thermal runaway. This issue becomes particularly acute in ultra-thin devices where space for cooling systems is severely limited.

Safety considerations impose substantial design constraints, requiring robust protection circuits, mechanical safeguards, and thermal management systems. These necessary safety features consume valuable space within the battery pack, reducing the volume available for active energy storage materials and limiting overall capacity. The balance between maximizing energy density and ensuring user safety remains a persistent engineering challenge.

Manufacturing complexity and cost factors significantly impact battery pack design. Current production processes involve numerous precision components and assembly steps, driving up costs and limiting design flexibility. The intricate balance of electrochemistry, electronics, and mechanical engineering requires specialized expertise and equipment, creating barriers to rapid innovation and cost reduction.

Form factor limitations represent a major constraint, as consumer electronics increasingly demand thinner, lighter, and sometimes flexible or uniquely shaped devices. Traditional rectangular battery cells limit design options, while newer flexible battery technologies still struggle with energy density and cycle life performance compared to conventional designs.

Charging speed limitations continue to frustrate both designers and consumers. Fast-charging capabilities are in high demand, but implementing them introduces additional thermal management challenges and potential long-term degradation issues. Current battery chemistries face fundamental limitations in charge acceptance rates without compromising safety or longevity.

Sustainability and environmental concerns add another layer of complexity. The industry faces growing pressure to develop battery packs that use more environmentally friendly materials, enable easier recycling, and reduce overall environmental impact. These requirements often conflict with performance objectives, creating difficult engineering trade-offs.

Standardization issues further complicate the landscape, with proprietary designs limiting interoperability and increasing electronic waste. The lack of universal standards for battery packs increases development costs and slows innovation across the industry.

Thermal management presents another critical challenge, as consumer electronics batteries generate considerable heat during charging and discharging cycles. Inadequate thermal solutions can lead to performance degradation, reduced battery lifespan, and safety risks including thermal runaway. This issue becomes particularly acute in ultra-thin devices where space for cooling systems is severely limited.

Safety considerations impose substantial design constraints, requiring robust protection circuits, mechanical safeguards, and thermal management systems. These necessary safety features consume valuable space within the battery pack, reducing the volume available for active energy storage materials and limiting overall capacity. The balance between maximizing energy density and ensuring user safety remains a persistent engineering challenge.

Manufacturing complexity and cost factors significantly impact battery pack design. Current production processes involve numerous precision components and assembly steps, driving up costs and limiting design flexibility. The intricate balance of electrochemistry, electronics, and mechanical engineering requires specialized expertise and equipment, creating barriers to rapid innovation and cost reduction.

Form factor limitations represent a major constraint, as consumer electronics increasingly demand thinner, lighter, and sometimes flexible or uniquely shaped devices. Traditional rectangular battery cells limit design options, while newer flexible battery technologies still struggle with energy density and cycle life performance compared to conventional designs.

Charging speed limitations continue to frustrate both designers and consumers. Fast-charging capabilities are in high demand, but implementing them introduces additional thermal management challenges and potential long-term degradation issues. Current battery chemistries face fundamental limitations in charge acceptance rates without compromising safety or longevity.

Sustainability and environmental concerns add another layer of complexity. The industry faces growing pressure to develop battery packs that use more environmentally friendly materials, enable easier recycling, and reduce overall environmental impact. These requirements often conflict with performance objectives, creating difficult engineering trade-offs.

Standardization issues further complicate the landscape, with proprietary designs limiting interoperability and increasing electronic waste. The lack of universal standards for battery packs increases development costs and slows innovation across the industry.

Contemporary Battery Pack Design Solutions

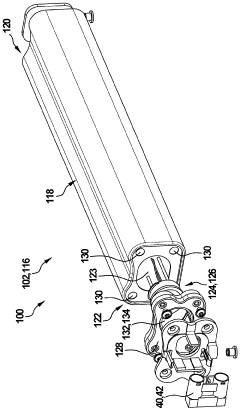

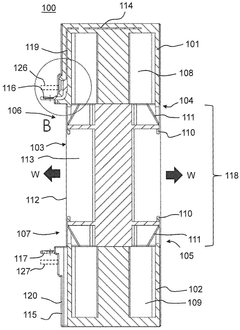

01 Battery pack thermal management systems

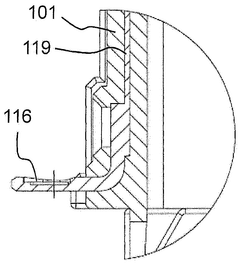

Thermal management systems for battery packs are designed to maintain optimal operating temperatures, prevent overheating, and ensure safety during charging and discharging cycles. These systems may include cooling channels, heat sinks, thermal interface materials, and temperature sensors that work together to dissipate heat effectively. Advanced thermal management solutions help extend battery life, improve performance, and prevent thermal runaway conditions in high-power applications.- Battery pack thermal management systems: Thermal management systems for battery packs are designed to maintain optimal operating temperatures, prevent overheating, and extend battery life. These systems may include cooling channels, heat sinks, thermal interface materials, and active cooling mechanisms. Advanced thermal management solutions can monitor temperature distribution across cells and adjust cooling accordingly, ensuring uniform temperature profiles and preventing thermal runaway conditions.

- Battery pack charging and power management: Charging and power management systems for battery packs include sophisticated control circuits that regulate charging current, voltage, and duration to optimize battery performance and lifespan. These systems may incorporate balancing circuits to ensure uniform charging across multiple cells, protection against overcharging or deep discharging, and smart charging algorithms that adapt to battery conditions and usage patterns.

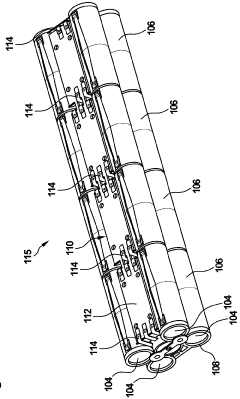

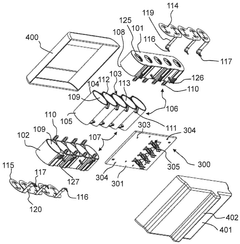

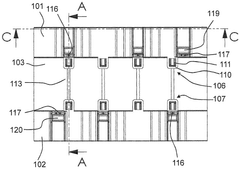

- Battery pack structural design and assembly: Structural designs for battery packs focus on mechanical integrity, space optimization, and ease of assembly/disassembly. Innovations include modular configurations that allow for scalable capacity, shock-absorbing frames to protect cells from physical damage, and integrated cooling pathways. Advanced designs may incorporate lightweight materials for improved energy density and specialized connectors for reliable electrical contacts between cells.

- Battery pack safety and protection mechanisms: Safety features in battery packs include multiple layers of protection against electrical, thermal, and mechanical failures. These may include fuses, circuit breakers, pressure relief mechanisms, and isolation systems to prevent cascading failures. Advanced battery packs incorporate sensors to detect abnormal conditions such as overheating, short circuits, or physical damage, with automated shutdown capabilities to prevent catastrophic failures.

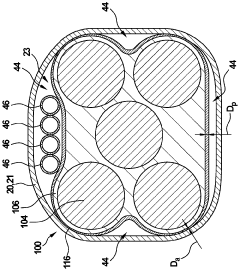

- Battery cell configuration and interconnection: Cell configuration and interconnection technologies focus on optimizing electrical performance, thermal behavior, and space utilization within battery packs. Innovations include novel cell arrangements (series, parallel, or hybrid configurations), advanced bus bar designs for current distribution, and flexible interconnects that accommodate thermal expansion. These technologies aim to minimize internal resistance, reduce weight, and improve overall energy density of the battery pack.

02 Battery pack charging control mechanisms

Charging control mechanisms for battery packs incorporate sophisticated algorithms and hardware to optimize charging processes, protect cells from damage, and extend battery lifespan. These systems monitor voltage, current, and temperature parameters to implement adaptive charging profiles. Features may include balancing circuits to ensure uniform charging across cells, protection against overcharging, and communication interfaces that enable smart charging based on battery condition and user requirements.Expand Specific Solutions03 Battery pack structural designs and configurations

Structural designs for battery packs focus on optimizing space utilization, mechanical integrity, and ease of assembly/disassembly. These designs include modular architectures that allow for scalability, housing structures that provide protection against environmental factors, and connection mechanisms that ensure reliable electrical contact between cells. Advanced configurations may incorporate shock absorption features, reinforcement elements, and innovative cell arrangements to maximize energy density while maintaining structural integrity.Expand Specific Solutions04 Battery management systems for monitoring and protection

Battery management systems (BMS) provide comprehensive monitoring and protection functions for battery packs. These systems track cell voltages, currents, temperatures, and state of charge to optimize performance and prevent dangerous conditions. Key features include fault detection algorithms, protection against short circuits, communication interfaces for system integration, and diagnostic capabilities. Advanced BMS implementations may incorporate machine learning to predict battery behavior and adapt management strategies accordingly.Expand Specific Solutions05 Battery pack electrode and cell connection technologies

Electrode and cell connection technologies focus on creating reliable electrical pathways within battery packs while minimizing resistance and heat generation. These technologies include bus bar designs, welding techniques for cell interconnections, and contact materials that maintain performance over time. Innovations in this area aim to improve current distribution, reduce weight, enhance manufacturing efficiency, and increase the overall reliability of battery packs under various operating conditions.Expand Specific Solutions

Leading Battery Pack Manufacturers and Innovators

The battery pack design market for consumer electronics is in a mature growth phase, with an estimated global market size exceeding $25 billion annually. Major players like Samsung SDI, LG Energy Solution, and Sony Group dominate with established technologies, while Apple and Panasonic maintain significant market share through vertical integration strategies. Emerging competitors such as BYD and SVOLT are disrupting the landscape with innovations in energy density and form factor flexibility. Technical maturity varies across applications, with smartphone battery packs highly standardized while wearable and IoT device solutions remain in development. Samsung and LG lead in high-density lithium polymer technologies, while Apple focuses on custom integration solutions that optimize space utilization and thermal management within compact consumer devices.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered advanced battery pack designs for consumer electronics with their "stacked" electrode technology that maximizes energy density in limited spaces. Their latest generation employs a proprietary multi-layer pouch cell architecture that achieves up to 25% higher capacity than conventional designs while maintaining the same physical dimensions. Samsung's battery packs feature integrated Battery Management Systems (BMS) with real-time cell monitoring and adaptive charging algorithms that optimize charging speeds based on temperature and usage patterns. Their "Z-stacking" technique allows for more efficient thermal management by creating micro-channels between cells for improved heat dissipation. Samsung has also implemented silicon-graphite composite anodes in their latest designs, increasing energy density by approximately 30% compared to traditional graphite anodes while maintaining structural integrity through their proprietary binding technology.

Strengths: Industry-leading energy density, advanced thermal management systems, and proprietary cell stacking technology that maximizes space utilization. Weaknesses: Higher production costs compared to competitors, and some designs prioritize energy density over cycle life, potentially reducing longevity in certain applications.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a modular battery pack architecture specifically for consumer electronics called "Free Form Battery" technology. This innovative approach allows battery cells to be shaped and configured to fit irregular spaces within devices, increasing volumetric efficiency by up to 40% compared to traditional rectangular designs. Their battery packs incorporate a distributed BMS architecture where monitoring circuits are embedded at the cell level rather than pack level, enabling more precise control and balancing. LG's "Safety Reinforced Separator" technology provides enhanced thermal stability and prevents internal short circuits through a ceramic-coated polymer membrane. For wearable devices, LG has pioneered ultra-thin (< 0.5mm) flexible battery packs using laminated cell technology that can withstand over 5,000 bending cycles without performance degradation. Their latest designs also feature rapid charging capabilities that can achieve 80% capacity in under 30 minutes while maintaining cell temperatures below critical thresholds.

Strengths: Exceptional form factor flexibility, industry-leading safety features, and advanced thermal management that prevents overheating even during rapid charging. Weaknesses: Higher manufacturing complexity leads to increased costs, and the distributed BMS architecture adds weight compared to more centralized approaches.

Key Patents and Innovations in Battery Pack Design

Battery pack and method for producing a battery pack

PatentPendingDE102022211711A1

Innovation

- A deformable and compressible frictional element within the battery pack's housing allows for optimal adaptation to the consumer's receiving shaft, ensuring a secure and compact connection, while also providing protection against splash water and moisture.

Battery pack

PatentWO2025186050A1

Innovation

- A battery pack design featuring a casing element that surrounds battery cells without gaps, with connecting means allowing easy automated connection between cell holders and the casing element, using snap-in connections and press-fit pins for electrical contact, and incorporating a thermally conductive plastic material for efficient heat dissipation.

Safety Standards and Regulatory Compliance

Safety standards and regulatory compliance are critical components in battery pack design for consumer electronics, serving as the foundation for ensuring product safety and market access. The landscape of battery regulations is complex and varies significantly across global markets, with key frameworks including IEC 62133/UL 62133 for portable batteries, UN 38.3 for transportation safety, and region-specific requirements like CE marking in Europe and UL certification in North America. These standards address critical safety aspects including thermal management, overcharge protection, short circuit prevention, and mechanical integrity.

Compliance with these regulations requires rigorous testing protocols that simulate extreme conditions batteries might encounter during normal use and foreseeable misuse. These include crush tests, puncture resistance evaluations, thermal cycling, and electrical safety assessments. The testing methodology must be comprehensive enough to validate safety across the battery's entire operational envelope.

Recent high-profile incidents involving lithium-ion batteries have prompted regulatory bodies to implement increasingly stringent requirements. The Samsung Galaxy Note 7 recall of 2016 and numerous incidents involving personal electronic devices have led to enhanced scrutiny of battery pack designs, particularly regarding thermal runaway prevention and containment strategies.

Manufacturers must navigate an evolving regulatory landscape where standards are continuously updated to address emerging risks. This includes new requirements for battery management systems (BMS) that provide real-time monitoring and protection against abnormal operating conditions. The trend toward higher energy densities in consumer electronics further complicates compliance efforts, as more energy-dense batteries typically present greater safety challenges.

Documentation and traceability have become equally important aspects of regulatory compliance. Manufacturers must maintain comprehensive records of component sourcing, quality control processes, and test results throughout the product lifecycle. This documentation serves both as evidence of compliance and as a resource for continuous improvement in safety design.

For global product launches, companies must develop strategic approaches to certification, often designing to meet the most stringent requirements across all target markets. This harmonized approach, while potentially increasing initial development costs, ultimately streamlines market access and reduces the risk of regional compliance issues.

Compliance with these regulations requires rigorous testing protocols that simulate extreme conditions batteries might encounter during normal use and foreseeable misuse. These include crush tests, puncture resistance evaluations, thermal cycling, and electrical safety assessments. The testing methodology must be comprehensive enough to validate safety across the battery's entire operational envelope.

Recent high-profile incidents involving lithium-ion batteries have prompted regulatory bodies to implement increasingly stringent requirements. The Samsung Galaxy Note 7 recall of 2016 and numerous incidents involving personal electronic devices have led to enhanced scrutiny of battery pack designs, particularly regarding thermal runaway prevention and containment strategies.

Manufacturers must navigate an evolving regulatory landscape where standards are continuously updated to address emerging risks. This includes new requirements for battery management systems (BMS) that provide real-time monitoring and protection against abnormal operating conditions. The trend toward higher energy densities in consumer electronics further complicates compliance efforts, as more energy-dense batteries typically present greater safety challenges.

Documentation and traceability have become equally important aspects of regulatory compliance. Manufacturers must maintain comprehensive records of component sourcing, quality control processes, and test results throughout the product lifecycle. This documentation serves both as evidence of compliance and as a resource for continuous improvement in safety design.

For global product launches, companies must develop strategic approaches to certification, often designing to meet the most stringent requirements across all target markets. This harmonized approach, while potentially increasing initial development costs, ultimately streamlines market access and reduces the risk of regional compliance issues.

Sustainability and Recycling Considerations

The environmental impact of battery pack design in consumer electronics has become a critical consideration as global electronic waste continues to grow at an alarming rate. Current estimates suggest that less than 20% of electronic waste is formally recycled, with battery components representing a significant portion of unrecovered materials. Designing battery packs with sustainability in mind requires a comprehensive approach that considers the entire lifecycle from raw material extraction to end-of-life management.

Material selection plays a pivotal role in sustainable battery pack design. Traditional lithium-ion batteries contain cobalt, nickel, and other materials with significant environmental extraction costs and limited global reserves. Forward-thinking manufacturers are increasingly exploring alternative chemistries such as lithium iron phosphate (LFP) and sodium-ion technologies, which utilize more abundant and less environmentally problematic materials. Additionally, reducing the use of toxic components like heavy metals and halogenated flame retardants significantly improves recycling potential.

Design for disassembly represents another crucial aspect of sustainable battery pack engineering. Current designs often prioritize compactness and weight reduction over recyclability, resulting in batteries that are difficult to dismantle at end-of-life. Implementing modular designs with standardized components, easily separable connections, and minimal use of adhesives can dramatically improve recycling rates. Some manufacturers have begun incorporating pull-tabs, removable fasteners, and color-coded components to facilitate easier disassembly.

Recycling infrastructure development must evolve alongside battery technology. Current recycling processes primarily focus on recovering high-value metals like cobalt and nickel while neglecting other materials. Advanced hydrometallurgical and direct recycling techniques are emerging that can recover up to 95% of battery materials with significantly lower energy requirements than traditional pyrometallurgical methods. Collaboration between electronics manufacturers and recycling facilities is essential to develop systems optimized for next-generation battery chemistries.

Extended producer responsibility (EPR) programs are gaining traction globally, shifting the burden of end-of-life management back to manufacturers. These initiatives incentivize companies to design products with recyclability in mind and establish take-back programs for used devices. Leading consumer electronics companies have implemented battery collection programs, with some achieving recovery rates exceeding 40% in certain markets. The integration of digital product passports containing material composition data could further enhance recycling efficiency by providing recyclers with precise information about battery components.

Second-life applications present an opportunity to extend the useful life of battery packs before recycling. Batteries that no longer meet the demanding requirements of consumer electronics may still retain 70-80% of their original capacity, making them suitable for less intensive applications such as energy storage. Several pilot programs have successfully repurposed smartphone and laptop batteries for solar energy storage systems, emergency backup power, and grid stabilization applications.

Material selection plays a pivotal role in sustainable battery pack design. Traditional lithium-ion batteries contain cobalt, nickel, and other materials with significant environmental extraction costs and limited global reserves. Forward-thinking manufacturers are increasingly exploring alternative chemistries such as lithium iron phosphate (LFP) and sodium-ion technologies, which utilize more abundant and less environmentally problematic materials. Additionally, reducing the use of toxic components like heavy metals and halogenated flame retardants significantly improves recycling potential.

Design for disassembly represents another crucial aspect of sustainable battery pack engineering. Current designs often prioritize compactness and weight reduction over recyclability, resulting in batteries that are difficult to dismantle at end-of-life. Implementing modular designs with standardized components, easily separable connections, and minimal use of adhesives can dramatically improve recycling rates. Some manufacturers have begun incorporating pull-tabs, removable fasteners, and color-coded components to facilitate easier disassembly.

Recycling infrastructure development must evolve alongside battery technology. Current recycling processes primarily focus on recovering high-value metals like cobalt and nickel while neglecting other materials. Advanced hydrometallurgical and direct recycling techniques are emerging that can recover up to 95% of battery materials with significantly lower energy requirements than traditional pyrometallurgical methods. Collaboration between electronics manufacturers and recycling facilities is essential to develop systems optimized for next-generation battery chemistries.

Extended producer responsibility (EPR) programs are gaining traction globally, shifting the burden of end-of-life management back to manufacturers. These initiatives incentivize companies to design products with recyclability in mind and establish take-back programs for used devices. Leading consumer electronics companies have implemented battery collection programs, with some achieving recovery rates exceeding 40% in certain markets. The integration of digital product passports containing material composition data could further enhance recycling efficiency by providing recyclers with precise information about battery components.

Second-life applications present an opportunity to extend the useful life of battery packs before recycling. Batteries that no longer meet the demanding requirements of consumer electronics may still retain 70-80% of their original capacity, making them suitable for less intensive applications such as energy storage. Several pilot programs have successfully repurposed smartphone and laptop batteries for solar energy storage systems, emergency backup power, and grid stabilization applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!