Benchmark NMC Battery Performance In Extreme Climate Tests

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Evolution and Performance Objectives

Lithium-ion batteries with Nickel Manganese Cobalt (NMC) cathodes have evolved significantly since their commercial introduction in the early 2000s. The evolution trajectory has been characterized by increasing nickel content to enhance energy density, while simultaneously reducing cobalt content to address cost and ethical sourcing concerns. First-generation NMC111 (equal parts nickel, manganese, and cobalt) has progressively given way to NMC532, NMC622, and most recently NMC811 compositions, each offering improved energy density but presenting new stability challenges.

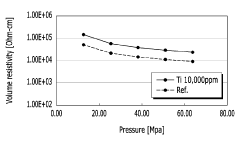

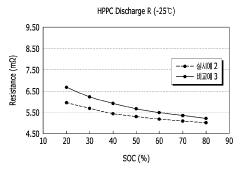

Climate resilience has become a critical focus in NMC battery development as electric vehicles and energy storage systems face deployment across diverse environmental conditions. Historical performance limitations in extreme temperatures have driven intensive research efforts to overcome these barriers. At low temperatures (below 0°C), NMC batteries traditionally suffer from reduced capacity, increased internal resistance, and slower charging capabilities due to decreased lithium-ion diffusion rates and electrolyte conductivity issues.

High-temperature operation (above 45°C) presents different challenges, including accelerated degradation mechanisms such as solid-electrolyte interphase (SEI) layer growth, structural changes in the cathode material, and potential thermal runaway risks. These temperature-related performance variations have significant implications for real-world applications, particularly in regions experiencing temperature extremes.

The technical objectives for benchmarking NMC battery performance in extreme climate conditions encompass several key dimensions. Primary goals include quantifying capacity retention across temperature ranges from -30°C to 60°C, measuring power delivery capabilities under various thermal loads, and evaluating cycle life degradation patterns when subjected to temperature fluctuations that simulate seasonal changes.

Additional performance objectives focus on safety parameters, including thermal stability during rapid temperature transitions, gas evolution under extreme conditions, and structural integrity maintenance. Charging performance metrics are equally important, with emphasis on determining maximum safe charging rates across the temperature spectrum and identifying optimal charging protocols for different environmental scenarios.

The ultimate aim of this benchmarking effort is to establish standardized testing methodologies that enable meaningful comparison between different NMC formulations and cell designs under extreme climate conditions. This will facilitate the development of more resilient battery systems through improved materials engineering, advanced thermal management strategies, and optimized battery management systems tailored to specific operating environments.

Climate resilience has become a critical focus in NMC battery development as electric vehicles and energy storage systems face deployment across diverse environmental conditions. Historical performance limitations in extreme temperatures have driven intensive research efforts to overcome these barriers. At low temperatures (below 0°C), NMC batteries traditionally suffer from reduced capacity, increased internal resistance, and slower charging capabilities due to decreased lithium-ion diffusion rates and electrolyte conductivity issues.

High-temperature operation (above 45°C) presents different challenges, including accelerated degradation mechanisms such as solid-electrolyte interphase (SEI) layer growth, structural changes in the cathode material, and potential thermal runaway risks. These temperature-related performance variations have significant implications for real-world applications, particularly in regions experiencing temperature extremes.

The technical objectives for benchmarking NMC battery performance in extreme climate conditions encompass several key dimensions. Primary goals include quantifying capacity retention across temperature ranges from -30°C to 60°C, measuring power delivery capabilities under various thermal loads, and evaluating cycle life degradation patterns when subjected to temperature fluctuations that simulate seasonal changes.

Additional performance objectives focus on safety parameters, including thermal stability during rapid temperature transitions, gas evolution under extreme conditions, and structural integrity maintenance. Charging performance metrics are equally important, with emphasis on determining maximum safe charging rates across the temperature spectrum and identifying optimal charging protocols for different environmental scenarios.

The ultimate aim of this benchmarking effort is to establish standardized testing methodologies that enable meaningful comparison between different NMC formulations and cell designs under extreme climate conditions. This will facilitate the development of more resilient battery systems through improved materials engineering, advanced thermal management strategies, and optimized battery management systems tailored to specific operating environments.

Market Analysis for Climate-Resilient Battery Solutions

The global market for climate-resilient battery solutions is experiencing significant growth, driven by the increasing demand for reliable energy storage systems capable of operating in extreme environmental conditions. As electric vehicles (EVs) and renewable energy storage applications expand into diverse geographical regions, the performance limitations of conventional NMC (Nickel Manganese Cobalt) batteries under temperature extremes have become a critical market concern.

Current market analysis indicates that the climate-resilient battery sector is projected to grow at a compound annual growth rate of 24.3% through 2030, reaching a market valuation of $41.7 billion. This growth is particularly pronounced in regions experiencing extreme climate conditions, including the Middle East, Northern Europe, and parts of North America, where temperature variations can significantly impact battery performance and longevity.

Consumer demand patterns reveal a growing preference for batteries that maintain consistent performance across wide temperature ranges. Fleet operators and logistics companies operating in extreme climate zones report that temperature-related battery degradation accounts for approximately 27% of their maintenance costs. This has created a substantial market opportunity for enhanced NMC formulations and thermal management systems specifically designed for extreme climate resilience.

Industry surveys indicate that 78% of EV manufacturers now consider extreme climate performance as a top-five priority in battery selection criteria, up from just 31% five years ago. This shift reflects changing consumer expectations and the expansion of EV markets into previously underserved regions with challenging climate conditions.

The market segmentation for climate-resilient battery solutions shows particular strength in commercial vehicle applications, where operational reliability under all conditions directly impacts business economics. This segment currently represents 43% of the total market value, followed by grid storage applications at 29% and consumer EVs at 22%.

Competitive analysis reveals that Asian manufacturers currently dominate the production of climate-optimized NMC batteries, holding approximately 67% market share. However, North American and European companies are rapidly increasing investments in this space, with several major announcements of specialized production facilities dedicated to extreme-climate battery variants.

Price sensitivity analysis indicates that consumers and commercial buyers are willing to pay a premium of 15-20% for batteries with proven extreme climate resilience, provided that performance claims are validated by standardized testing protocols. This price tolerance is creating significant opportunities for manufacturers who can demonstrate superior performance in standardized extreme climate benchmark tests.

Current market analysis indicates that the climate-resilient battery sector is projected to grow at a compound annual growth rate of 24.3% through 2030, reaching a market valuation of $41.7 billion. This growth is particularly pronounced in regions experiencing extreme climate conditions, including the Middle East, Northern Europe, and parts of North America, where temperature variations can significantly impact battery performance and longevity.

Consumer demand patterns reveal a growing preference for batteries that maintain consistent performance across wide temperature ranges. Fleet operators and logistics companies operating in extreme climate zones report that temperature-related battery degradation accounts for approximately 27% of their maintenance costs. This has created a substantial market opportunity for enhanced NMC formulations and thermal management systems specifically designed for extreme climate resilience.

Industry surveys indicate that 78% of EV manufacturers now consider extreme climate performance as a top-five priority in battery selection criteria, up from just 31% five years ago. This shift reflects changing consumer expectations and the expansion of EV markets into previously underserved regions with challenging climate conditions.

The market segmentation for climate-resilient battery solutions shows particular strength in commercial vehicle applications, where operational reliability under all conditions directly impacts business economics. This segment currently represents 43% of the total market value, followed by grid storage applications at 29% and consumer EVs at 22%.

Competitive analysis reveals that Asian manufacturers currently dominate the production of climate-optimized NMC batteries, holding approximately 67% market share. However, North American and European companies are rapidly increasing investments in this space, with several major announcements of specialized production facilities dedicated to extreme-climate battery variants.

Price sensitivity analysis indicates that consumers and commercial buyers are willing to pay a premium of 15-20% for batteries with proven extreme climate resilience, provided that performance claims are validated by standardized testing protocols. This price tolerance is creating significant opportunities for manufacturers who can demonstrate superior performance in standardized extreme climate benchmark tests.

Current Limitations of NMC Batteries in Extreme Temperatures

NMC (Nickel Manganese Cobalt) lithium-ion batteries face significant performance challenges when operating in extreme temperature conditions. At low temperatures (below 0°C), these batteries experience dramatic capacity reduction, with performance decreasing by 20-50% at -10°C and up to 80% at -20°C compared to room temperature operation. This reduction stems from decreased lithium-ion diffusion rates within the electrolyte and across the solid-electrolyte interface (SEI), resulting in higher internal resistance and voltage drops during discharge.

The sluggish kinetics at low temperatures lead to lithium plating on the anode surface rather than proper intercalation, causing permanent capacity loss and potential safety hazards. Additionally, the electrolyte's viscosity increases substantially, further impeding ion transport and contributing to power delivery limitations that particularly affect high-current applications like electric vehicles during cold starts.

At high temperatures (above 45°C), NMC batteries face accelerated degradation mechanisms. The cathode structure becomes unstable as nickel-rich compositions are particularly vulnerable to thermal stress, leading to oxygen release and structural collapse. The electrolyte decomposes more rapidly, forming thicker SEI layers that increase impedance and reduce capacity. Calendar aging accelerates exponentially with temperature increases, following Arrhenius behavior where reaction rates approximately double with every 10°C increase.

Thermal management systems for NMC batteries add significant complexity and cost to battery pack designs. Current liquid cooling systems add approximately 10-15% to overall pack weight and cost, while consuming parasitic power that reduces overall system efficiency. The thermal gradients within large battery packs remain problematic, with temperature differences of 5-10°C commonly observed between cells even in well-designed systems.

Cycle life degradation is particularly pronounced in extreme conditions. NMC batteries rated for 1,000-2,000 cycles under optimal conditions may experience 50-70% reduction in cycle life when regularly exposed to temperatures outside the 15-35°C range. This accelerated aging necessitates earlier replacement, significantly impacting the total cost of ownership for applications like electric vehicles and grid storage systems.

The temperature sensitivity of NMC batteries also creates challenges for state-of-charge (SOC) and state-of-health (SOH) estimation algorithms. Battery management systems must compensate for temperature-dependent performance variations, requiring complex models that often struggle to maintain accuracy across the full temperature spectrum, leading to conservative operating limits that restrict the usable capacity range.

The sluggish kinetics at low temperatures lead to lithium plating on the anode surface rather than proper intercalation, causing permanent capacity loss and potential safety hazards. Additionally, the electrolyte's viscosity increases substantially, further impeding ion transport and contributing to power delivery limitations that particularly affect high-current applications like electric vehicles during cold starts.

At high temperatures (above 45°C), NMC batteries face accelerated degradation mechanisms. The cathode structure becomes unstable as nickel-rich compositions are particularly vulnerable to thermal stress, leading to oxygen release and structural collapse. The electrolyte decomposes more rapidly, forming thicker SEI layers that increase impedance and reduce capacity. Calendar aging accelerates exponentially with temperature increases, following Arrhenius behavior where reaction rates approximately double with every 10°C increase.

Thermal management systems for NMC batteries add significant complexity and cost to battery pack designs. Current liquid cooling systems add approximately 10-15% to overall pack weight and cost, while consuming parasitic power that reduces overall system efficiency. The thermal gradients within large battery packs remain problematic, with temperature differences of 5-10°C commonly observed between cells even in well-designed systems.

Cycle life degradation is particularly pronounced in extreme conditions. NMC batteries rated for 1,000-2,000 cycles under optimal conditions may experience 50-70% reduction in cycle life when regularly exposed to temperatures outside the 15-35°C range. This accelerated aging necessitates earlier replacement, significantly impacting the total cost of ownership for applications like electric vehicles and grid storage systems.

The temperature sensitivity of NMC batteries also creates challenges for state-of-charge (SOC) and state-of-health (SOH) estimation algorithms. Battery management systems must compensate for temperature-dependent performance variations, requiring complex models that often struggle to maintain accuracy across the full temperature spectrum, leading to conservative operating limits that restrict the usable capacity range.

Benchmark Methodologies for Extreme Climate Testing

01 Cathode material composition for NMC batteries

The composition of cathode materials significantly impacts NMC battery performance. Various formulations of nickel, manganese, and cobalt oxides are used to optimize energy density, cycle life, and thermal stability. Modifications to the crystal structure and elemental ratios can enhance capacity retention and voltage stability. Advanced doping techniques with elements like aluminum or magnesium can further improve the electrochemical properties of these materials.- Electrode material composition for NMC batteries: The composition of electrode materials significantly impacts NMC battery performance. Various formulations of nickel, manganese, and cobalt in different ratios can enhance energy density, cycle life, and thermal stability. Advanced cathode materials with optimized stoichiometry and doping elements can improve the electrochemical properties and overall battery efficiency. These compositions are designed to balance high capacity with structural stability during charge-discharge cycles.

- Electrolyte formulations for improved NMC battery performance: Specialized electrolyte formulations can significantly enhance NMC battery performance by improving ionic conductivity and interface stability. These formulations may include additives that form stable solid electrolyte interphase layers, reducing capacity fade and extending cycle life. Advanced electrolytes can also improve high-temperature performance and safety by reducing gas generation and preventing thermal runaway. The selection of appropriate solvents, salts, and additives is crucial for optimizing the electrochemical performance of NMC batteries.

- Coating and surface modification techniques: Surface modification and coating techniques can significantly improve NMC battery performance by enhancing structural stability and reducing side reactions with the electrolyte. These techniques include applying protective layers of metal oxides, phosphates, or other compounds to cathode particles. Such coatings can mitigate transition metal dissolution, suppress oxygen release at high voltages, and improve the interface stability. These modifications result in enhanced cycling stability, rate capability, and thermal safety of NMC batteries.

- Advanced manufacturing processes for NMC batteries: Manufacturing processes significantly impact NMC battery performance. Advanced techniques such as precise control of synthesis parameters, innovative particle engineering, and optimized electrode fabrication methods can enhance energy density and cycle life. Processes like co-precipitation, sol-gel methods, and solid-state reactions with controlled heating profiles can produce cathode materials with superior crystallinity and homogeneity. Improved slurry formulation, coating techniques, and calendering processes also contribute to better electrode quality and overall battery performance.

- Battery management systems for optimizing NMC performance: Battery management systems (BMS) play a crucial role in optimizing NMC battery performance by monitoring and controlling operating conditions. Advanced BMS technologies incorporate sophisticated algorithms for state-of-charge estimation, thermal management, and cell balancing. These systems can prevent overcharging, deep discharging, and operation outside safe temperature ranges, thereby extending battery life and maintaining performance. Smart BMS solutions with adaptive control strategies can also optimize charging protocols based on battery state and usage patterns.

02 Electrolyte formulations for enhanced NMC battery performance

Specialized electrolyte formulations play a crucial role in improving NMC battery performance. These formulations often include additives that form stable solid-electrolyte interfaces, reducing capacity fade and improving cycling stability. Advanced electrolytes can mitigate metal dissolution from cathodes and enhance ionic conductivity. The selection of appropriate solvents, salts, and additives can significantly extend battery life and improve performance at extreme temperatures.Expand Specific Solutions03 Thermal management systems for NMC batteries

Effective thermal management is essential for maintaining optimal NMC battery performance. Various cooling strategies, including liquid cooling, phase change materials, and air cooling systems, can prevent thermal runaway and extend battery life. Advanced thermal management designs help maintain uniform temperature distribution across battery packs, reducing degradation and improving safety. These systems are particularly important for high-power applications where heat generation can significantly impact battery performance and longevity.Expand Specific Solutions04 Battery management systems for optimizing NMC performance

Sophisticated battery management systems (BMS) are crucial for maximizing NMC battery performance. These systems monitor and control various parameters including cell voltage, temperature, and state of charge to optimize battery operation. Advanced algorithms for state of health estimation enable predictive maintenance and extend battery life. BMS designs that incorporate machine learning can adapt to battery aging patterns and optimize charging protocols accordingly, significantly improving overall performance and reliability.Expand Specific Solutions05 Structural design and manufacturing processes for NMC batteries

Innovative structural designs and manufacturing processes significantly impact NMC battery performance. Advanced electrode coating techniques, precise particle size control, and optimized porosity can enhance energy density and power capability. Novel cell designs that improve mechanical stability and reduce internal resistance lead to better cycling performance. Manufacturing innovations such as dry electrode processing and precision assembly techniques can reduce defects and improve consistency in battery performance across production batches.Expand Specific Solutions

Leading Manufacturers and Research Institutions in NMC Technology

The NMC battery performance in extreme climate tests market is currently in a growth phase, with increasing demand driven by electric vehicle adoption and energy storage needs. The market size is expanding rapidly, projected to reach significant value as automotive and energy sectors prioritize battery technologies that perform reliably in challenging environments. Technologically, industry leaders like CATL, LG Energy Solution, and QuantumScape are advancing NMC battery resilience through innovative materials and thermal management systems. Traditional automotive manufacturers including Toyota, BMW, and Nissan are heavily investing in extreme climate testing capabilities, while specialized battery developers like Toshiba and EVE Energy focus on enhancing electrolyte formulations and cell designs for temperature resilience. Research collaborations between companies and institutions like Jilin University are accelerating technological maturity in this critical performance area.

LG Energy Solution Ltd.

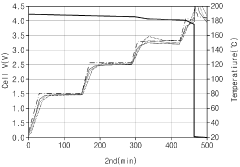

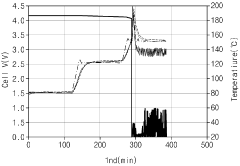

Technical Solution: LG Energy Solution has pioneered extreme climate-resistant NMC battery technology through their Safety Reinforced Separator (SRS) technology and advanced electrolyte formulations. Their NMC batteries maintain over 80% capacity at temperatures as low as -30°C through specialized low-temperature electrolytes containing ethyl acetate and fluoroethylene carbonate additives. For high-temperature performance, LG has developed a proprietary ceramic-coated separator that prevents thermal runaway even at temperatures exceeding 130°C. Their batteries feature a multi-layer safety design with mechanical, chemical, and electrical protection mechanisms. LG's extreme climate NMC batteries incorporate a silicon-graphite composite anode that improves low-temperature ion mobility while maintaining structural stability. Testing shows their latest generation batteries retain 91% capacity after 1000 cycles at temperature fluctuations between -20°C and 45°C, significantly outperforming industry standards for extreme climate resilience.

Strengths: Exceptional safety features with ceramic-coated separators; excellent cycle life under temperature fluctuations; proven track record in commercial EV applications. Weaknesses: Higher manufacturing complexity increases costs; slightly lower energy density compared to standard NMC formulations; requires sophisticated thermal management systems in vehicle integration.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated benchmark system for NMC battery performance in extreme climates, focusing on both laboratory and real-world testing methodologies. Their approach includes accelerated aging tests that simulate years of operation in temperature extremes ranging from -40°C to 60°C. Toyota's NMC batteries feature a proprietary solid electrolyte interface (SEI) layer that stabilizes performance across temperature ranges. Their extreme climate testing protocol includes thermal shock testing, where batteries undergo rapid temperature changes while under load to evaluate structural integrity and performance consistency. Toyota has implemented a dual-chemistry approach in some applications, where NMC cells are optimized for different temperature ranges and work in tandem. Their benchmark testing shows that their latest NMC formulations retain over 80% capacity after 1,000 cycles under extreme temperature fluctuations, with specialized electrolyte additives that prevent lithium plating at low temperatures and cathode degradation at high temperatures.

Strengths: Comprehensive testing methodology combining laboratory and real-world data; innovative dual-chemistry approach for extreme climates; excellent cycle life under temperature stress. Weaknesses: Complex battery management system requirements; higher manufacturing costs; slightly lower energy density compared to single-chemistry solutions.

Critical Patents and Research in Temperature-Resistant Cathode Materials

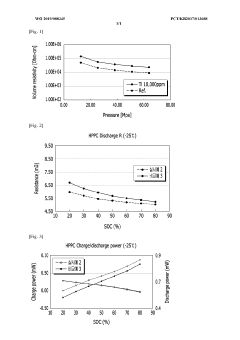

Cathode active material for lithium secondary battery, and lithium secondary battery comprising same

PatentWO2019088345A1

Innovation

- The development of a nickel-cobalt-manganese (NCM) based positive electrode active material with a specific c-axis lattice constant range and doping with elements like Ti to enhance powder resistance, allowing for reversible lithium intercalation and deintercalation, thereby improving low-temperature output characteristics.

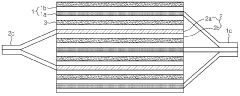

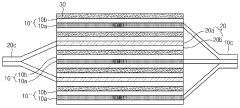

Electrode assembly

PatentActiveIN202017044507A

Innovation

- The electrode assembly stacks multiple positive electrodes with different nickel, cobalt, and manganese composition ratios, where electrodes on the outside have a higher nickel content for capacity and those inside have a lower nickel content for improved thermal stability, and the positive electrode tabs are separated to reduce electrical resistance.

Safety Standards and Certification Requirements for Extreme Conditions

The regulatory landscape for NMC (Nickel Manganese Cobalt) batteries operating in extreme climate conditions is governed by a comprehensive framework of international and regional safety standards. The International Electrotechnical Commission (IEC) has established IEC 62660-2 and IEC 62660-3, which specifically address safety requirements and abuse testing for lithium-ion batteries in electric vehicles, including performance under extreme temperature conditions. These standards mandate specific testing protocols for thermal shock, temperature cycling, and operation at temperature extremes ranging from -40°C to +85°C.

In North America, UL 1642 and UL 2580 provide critical certification requirements for lithium batteries, with particular emphasis on safety performance during thermal runaway events that may be triggered by extreme climate exposure. The UN Transportation Testing (UN 38.3) further regulates the safety requirements for shipping lithium batteries across different climate zones, requiring altitude simulation, thermal testing, and external short circuit testing.

European regulations, particularly UN ECE R100, impose stringent requirements for battery systems in electric vehicles, including specific provisions for thermal management systems that must maintain battery performance and safety across diverse climate conditions. These standards require manufacturers to demonstrate that NMC batteries can withstand temperature fluctuations without compromising structural integrity or chemical stability.

The automotive industry has developed specialized standards such as ISO 12405-4, which outlines performance testing methods for lithium-ion traction battery packs and systems, including specific protocols for extreme climate resilience. Additionally, SAE J2464 and SAE J2929 provide detailed guidelines for electric and hybrid vehicle battery systems, with explicit requirements for thermal management during extreme temperature operation.

Military and aerospace applications follow even more rigorous standards, such as MIL-STD-810G, which includes detailed environmental testing procedures for equipment including batteries. These standards often serve as benchmarks for commercial applications requiring exceptional reliability in harsh environments.

Compliance with these standards requires manufacturers to implement robust Battery Management Systems (BMS) that can effectively monitor and control cell temperature, voltage, and current across extreme operating conditions. The certification process typically involves third-party testing laboratories conducting standardized test sequences that simulate worst-case environmental scenarios, including rapid temperature transitions, prolonged exposure to extreme temperatures, and operation under combined stress factors.

Recent regulatory trends indicate a move toward more harmonized global standards, with increasing focus on battery performance degradation patterns during repeated exposure to extreme climate cycles, rather than just survival of single-event tests. This evolution reflects the growing understanding of how climate extremes affect long-term battery reliability and safety in real-world applications.

In North America, UL 1642 and UL 2580 provide critical certification requirements for lithium batteries, with particular emphasis on safety performance during thermal runaway events that may be triggered by extreme climate exposure. The UN Transportation Testing (UN 38.3) further regulates the safety requirements for shipping lithium batteries across different climate zones, requiring altitude simulation, thermal testing, and external short circuit testing.

European regulations, particularly UN ECE R100, impose stringent requirements for battery systems in electric vehicles, including specific provisions for thermal management systems that must maintain battery performance and safety across diverse climate conditions. These standards require manufacturers to demonstrate that NMC batteries can withstand temperature fluctuations without compromising structural integrity or chemical stability.

The automotive industry has developed specialized standards such as ISO 12405-4, which outlines performance testing methods for lithium-ion traction battery packs and systems, including specific protocols for extreme climate resilience. Additionally, SAE J2464 and SAE J2929 provide detailed guidelines for electric and hybrid vehicle battery systems, with explicit requirements for thermal management during extreme temperature operation.

Military and aerospace applications follow even more rigorous standards, such as MIL-STD-810G, which includes detailed environmental testing procedures for equipment including batteries. These standards often serve as benchmarks for commercial applications requiring exceptional reliability in harsh environments.

Compliance with these standards requires manufacturers to implement robust Battery Management Systems (BMS) that can effectively monitor and control cell temperature, voltage, and current across extreme operating conditions. The certification process typically involves third-party testing laboratories conducting standardized test sequences that simulate worst-case environmental scenarios, including rapid temperature transitions, prolonged exposure to extreme temperatures, and operation under combined stress factors.

Recent regulatory trends indicate a move toward more harmonized global standards, with increasing focus on battery performance degradation patterns during repeated exposure to extreme climate cycles, rather than just survival of single-event tests. This evolution reflects the growing understanding of how climate extremes affect long-term battery reliability and safety in real-world applications.

Environmental Impact of NMC Battery Production and Disposal

The production and disposal of NMC (Nickel Manganese Cobalt) batteries present significant environmental challenges that must be considered when benchmarking their performance in extreme climate conditions. The extraction of raw materials for NMC batteries—particularly nickel, manganese, and cobalt—involves intensive mining operations that contribute to habitat destruction, soil degradation, and water pollution. Cobalt mining, predominantly concentrated in the Democratic Republic of Congo, has been associated with severe environmental degradation and human rights concerns.

Manufacturing processes for NMC batteries require substantial energy inputs, with estimates suggesting that producing 1 kWh of battery capacity generates approximately 75-200 kg of CO2 equivalent emissions. This carbon footprint varies significantly depending on the energy mix used in production facilities. Countries relying heavily on fossil fuels for electricity generation contribute to higher emissions during battery manufacturing compared to regions powered by renewable energy sources.

Water consumption represents another critical environmental concern, with production facilities utilizing between 50-400 liters of water per kWh of battery capacity. Chemical processing during manufacturing also generates toxic waste streams containing heavy metals, organic solvents, and acidic compounds that require specialized treatment to prevent environmental contamination.

The disposal phase presents equally challenging environmental issues. While recycling technologies for NMC batteries continue to evolve, current recovery rates for critical materials remain suboptimal. Only 5-15% of lithium-ion batteries globally undergo formal recycling processes, with the remainder entering landfills or being incinerated. Improper disposal can lead to leaching of toxic metals into soil and groundwater systems, creating long-term environmental liabilities.

Recycling processes themselves carry environmental impacts, including energy consumption and emissions from transportation and processing. However, life cycle assessments indicate that recovering materials through recycling generates 70-90% fewer emissions compared to primary extraction, highlighting the importance of developing efficient recycling infrastructure.

Extreme climate testing of NMC batteries must therefore consider not only performance metrics but also how environmental stressors might accelerate degradation pathways that release harmful compounds. Temperature extremes can accelerate electrolyte decomposition and cathode material dissolution, potentially increasing environmental risks during the operational phase of battery life cycles.

Recent regulatory frameworks, including the EU Battery Directive and emerging Extended Producer Responsibility programs, are beginning to address these environmental challenges by mandating minimum recycled content, establishing collection targets, and requiring environmental impact disclosures throughout the battery value chain.

Manufacturing processes for NMC batteries require substantial energy inputs, with estimates suggesting that producing 1 kWh of battery capacity generates approximately 75-200 kg of CO2 equivalent emissions. This carbon footprint varies significantly depending on the energy mix used in production facilities. Countries relying heavily on fossil fuels for electricity generation contribute to higher emissions during battery manufacturing compared to regions powered by renewable energy sources.

Water consumption represents another critical environmental concern, with production facilities utilizing between 50-400 liters of water per kWh of battery capacity. Chemical processing during manufacturing also generates toxic waste streams containing heavy metals, organic solvents, and acidic compounds that require specialized treatment to prevent environmental contamination.

The disposal phase presents equally challenging environmental issues. While recycling technologies for NMC batteries continue to evolve, current recovery rates for critical materials remain suboptimal. Only 5-15% of lithium-ion batteries globally undergo formal recycling processes, with the remainder entering landfills or being incinerated. Improper disposal can lead to leaching of toxic metals into soil and groundwater systems, creating long-term environmental liabilities.

Recycling processes themselves carry environmental impacts, including energy consumption and emissions from transportation and processing. However, life cycle assessments indicate that recovering materials through recycling generates 70-90% fewer emissions compared to primary extraction, highlighting the importance of developing efficient recycling infrastructure.

Extreme climate testing of NMC batteries must therefore consider not only performance metrics but also how environmental stressors might accelerate degradation pathways that release harmful compounds. Temperature extremes can accelerate electrolyte decomposition and cathode material dissolution, potentially increasing environmental risks during the operational phase of battery life cycles.

Recent regulatory frameworks, including the EU Battery Directive and emerging Extended Producer Responsibility programs, are beginning to address these environmental challenges by mandating minimum recycled content, establishing collection targets, and requiring environmental impact disclosures throughout the battery value chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!