Benchmarking GDI Engine Material Wear: Case Studies

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Material Wear Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing the automotive industry with its improved fuel efficiency and reduced emissions. The technology first emerged in the late 1990s but gained substantial market penetration in the 2010s as manufacturers sought to meet increasingly stringent emissions regulations while maintaining performance standards. GDI engines inject fuel directly into the combustion chamber at high pressure, allowing for more precise fuel delivery and combustion control compared to traditional port fuel injection systems.

Material wear in GDI engines represents a critical challenge that impacts engine longevity, performance, and emissions compliance. The high-pressure fuel delivery system, operating at pressures exceeding 200 bar, creates unique wear conditions on injectors, valves, cylinder walls, and piston rings. Additionally, the direct injection process can lead to increased carbon deposits on intake valves due to the absence of fuel washing effect present in port injection systems.

The evolution of GDI technology has been marked by progressive improvements in materials science, with manufacturers exploring various coating technologies and alloy compositions to mitigate wear issues. Early GDI systems suffered from accelerated injector fouling and premature component degradation, problems that have been partially addressed through material innovations but remain significant concerns for long-term durability.

This technical research aims to establish standardized benchmarking methodologies for evaluating material wear in GDI engines across different operational conditions and manufacturer designs. The primary objectives include quantifying wear rates for critical engine components, identifying key wear mechanisms specific to GDI operation, and correlating material properties with wear resistance performance under various driving cycles.

The research will focus on comparative case studies of production GDI engines from major manufacturers, examining both in-service wear patterns and accelerated testing results. By analyzing these patterns across different engine designs and operational parameters, we seek to develop predictive models for material degradation that can inform future material selection and component design.

Furthermore, this study aims to establish correlations between material wear and other engine performance metrics, including fuel economy, emissions profiles, and power output degradation over time. Understanding these relationships will provide valuable insights for balancing durability requirements with performance objectives in next-generation GDI engine development.

The ultimate goal is to create a comprehensive framework for evaluating and predicting GDI engine material wear that can guide material selection, design optimization, and maintenance scheduling across the automotive industry, thereby extending engine service life while maintaining optimal performance and emissions compliance throughout the vehicle lifecycle.

Material wear in GDI engines represents a critical challenge that impacts engine longevity, performance, and emissions compliance. The high-pressure fuel delivery system, operating at pressures exceeding 200 bar, creates unique wear conditions on injectors, valves, cylinder walls, and piston rings. Additionally, the direct injection process can lead to increased carbon deposits on intake valves due to the absence of fuel washing effect present in port injection systems.

The evolution of GDI technology has been marked by progressive improvements in materials science, with manufacturers exploring various coating technologies and alloy compositions to mitigate wear issues. Early GDI systems suffered from accelerated injector fouling and premature component degradation, problems that have been partially addressed through material innovations but remain significant concerns for long-term durability.

This technical research aims to establish standardized benchmarking methodologies for evaluating material wear in GDI engines across different operational conditions and manufacturer designs. The primary objectives include quantifying wear rates for critical engine components, identifying key wear mechanisms specific to GDI operation, and correlating material properties with wear resistance performance under various driving cycles.

The research will focus on comparative case studies of production GDI engines from major manufacturers, examining both in-service wear patterns and accelerated testing results. By analyzing these patterns across different engine designs and operational parameters, we seek to develop predictive models for material degradation that can inform future material selection and component design.

Furthermore, this study aims to establish correlations between material wear and other engine performance metrics, including fuel economy, emissions profiles, and power output degradation over time. Understanding these relationships will provide valuable insights for balancing durability requirements with performance objectives in next-generation GDI engine development.

The ultimate goal is to create a comprehensive framework for evaluating and predicting GDI engine material wear that can guide material selection, design optimization, and maintenance scheduling across the automotive industry, thereby extending engine service life while maintaining optimal performance and emissions compliance throughout the vehicle lifecycle.

Market Demand Analysis for Durable GDI Engine Components

The global market for durable GDI (Gasoline Direct Injection) engine components has experienced significant growth over the past decade, driven primarily by stringent emission regulations and the automotive industry's push for improved fuel efficiency. Current market analysis indicates that the GDI engine component market is valued at approximately $4.2 billion as of 2023, with projections suggesting a compound annual growth rate of 6.8% through 2028.

Consumer demand for vehicles with enhanced performance and fuel economy continues to drive adoption of GDI technology across various vehicle segments. This trend is particularly evident in regions with strict emission standards such as Europe, North America, and increasingly in Asia-Pacific markets. The implementation of Euro 7, China 7, and similar regulatory frameworks worldwide is accelerating the transition toward more durable and efficient engine components.

Material wear in GDI engines represents a critical concern for manufacturers, with studies indicating that premature component degradation can reduce engine efficiency by up to 15% and increase maintenance costs by 20-30% over vehicle lifetime. This has created a substantial market opportunity for advanced materials and surface treatments that can withstand the harsh operating conditions of GDI systems.

The aftermarket segment for GDI components is experiencing rapid expansion, with replacement parts for injectors, pumps, and valves showing annual growth rates of 8-10%. This growth is attributed to the aging fleet of first-generation GDI vehicles now requiring maintenance and component replacement. Industry surveys reveal that fleet operators and vehicle owners are increasingly willing to pay premium prices for components with demonstrated durability advantages.

Regional market analysis shows varying demand patterns, with mature markets focusing on premium materials with extended service intervals, while emerging markets prioritize cost-effective solutions that balance durability with affordability. North America and Europe currently account for 62% of the global market share for high-durability GDI components, though Asia-Pacific markets are expected to show the highest growth rates in the coming years.

Material innovation represents a key differentiator in this competitive landscape. Components utilizing advanced ceramics, diamond-like carbon coatings, and specialized metal alloys command price premiums of 30-45% compared to standard components, yet demonstrate total cost of ownership advantages through extended service life and reduced maintenance requirements.

Market research indicates that OEMs are increasingly incorporating material wear performance as a key specification in supplier selection processes, with 78% of procurement managers citing durability as a "very important" or "critical" factor in component sourcing decisions. This represents a significant shift from previous procurement practices that primarily emphasized initial component cost.

Consumer demand for vehicles with enhanced performance and fuel economy continues to drive adoption of GDI technology across various vehicle segments. This trend is particularly evident in regions with strict emission standards such as Europe, North America, and increasingly in Asia-Pacific markets. The implementation of Euro 7, China 7, and similar regulatory frameworks worldwide is accelerating the transition toward more durable and efficient engine components.

Material wear in GDI engines represents a critical concern for manufacturers, with studies indicating that premature component degradation can reduce engine efficiency by up to 15% and increase maintenance costs by 20-30% over vehicle lifetime. This has created a substantial market opportunity for advanced materials and surface treatments that can withstand the harsh operating conditions of GDI systems.

The aftermarket segment for GDI components is experiencing rapid expansion, with replacement parts for injectors, pumps, and valves showing annual growth rates of 8-10%. This growth is attributed to the aging fleet of first-generation GDI vehicles now requiring maintenance and component replacement. Industry surveys reveal that fleet operators and vehicle owners are increasingly willing to pay premium prices for components with demonstrated durability advantages.

Regional market analysis shows varying demand patterns, with mature markets focusing on premium materials with extended service intervals, while emerging markets prioritize cost-effective solutions that balance durability with affordability. North America and Europe currently account for 62% of the global market share for high-durability GDI components, though Asia-Pacific markets are expected to show the highest growth rates in the coming years.

Material innovation represents a key differentiator in this competitive landscape. Components utilizing advanced ceramics, diamond-like carbon coatings, and specialized metal alloys command price premiums of 30-45% compared to standard components, yet demonstrate total cost of ownership advantages through extended service life and reduced maintenance requirements.

Market research indicates that OEMs are increasingly incorporating material wear performance as a key specification in supplier selection processes, with 78% of procurement managers citing durability as a "very important" or "critical" factor in component sourcing decisions. This represents a significant shift from previous procurement practices that primarily emphasized initial component cost.

Current Challenges in GDI Engine Material Durability

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, material durability remains a critical challenge that impacts performance, efficiency, and longevity. The high-pressure fuel injection system in GDI engines creates an operating environment that is particularly harsh on component materials. Current research indicates that injector tips experience temperatures exceeding 200°C during operation, while being subjected to pressures up to 350 bar, creating conditions conducive to accelerated wear and corrosion.

One of the primary durability challenges is carbon deposit formation on injector nozzles. These deposits alter spray patterns and reduce atomization efficiency, leading to incomplete combustion and increased emissions. Studies from major automotive research centers have documented up to 25% reduction in flow rates after just 10,000 miles of operation in severe cases, significantly impacting engine performance and fuel economy.

Material compatibility issues represent another significant challenge. The ethanol content in modern fuels (E10, E15, and higher blends) creates corrosive conditions that traditional materials struggle to withstand. Recent metallurgical analyses have identified accelerated degradation of certain stainless steel variants and aluminum alloys commonly used in fuel system components when exposed to these fuel blends under GDI operating conditions.

Thermal cycling effects pose substantial durability concerns as well. The rapid temperature fluctuations experienced by GDI components—from ambient to over 200°C during a typical drive cycle—induce thermal stress that can lead to material fatigue and eventual failure. This is particularly problematic for components with dissimilar materials joined together, where different thermal expansion coefficients create additional stress at interface points.

Cavitation erosion presents a persistent challenge in high-pressure fuel systems. The collapse of vapor bubbles formed during the injection process creates localized high-pressure impacts on material surfaces. Recent microscopic examinations of failed injectors reveal distinctive erosion patterns consistent with cavitation damage, particularly in areas where flow geometry creates pressure differentials.

Particulate contamination effects have been increasingly recognized as fuel quality varies globally. Even microscopic particulates can accelerate three-body abrasive wear in precision components with clearances measured in microns. Benchmark testing indicates that injectors operating in markets with less stringent fuel standards show up to 40% faster wear rates compared to those in regions with premium fuel quality.

Advanced coating technologies offer promising solutions but face their own durability challenges. Diamond-like carbon (DLC) coatings have demonstrated excellent wear resistance in laboratory testing but show inconsistent performance in real-world applications due to adhesion issues and thermal degradation over time. The cost-benefit analysis of implementing such advanced materials remains a significant consideration for mass-market applications.

One of the primary durability challenges is carbon deposit formation on injector nozzles. These deposits alter spray patterns and reduce atomization efficiency, leading to incomplete combustion and increased emissions. Studies from major automotive research centers have documented up to 25% reduction in flow rates after just 10,000 miles of operation in severe cases, significantly impacting engine performance and fuel economy.

Material compatibility issues represent another significant challenge. The ethanol content in modern fuels (E10, E15, and higher blends) creates corrosive conditions that traditional materials struggle to withstand. Recent metallurgical analyses have identified accelerated degradation of certain stainless steel variants and aluminum alloys commonly used in fuel system components when exposed to these fuel blends under GDI operating conditions.

Thermal cycling effects pose substantial durability concerns as well. The rapid temperature fluctuations experienced by GDI components—from ambient to over 200°C during a typical drive cycle—induce thermal stress that can lead to material fatigue and eventual failure. This is particularly problematic for components with dissimilar materials joined together, where different thermal expansion coefficients create additional stress at interface points.

Cavitation erosion presents a persistent challenge in high-pressure fuel systems. The collapse of vapor bubbles formed during the injection process creates localized high-pressure impacts on material surfaces. Recent microscopic examinations of failed injectors reveal distinctive erosion patterns consistent with cavitation damage, particularly in areas where flow geometry creates pressure differentials.

Particulate contamination effects have been increasingly recognized as fuel quality varies globally. Even microscopic particulates can accelerate three-body abrasive wear in precision components with clearances measured in microns. Benchmark testing indicates that injectors operating in markets with less stringent fuel standards show up to 40% faster wear rates compared to those in regions with premium fuel quality.

Advanced coating technologies offer promising solutions but face their own durability challenges. Diamond-like carbon (DLC) coatings have demonstrated excellent wear resistance in laboratory testing but show inconsistent performance in real-world applications due to adhesion issues and thermal degradation over time. The cost-benefit analysis of implementing such advanced materials remains a significant consideration for mass-market applications.

Current Methodologies for GDI Material Wear Testing

01 Coating technologies for GDI engine components

Various coating technologies are employed to enhance the wear resistance of gasoline direct injection (GDI) engine components. These coatings include thermal spray coatings, PVD/CVD coatings, and specialized surface treatments that create protective layers on critical engine parts such as injectors, pistons, and cylinder walls. These coatings significantly reduce friction and wear in high-pressure, high-temperature GDI environments, extending component lifespan and maintaining engine efficiency.- Coating technologies for GDI engine components: Various coating technologies are employed to enhance the wear resistance of GDI engine components. These include thermal spray coatings, PVD/CVD coatings, and specialized surface treatments that create protective layers on critical engine parts such as injectors, pistons, and cylinder walls. These coatings significantly reduce friction and wear in high-pressure direct injection environments, extending component lifespan and maintaining engine efficiency over time.

- Advanced materials for GDI engine components: Innovative materials are being developed specifically for GDI engine applications to withstand the harsh operating conditions. These include high-strength alloys, ceramic composites, and specialized steel formulations with enhanced hardness and temperature resistance. These materials are particularly important for components like fuel injectors, valves, and cylinder liners that experience significant wear due to the high-pressure fuel injection process characteristic of GDI engines.

- Wear monitoring and detection systems: Advanced monitoring systems have been developed to detect and analyze wear patterns in GDI engines. These systems utilize various sensing technologies, including optical methods, vibration analysis, and real-time lubricant condition monitoring to identify early signs of component degradation. Early detection allows for preventive maintenance before catastrophic failure occurs, reducing downtime and repair costs while extending overall engine life.

- Fuel and lubricant formulations to reduce wear: Specialized fuel additives and lubricant formulations have been developed to minimize wear in GDI engines. These formulations include detergents that prevent deposit formation on injectors, anti-wear additives that form protective films on metal surfaces, and friction modifiers that reduce component-to-component wear. The proper selection and formulation of these fluids can significantly extend the service life of GDI engine components by reducing friction and preventing deposit-related wear issues.

- Design modifications to reduce material wear: Innovative design approaches are being implemented to address wear issues in GDI engines. These include optimized component geometries, improved fuel spray patterns, and enhanced cooling systems that reduce thermal stress. Design modifications focus on critical areas such as injector tips, valve seats, and piston rings where wear is most prevalent. By redistributing mechanical loads and improving thermal management, these design innovations significantly extend component life and maintain engine performance.

02 Advanced materials for GDI engine components

Specialized materials are developed specifically to withstand the harsh operating conditions in GDI engines. These include high-strength alloys, ceramic composites, and engineered metal matrices that offer superior wear resistance. The materials are designed to maintain structural integrity under high combustion pressures and temperatures while resisting corrosion from fuel contaminants. Implementation of these advanced materials in critical components like valve seats, cylinder liners, and piston rings significantly reduces material degradation and wear.Expand Specific Solutions03 Fuel quality and additive solutions for wear reduction

Fuel quality and specialized additives play a crucial role in mitigating wear in GDI engines. Detergent additives help prevent deposit formation on injectors and valves, while lubricity enhancers reduce friction between moving parts. Anti-corrosion additives protect metal surfaces from chemical attack. These solutions address the unique challenges of direct fuel injection systems where fuel quality directly impacts component longevity and performance maintenance.Expand Specific Solutions04 Diagnostic and monitoring systems for wear detection

Advanced diagnostic and monitoring systems are developed to detect and analyze wear patterns in GDI engines before catastrophic failure occurs. These systems utilize sensors, optical inspection methods, and data analysis algorithms to monitor engine parameters and material conditions in real-time. Early detection of abnormal wear patterns allows for preventive maintenance, reducing downtime and repair costs while extending overall engine lifespan.Expand Specific Solutions05 Design optimizations to reduce mechanical stress

Innovative design approaches focus on optimizing GDI engine component geometries to minimize mechanical stress and wear. These include redesigned injector nozzles with improved spray patterns, modified piston crown shapes, and optimized combustion chamber configurations. By redistributing mechanical loads and improving thermal management, these design innovations reduce localized wear points and extend component service life while maintaining or improving engine performance and efficiency.Expand Specific Solutions

Key Industry Players in GDI Engine Manufacturing

The GDI Engine Material Wear benchmarking landscape is currently in a growth phase, with the market expanding as automotive and industrial sectors seek more efficient engine solutions. The global market size for wear-resistant materials in GDI engines is projected to increase significantly due to stringent emission regulations and fuel efficiency demands. Technologically, the field shows varying maturity levels across different applications. Leading companies like DuPont de Nemours and Chevron Oronite are advancing proprietary coating technologies, while Robert Bosch and Hyundai Motor focus on system integration. Academic institutions including Tsinghua University and Wuhan University of Technology are contributing fundamental research, creating a competitive ecosystem where industrial-academic partnerships drive innovation in material science and tribological applications.

Chevron Oronite Co. LLC

Technical Solution: Chevron Oronite has established comprehensive benchmarking protocols for GDI engine material wear through their Fuel System Durability Program. Their methodology integrates standardized industry tests with proprietary evaluation techniques specifically designed for GDI systems. Chevron employs specialized test engines instrumented with in-situ wear monitoring capabilities, including real-time particulate analysis and injector flow characterization. Their approach emphasizes the correlation between fuel composition, combustion dynamics, and material degradation pathways. Chevron has developed advanced fuel additive technologies that form protective molecular films on metal surfaces exposed to GDI operating conditions, effectively reducing micro-welding and abrasive wear mechanisms. Their case studies have documented the performance of various material combinations under different fuel formulations, establishing a comprehensive database of compatibility metrics. Chevron's research has demonstrated that properly formulated fuel additives can extend GDI injector service life by up to 25% through reduced deposit formation and improved boundary lubrication during critical injection events.

Strengths: Extensive fuel chemistry expertise applied to material wear challenges; global testing capabilities across diverse operating conditions; strong correlation methodologies between laboratory and field performance. Weaknesses: Solutions primarily focused on fuel-side interventions rather than base material improvements; some testing protocols optimized for conventional engine architectures adapted to GDI.

The Lubrizol Corp.

Technical Solution: Lubrizol has developed specialized benchmarking methodologies for evaluating GDI engine material wear through their Advanced Materials Testing program. Their approach focuses on the interaction between fuel additives, lubricants, and engine materials under GDI-specific conditions. Lubrizol employs custom-designed tribological test apparatus that simulates the unique conditions of GDI operation, including high-pressure fuel impingement, elevated temperatures, and varying fuel compositions. Their testing protocols incorporate both standardized ASTM methods and proprietary techniques that capture GDI-specific wear mechanisms. Lubrizol has pioneered the development of fuel additives specifically designed to mitigate GDI injector deposits and related wear issues, with formulations that maintain surface cleanliness while providing boundary lubrication during critical operating conditions. Their case studies have demonstrated up to 30% reduction in injector deposit formation and associated wear through optimized additive packages, with corresponding improvements in emissions performance and fuel economy over extended vehicle operation.

Strengths: Unparalleled expertise in fuel and lubricant chemistry effects on material wear; extensive laboratory infrastructure for controlled testing; ability to develop customized solutions for specific material combinations. Weaknesses: Primary focus on chemical solutions rather than base material development; testing sometimes emphasizes deposit formation over mechanical wear mechanisms.

Critical Analysis of Benchmark Case Studies

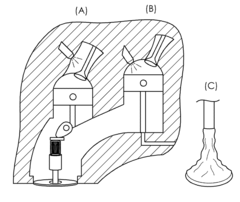

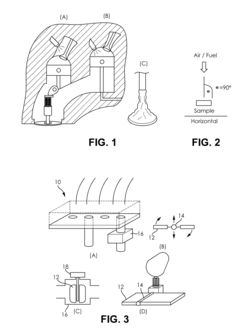

Evaluation of the delivery and effectiveness of engine performance chemicals and products

PatentActiveUS20170114716A1

Innovation

- A method and system for evaluating the delivery and effectiveness of engine performance chemicals and products for reducing intake valve deposits, utilizing a controlled environment with simulated engine conditions to quantify improvements, including adjustable parameters like air-fuel ratio, temperature, and oscillation frequency, and employing three approaches to introduce cleaners: airstream addition, suction-based distribution, and fuel additive application.

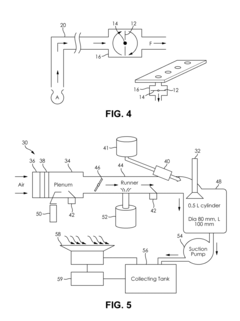

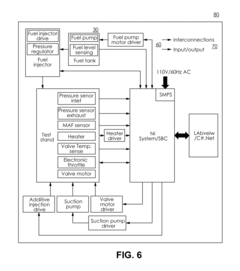

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Environmental Impact of GDI Engine Materials

The environmental implications of materials used in Gasoline Direct Injection (GDI) engines represent a critical dimension of automotive sustainability. GDI engine components, particularly those subject to wear testing in benchmarking studies, contain various metals and alloys that pose significant environmental concerns throughout their lifecycle.

Material extraction processes for GDI engine components contribute substantially to environmental degradation. Mining operations for metals like chromium, nickel, and aluminum used in cylinder liners, pistons, and fuel injectors generate considerable carbon emissions while depleting finite natural resources. These extraction activities frequently result in habitat destruction, soil contamination, and water pollution in mining regions.

Manufacturing processes for specialized GDI engine materials involve energy-intensive procedures including precision machining, thermal treatments, and coating applications. These processes typically require substantial energy inputs, contributing to greenhouse gas emissions. Additionally, the application of specialized coatings often involves volatile organic compounds (VOCs) and other hazardous substances that may impact air quality and worker health.

Wear particles generated during GDI engine operation represent an emerging environmental concern. As benchmarking studies demonstrate, material wear produces microscopic particulates that can be released through exhaust emissions. These metallic nanoparticles may contain environmentally persistent elements that bioaccumulate in ecosystems. Recent research indicates these particles can travel significant distances from their source, potentially affecting air quality in areas far removed from roadways.

End-of-life considerations for GDI engine materials present both challenges and opportunities. While many metallic components are theoretically recyclable, the complex alloys and composite materials increasingly used to enhance wear resistance often complicate recycling processes. Separation technologies for these advanced materials remain underdeveloped, resulting in valuable resources being landfilled rather than reclaimed.

Emerging sustainable material alternatives show promise for reducing environmental impact. Silicon-based ceramics, carbon-fiber reinforced polymers, and bio-inspired surface treatments are being explored as replacements for traditional wear-resistant materials. These alternatives often require less energy-intensive manufacturing while offering comparable or superior performance characteristics in benchmarking wear tests.

Regulatory frameworks increasingly address the environmental dimensions of automotive materials. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are driving manufacturers to consider full lifecycle environmental impacts when selecting GDI engine materials. These regulations incentivize designs that facilitate material recovery and minimize hazardous substance content.

Material extraction processes for GDI engine components contribute substantially to environmental degradation. Mining operations for metals like chromium, nickel, and aluminum used in cylinder liners, pistons, and fuel injectors generate considerable carbon emissions while depleting finite natural resources. These extraction activities frequently result in habitat destruction, soil contamination, and water pollution in mining regions.

Manufacturing processes for specialized GDI engine materials involve energy-intensive procedures including precision machining, thermal treatments, and coating applications. These processes typically require substantial energy inputs, contributing to greenhouse gas emissions. Additionally, the application of specialized coatings often involves volatile organic compounds (VOCs) and other hazardous substances that may impact air quality and worker health.

Wear particles generated during GDI engine operation represent an emerging environmental concern. As benchmarking studies demonstrate, material wear produces microscopic particulates that can be released through exhaust emissions. These metallic nanoparticles may contain environmentally persistent elements that bioaccumulate in ecosystems. Recent research indicates these particles can travel significant distances from their source, potentially affecting air quality in areas far removed from roadways.

End-of-life considerations for GDI engine materials present both challenges and opportunities. While many metallic components are theoretically recyclable, the complex alloys and composite materials increasingly used to enhance wear resistance often complicate recycling processes. Separation technologies for these advanced materials remain underdeveloped, resulting in valuable resources being landfilled rather than reclaimed.

Emerging sustainable material alternatives show promise for reducing environmental impact. Silicon-based ceramics, carbon-fiber reinforced polymers, and bio-inspired surface treatments are being explored as replacements for traditional wear-resistant materials. These alternatives often require less energy-intensive manufacturing while offering comparable or superior performance characteristics in benchmarking wear tests.

Regulatory frameworks increasingly address the environmental dimensions of automotive materials. The European Union's End-of-Life Vehicle Directive and similar regulations worldwide are driving manufacturers to consider full lifecycle environmental impacts when selecting GDI engine materials. These regulations incentivize designs that facilitate material recovery and minimize hazardous substance content.

Standardization of GDI Wear Testing Protocols

The standardization of testing protocols for Gasoline Direct Injection (GDI) engine wear represents a critical advancement in automotive engineering research methodology. Current practices in evaluating material wear in GDI systems suffer from significant inconsistencies across laboratories, manufacturers, and research institutions, making comparative analysis challenging and often unreliable. These variations stem from differences in test parameters, environmental conditions, measurement techniques, and reporting standards.

To address these challenges, industry stakeholders have begun developing comprehensive standardized protocols that specify precise testing conditions. These protocols define critical parameters including fuel composition specifications (particularly sulfur content and aromatic compounds), injection pressure ranges (typically 200-350 bar), temperature profiles during testing cycles, and duration requirements for meaningful wear pattern development. Additionally, they establish standardized cleaning procedures to ensure accurate surface analysis before and after testing.

The emerging standards also emphasize the importance of consistent sample preparation techniques. This includes specifications for material surface finishing, pre-test conditioning requirements, and handling procedures that minimize contamination risks. Such standardization ensures that baseline material conditions remain comparable across different testing facilities and research groups.

Measurement methodologies constitute another crucial component of these protocols. Advanced techniques being standardized include profilometry parameters for surface roughness assessment, scanning electron microscopy (SEM) procedures for microstructural analysis, and energy-dispersive X-ray spectroscopy (EDS) for chemical composition evaluation. The protocols define specific measurement locations, sampling frequencies, and data processing algorithms to ensure consistency.

Data reporting frameworks represent the final element of standardization efforts. These frameworks establish uniform terminology, wear classification systems, and statistical analysis methods. They also define minimum reporting requirements including raw data preservation, uncertainty calculations, and calibration verification documentation. Such standardization facilitates meaningful cross-study comparisons and meta-analyses.

Several international organizations including SAE International, ASTM, and ISO are currently collaborating to formalize these protocols. Their efforts focus on creating testing standards that balance scientific rigor with practical implementation considerations. The development process incorporates feedback from automotive manufacturers, fuel suppliers, material scientists, and testing equipment providers to ensure broad applicability and adoption across the industry.

To address these challenges, industry stakeholders have begun developing comprehensive standardized protocols that specify precise testing conditions. These protocols define critical parameters including fuel composition specifications (particularly sulfur content and aromatic compounds), injection pressure ranges (typically 200-350 bar), temperature profiles during testing cycles, and duration requirements for meaningful wear pattern development. Additionally, they establish standardized cleaning procedures to ensure accurate surface analysis before and after testing.

The emerging standards also emphasize the importance of consistent sample preparation techniques. This includes specifications for material surface finishing, pre-test conditioning requirements, and handling procedures that minimize contamination risks. Such standardization ensures that baseline material conditions remain comparable across different testing facilities and research groups.

Measurement methodologies constitute another crucial component of these protocols. Advanced techniques being standardized include profilometry parameters for surface roughness assessment, scanning electron microscopy (SEM) procedures for microstructural analysis, and energy-dispersive X-ray spectroscopy (EDS) for chemical composition evaluation. The protocols define specific measurement locations, sampling frequencies, and data processing algorithms to ensure consistency.

Data reporting frameworks represent the final element of standardization efforts. These frameworks establish uniform terminology, wear classification systems, and statistical analysis methods. They also define minimum reporting requirements including raw data preservation, uncertainty calculations, and calibration verification documentation. Such standardization facilitates meaningful cross-study comparisons and meta-analyses.

Several international organizations including SAE International, ASTM, and ISO are currently collaborating to formalize these protocols. Their efforts focus on creating testing standards that balance scientific rigor with practical implementation considerations. The development process incorporates feedback from automotive manufacturers, fuel suppliers, material scientists, and testing equipment providers to ensure broad applicability and adoption across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!