Binder Jetting And Post-Processing Chains: Heat Treatment, HIP And Precision Machining

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting technology emerged in the early 1990s as one of the pioneering additive manufacturing (AM) processes, initially developed at the Massachusetts Institute of Technology. The technology has evolved significantly over three decades, transitioning from prototype production to functional part manufacturing. Early iterations focused primarily on creating visual models and prototypes with limited mechanical properties, utilizing primarily polymer-based binders with ceramic or metal powders.

The mid-2000s marked a significant evolution with the introduction of more robust binder systems and improved powder metallurgy techniques, enabling the production of parts with enhanced mechanical properties. This period saw the first commercial applications in industries such as aerospace and medical, though primarily for non-critical components due to remaining limitations in material density and structural integrity.

Recent technological advancements have propelled Binder Jetting into a mature manufacturing technology capable of producing complex geometries with increasingly reliable material properties. The integration of advanced computational modeling, precise droplet control systems, and sophisticated powder spreading mechanisms has dramatically improved dimensional accuracy and surface finish quality.

Current development focuses on expanding the material portfolio beyond traditional metals to include ceramics, composites, and multi-material capabilities. Significant research efforts are directed toward optimizing post-processing chains, particularly heat treatment protocols and Hot Isostatic Pressing (HIP) parameters, to achieve near-full density parts with properties comparable to traditionally manufactured components.

The primary technological objectives for Binder Jetting development include achieving consistent part density exceeding 99.5% across various geometries, reducing dimensional variability to less than 0.1% for critical features, and developing standardized post-processing protocols that can be reliably implemented across different material systems. Additionally, there is a strong focus on reducing the energy consumption of the entire manufacturing chain by at least 25% compared to current standards.

Future evolution trajectories point toward fully automated post-processing chains that integrate in-situ monitoring and adaptive control systems. These developments aim to eliminate manual intervention between process steps while ensuring consistent quality through real-time adjustments based on material behavior during sintering and other thermal treatments.

The technology roadmap also emphasizes developing hybrid approaches that combine Binder Jetting with precision machining techniques to achieve superior surface finishes and tight tolerances for critical features, potentially expanding applications into high-performance sectors such as aerospace turbine components and precision medical implants.

The mid-2000s marked a significant evolution with the introduction of more robust binder systems and improved powder metallurgy techniques, enabling the production of parts with enhanced mechanical properties. This period saw the first commercial applications in industries such as aerospace and medical, though primarily for non-critical components due to remaining limitations in material density and structural integrity.

Recent technological advancements have propelled Binder Jetting into a mature manufacturing technology capable of producing complex geometries with increasingly reliable material properties. The integration of advanced computational modeling, precise droplet control systems, and sophisticated powder spreading mechanisms has dramatically improved dimensional accuracy and surface finish quality.

Current development focuses on expanding the material portfolio beyond traditional metals to include ceramics, composites, and multi-material capabilities. Significant research efforts are directed toward optimizing post-processing chains, particularly heat treatment protocols and Hot Isostatic Pressing (HIP) parameters, to achieve near-full density parts with properties comparable to traditionally manufactured components.

The primary technological objectives for Binder Jetting development include achieving consistent part density exceeding 99.5% across various geometries, reducing dimensional variability to less than 0.1% for critical features, and developing standardized post-processing protocols that can be reliably implemented across different material systems. Additionally, there is a strong focus on reducing the energy consumption of the entire manufacturing chain by at least 25% compared to current standards.

Future evolution trajectories point toward fully automated post-processing chains that integrate in-situ monitoring and adaptive control systems. These developments aim to eliminate manual intervention between process steps while ensuring consistent quality through real-time adjustments based on material behavior during sintering and other thermal treatments.

The technology roadmap also emphasizes developing hybrid approaches that combine Binder Jetting with precision machining techniques to achieve superior surface finishes and tight tolerances for critical features, potentially expanding applications into high-performance sectors such as aerospace turbine components and precision medical implants.

Market Analysis for Binder Jetting Additive Manufacturing

The global binder jetting additive manufacturing market has experienced significant growth in recent years, with a market value reaching approximately $300 million in 2022. Industry analysts project this market to expand at a compound annual growth rate (CAGR) of 21.5% through 2028, potentially reaching $1.2 billion. This remarkable growth trajectory is primarily driven by increasing industrial adoption across automotive, aerospace, healthcare, and general manufacturing sectors.

Metal binder jetting technology has emerged as a particularly promising segment, accounting for nearly 60% of the overall binder jetting market. The technology's ability to produce complex geometries with minimal material waste positions it favorably against traditional manufacturing methods, especially for high-value components in aerospace and medical applications.

Regional analysis reveals North America currently dominates the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 24.3% annually, driven by rapid industrialization in China, Japan, and South Korea, along with increasing government initiatives supporting advanced manufacturing technologies.

The post-processing segment, specifically heat treatment, HIP (Hot Isostatic Pressing), and precision machining, represents a critical value-added component of the binder jetting ecosystem. This post-processing market is estimated at $120 million currently, with projections to reach $450 million by 2028. The demand for specialized post-processing equipment has created significant opportunities for both established industrial equipment manufacturers and specialized additive manufacturing service providers.

End-user analysis indicates that aerospace and defense industries account for 35% of binder jetting applications, followed by automotive (28%), medical and dental (18%), and general industrial applications (19%). The aerospace sector's demand is primarily driven by the need for lightweight, high-performance components with complex geometries that can withstand extreme operating conditions.

Cost analysis reveals that while initial equipment investment remains high, the total cost of ownership has been decreasing by approximately 15% annually as technology matures and competition intensifies. Material costs continue to represent 30-40% of production expenses, with post-processing accounting for another 25-35%, highlighting the importance of integrated process optimization.

Customer demand patterns show increasing preference for complete end-to-end solutions that integrate binder jetting with optimized post-processing chains, reflecting the market's evolution toward more mature, production-oriented applications rather than prototyping.

Metal binder jetting technology has emerged as a particularly promising segment, accounting for nearly 60% of the overall binder jetting market. The technology's ability to produce complex geometries with minimal material waste positions it favorably against traditional manufacturing methods, especially for high-value components in aerospace and medical applications.

Regional analysis reveals North America currently dominates the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is expected to witness the fastest growth rate of 24.3% annually, driven by rapid industrialization in China, Japan, and South Korea, along with increasing government initiatives supporting advanced manufacturing technologies.

The post-processing segment, specifically heat treatment, HIP (Hot Isostatic Pressing), and precision machining, represents a critical value-added component of the binder jetting ecosystem. This post-processing market is estimated at $120 million currently, with projections to reach $450 million by 2028. The demand for specialized post-processing equipment has created significant opportunities for both established industrial equipment manufacturers and specialized additive manufacturing service providers.

End-user analysis indicates that aerospace and defense industries account for 35% of binder jetting applications, followed by automotive (28%), medical and dental (18%), and general industrial applications (19%). The aerospace sector's demand is primarily driven by the need for lightweight, high-performance components with complex geometries that can withstand extreme operating conditions.

Cost analysis reveals that while initial equipment investment remains high, the total cost of ownership has been decreasing by approximately 15% annually as technology matures and competition intensifies. Material costs continue to represent 30-40% of production expenses, with post-processing accounting for another 25-35%, highlighting the importance of integrated process optimization.

Customer demand patterns show increasing preference for complete end-to-end solutions that integrate binder jetting with optimized post-processing chains, reflecting the market's evolution toward more mature, production-oriented applications rather than prototyping.

Current Challenges in Binder Jetting Post-Processing

Despite the significant advancements in binder jetting technology, the post-processing phase remains a critical bottleneck that limits widespread industrial adoption. The porous nature of green parts produced through binder jetting necessitates complex post-processing chains to achieve desired mechanical properties and dimensional accuracy. Current post-processing typically involves debinding, sintering, hot isostatic pressing (HIP), and precision machining, each presenting unique challenges.

Thermal post-processing presents significant technical hurdles, particularly in controlling shrinkage during sintering. Parts typically experience 15-25% volumetric shrinkage, which varies based on geometry and material composition, making it difficult to predict final dimensions. This unpredictability necessitates oversizing of green parts and subsequent precision machining, increasing production costs and lead times.

Temperature uniformity during heat treatment represents another major challenge. Larger or geometrically complex components often experience thermal gradients that lead to differential sintering rates, resulting in warpage, internal stresses, and potential cracking. Current furnace technologies struggle to maintain uniform temperature profiles throughout large build volumes, particularly for materials requiring precise sintering protocols.

The energy intensity of post-processing operations presents both economic and environmental challenges. Sintering and HIP processes typically require sustained high temperatures (often exceeding 1000°C) for extended periods, resulting in substantial energy consumption. This energy requirement not only increases operational costs but also contributes significantly to the carbon footprint of binder jet manufacturing.

Material-specific challenges further complicate post-processing. Different metal alloys and ceramics require tailored sintering profiles, with some materials being particularly sensitive to processing parameters. For instance, titanium alloys require specialized atmospheres to prevent oxygen contamination, while tungsten carbide composites demand precise carbon control during sintering to maintain optimal phase composition.

The integration of post-processing steps into cohesive production workflows remains problematic. Current solutions often involve multiple discrete operations across different equipment platforms, increasing handling requirements, production time, and quality control complexity. The lack of standardized interfaces between process steps creates inefficiencies and increases the risk of part damage during transfers.

Quality assurance during post-processing presents additional challenges, as internal defects may only become apparent after significant value has been added to the part. Non-destructive testing methods capable of detecting internal voids or cracks in complex geometries remain limited, particularly for in-process monitoring during thermal treatments.

Thermal post-processing presents significant technical hurdles, particularly in controlling shrinkage during sintering. Parts typically experience 15-25% volumetric shrinkage, which varies based on geometry and material composition, making it difficult to predict final dimensions. This unpredictability necessitates oversizing of green parts and subsequent precision machining, increasing production costs and lead times.

Temperature uniformity during heat treatment represents another major challenge. Larger or geometrically complex components often experience thermal gradients that lead to differential sintering rates, resulting in warpage, internal stresses, and potential cracking. Current furnace technologies struggle to maintain uniform temperature profiles throughout large build volumes, particularly for materials requiring precise sintering protocols.

The energy intensity of post-processing operations presents both economic and environmental challenges. Sintering and HIP processes typically require sustained high temperatures (often exceeding 1000°C) for extended periods, resulting in substantial energy consumption. This energy requirement not only increases operational costs but also contributes significantly to the carbon footprint of binder jet manufacturing.

Material-specific challenges further complicate post-processing. Different metal alloys and ceramics require tailored sintering profiles, with some materials being particularly sensitive to processing parameters. For instance, titanium alloys require specialized atmospheres to prevent oxygen contamination, while tungsten carbide composites demand precise carbon control during sintering to maintain optimal phase composition.

The integration of post-processing steps into cohesive production workflows remains problematic. Current solutions often involve multiple discrete operations across different equipment platforms, increasing handling requirements, production time, and quality control complexity. The lack of standardized interfaces between process steps creates inefficiencies and increases the risk of part damage during transfers.

Quality assurance during post-processing presents additional challenges, as internal defects may only become apparent after significant value has been added to the part. Non-destructive testing methods capable of detecting internal voids or cracks in complex geometries remain limited, particularly for in-process monitoring during thermal treatments.

State-of-the-Art Post-Processing Solutions

01 Debinding and sintering processes for binder jetted parts

After binder jetting, parts undergo debinding processes to remove the binding agent, followed by sintering to consolidate the material. This post-processing chain is critical for achieving desired mechanical properties. The debinding can be thermal or solvent-based, while sintering typically occurs at high temperatures in controlled atmospheres. These processes must be carefully controlled to prevent defects such as warping, cracking, or dimensional inaccuracies in the final parts.- Debinding and sintering processes for binder jetted parts: After binder jetting, parts undergo debinding processes to remove the binder material, followed by sintering to consolidate the powder particles. These post-processing steps are crucial for achieving desired mechanical properties and dimensional accuracy. The debinding process can involve thermal, solvent, or catalytic methods to remove the polymer binder, while sintering involves heating the parts to temperatures below the melting point to create strong bonds between particles.

- Infiltration techniques for enhancing material properties: Infiltration is a key post-processing technique for binder jetted parts where a secondary material is introduced into the porous structure to improve mechanical properties. This process can involve metals, polymers, or ceramics as infiltrants to fill the voids left after debinding. Infiltration enhances strength, density, and durability while reducing porosity. The technique can be performed under vacuum or pressure to ensure complete penetration of the infiltrant throughout the part.

- Surface treatment and finishing methods: Surface treatments are applied to binder jetted parts to improve surface quality, appearance, and functional properties. These treatments include mechanical processes like shot peening, tumbling, and polishing, as well as chemical processes such as etching and passivation. Advanced coating techniques can also be applied to enhance wear resistance, corrosion protection, or aesthetic appeal. These finishing methods are essential for achieving the required surface roughness and dimensional tolerances.

- Heat treatment for microstructure optimization: Heat treatment processes are employed to optimize the microstructure and mechanical properties of binder jetted parts. These processes include annealing, quenching, tempering, and aging, which can be tailored to specific material compositions. Heat treatments help relieve internal stresses, improve ductility, increase hardness, and enhance overall part performance. Controlled cooling rates and temperature profiles are critical for achieving desired material characteristics.

- Automated post-processing chains and quality control: Automated post-processing chains integrate multiple steps into a streamlined workflow to increase efficiency and consistency. These systems may combine debinding, sintering, infiltration, and finishing operations with robotic handling and transport mechanisms. Integrated quality control methods such as in-line inspection, dimensional verification, and non-destructive testing ensure that parts meet specifications throughout the post-processing chain. This automation reduces labor costs and improves repeatability in the production of binder jetted components.

02 Infiltration techniques for enhancing material properties

Infiltration is a key post-processing technique where secondary materials are introduced into the porous structure of binder jetted parts. This process enhances mechanical properties, density, and functionality of the printed components. Various infiltrants including metals, polymers, and ceramics can be used depending on the desired final properties. The infiltration process typically involves heating the part to allow capillary action to draw the infiltrant into the porous structure, resulting in improved strength, hardness, and reduced porosity.Expand Specific Solutions03 Surface treatment and finishing methods

Surface treatments are applied to binder jetted parts to improve surface quality, dimensional accuracy, and aesthetic appearance. These treatments include mechanical processes like shot peening, tumbling, and polishing, as well as chemical processes such as etching and passivation. Advanced surface treatments may also involve coating applications or heat treatments to enhance wear resistance, corrosion protection, or other functional properties. These finishing steps are crucial for parts requiring precise tolerances or specific surface characteristics.Expand Specific Solutions04 Heat treatment protocols for microstructure optimization

Heat treatment protocols are essential post-processing steps for optimizing the microstructure of binder jetted parts. These treatments include annealing, quenching, tempering, and aging processes that can be tailored to achieve specific material properties. The controlled heating and cooling cycles help relieve internal stresses, homogenize the microstructure, and enhance mechanical properties such as strength, ductility, and hardness. The parameters of these heat treatments must be carefully designed based on the material composition and desired final properties.Expand Specific Solutions05 Automated post-processing systems and quality control

Automated systems for post-processing binder jetted parts integrate multiple steps into streamlined production chains. These systems incorporate robotics, conveyor systems, and specialized equipment for handling, cleaning, debinding, sintering, and finishing operations. Quality control measures are embedded throughout the post-processing chain, including dimensional inspection, material testing, and non-destructive evaluation techniques. These automated systems improve consistency, reduce labor costs, and ensure repeatable quality in high-volume production environments.Expand Specific Solutions

Leading Companies in Binder Jetting Ecosystem

Binder Jetting and post-processing technologies are currently in a growth phase, with the market expanding rapidly due to increasing adoption in aerospace, automotive, and medical industries. The global market size for these technologies is projected to reach several billion dollars by 2025, driven by demand for complex metal parts with enhanced properties. Technologically, the field shows varying maturity levels across different post-processing methods. Leading players like Quintus Technologies AB and Carpenter Technology Corp. have established advanced heat treatment and HIP (Hot Isostatic Pressing) capabilities, while companies such as Boeing, Volkswagen AG, and Komatsu Ltd. are integrating these technologies into their manufacturing processes. Academic institutions including Huazhong University of Science & Technology and Beihang University are contributing significant research to advance precision machining techniques for binder jetted parts.

Carpenter Technology Corp.

Technical Solution: Carpenter Technology has developed advanced post-processing chains for binder jetted metal parts that focus on optimized heat treatment protocols. Their approach involves a multi-stage thermal processing sequence that begins with a carefully controlled debinding phase to remove polymer binders without distorting the printed geometry. This is followed by sintering in specialized vacuum furnaces with precise temperature ramps and holds to achieve optimal densification while minimizing part distortion. For high-performance applications, Carpenter implements proprietary HIP (Hot Isostatic Pressing) cycles specifically calibrated for different metal powder compositions, applying pressures up to 200 MPa at elevated temperatures to eliminate residual porosity. Their technology includes material-specific heat treatment recipes that can achieve mechanical properties comparable to wrought materials, particularly for their nickel-based superalloys and specialty stainless steels used in aerospace and medical applications. Carpenter has also developed specialized machining protocols for post-HIP components that account for the unique microstructural characteristics of binder jetted parts.

Strengths: Exceptional material science expertise with proprietary powder formulations optimized for binder jetting; extensive metallurgical knowledge enabling near-wrought properties in finished parts; vertical integration from powder production to final processing. Weaknesses: Higher cost structure compared to competitors; longer processing times for their multi-stage approach; limited flexibility for small batch production.

The Boeing Co.

Technical Solution: Boeing has pioneered an integrated post-processing approach for binder jetted aerospace components that emphasizes quality assurance throughout the thermal processing chain. Their system begins with specialized debinding protocols that utilize a combination of solvent and thermal debinding to efficiently remove binders while preserving complex geometries. Boeing's sintering technology employs atmosphere-controlled furnaces with real-time monitoring systems that adjust temperature profiles based on feedback from embedded sensors, ensuring uniform densification across varying part geometries. For critical components, Boeing utilizes a proprietary HIP process that combines optimized pressure-temperature cycles with specialized fixturing to minimize distortion in thin-walled structures and complex internal features. Their approach includes a comprehensive quality validation system that incorporates CT scanning between processing steps to verify internal integrity before proceeding to subsequent treatments. Boeing has also developed specialized heat treatment protocols for precipitation-hardening alloys that achieve the precise microstructural characteristics required for flight-critical applications, with particular success in titanium alloys and high-temperature nickel-based superalloys.

Strengths: Industry-leading quality control systems integrated throughout the post-processing chain; extensive experience with certification of additive parts for aerospace applications; advanced simulation capabilities for predicting sintering behavior. Weaknesses: Highly specialized processes not easily adaptable to non-aerospace applications; significant capital investment requirements; longer qualification timelines compared to conventional manufacturing.

Critical Patents in Heat Treatment and HIP Technologies

Repair of casting defects

PatentWO2014051830A1

Innovation

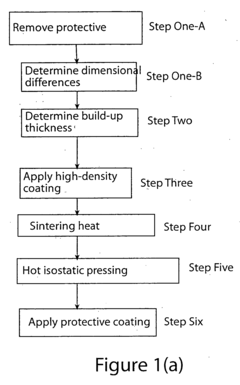

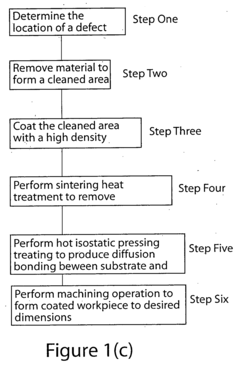

- A method involving removal of defects to form a cavity, filling with a filler material, fusion welding, brazing to seal surface cracks, and applying hot isostatic pressure (HIP) to close sub-surface cracks, which can be combined with a post-repair heat treatment to reduce costs.

Hardface alloy

PatentInactiveUS20060039788A1

Innovation

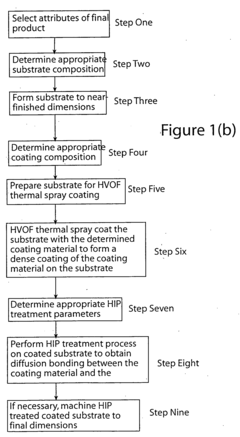

- A method involving a high-density coating process, such as hyper-velocity oxy-fuel thermal spray, followed by a hot isostatic pressing (HIP) treatment to form a diffusion bond between the coating and the substrate, which enhances the mechanical properties and dimensional accuracy of the airfoil parts, allowing for the restoration of critical dimensions and improved wear resistance.

Material Compatibility and Property Enhancement Methods

Material compatibility is a critical factor in binder jetting processes, as it directly influences the achievable mechanical properties and functional performance of the final components. Different metal powders exhibit varying behaviors during the printing process and subsequent post-processing treatments. Stainless steels (316L, 17-4PH) and tool steels demonstrate excellent compatibility with binder jetting, while titanium alloys and aluminum present more challenges due to their reactivity and oxidation tendencies.

The selection of appropriate binder systems must be tailored to specific metal powders to ensure optimal green part strength and clean burnout during thermal debinding. Water-based binders generally offer environmental advantages but may limit material options compared to solvent-based alternatives that provide enhanced green strength and feature definition.

Heat treatment protocols significantly impact material property enhancement in binder jetted parts. Sintering parameters must be precisely controlled to achieve optimal densification while minimizing distortion. Temperature ramp rates, holding times, and atmospheric conditions require careful optimization for each material system. For example, stainless steel components typically require sintering temperatures between 1300-1380°C with controlled atmosphere to prevent oxidation and carbon loss.

Hot Isostatic Pressing (HIP) represents a transformative post-processing technique for binder jetted components, capable of eliminating residual porosity and dramatically improving mechanical properties. HIP parameters—including pressure (typically 100-200 MPa), temperature, and dwell time—must be calibrated for specific materials to maximize density without inducing microstructural changes that could compromise performance.

Surface modification techniques offer additional pathways for property enhancement. Shot peening introduces compressive stresses that improve fatigue resistance, while chemical treatments can enhance corrosion resistance. Advanced coating technologies, including Physical Vapor Deposition (PVD) and thermal spray coatings, provide opportunities to impart specialized surface properties without altering bulk material characteristics.

Emerging research focuses on developing novel material systems specifically optimized for binder jetting processes. These include custom alloy formulations with improved sintering kinetics and reduced sensitivity to processing variables. Additionally, composite materials incorporating ceramic reinforcements or metal matrix composites offer promising avenues for achieving enhanced mechanical properties and functional characteristics beyond those possible with conventional alloys.

The selection of appropriate binder systems must be tailored to specific metal powders to ensure optimal green part strength and clean burnout during thermal debinding. Water-based binders generally offer environmental advantages but may limit material options compared to solvent-based alternatives that provide enhanced green strength and feature definition.

Heat treatment protocols significantly impact material property enhancement in binder jetted parts. Sintering parameters must be precisely controlled to achieve optimal densification while minimizing distortion. Temperature ramp rates, holding times, and atmospheric conditions require careful optimization for each material system. For example, stainless steel components typically require sintering temperatures between 1300-1380°C with controlled atmosphere to prevent oxidation and carbon loss.

Hot Isostatic Pressing (HIP) represents a transformative post-processing technique for binder jetted components, capable of eliminating residual porosity and dramatically improving mechanical properties. HIP parameters—including pressure (typically 100-200 MPa), temperature, and dwell time—must be calibrated for specific materials to maximize density without inducing microstructural changes that could compromise performance.

Surface modification techniques offer additional pathways for property enhancement. Shot peening introduces compressive stresses that improve fatigue resistance, while chemical treatments can enhance corrosion resistance. Advanced coating technologies, including Physical Vapor Deposition (PVD) and thermal spray coatings, provide opportunities to impart specialized surface properties without altering bulk material characteristics.

Emerging research focuses on developing novel material systems specifically optimized for binder jetting processes. These include custom alloy formulations with improved sintering kinetics and reduced sensitivity to processing variables. Additionally, composite materials incorporating ceramic reinforcements or metal matrix composites offer promising avenues for achieving enhanced mechanical properties and functional characteristics beyond those possible with conventional alloys.

Cost-Efficiency Analysis of Integrated Post-Processing Chains

The economic viability of Binder Jetting technology is significantly influenced by the efficiency of its post-processing chains. When evaluating the cost-efficiency of integrated post-processing for Binder Jetting, several key factors must be considered in a comprehensive analysis.

Initial investment costs for post-processing equipment represent a substantial portion of the total manufacturing system expenditure. Heat treatment furnaces suitable for additive manufacturing parts range from $50,000 to $250,000 depending on size and specifications. Hot Isostatic Pressing (HIP) equipment demands even higher capital investment, typically between $500,000 and $2 million, creating a significant barrier to entry for smaller manufacturers.

Operational expenses present another critical dimension in the cost analysis. Energy consumption during heat treatment and HIP processes contributes substantially to recurring costs, with HIP operations consuming approximately 40-60 kWh per cycle. Labor costs vary based on the level of automation, with precision machining typically requiring skilled technicians commanding higher wages than operators managing heat treatment processes.

Material efficiency metrics reveal interesting cost dynamics. While Binder Jetting itself offers material efficiency advantages with recyclable powder rates of 95-98%, post-processing can introduce additional material losses. Precision machining may remove 10-30% of the part volume, representing a significant cost factor when working with expensive metal powders such as titanium alloys or nickel superalloys.

Time-to-market considerations demonstrate that integrated post-processing chains can reduce overall production timelines by 30-40% compared to disconnected processes. This efficiency gain translates directly to economic benefits through faster capital recovery and increased production capacity.

Economies of scale present compelling opportunities for cost reduction. Analysis shows that batch processing during heat treatment and HIP can reduce per-part costs by 50-70% when operating at full capacity compared to single-part processing. This factor strongly influences the economic viability of these technologies for different production volumes.

Quality-cost trade-offs must be carefully balanced. Data indicates that while comprehensive post-processing chains increase part costs by 30-60%, they simultaneously reduce rejection rates by 70-85%, potentially yielding net economic benefits through reduced waste and rework expenses.

The integration level between different post-processing steps offers additional efficiency gains. Fully integrated systems with automated part handling between heat treatment, HIP, and machining operations demonstrate 15-25% lower total processing costs compared to disconnected workflows requiring manual transfers and additional setup procedures.

Initial investment costs for post-processing equipment represent a substantial portion of the total manufacturing system expenditure. Heat treatment furnaces suitable for additive manufacturing parts range from $50,000 to $250,000 depending on size and specifications. Hot Isostatic Pressing (HIP) equipment demands even higher capital investment, typically between $500,000 and $2 million, creating a significant barrier to entry for smaller manufacturers.

Operational expenses present another critical dimension in the cost analysis. Energy consumption during heat treatment and HIP processes contributes substantially to recurring costs, with HIP operations consuming approximately 40-60 kWh per cycle. Labor costs vary based on the level of automation, with precision machining typically requiring skilled technicians commanding higher wages than operators managing heat treatment processes.

Material efficiency metrics reveal interesting cost dynamics. While Binder Jetting itself offers material efficiency advantages with recyclable powder rates of 95-98%, post-processing can introduce additional material losses. Precision machining may remove 10-30% of the part volume, representing a significant cost factor when working with expensive metal powders such as titanium alloys or nickel superalloys.

Time-to-market considerations demonstrate that integrated post-processing chains can reduce overall production timelines by 30-40% compared to disconnected processes. This efficiency gain translates directly to economic benefits through faster capital recovery and increased production capacity.

Economies of scale present compelling opportunities for cost reduction. Analysis shows that batch processing during heat treatment and HIP can reduce per-part costs by 50-70% when operating at full capacity compared to single-part processing. This factor strongly influences the economic viability of these technologies for different production volumes.

Quality-cost trade-offs must be carefully balanced. Data indicates that while comprehensive post-processing chains increase part costs by 30-60%, they simultaneously reduce rejection rates by 70-85%, potentially yielding net economic benefits through reduced waste and rework expenses.

The integration level between different post-processing steps offers additional efficiency gains. Fully integrated systems with automated part handling between heat treatment, HIP, and machining operations demonstrate 15-25% lower total processing costs compared to disconnected workflows requiring manual transfers and additional setup procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!