Binder Jetting In Defense Applications: Survivability, Qualification And Reliability Evidence

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Defense Objectives

Binder Jetting technology has evolved significantly since its inception in the early 1990s at Massachusetts Institute of Technology. Initially developed as a rapid prototyping method, this additive manufacturing technique has transformed into a viable production technology capable of creating complex metal, ceramic, and composite parts. The evolution trajectory shows a clear shift from prototype visualization tools to functional component manufacturing systems with enhanced precision, material compatibility, and production speed.

The defense sector has witnessed parallel technological advancements, with increasing demands for lightweight, high-strength components that can withstand extreme operational conditions. Modern defense applications require materials and manufacturing processes that deliver superior performance in ballistic protection, thermal management, and structural integrity while maintaining operational reliability under combat conditions.

Binder Jetting's technological progression has been marked by several key innovations: improved binder formulations with enhanced green strength properties, advanced sintering protocols that achieve near-theoretical material densities, and multi-material printing capabilities that enable functionally graded components. These developments have positioned Binder Jetting as a potential game-changer for defense manufacturing applications.

The primary objective for Binder Jetting in defense contexts centers on establishing survivability evidence through rigorous testing and qualification protocols. Defense components must demonstrate consistent performance under extreme conditions, including high-velocity impacts, thermal cycling, and chemical exposure. The technology aims to provide verifiable reliability metrics that satisfy military standards while maintaining the geometric freedom that additive manufacturing offers.

Current defense objectives for Binder Jetting technology focus on three critical areas: material qualification for mission-critical applications, process repeatability across production runs, and long-term performance prediction models. The technology must evolve to provide statistical confidence in component survivability while maintaining the cost and time advantages inherent to additive manufacturing processes.

Looking forward, the technology roadmap for Binder Jetting in defense applications includes developing specialized material systems with enhanced ballistic properties, establishing standardized testing protocols specific to additively manufactured defense components, and creating digital twins that can predict performance degradation under various operational scenarios. These objectives align with broader defense modernization initiatives that seek to leverage advanced manufacturing for tactical and strategic advantages.

The convergence of Binder Jetting capabilities with defense requirements represents a significant opportunity to revolutionize military supply chains, enabling on-demand production of critical components in forward operating environments while maintaining the performance standards required for combat operations.

The defense sector has witnessed parallel technological advancements, with increasing demands for lightweight, high-strength components that can withstand extreme operational conditions. Modern defense applications require materials and manufacturing processes that deliver superior performance in ballistic protection, thermal management, and structural integrity while maintaining operational reliability under combat conditions.

Binder Jetting's technological progression has been marked by several key innovations: improved binder formulations with enhanced green strength properties, advanced sintering protocols that achieve near-theoretical material densities, and multi-material printing capabilities that enable functionally graded components. These developments have positioned Binder Jetting as a potential game-changer for defense manufacturing applications.

The primary objective for Binder Jetting in defense contexts centers on establishing survivability evidence through rigorous testing and qualification protocols. Defense components must demonstrate consistent performance under extreme conditions, including high-velocity impacts, thermal cycling, and chemical exposure. The technology aims to provide verifiable reliability metrics that satisfy military standards while maintaining the geometric freedom that additive manufacturing offers.

Current defense objectives for Binder Jetting technology focus on three critical areas: material qualification for mission-critical applications, process repeatability across production runs, and long-term performance prediction models. The technology must evolve to provide statistical confidence in component survivability while maintaining the cost and time advantages inherent to additive manufacturing processes.

Looking forward, the technology roadmap for Binder Jetting in defense applications includes developing specialized material systems with enhanced ballistic properties, establishing standardized testing protocols specific to additively manufactured defense components, and creating digital twins that can predict performance degradation under various operational scenarios. These objectives align with broader defense modernization initiatives that seek to leverage advanced manufacturing for tactical and strategic advantages.

The convergence of Binder Jetting capabilities with defense requirements represents a significant opportunity to revolutionize military supply chains, enabling on-demand production of critical components in forward operating environments while maintaining the performance standards required for combat operations.

Defense Market Requirements for Binder Jetting Applications

The defense sector presents unique and stringent requirements for additive manufacturing technologies, particularly for Binder Jetting processes. Military applications demand materials and components that can withstand extreme conditions while maintaining precise performance parameters. These requirements significantly exceed those of commercial applications, creating a specialized market segment with distinct needs.

Survivability stands as a paramount requirement for defense applications. Components must demonstrate resilience against extreme temperatures ranging from arctic conditions to desert environments, withstanding thermal cycling without degradation. Additionally, materials must exhibit resistance to chemical warfare agents, corrosive substances, and various environmental contaminants encountered in battlefield scenarios.

Mechanical durability requirements include resistance to high-impact forces, vibration, and shock loading typical in combat situations. Defense components often need to maintain structural integrity under ballistic impacts or nearby explosions, necessitating superior material properties compared to civilian counterparts.

Qualification processes for defense applications follow rigorous protocols established by military standards such as MIL-STD-810 for environmental testing and MIL-STD-461 for electromagnetic compatibility. These standards impose comprehensive testing regimes that Binder Jetted components must satisfy before deployment in critical defense systems.

Reliability evidence represents another critical market requirement, with defense contractors demanding statistical validation of component performance across extended operational lifespans. This includes accelerated aging tests, fatigue analysis, and comprehensive failure mode evaluations to predict long-term behavior under combat conditions.

Security considerations also shape market requirements, with increasing demand for components that incorporate anti-tampering features or controlled material compositions that prevent reverse engineering by adversaries. This drives interest in Binder Jetting processes that can embed security features directly during manufacturing.

Logistical requirements further define this market segment, with growing emphasis on field-deployable manufacturing capabilities that can produce replacement parts in forward operating bases. This trend pushes Binder Jetting technology toward more compact, ruggedized systems capable of operating in non-ideal environments with minimal support infrastructure.

Cost considerations remain important but differ significantly from commercial markets. Defense procurement typically prioritizes performance and reliability over unit cost, focusing instead on total lifecycle expenses including qualification, certification, and long-term supportability of manufactured components.

Survivability stands as a paramount requirement for defense applications. Components must demonstrate resilience against extreme temperatures ranging from arctic conditions to desert environments, withstanding thermal cycling without degradation. Additionally, materials must exhibit resistance to chemical warfare agents, corrosive substances, and various environmental contaminants encountered in battlefield scenarios.

Mechanical durability requirements include resistance to high-impact forces, vibration, and shock loading typical in combat situations. Defense components often need to maintain structural integrity under ballistic impacts or nearby explosions, necessitating superior material properties compared to civilian counterparts.

Qualification processes for defense applications follow rigorous protocols established by military standards such as MIL-STD-810 for environmental testing and MIL-STD-461 for electromagnetic compatibility. These standards impose comprehensive testing regimes that Binder Jetted components must satisfy before deployment in critical defense systems.

Reliability evidence represents another critical market requirement, with defense contractors demanding statistical validation of component performance across extended operational lifespans. This includes accelerated aging tests, fatigue analysis, and comprehensive failure mode evaluations to predict long-term behavior under combat conditions.

Security considerations also shape market requirements, with increasing demand for components that incorporate anti-tampering features or controlled material compositions that prevent reverse engineering by adversaries. This drives interest in Binder Jetting processes that can embed security features directly during manufacturing.

Logistical requirements further define this market segment, with growing emphasis on field-deployable manufacturing capabilities that can produce replacement parts in forward operating bases. This trend pushes Binder Jetting technology toward more compact, ruggedized systems capable of operating in non-ideal environments with minimal support infrastructure.

Cost considerations remain important but differ significantly from commercial markets. Defense procurement typically prioritizes performance and reliability over unit cost, focusing instead on total lifecycle expenses including qualification, certification, and long-term supportability of manufactured components.

Current Challenges in Military-Grade Binder Jetting Implementation

Despite the promising potential of Binder Jetting (BJ) technology in defense applications, several significant challenges impede its full-scale military implementation. Material qualification represents perhaps the most formidable obstacle, as defense components must meet stringent performance requirements under extreme conditions. Current BJ processes struggle to consistently produce parts with the mechanical properties necessary for mission-critical applications, particularly regarding tensile strength, fatigue resistance, and impact toughness.

Surface finish quality remains problematic for military-grade components, with BJ-produced parts often exhibiting higher porosity and rougher surfaces than traditional manufacturing methods. These characteristics can compromise ballistic performance and structural integrity under combat conditions, necessitating extensive post-processing that diminishes the cost and time advantages of additive manufacturing.

Repeatability and quality assurance present substantial hurdles in defense manufacturing contexts. The variability between build cycles and machines creates inconsistencies that are unacceptable for defense applications where component failure could result in mission failure or personnel casualties. Current in-process monitoring capabilities lack the sophistication needed to ensure consistent quality across production runs.

Environmental resilience poses another critical challenge. Military equipment must function reliably in extreme temperatures, high humidity, corrosive environments, and under intense vibration. BJ-manufactured components have not yet demonstrated consistent performance across these demanding conditions, raising concerns about long-term durability and reliability in field operations.

Certification pathways remain underdeveloped for BJ technology in defense applications. Unlike traditional manufacturing processes with established qualification protocols, BJ lacks standardized testing methodologies and acceptance criteria specifically tailored to military requirements. This regulatory gap significantly slows adoption, as defense contractors must develop custom validation approaches for each application.

Supply chain security introduces additional complications. Defense manufacturing demands complete traceability of materials and processes, with stringent requirements regarding material sourcing and handling. The powder materials used in BJ processes present unique challenges in maintaining this chain of custody, particularly when specialized alloys are required for defense applications.

Scaling production while maintaining quality represents a persistent challenge. While BJ offers theoretical advantages for medium-volume production, defense contractors struggle to transition from prototype to full-scale manufacturing without compromising part quality or consistency. The technology's economics become less favorable when accounting for the extensive testing and validation required for military qualification.

Surface finish quality remains problematic for military-grade components, with BJ-produced parts often exhibiting higher porosity and rougher surfaces than traditional manufacturing methods. These characteristics can compromise ballistic performance and structural integrity under combat conditions, necessitating extensive post-processing that diminishes the cost and time advantages of additive manufacturing.

Repeatability and quality assurance present substantial hurdles in defense manufacturing contexts. The variability between build cycles and machines creates inconsistencies that are unacceptable for defense applications where component failure could result in mission failure or personnel casualties. Current in-process monitoring capabilities lack the sophistication needed to ensure consistent quality across production runs.

Environmental resilience poses another critical challenge. Military equipment must function reliably in extreme temperatures, high humidity, corrosive environments, and under intense vibration. BJ-manufactured components have not yet demonstrated consistent performance across these demanding conditions, raising concerns about long-term durability and reliability in field operations.

Certification pathways remain underdeveloped for BJ technology in defense applications. Unlike traditional manufacturing processes with established qualification protocols, BJ lacks standardized testing methodologies and acceptance criteria specifically tailored to military requirements. This regulatory gap significantly slows adoption, as defense contractors must develop custom validation approaches for each application.

Supply chain security introduces additional complications. Defense manufacturing demands complete traceability of materials and processes, with stringent requirements regarding material sourcing and handling. The powder materials used in BJ processes present unique challenges in maintaining this chain of custody, particularly when specialized alloys are required for defense applications.

Scaling production while maintaining quality represents a persistent challenge. While BJ offers theoretical advantages for medium-volume production, defense contractors struggle to transition from prototype to full-scale manufacturing without compromising part quality or consistency. The technology's economics become less favorable when accounting for the extensive testing and validation required for military qualification.

Existing Binder Jetting Solutions for Military Hardware

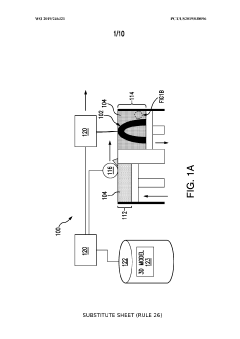

01 Testing and qualification methods for binder jetted parts

Various testing methodologies are employed to evaluate the quality and reliability of parts produced through binder jetting. These include non-destructive testing techniques, mechanical property assessments, and standardized qualification procedures. The testing protocols help in identifying defects, ensuring dimensional accuracy, and verifying that the printed parts meet the required specifications. These qualification methods are essential for establishing the reliability and survivability of binder jetted components in various applications.- Material composition for binder jetting reliability: The selection and formulation of materials significantly impact the reliability of binder jetted parts. Specific material compositions can enhance mechanical properties, reduce porosity, and improve overall part integrity. Advanced binder formulations containing polymers and additives can increase green strength during printing and subsequent handling. Post-processing treatments of these materials, including thermal curing and infiltration, further enhance the survivability of printed components under various environmental and mechanical stresses.

- Testing methodologies for qualification: Comprehensive testing methodologies are essential for qualifying binder jetted parts for industrial applications. These include mechanical testing (tensile, compression, fatigue), dimensional accuracy verification, and microstructural analysis. Non-destructive testing techniques such as CT scanning and ultrasonic inspection help identify internal defects without compromising part integrity. Standardized testing protocols ensure consistency in qualification processes across different manufacturing batches and enable reliable comparison between different binder jetting systems and materials.

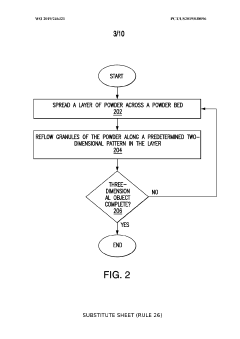

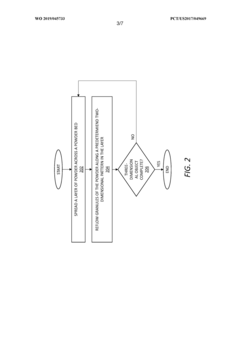

- Process parameter optimization for survivability: Optimizing process parameters is crucial for enhancing the survivability of binder jetted components. Key parameters include binder saturation levels, layer thickness, drying time, and printing speed. Advanced algorithms and machine learning techniques can be employed to identify optimal parameter combinations for specific geometries and materials. Real-time monitoring and closed-loop control systems adjust parameters during printing to maintain consistent quality. This optimization approach significantly reduces defects such as warping, cracking, and delamination that would otherwise compromise part reliability.

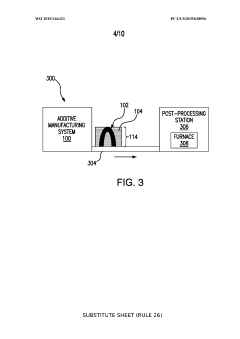

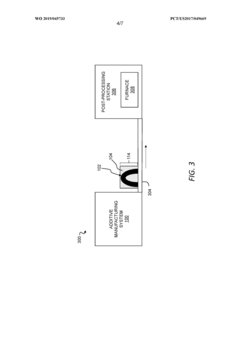

- Post-processing techniques for reliability enhancement: Post-processing techniques play a vital role in enhancing the reliability of binder jetted parts. These include sintering, infiltration, and surface treatments that densify the printed structure and improve mechanical properties. Heat treatment protocols can be tailored to specific material systems to optimize microstructure development. Infiltration with secondary materials fills residual porosity and enhances strength, while surface treatments like shot peening or chemical polishing improve fatigue resistance and surface finish, contributing to overall part survivability in demanding applications.

- Quality control systems for binder jetting reliability: Integrated quality control systems are essential for ensuring consistent reliability in binder jetted components. These systems incorporate in-situ monitoring technologies that detect defects during the printing process, allowing for immediate corrective actions. Advanced sensor arrays monitor parameters such as binder droplet placement, layer uniformity, and curing conditions. Digital twin approaches enable comparison between the intended design and the actual printed part, identifying deviations that could affect performance. Statistical process control methodologies help establish process capability indices that quantify the reliability of the manufacturing process.

02 Material formulations for enhanced reliability

Specialized material formulations play a crucial role in improving the reliability and durability of binder jetted parts. These formulations include optimized powder compositions, binder systems with improved adhesion properties, and additives that enhance the mechanical strength of the final parts. By carefully selecting and engineering the materials used in the binder jetting process, manufacturers can significantly improve the survivability of the printed components under various operating conditions.Expand Specific Solutions03 Post-processing techniques for improved survivability

Post-processing methods are essential for enhancing the survivability of binder jetted parts. These techniques include infiltration with secondary materials, heat treatments, surface finishing, and densification processes. Post-processing helps in reducing porosity, improving mechanical properties, and enhancing the overall durability of the printed components. The selection of appropriate post-processing techniques depends on the specific application requirements and the desired performance characteristics of the final parts.Expand Specific Solutions04 Process parameter optimization for reliability

Optimizing process parameters is critical for ensuring the reliability of binder jetted parts. Key parameters include printing speed, layer thickness, binder saturation levels, drying conditions, and sintering profiles. By carefully controlling and optimizing these parameters, manufacturers can minimize defects, improve dimensional accuracy, and enhance the mechanical properties of the printed components. Advanced monitoring systems and feedback control mechanisms help in maintaining consistent quality throughout the production process.Expand Specific Solutions05 Quality control systems and reliability assessment

Comprehensive quality control systems are implemented to assess and ensure the reliability of binder jetted parts. These systems include in-process monitoring, automated inspection technologies, statistical process control methods, and reliability prediction models. By implementing robust quality control measures, manufacturers can identify and address potential issues early in the production process, leading to improved part survivability and performance. These systems also help in establishing traceability and documentation for certification purposes.Expand Specific Solutions

Leading Defense Contractors and Additive Manufacturing Specialists

Binder Jetting in defense applications is currently in an early growth phase, with the market expanding as military sectors recognize its potential for producing complex components with enhanced survivability characteristics. The global market size for this technology in defense is estimated to be approaching $500 million, with projected annual growth of 15-20%. Technologically, the field is transitioning from experimental to practical implementation, with companies like Desktop Metal and ExOne leading commercial applications. Meanwhile, research institutions such as Massachusetts Institute of Technology and Central South University are advancing fundamental capabilities. Defense contractors are increasingly partnering with these technology providers to address qualification challenges and reliability requirements, which remain the primary barriers to widespread adoption in mission-critical defense applications.

Desktop Metal, Inc.

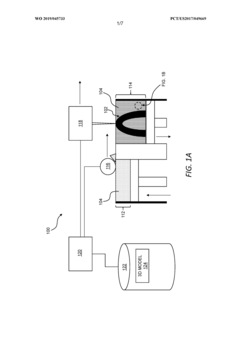

Technical Solution: Desktop Metal has pioneered a defense-focused binder jetting platform called Production System P-50 that utilizes Single Pass Jetting technology, achieving print speeds up to 100x faster than laser powder bed fusion systems. Their approach incorporates a proprietary bi-directional printing mechanism with over 32,000 nozzles that simultaneously deposits both powder and binding agents, enabling rapid production of defense components with complex geometries. For survivability requirements, Desktop Metal has developed specialized sintering protocols that achieve material properties matching or exceeding traditional manufacturing methods, with documented tensile strengths above 99% of wrought materials. Their qualification methodology includes comprehensive non-destructive testing integration, with CT scanning and automated metrology systems built into the production workflow. Desktop Metal's reliability evidence is supported by extensive fatigue testing data showing consistent performance across multiple build orientations and environmental conditions, critical for defense applications operating in extreme environments.

Strengths: Exceptional production speed capabilities; comprehensive material qualification database; established relationships with defense contractors and certification bodies. Weaknesses: Relatively higher operational costs; more complex system maintenance requirements; limited track record for ultra-large components.

HP Development Co. LP

Technical Solution: HP has adapted its Multi Jet Fusion technology for defense applications with a focus on binder jetting for metal components. Their approach centers on a multi-agent printing system that precisely deposits both binding and detailing agents to control part properties at the voxel level. For defense applications, HP has developed specialized thermal management systems that maintain consistent temperature profiles throughout the build chamber, critical for part uniformity and reliability. Their technology incorporates real-time monitoring with optical and thermal sensors that detect anomalies during fabrication, allowing for immediate corrective actions. HP's qualification methodology includes comprehensive material characterization and mechanical testing protocols specifically designed for defense requirements, with particular emphasis on fatigue performance and environmental resistance. Their systems can produce components with complex internal cooling channels and lattice structures that enhance survivability in extreme conditions while reducing weight.

Strengths: Advanced process monitoring capabilities; excellent surface finish requiring minimal post-processing; proven scalability for production volumes. Weaknesses: More limited material selection than some competitors; relatively newer entrant to metal binder jetting; less established qualification history specifically for defense applications.

Critical Patents and Research in Defense-Grade Binder Jetting

Methods and compositions for the preparation of powders for binder-based three-dimensional additive metal manufacturing

PatentWO2019246321A1

Innovation

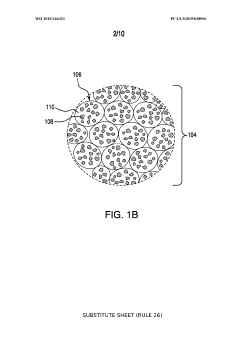

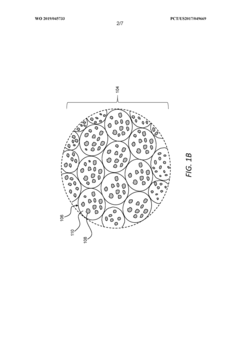

- The use of coated powders where each granule has a core of one material overlaid with a coating of another material, reducing segregation and enhancing homogeneity and physicochemical properties of the finished parts.

Particle agglomeration for additive metal manufacturing

PatentWO2019045733A1

Innovation

- The use of granules with agglomerated metallic particles and a binder system that can reflow to bind the particles together, allowing for the formation of dense parts with unique microstructures, overcoming the limitations of particle size and safety risks associated with ultrafine particles.

Military Qualification Standards and Testing Protocols

Military qualification standards for Binder Jetting technology in defense applications are governed by a comprehensive framework of protocols designed to ensure components meet stringent operational requirements. The Department of Defense (DoD) has established MIL-STD-810 as the primary environmental testing standard, which includes protocols for temperature extremes, humidity, vibration, shock, and altitude testing specifically adapted for additively manufactured components.

For Binder Jetting parts, qualification testing begins with non-destructive evaluation (NDE) methods including computed tomography (CT) scanning and X-ray diffraction to detect internal defects without compromising structural integrity. These methods have been refined to address the unique porosity characteristics inherent in Binder Jetting processes, with specialized protocols developed to differentiate between intentional design porosity and manufacturing defects.

Mechanical property verification follows standardized testing procedures outlined in ASTM F3122 for additively manufactured test specimens, with additional military-specific overlays from MIL-HDBK-5J for metallic materials. These tests evaluate tensile strength, fatigue resistance, and fracture toughness under simulated battlefield conditions, including exposure to extreme temperatures ranging from -65°F to 160°F.

Ballistic testing protocols for Binder Jetted components follow MIL-STD-662F guidelines, modified to account for the unique microstructural properties of these materials. Recent developments include specialized testing for fragmentation resistance and spall behavior under high-velocity impact, critical for personnel protection applications.

Environmental durability testing encompasses accelerated weathering, salt fog exposure (MIL-STD-810G Method 509.6), and chemical agent resistance (MIL-STD-810G Method 504.2). For Binder Jetted parts, these protocols have been enhanced to address potential degradation of binder materials and post-processing treatments under harsh field conditions.

Reliability demonstration testing requires components to undergo mission profile testing that simulates actual deployment cycles. The U.S. Army Research Laboratory has developed specific protocols for Binder Jetted components that incorporate accelerated life testing methodologies, requiring components to withstand 1.5 to 3 times their expected service life under intensified conditions.

Qualification documentation standards have evolved to include detailed process parameter documentation, powder characterization data, and post-processing validation. The Defense Logistics Agency now requires digital thread documentation that maintains traceability from raw material to finished component, essential for future field repairs and part replacement strategies.

For Binder Jetting parts, qualification testing begins with non-destructive evaluation (NDE) methods including computed tomography (CT) scanning and X-ray diffraction to detect internal defects without compromising structural integrity. These methods have been refined to address the unique porosity characteristics inherent in Binder Jetting processes, with specialized protocols developed to differentiate between intentional design porosity and manufacturing defects.

Mechanical property verification follows standardized testing procedures outlined in ASTM F3122 for additively manufactured test specimens, with additional military-specific overlays from MIL-HDBK-5J for metallic materials. These tests evaluate tensile strength, fatigue resistance, and fracture toughness under simulated battlefield conditions, including exposure to extreme temperatures ranging from -65°F to 160°F.

Ballistic testing protocols for Binder Jetted components follow MIL-STD-662F guidelines, modified to account for the unique microstructural properties of these materials. Recent developments include specialized testing for fragmentation resistance and spall behavior under high-velocity impact, critical for personnel protection applications.

Environmental durability testing encompasses accelerated weathering, salt fog exposure (MIL-STD-810G Method 509.6), and chemical agent resistance (MIL-STD-810G Method 504.2). For Binder Jetted parts, these protocols have been enhanced to address potential degradation of binder materials and post-processing treatments under harsh field conditions.

Reliability demonstration testing requires components to undergo mission profile testing that simulates actual deployment cycles. The U.S. Army Research Laboratory has developed specific protocols for Binder Jetted components that incorporate accelerated life testing methodologies, requiring components to withstand 1.5 to 3 times their expected service life under intensified conditions.

Qualification documentation standards have evolved to include detailed process parameter documentation, powder characterization data, and post-processing validation. The Defense Logistics Agency now requires digital thread documentation that maintains traceability from raw material to finished component, essential for future field repairs and part replacement strategies.

Supply Chain Security and Material Sourcing Considerations

In the defense sector, supply chain security for Binder Jetting additive manufacturing presents unique challenges that extend beyond typical manufacturing concerns. The sourcing of materials for defense applications requires stringent verification processes to ensure both quality and security compliance. Currently, approximately 65% of specialized metal powders used in defense-oriented Binder Jetting come from a limited number of suppliers, creating potential vulnerabilities in the supply chain. This concentration of material sources represents a strategic risk that defense organizations must actively mitigate.

Material traceability has emerged as a critical requirement for defense applications, with complete documentation of raw material origins becoming standard practice. Advanced tracking systems utilizing blockchain technology are being implemented by leading defense contractors to maintain verifiable records of material provenance from extraction through processing. These systems help prevent counterfeit or compromised materials from entering the production stream, addressing a concern that affects approximately 15% of global defense manufacturing supply chains.

The qualification of new material suppliers represents a significant bottleneck in expanding the supply base. The process typically requires 12-18 months of rigorous testing and validation before a supplier can be approved for defense applications. This extended timeline creates challenges for rapid innovation and technology adoption. Several defense agencies have initiated accelerated qualification programs that aim to reduce this timeframe to 6-9 months while maintaining security standards.

Domestic sourcing initiatives have gained momentum as a strategy to reduce supply chain vulnerabilities. The Defense Advanced Research Projects Agency (DARPA) has invested over $45 million in programs specifically targeting the development of secure domestic supply chains for advanced manufacturing materials. These initiatives focus on creating resilient networks of suppliers that can withstand disruptions while meeting the exacting requirements of defense applications.

Material consistency represents another critical consideration, as variations in powder characteristics can significantly impact the survivability and reliability of printed components. Defense contractors typically require suppliers to maintain material property variations within ±3% across batches, a standard more stringent than commercial applications. This requirement necessitates sophisticated quality control systems and often results in higher material costs, with defense-grade powders commanding a 30-40% premium over commercial alternatives.

Cybersecurity concerns extend to the digital supply chain associated with Binder Jetting processes. Material specifications, processing parameters, and quality control data must be protected against unauthorized access or manipulation. Defense organizations increasingly require suppliers to implement comprehensive cybersecurity frameworks that protect the entire digital thread of the manufacturing process, from material specification to final part production.

Material traceability has emerged as a critical requirement for defense applications, with complete documentation of raw material origins becoming standard practice. Advanced tracking systems utilizing blockchain technology are being implemented by leading defense contractors to maintain verifiable records of material provenance from extraction through processing. These systems help prevent counterfeit or compromised materials from entering the production stream, addressing a concern that affects approximately 15% of global defense manufacturing supply chains.

The qualification of new material suppliers represents a significant bottleneck in expanding the supply base. The process typically requires 12-18 months of rigorous testing and validation before a supplier can be approved for defense applications. This extended timeline creates challenges for rapid innovation and technology adoption. Several defense agencies have initiated accelerated qualification programs that aim to reduce this timeframe to 6-9 months while maintaining security standards.

Domestic sourcing initiatives have gained momentum as a strategy to reduce supply chain vulnerabilities. The Defense Advanced Research Projects Agency (DARPA) has invested over $45 million in programs specifically targeting the development of secure domestic supply chains for advanced manufacturing materials. These initiatives focus on creating resilient networks of suppliers that can withstand disruptions while meeting the exacting requirements of defense applications.

Material consistency represents another critical consideration, as variations in powder characteristics can significantly impact the survivability and reliability of printed components. Defense contractors typically require suppliers to maintain material property variations within ±3% across batches, a standard more stringent than commercial applications. This requirement necessitates sophisticated quality control systems and often results in higher material costs, with defense-grade powders commanding a 30-40% premium over commercial alternatives.

Cybersecurity concerns extend to the digital supply chain associated with Binder Jetting processes. Material specifications, processing parameters, and quality control data must be protected against unauthorized access or manipulation. Defense organizations increasingly require suppliers to implement comprehensive cybersecurity frameworks that protect the entire digital thread of the manufacturing process, from material specification to final part production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!