Binder Jetting Quality Gates: Sensor-Based Control, Metrology And Data Integrity

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting technology has evolved significantly since its inception in the early 1990s at Massachusetts Institute of Technology. Initially developed as a rapid prototyping method, this powder bed-based additive manufacturing technique has transformed into a viable production technology for various industries. The evolution trajectory shows a clear shift from prototype creation to functional part production, with increasing emphasis on material diversity, dimensional accuracy, and mechanical properties.

The fundamental principle of Binder Jetting involves selectively depositing a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures layer by layer. Early iterations focused primarily on concept models and visual prototypes with limited functional applications. However, technological advancements have progressively enhanced process capabilities, enabling the production of components with improved density, surface finish, and mechanical performance.

A significant evolutionary milestone occurred in the mid-2000s with the introduction of multi-material capabilities and enhanced binder formulations. This advancement expanded the application scope beyond traditional ceramics and metals to include composites and specialized materials. The subsequent decade witnessed substantial improvements in print resolution, build volume, and process repeatability, further solidifying Binder Jetting's position in the additive manufacturing landscape.

Recent technological developments have concentrated on process monitoring and quality control mechanisms, particularly sensor-based control systems. These innovations represent a critical advancement in addressing historical challenges related to part consistency, dimensional accuracy, and material property uniformity. The integration of in-situ monitoring capabilities has enabled real-time process adjustments, significantly reducing defect rates and improving overall production yield.

The primary objectives for Binder Jetting technology advancement now center on establishing robust quality gates throughout the manufacturing process. This includes developing comprehensive sensor networks for continuous monitoring, implementing advanced metrology systems for dimensional verification, and ensuring data integrity across the production workflow. These objectives align with industry demands for certified production parts that meet stringent quality standards across aerospace, automotive, medical, and industrial sectors.

Future technological trajectories indicate a continued focus on process automation, artificial intelligence integration for predictive quality control, and closed-loop feedback systems. These advancements aim to achieve near-zero defect manufacturing while maintaining the inherent advantages of Binder Jetting, such as high productivity, material efficiency, and design freedom. The ultimate goal is to position Binder Jetting as a fully qualified, production-ready technology capable of consistently delivering components that meet or exceed the performance characteristics of traditionally manufactured parts.

The fundamental principle of Binder Jetting involves selectively depositing a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures layer by layer. Early iterations focused primarily on concept models and visual prototypes with limited functional applications. However, technological advancements have progressively enhanced process capabilities, enabling the production of components with improved density, surface finish, and mechanical performance.

A significant evolutionary milestone occurred in the mid-2000s with the introduction of multi-material capabilities and enhanced binder formulations. This advancement expanded the application scope beyond traditional ceramics and metals to include composites and specialized materials. The subsequent decade witnessed substantial improvements in print resolution, build volume, and process repeatability, further solidifying Binder Jetting's position in the additive manufacturing landscape.

Recent technological developments have concentrated on process monitoring and quality control mechanisms, particularly sensor-based control systems. These innovations represent a critical advancement in addressing historical challenges related to part consistency, dimensional accuracy, and material property uniformity. The integration of in-situ monitoring capabilities has enabled real-time process adjustments, significantly reducing defect rates and improving overall production yield.

The primary objectives for Binder Jetting technology advancement now center on establishing robust quality gates throughout the manufacturing process. This includes developing comprehensive sensor networks for continuous monitoring, implementing advanced metrology systems for dimensional verification, and ensuring data integrity across the production workflow. These objectives align with industry demands for certified production parts that meet stringent quality standards across aerospace, automotive, medical, and industrial sectors.

Future technological trajectories indicate a continued focus on process automation, artificial intelligence integration for predictive quality control, and closed-loop feedback systems. These advancements aim to achieve near-zero defect manufacturing while maintaining the inherent advantages of Binder Jetting, such as high productivity, material efficiency, and design freedom. The ultimate goal is to position Binder Jetting as a fully qualified, production-ready technology capable of consistently delivering components that meet or exceed the performance characteristics of traditionally manufactured parts.

Market Analysis for Sensor-Controlled Additive Manufacturing

The global market for sensor-controlled additive manufacturing systems is experiencing robust growth, driven by increasing demand for high-precision manufacturing capabilities across various industries. The Binder Jetting segment specifically has shown a compound annual growth rate of approximately 23% since 2018, with particular acceleration in the last two years as quality control technologies have matured.

Industrial sectors including aerospace, automotive, medical devices, and consumer electronics represent the primary demand sources for advanced sensor-based quality control systems in additive manufacturing. Aerospace and medical device manufacturers have been early adopters, willing to invest premium prices for systems that can ensure consistent part quality and regulatory compliance.

Market research indicates that manufacturers are increasingly prioritizing closed-loop quality control systems that can detect and correct defects in real-time during the binder jetting process. This trend is reflected in recent procurement patterns where buyers are showing preference for systems with integrated metrology capabilities over traditional post-process inspection methods.

The market for sensor technologies specifically designed for binder jetting quality control is currently valued at approximately $450 million globally, with projections suggesting growth to reach $1.2 billion by 2027. North America currently leads market share at 42%, followed by Europe at 31% and Asia-Pacific at 24%, with the remainder distributed across other regions.

Customer feedback analysis reveals that manufacturing companies are willing to pay 15-20% premium pricing for additive manufacturing systems that incorporate advanced sensor arrays and real-time quality monitoring capabilities. This price elasticity is particularly evident in industries where component failure carries significant consequences, such as medical implants or critical aerospace parts.

The market is currently experiencing a shift from standalone quality inspection systems toward fully integrated sensor networks that monitor multiple process parameters simultaneously. Data integrity solutions that ensure traceability and compliance with industry standards are showing the highest growth rate within the sensor ecosystem, reflecting increasing regulatory scrutiny across manufacturing sectors.

Competition in this market segment is intensifying, with traditional additive manufacturing equipment providers facing new entrants from the industrial automation and quality control sectors. This competitive landscape is driving innovation in sensor technologies specifically optimized for powder bed monitoring, binder distribution analysis, and layer consistency verification in binder jetting processes.

Industrial sectors including aerospace, automotive, medical devices, and consumer electronics represent the primary demand sources for advanced sensor-based quality control systems in additive manufacturing. Aerospace and medical device manufacturers have been early adopters, willing to invest premium prices for systems that can ensure consistent part quality and regulatory compliance.

Market research indicates that manufacturers are increasingly prioritizing closed-loop quality control systems that can detect and correct defects in real-time during the binder jetting process. This trend is reflected in recent procurement patterns where buyers are showing preference for systems with integrated metrology capabilities over traditional post-process inspection methods.

The market for sensor technologies specifically designed for binder jetting quality control is currently valued at approximately $450 million globally, with projections suggesting growth to reach $1.2 billion by 2027. North America currently leads market share at 42%, followed by Europe at 31% and Asia-Pacific at 24%, with the remainder distributed across other regions.

Customer feedback analysis reveals that manufacturing companies are willing to pay 15-20% premium pricing for additive manufacturing systems that incorporate advanced sensor arrays and real-time quality monitoring capabilities. This price elasticity is particularly evident in industries where component failure carries significant consequences, such as medical implants or critical aerospace parts.

The market is currently experiencing a shift from standalone quality inspection systems toward fully integrated sensor networks that monitor multiple process parameters simultaneously. Data integrity solutions that ensure traceability and compliance with industry standards are showing the highest growth rate within the sensor ecosystem, reflecting increasing regulatory scrutiny across manufacturing sectors.

Competition in this market segment is intensifying, with traditional additive manufacturing equipment providers facing new entrants from the industrial automation and quality control sectors. This competitive landscape is driving innovation in sensor technologies specifically optimized for powder bed monitoring, binder distribution analysis, and layer consistency verification in binder jetting processes.

Current Challenges in Binder Jetting Quality Control

Binder Jetting technology faces several significant challenges in quality control that impede its wider industrial adoption. The primary issue lies in the inconsistency of part quality across production batches, which stems from inadequate real-time monitoring capabilities during the printing process. Current sensor systems often fail to detect critical defects such as powder bed irregularities, binder saturation variations, and layer misalignments until post-processing inspection, resulting in material waste and production inefficiencies.

The metrology infrastructure for Binder Jetting presents another substantial challenge. Existing measurement systems struggle to accurately characterize the complex geometries and internal structures of printed parts, particularly when dealing with fine features or intricate lattice structures. This limitation is exacerbated by the lack of standardized measurement protocols specifically designed for Binder Jetting processes, making quality benchmarking across different systems and manufacturers problematic.

Data integrity issues further complicate quality control efforts. The vast amounts of process data generated during Binder Jetting operations often exist in proprietary formats with limited interoperability between different machine systems and analysis software. This fragmentation creates significant barriers to implementing comprehensive quality management systems that can track part quality from design through production to final inspection.

Material-specific challenges also impact quality control effectiveness. Different powder materials exhibit varying behaviors during the binding process, requiring tailored sensing approaches and quality parameters. Current one-size-fits-all quality control methodologies fail to account for these material-specific considerations, leading to suboptimal detection of defects in certain material systems.

The post-processing phase introduces additional quality control complexities. Sintering and infiltration processes can introduce dimensional changes and defects that are difficult to predict based solely on green part measurements. The lack of integrated quality control systems that span the entire production chain from printing through post-processing creates blind spots in quality assurance protocols.

Regulatory compliance presents another significant hurdle, particularly in highly regulated industries such as aerospace and medical devices. The absence of established quality certification pathways for Binder Jetting processes makes validation challenging, with manufacturers often resorting to costly overengineering and extensive testing to ensure compliance with industry standards.

Finally, there is a notable skills gap in the workforce regarding advanced quality control methodologies for Binder Jetting. The technology requires specialized knowledge in both additive manufacturing principles and advanced sensing technologies, creating a bottleneck in implementing sophisticated quality control systems in production environments.

The metrology infrastructure for Binder Jetting presents another substantial challenge. Existing measurement systems struggle to accurately characterize the complex geometries and internal structures of printed parts, particularly when dealing with fine features or intricate lattice structures. This limitation is exacerbated by the lack of standardized measurement protocols specifically designed for Binder Jetting processes, making quality benchmarking across different systems and manufacturers problematic.

Data integrity issues further complicate quality control efforts. The vast amounts of process data generated during Binder Jetting operations often exist in proprietary formats with limited interoperability between different machine systems and analysis software. This fragmentation creates significant barriers to implementing comprehensive quality management systems that can track part quality from design through production to final inspection.

Material-specific challenges also impact quality control effectiveness. Different powder materials exhibit varying behaviors during the binding process, requiring tailored sensing approaches and quality parameters. Current one-size-fits-all quality control methodologies fail to account for these material-specific considerations, leading to suboptimal detection of defects in certain material systems.

The post-processing phase introduces additional quality control complexities. Sintering and infiltration processes can introduce dimensional changes and defects that are difficult to predict based solely on green part measurements. The lack of integrated quality control systems that span the entire production chain from printing through post-processing creates blind spots in quality assurance protocols.

Regulatory compliance presents another significant hurdle, particularly in highly regulated industries such as aerospace and medical devices. The absence of established quality certification pathways for Binder Jetting processes makes validation challenging, with manufacturers often resorting to costly overengineering and extensive testing to ensure compliance with industry standards.

Finally, there is a notable skills gap in the workforce regarding advanced quality control methodologies for Binder Jetting. The technology requires specialized knowledge in both additive manufacturing principles and advanced sensing technologies, creating a bottleneck in implementing sophisticated quality control systems in production environments.

Existing Quality Gate Solutions for Binder Jetting

01 Process monitoring and quality control in binder jetting

Binder jetting processes require robust monitoring systems to ensure quality control throughout the manufacturing process. These systems include sensors and cameras that track various parameters such as binder distribution, powder bed uniformity, and curing conditions. Quality gates are established at critical points in the workflow to verify that components meet specified requirements before proceeding to subsequent processing steps. Real-time monitoring enables immediate detection of defects and process deviations, allowing for corrective actions to maintain consistent part quality.- Quality control systems for binder jetting processes: Quality control systems are implemented in binder jetting processes to monitor and ensure the quality of printed parts. These systems include sensors, cameras, and other monitoring devices that track various parameters during the printing process. The data collected is analyzed in real-time to detect defects or deviations from specifications, allowing for immediate corrective actions. Quality gates are established at critical stages of the process to verify that the parts meet predetermined quality standards before proceeding to the next stage.

- Material composition and binder formulation for quality improvement: The composition of materials and binder formulations significantly impacts the quality of parts produced through binder jetting. Specific additives and compounds are incorporated into the binder to enhance binding strength, reduce porosity, and improve surface finish. The particle size distribution and morphology of the powder material are optimized to achieve better packing density and flowability. These formulation improvements help to establish effective quality gates by ensuring consistent material properties throughout the printing process.

- Post-processing quality verification methods: After the binder jetting process, various post-processing methods are employed to verify and enhance the quality of printed parts. These methods include sintering, infiltration, and surface treatments that improve mechanical properties and dimensional accuracy. Quality gates are established during post-processing to verify that parts meet specifications for density, strength, and surface finish. Non-destructive testing techniques such as CT scanning and ultrasonic inspection are used to detect internal defects before final approval.

- Digital workflow and data management for quality assurance: Digital workflows and data management systems are implemented to ensure quality throughout the binder jetting process. These systems track and document each stage of production, from design to final inspection. Quality gates are integrated into the digital workflow to prevent progression to subsequent stages until quality criteria are met. Machine learning algorithms analyze process data to identify patterns and predict potential quality issues before they occur. This digital approach enables traceability and continuous improvement of the manufacturing process.

- Process parameter optimization for quality control: Optimizing process parameters is crucial for maintaining quality in binder jetting operations. Parameters such as binder saturation, layer thickness, drying time, and printing speed are carefully controlled to achieve desired part properties. Quality gates are established to verify that these parameters remain within acceptable ranges during production. Experimental design methods are used to determine the optimal combination of parameters for specific materials and geometries. Feedback loops adjust parameters in real-time based on quality measurements to maintain consistent part quality.

02 Material qualification and testing protocols

Quality gates in binder jetting include rigorous material qualification and testing protocols to ensure consistent performance. These protocols involve evaluating powder characteristics such as particle size distribution, flowability, and chemical composition. Testing procedures are implemented at various stages to verify material properties meet specifications before use in production. Advanced characterization techniques help identify potential issues that could affect final part quality. Establishing standardized material qualification processes is essential for achieving reproducible results across manufacturing batches.Expand Specific Solutions03 Post-processing quality verification

Post-processing steps in binder jetting require specific quality gates to ensure final part integrity. These include inspection points after debinding, sintering, and finishing operations to verify dimensional accuracy, surface quality, and mechanical properties. Non-destructive testing methods are employed to detect internal defects without compromising part integrity. Quality gates during post-processing help identify issues that may have originated in earlier manufacturing stages but only become apparent after thermal treatments. Establishing clear acceptance criteria for each post-processing stage ensures consistent final product quality.Expand Specific Solutions04 Digital workflow integration and data management

Quality gates in binder jetting are increasingly integrated into digital workflows that capture and analyze process data throughout the manufacturing chain. These systems enable traceability from raw materials to finished parts, with quality checkpoints generating digital records that document compliance with specifications. Machine learning algorithms can identify patterns and predict potential quality issues before they occur. Digital twins of the manufacturing process allow for virtual testing and optimization of quality parameters. Comprehensive data management systems ensure that all quality-related information is accessible for process improvement and regulatory compliance.Expand Specific Solutions05 Design validation and pre-production quality gates

Before full-scale production begins, binder jetting processes incorporate design validation and pre-production quality gates to verify manufacturability and performance. These include simulation-based analyses to predict potential issues such as warping, cracking, or insufficient structural integrity. Test prints are evaluated against design specifications to confirm that the intended geometry and properties can be achieved. Pre-production quality gates help identify design modifications needed to ensure successful manufacturing outcomes. Establishing clear acceptance criteria at this stage prevents costly issues during production and ensures that final parts will meet functional requirements.Expand Specific Solutions

Industry Leaders in Binder Jetting and Sensor Technologies

Binder Jetting Quality Control is currently in a transitional phase from early adoption to mainstream implementation, with the market expected to grow significantly as additive manufacturing expands. The technology maturity varies across players, with established industrial leaders like Robert Bosch, DENSO, and Rolls-Royce Solutions developing sophisticated sensor-based control systems, while technology specialists such as Zebra Technologies and HP Development focus on metrology integration. Companies like Texas Instruments, STMicroelectronics, and NXP Semiconductors are advancing the data integrity aspects through specialized sensor technologies. The competitive landscape is characterized by cross-industry collaboration, with automotive and aerospace companies partnering with semiconductor and measurement specialists to establish comprehensive quality control frameworks for binder jetting processes.

HP Development Co. LP

Technical Solution: HP's Binder Jetting technology incorporates advanced sensor-based control systems that monitor and regulate the printing process in real-time. Their Multi Jet Fusion technology utilizes thermal inkjet arrays with thousands of nozzles that deposit both fusing and detailing agents with precise control. HP has implemented a closed-loop feedback system that continuously monitors powder bed temperature, humidity, and material distribution to ensure optimal printing conditions. Their quality control system includes in-situ optical sensors that detect anomalies during the printing process, allowing for immediate adjustments to printing parameters. HP's data integrity approach involves comprehensive logging of all process parameters, creating a digital twin of each printed part that can be used for quality verification and process optimization. Their systems also incorporate machine learning algorithms that analyze historical data to predict potential quality issues before they occur.

Strengths: HP's extensive experience in 2D printing technologies has translated well to 3D printing, giving them superior control over fluid deposition. Their integrated end-to-end software solution provides excellent data integrity and traceability. Weaknesses: Their systems are primarily optimized for their proprietary materials, which can limit flexibility for specialized applications requiring custom materials.

FANUC Corp.

Technical Solution: FANUC has developed sophisticated sensor integration systems for Binder Jetting processes that focus on industrial automation and precision control. Their approach combines robotics expertise with additive manufacturing to create highly automated Binder Jetting systems. FANUC's quality gates include multi-modal sensing technologies that monitor not just the printing process but also material handling and post-processing stages. Their systems employ high-precision servo motors and motion control systems to ensure accurate deposition of binder agents. FANUC has implemented real-time monitoring using thermal cameras, optical sensors, and acoustic emission sensors to detect process anomalies. Their FIELD (FANUC Intelligent Edge Link and Drive) system serves as the backbone for data collection and integrity, creating a comprehensive digital thread throughout the manufacturing process. This system enables seamless integration with their CNC and robotic systems, allowing for automated quality control and part handling.

Strengths: FANUC's expertise in industrial automation and robotics enables highly repeatable and precise control of the Binder Jetting process. Their integrated approach to factory automation allows for seamless quality control across the entire production line. Weaknesses: Their solutions tend to be more focused on high-volume industrial applications and may be less adaptable for research or small-batch production environments.

Key Metrology Innovations for Additive Manufacturing

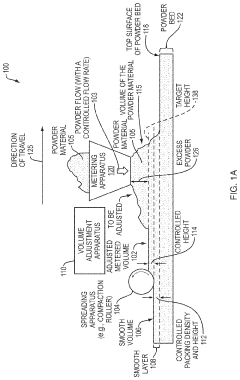

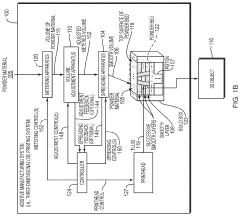

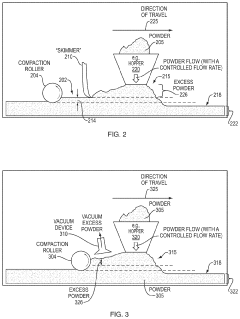

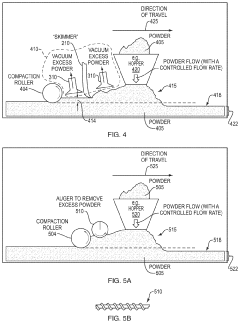

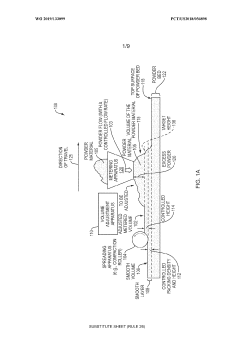

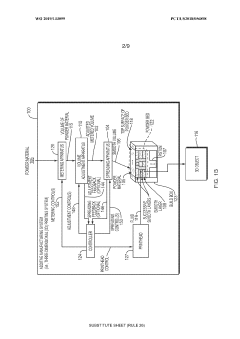

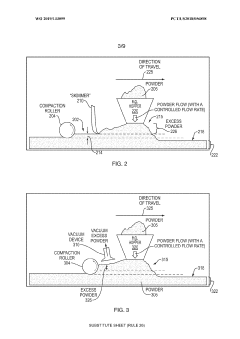

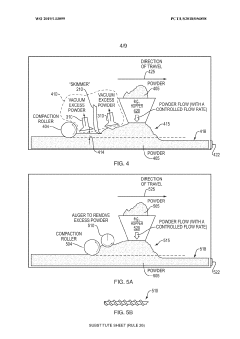

System and method for controlling powder bed density for 3D printing

PatentActiveUS11998982B2

Innovation

- A system comprising a metering apparatus, volume adjustment apparatus, and spreading apparatus that controls the height and packing density of powder layers, using a skimmer, vacuum, or compaction rollers to ensure a smooth, uniform layer formation across the powder bed, with a controller to manage the process and maintain consistent packing density.

System and method for controlling powder bed density for 3D printing

PatentWO2019133099A1

Innovation

- A system comprising a metering apparatus, volume adjustment apparatus, and spreading apparatus that controls the height and packing density of powder layers, using tools like skimmers, vacuum devices, and compaction rollers to ensure uniform powder distribution and compaction across the powder bed, with a controller to manage the process and maintain consistent layer formation.

Standards and Certification Requirements for AM Quality

The standardization landscape for Binder Jetting quality control is rapidly evolving to address the unique challenges of this additive manufacturing process. Currently, organizations such as ASTM International, ISO, and the America Makes & ANSI Additive Manufacturing Standardization Collaborative (AMSC) are developing comprehensive frameworks specifically tailored to powder bed fusion technologies including Binder Jetting.

Key standards under development focus on establishing uniform protocols for sensor-based monitoring systems, metrology techniques, and data integrity verification throughout the Binder Jetting process chain. ASTM F42 committee has been particularly active in creating standards for testing methods, process control, and quality assurance specific to binder technologies, with recent publications addressing powder characterization, binder saturation parameters, and green part handling.

ISO/TC 261 complements these efforts with standards focusing on the digital thread aspects of quality control, emphasizing data formats, sensor calibration requirements, and validation methodologies for in-process monitoring systems. These standards aim to establish minimum requirements for sensor resolution, sampling rates, and data processing algorithms to ensure consistent quality assessment across different machine platforms.

Certification pathways for Binder Jetting processes are emerging through industry-specific frameworks. Aerospace applications follow guidelines such as those in development by the National Aerospace and Defense Contractors Accreditation Program (NADCAP), which is creating specialized audit criteria for binder-based AM processes. Medical device manufacturers must navigate FDA guidance documents that increasingly reference AM-specific quality controls, including those for binder technologies.

The integration of sensor data with quality management systems presents a significant standardization challenge. Emerging standards are addressing data integrity through blockchain-based verification systems, digital signature protocols, and secure data transfer methodologies. These approaches ensure that quality data remains tamper-proof throughout the product lifecycle.

Material-specific certification requirements are also being developed, with standards bodies creating testing protocols for different powder-binder combinations. These standards define acceptable ranges for key process parameters and establish correlations between sensor readings and final part quality, enabling statistical process control methodologies.

Traceability requirements represent another critical area of standardization, with emerging frameworks mandating comprehensive documentation of sensor calibration histories, measurement uncertainties, and data processing algorithms. These standards ensure that quality decisions can be audited and verified by regulatory authorities or customers.

Key standards under development focus on establishing uniform protocols for sensor-based monitoring systems, metrology techniques, and data integrity verification throughout the Binder Jetting process chain. ASTM F42 committee has been particularly active in creating standards for testing methods, process control, and quality assurance specific to binder technologies, with recent publications addressing powder characterization, binder saturation parameters, and green part handling.

ISO/TC 261 complements these efforts with standards focusing on the digital thread aspects of quality control, emphasizing data formats, sensor calibration requirements, and validation methodologies for in-process monitoring systems. These standards aim to establish minimum requirements for sensor resolution, sampling rates, and data processing algorithms to ensure consistent quality assessment across different machine platforms.

Certification pathways for Binder Jetting processes are emerging through industry-specific frameworks. Aerospace applications follow guidelines such as those in development by the National Aerospace and Defense Contractors Accreditation Program (NADCAP), which is creating specialized audit criteria for binder-based AM processes. Medical device manufacturers must navigate FDA guidance documents that increasingly reference AM-specific quality controls, including those for binder technologies.

The integration of sensor data with quality management systems presents a significant standardization challenge. Emerging standards are addressing data integrity through blockchain-based verification systems, digital signature protocols, and secure data transfer methodologies. These approaches ensure that quality data remains tamper-proof throughout the product lifecycle.

Material-specific certification requirements are also being developed, with standards bodies creating testing protocols for different powder-binder combinations. These standards define acceptable ranges for key process parameters and establish correlations between sensor readings and final part quality, enabling statistical process control methodologies.

Traceability requirements represent another critical area of standardization, with emerging frameworks mandating comprehensive documentation of sensor calibration histories, measurement uncertainties, and data processing algorithms. These standards ensure that quality decisions can be audited and verified by regulatory authorities or customers.

Digital Twin Integration for Process Validation

Digital Twin technology represents a transformative approach for validating and optimizing Binder Jetting processes. By creating virtual replicas of physical manufacturing systems, Digital Twins enable real-time monitoring, simulation, and prediction capabilities that significantly enhance process validation procedures. These virtual models continuously synchronize with sensor data from physical equipment, creating a comprehensive framework for quality assurance.

In the context of Binder Jetting, Digital Twins can integrate data from multiple sensor-based quality gates throughout the manufacturing process. This integration allows for the creation of a holistic validation ecosystem where physical measurements are constantly compared against virtual predictions. When discrepancies arise, the system can automatically flag potential quality issues before they manifest in finished parts.

The implementation architecture typically consists of three primary layers: the physical layer (actual Binder Jetting equipment and sensors), the data layer (collection and processing infrastructure), and the digital model layer (simulation and prediction algorithms). These layers work in concert to provide a comprehensive validation framework that evolves with the manufacturing process.

Key benefits of Digital Twin integration include predictive maintenance capabilities, where potential equipment failures can be identified before they impact part quality. Additionally, process parameter optimization becomes more efficient as virtual experimentation can be conducted without consuming physical resources or disrupting production schedules.

For metrology validation, Digital Twins enable multi-dimensional quality assessment by comparing as-designed specifications with as-manufactured outcomes across numerous parameters simultaneously. This capability extends beyond traditional quality control methods by incorporating temporal data that tracks how parts evolve throughout the manufacturing process.

Data integrity within Digital Twin frameworks is maintained through blockchain-inspired verification protocols that create immutable records of sensor readings and process parameters. This approach ensures that validation data remains tamper-proof and traceable, addressing regulatory requirements in industries such as aerospace and medical device manufacturing.

Looking forward, the evolution of Digital Twin technology for Binder Jetting validation will likely incorporate advanced AI algorithms capable of autonomous process optimization. These systems will not only validate current processes but will also suggest improvements based on historical performance data and theoretical models, creating a continuous improvement cycle that drives manufacturing excellence.

In the context of Binder Jetting, Digital Twins can integrate data from multiple sensor-based quality gates throughout the manufacturing process. This integration allows for the creation of a holistic validation ecosystem where physical measurements are constantly compared against virtual predictions. When discrepancies arise, the system can automatically flag potential quality issues before they manifest in finished parts.

The implementation architecture typically consists of three primary layers: the physical layer (actual Binder Jetting equipment and sensors), the data layer (collection and processing infrastructure), and the digital model layer (simulation and prediction algorithms). These layers work in concert to provide a comprehensive validation framework that evolves with the manufacturing process.

Key benefits of Digital Twin integration include predictive maintenance capabilities, where potential equipment failures can be identified before they impact part quality. Additionally, process parameter optimization becomes more efficient as virtual experimentation can be conducted without consuming physical resources or disrupting production schedules.

For metrology validation, Digital Twins enable multi-dimensional quality assessment by comparing as-designed specifications with as-manufactured outcomes across numerous parameters simultaneously. This capability extends beyond traditional quality control methods by incorporating temporal data that tracks how parts evolve throughout the manufacturing process.

Data integrity within Digital Twin frameworks is maintained through blockchain-inspired verification protocols that create immutable records of sensor readings and process parameters. This approach ensures that validation data remains tamper-proof and traceable, addressing regulatory requirements in industries such as aerospace and medical device manufacturing.

Looking forward, the evolution of Digital Twin technology for Binder Jetting validation will likely incorporate advanced AI algorithms capable of autonomous process optimization. These systems will not only validate current processes but will also suggest improvements based on historical performance data and theoretical models, creating a continuous improvement cycle that drives manufacturing excellence.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!