Binder Jetting Surface Integrity: Roughness Reduction, Edge Fidelity And Machining Synergy

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Background and Objectives

Binder Jetting (BJ) technology emerged in the early 1990s as one of the pioneering additive manufacturing (AM) processes, developed at the Massachusetts Institute of Technology. This powder-bed based technology has evolved significantly over the past three decades, transitioning from primarily prototyping applications to becoming a viable manufacturing method for functional components across various industries.

The fundamental principle of Binder Jetting involves selectively depositing a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures through a layer-by-layer approach. Unlike other AM technologies that require thermal energy for material fusion, BJ's room-temperature process offers distinct advantages in terms of material compatibility, processing speed, and cost-effectiveness.

Historical development of BJ technology shows three distinct evolutionary phases: initial conceptualization and proof-of-concept (1990-2000), industrial adoption and process refinement (2000-2015), and the current advanced manufacturing integration phase (2015-present). Each phase has been characterized by significant improvements in binder formulations, printhead technology, and post-processing techniques.

Despite its advantages, Binder Jetting faces persistent challenges related to surface integrity. Components typically exhibit relatively high surface roughness (Ra values often exceeding 15μm), compromised edge definition, and inconsistent mechanical properties that necessitate additional post-processing. These surface integrity issues have limited BJ's application in industries requiring high-precision components.

The current technological trajectory is focused on addressing these surface integrity challenges through multi-faceted approaches. Research efforts are increasingly concentrated on advanced binder formulations, optimized printing parameters, innovative post-processing techniques, and the integration of complementary manufacturing processes to enhance surface quality.

The primary objectives of current research initiatives include: reducing surface roughness to achieve Ra values below 5μm without extensive post-processing; improving edge fidelity to enable the production of sharp features with dimensional accuracy within ±0.1mm; and developing synergistic approaches that combine BJ with traditional machining processes to optimize both manufacturing efficiency and component quality.

Industry trends indicate growing interest in hybrid manufacturing approaches that leverage the geometric freedom of Binder Jetting while incorporating conventional machining techniques to address surface integrity concerns. This convergence represents a promising direction for overcoming the inherent limitations of BJ technology while capitalizing on its unique capabilities for complex geometry creation and material flexibility.

The fundamental principle of Binder Jetting involves selectively depositing a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures through a layer-by-layer approach. Unlike other AM technologies that require thermal energy for material fusion, BJ's room-temperature process offers distinct advantages in terms of material compatibility, processing speed, and cost-effectiveness.

Historical development of BJ technology shows three distinct evolutionary phases: initial conceptualization and proof-of-concept (1990-2000), industrial adoption and process refinement (2000-2015), and the current advanced manufacturing integration phase (2015-present). Each phase has been characterized by significant improvements in binder formulations, printhead technology, and post-processing techniques.

Despite its advantages, Binder Jetting faces persistent challenges related to surface integrity. Components typically exhibit relatively high surface roughness (Ra values often exceeding 15μm), compromised edge definition, and inconsistent mechanical properties that necessitate additional post-processing. These surface integrity issues have limited BJ's application in industries requiring high-precision components.

The current technological trajectory is focused on addressing these surface integrity challenges through multi-faceted approaches. Research efforts are increasingly concentrated on advanced binder formulations, optimized printing parameters, innovative post-processing techniques, and the integration of complementary manufacturing processes to enhance surface quality.

The primary objectives of current research initiatives include: reducing surface roughness to achieve Ra values below 5μm without extensive post-processing; improving edge fidelity to enable the production of sharp features with dimensional accuracy within ±0.1mm; and developing synergistic approaches that combine BJ with traditional machining processes to optimize both manufacturing efficiency and component quality.

Industry trends indicate growing interest in hybrid manufacturing approaches that leverage the geometric freedom of Binder Jetting while incorporating conventional machining techniques to address surface integrity concerns. This convergence represents a promising direction for overcoming the inherent limitations of BJ technology while capitalizing on its unique capabilities for complex geometry creation and material flexibility.

Market Analysis for High-Quality Binder Jetted Components

The global market for high-quality binder jetted components is experiencing significant growth, driven by increasing demand across multiple industries including aerospace, automotive, medical devices, and consumer goods. Current market estimates value the additive manufacturing market at approximately $12 billion, with binder jetting technology representing a rapidly growing segment due to its cost-effectiveness and scalability advantages over other 3D printing methods.

Demand for binder jetted components is particularly strong in sectors requiring complex geometries with precise surface finishes. The aerospace industry leads adoption, seeking lightweight components with specific surface integrity requirements for fuel efficiency and performance optimization. Following closely is the automotive sector, where manufacturers are increasingly incorporating binder jetted parts in both prototyping and end-use applications, especially for low-volume specialty vehicles and customized components.

Medical device manufacturing represents another significant growth area, with demand for patient-specific implants and surgical instruments driving adoption of binder jetting technology. The technology's ability to produce porous structures with controlled surface characteristics makes it particularly valuable for orthopedic and dental applications.

Market research indicates that surface quality remains a critical factor influencing adoption rates. Surveys of industrial end-users consistently rank surface finish among the top three considerations when evaluating binder jetted components, alongside dimensional accuracy and mechanical properties. This highlights the commercial relevance of research focused on surface integrity improvements.

Regional analysis shows North America currently leads the market for high-quality binder jetted components, accounting for approximately 40% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, with China, Japan, and South Korea making significant investments in additive manufacturing capabilities.

The competitive landscape features established industrial 3D printing companies like ExOne (now part of Desktop Metal), HP, and Digital Metal, alongside newer entrants developing specialized solutions for surface quality optimization. Material suppliers are also playing an increasingly important role, developing powders specifically engineered to achieve superior surface characteristics in binder jetted parts.

Market forecasts project continued strong growth for high-quality binder jetted components, with a compound annual growth rate exceeding 20% over the next five years. This growth trajectory is supported by ongoing technological improvements addressing current limitations, particularly in surface finish quality, which remains a key barrier to wider adoption in high-precision applications.

Demand for binder jetted components is particularly strong in sectors requiring complex geometries with precise surface finishes. The aerospace industry leads adoption, seeking lightweight components with specific surface integrity requirements for fuel efficiency and performance optimization. Following closely is the automotive sector, where manufacturers are increasingly incorporating binder jetted parts in both prototyping and end-use applications, especially for low-volume specialty vehicles and customized components.

Medical device manufacturing represents another significant growth area, with demand for patient-specific implants and surgical instruments driving adoption of binder jetting technology. The technology's ability to produce porous structures with controlled surface characteristics makes it particularly valuable for orthopedic and dental applications.

Market research indicates that surface quality remains a critical factor influencing adoption rates. Surveys of industrial end-users consistently rank surface finish among the top three considerations when evaluating binder jetted components, alongside dimensional accuracy and mechanical properties. This highlights the commercial relevance of research focused on surface integrity improvements.

Regional analysis shows North America currently leads the market for high-quality binder jetted components, accounting for approximately 40% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate, with China, Japan, and South Korea making significant investments in additive manufacturing capabilities.

The competitive landscape features established industrial 3D printing companies like ExOne (now part of Desktop Metal), HP, and Digital Metal, alongside newer entrants developing specialized solutions for surface quality optimization. Material suppliers are also playing an increasingly important role, developing powders specifically engineered to achieve superior surface characteristics in binder jetted parts.

Market forecasts project continued strong growth for high-quality binder jetted components, with a compound annual growth rate exceeding 20% over the next five years. This growth trajectory is supported by ongoing technological improvements addressing current limitations, particularly in surface finish quality, which remains a key barrier to wider adoption in high-precision applications.

Surface Integrity Challenges in Binder Jetting

Binder Jetting (BJ) technology faces significant surface integrity challenges that impact the quality, functionality, and performance of manufactured parts. The layer-by-layer powder deposition and selective binding process inherently creates surface irregularities that require addressing through various optimization strategies.

The primary surface integrity issue in BJ is surface roughness, which typically ranges from Ra 15-30 μm in as-printed parts. This roughness stems from the stair-stepping effect inherent to layer-wise manufacturing, powder particle size distribution, and binder-powder interaction dynamics. The rough surface texture not only affects aesthetic qualities but also influences mechanical properties, fatigue resistance, and functional performance of components.

Edge fidelity represents another critical challenge, particularly for components with complex geometries or fine features. BJ processes often struggle to maintain sharp edges and precise dimensional accuracy due to binder bleeding, powder spreading inconsistencies, and shrinkage during sintering. These issues become more pronounced as feature sizes approach the resolution limits of the printing system.

Porosity control presents a multifaceted challenge affecting both surface and subsurface integrity. The incomplete densification during printing and subsequent sintering processes can lead to interconnected surface pores that compromise mechanical properties, corrosion resistance, and fluid sealing capabilities. Surface-connected porosity creates pathways for fluid infiltration and potential failure initiation sites.

Material-specific challenges further complicate surface integrity management. Different powder materials exhibit varying degrees of wettability with binders, sintering behaviors, and thermal expansion characteristics. These material-dependent factors significantly influence the resultant surface quality and require tailored process parameters for optimization.

Post-processing dependencies represent a substantial consideration in BJ manufacturing. Unlike some additive manufacturing techniques that produce near-net-shape parts with acceptable surface finish, BJ typically requires extensive post-processing operations including de-powdering, curing, sintering, and often secondary machining or finishing processes to achieve desired surface integrity specifications.

The interplay between process parameters and surface integrity outcomes creates a complex optimization challenge. Parameters such as layer thickness, binder saturation, drying time, powder characteristics, and sintering profiles all influence surface quality through different mechanisms, necessitating a systems approach to surface integrity improvement.

The primary surface integrity issue in BJ is surface roughness, which typically ranges from Ra 15-30 μm in as-printed parts. This roughness stems from the stair-stepping effect inherent to layer-wise manufacturing, powder particle size distribution, and binder-powder interaction dynamics. The rough surface texture not only affects aesthetic qualities but also influences mechanical properties, fatigue resistance, and functional performance of components.

Edge fidelity represents another critical challenge, particularly for components with complex geometries or fine features. BJ processes often struggle to maintain sharp edges and precise dimensional accuracy due to binder bleeding, powder spreading inconsistencies, and shrinkage during sintering. These issues become more pronounced as feature sizes approach the resolution limits of the printing system.

Porosity control presents a multifaceted challenge affecting both surface and subsurface integrity. The incomplete densification during printing and subsequent sintering processes can lead to interconnected surface pores that compromise mechanical properties, corrosion resistance, and fluid sealing capabilities. Surface-connected porosity creates pathways for fluid infiltration and potential failure initiation sites.

Material-specific challenges further complicate surface integrity management. Different powder materials exhibit varying degrees of wettability with binders, sintering behaviors, and thermal expansion characteristics. These material-dependent factors significantly influence the resultant surface quality and require tailored process parameters for optimization.

Post-processing dependencies represent a substantial consideration in BJ manufacturing. Unlike some additive manufacturing techniques that produce near-net-shape parts with acceptable surface finish, BJ typically requires extensive post-processing operations including de-powdering, curing, sintering, and often secondary machining or finishing processes to achieve desired surface integrity specifications.

The interplay between process parameters and surface integrity outcomes creates a complex optimization challenge. Parameters such as layer thickness, binder saturation, drying time, powder characteristics, and sintering profiles all influence surface quality through different mechanisms, necessitating a systems approach to surface integrity improvement.

Current Surface Treatment Solutions for Binder Jetted Parts

01 Surface treatment methods for improving binder jetting surface integrity

Various post-processing techniques can be applied to improve the surface integrity of binder jetted parts. These methods include infiltration with resins or metals, heat treatment, and mechanical finishing processes. These treatments help to densify the printed structure, reduce porosity, and enhance the overall surface quality, resulting in improved mechanical properties and surface integrity of the final parts.- Surface treatment methods for improving binder jetting surface integrity: Various surface treatment methods can be applied to improve the surface integrity of parts produced by binder jetting. These treatments include mechanical finishing, chemical processing, and thermal treatments that can reduce surface roughness and enhance structural integrity. These post-processing techniques help to densify the printed parts and eliminate surface defects, resulting in improved mechanical properties and surface quality.

- Binder formulations for enhanced edge fidelity: Specialized binder formulations can significantly impact the edge fidelity of printed parts. By optimizing the rheological properties of binders, controlling their viscosity, and incorporating specific additives, the definition of edges and fine features can be improved. Advanced binder systems may include polymeric components that provide better green strength and minimize edge distortion during the printing and curing processes.

- Powder characteristics affecting surface roughness: The characteristics of the powder used in binder jetting significantly influence the final surface roughness of printed parts. Factors such as particle size distribution, particle shape, and powder flowability directly impact the layer formation and packing density. Finer powders generally result in smoother surfaces but may present challenges in spreading and recoating. Optimized powder compositions can lead to reduced surface roughness and improved dimensional accuracy.

- Process parameters optimization for surface quality: Optimizing process parameters is crucial for achieving high surface quality in binder jetting. Parameters such as layer thickness, binder saturation level, drying time, and printing speed significantly affect surface integrity and roughness. Careful control of these parameters can minimize defects such as bleeding, warping, and porosity, resulting in parts with improved surface finish and dimensional accuracy.

- Infiltration techniques for reducing porosity and improving surface finish: Infiltration techniques are effective methods for reducing porosity and enhancing the surface finish of binder jetted parts. By introducing secondary materials such as resins, metals, or ceramics into the porous structure of green parts, the overall density increases and surface roughness decreases. These techniques can significantly improve mechanical properties, surface integrity, and edge definition while maintaining dimensional accuracy.

02 Binder formulations for enhanced surface roughness control

Specialized binder formulations can significantly impact the surface roughness of printed parts. By optimizing the rheological properties, drying behavior, and interaction with powder particles, these formulations can minimize surface irregularities. Advanced binders containing surfactants, viscosity modifiers, and adhesion promoters help achieve smoother surfaces and better edge definition in binder jetting processes.Expand Specific Solutions03 Powder characteristics and their effect on edge fidelity

The physical and chemical properties of powder materials significantly influence edge fidelity in binder jetting. Particle size distribution, shape, flowability, and packing density all affect how precisely edges can be defined during printing. Optimized powder compositions with controlled particle morphology and size distribution can dramatically improve edge definition and dimensional accuracy of printed components.Expand Specific Solutions04 Process parameters optimization for surface quality

Critical process parameters such as layer thickness, binder saturation level, drying time, and printing speed can be optimized to enhance surface quality. The careful control of these parameters helps minimize surface defects like warping, cracking, and roughness. Advanced process control systems that monitor and adjust these parameters in real-time can significantly improve the surface integrity and dimensional accuracy of binder jetted parts.Expand Specific Solutions05 Multi-material approaches for improved surface characteristics

Incorporating multiple materials or gradients within a single print can enhance surface characteristics. By strategically combining materials with complementary properties, manufacturers can achieve improved surface finish while maintaining structural integrity. This approach may involve using different binder formulations for the core and surface regions or applying specialized coatings during or after the printing process to enhance surface properties.Expand Specific Solutions

Leading Companies and Research Institutions in Binder Jetting

Binder Jetting Surface Integrity research is currently in a growth phase, with increasing market adoption driven by additive manufacturing expansion. The global market is experiencing significant growth as industries seek improved surface quality in 3D printed components. Technologically, the field shows moderate maturity with ongoing innovations focused on roughness reduction and edge fidelity. Leading players include established manufacturing companies like Honda Motor, GM Global Technology, and Tokyo Electron, alongside academic institutions such as Dalian University of Technology and Politecnico di Milano. Research synergies between traditional machining and binder jetting processes are being explored by companies like Sumitomo Electric Hardmetal and Kondex Corp, indicating a trend toward hybrid manufacturing approaches that optimize surface integrity while maintaining production efficiency.

DBI Holding LLC

Technical Solution: DBI Holding LLC has developed a comprehensive approach to Binder Jetting surface integrity focusing on multi-stage post-processing. Their technology combines controlled infiltration processes with specialized surface treatments to address roughness reduction. The company employs a proprietary two-step sintering protocol that first removes binding agents at lower temperatures before final densification, which significantly reduces surface porosity and improves edge definition. DBI's research has demonstrated that their post-processing techniques can achieve surface roughness reductions of up to 60% compared to as-printed parts. Additionally, they've pioneered a hybrid manufacturing approach that integrates machining operations with binder jetting to target critical surfaces while maintaining the geometric freedom of additive manufacturing. This approach allows for selective surface finishing of functional features while preserving complex internal geometries that would be inaccessible to traditional machining.

Strengths: Their integrated post-processing workflow offers comprehensive surface quality improvement without sacrificing the geometric complexity advantages of binder jetting. The hybrid manufacturing approach provides excellent dimensional control for critical features. Weaknesses: The multi-stage post-processing increases production time and costs, potentially limiting throughput for high-volume applications. Some of their techniques require specialized equipment that may not be widely accessible.

Politecnico di Milano

Technical Solution: Politecnico di Milano has developed an advanced multi-physics modeling approach to binder jetting surface integrity that combines experimental validation with computational simulation. Their research focuses on understanding the fundamental mechanisms that contribute to surface roughness and edge definition issues in binder jetted parts. The university's approach includes a novel particle packing optimization algorithm that predicts and minimizes surface irregularities by controlling powder distribution during the printing process. Their studies have demonstrated that optimized powder spreading parameters can reduce as-printed surface roughness by up to 40% before any post-processing is applied. Additionally, they've pioneered a selective surface modification technique using localized chemical treatments that preferentially smooth external surfaces while preserving internal features. The research team has also established correlations between printing parameters, powder characteristics, and optimal machining strategies, creating a comprehensive database that guides process parameter selection based on desired surface quality outcomes.

Strengths: Their fundamental research approach addresses root causes of surface quality issues rather than just symptoms, potentially leading to more robust solutions. Their computational models provide valuable predictive capabilities for process optimization. Weaknesses: As an academic institution, their solutions may be less industrially integrated than commercial alternatives. Some of their more advanced modeling approaches require significant computational resources that may limit practical implementation.

Key Innovations in Roughness Reduction and Edge Preservation

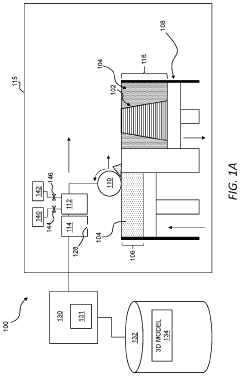

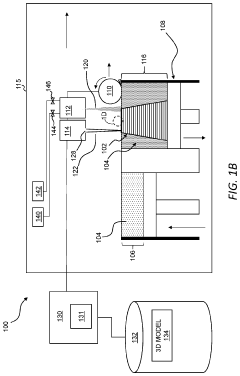

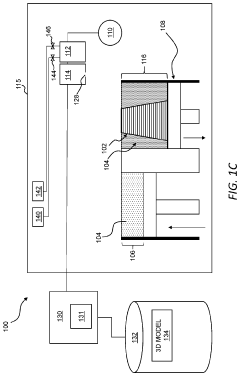

Managing powder mobility in binder jetting for additive manufacturing

PatentActiveUS11858210B2

Innovation

- The use of a vapor phase change to manage powder mobility by directing a first fluid vapor towards the powder layer, condensing it to reduce particle mobility and prevent ejection, and delivering a second fluid in a controlled pattern to bind the powder, thereby reducing printhead degradation and improving part quality.

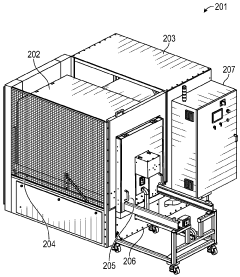

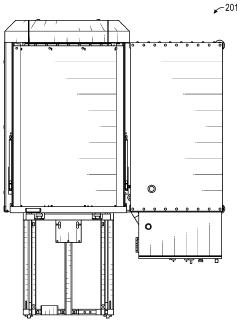

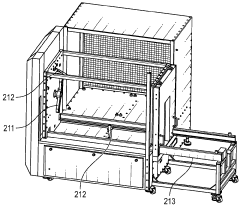

Build material powder curing station

PatentWO2023158652A2

Innovation

- A curing station equipped with a heating system, agitation system, and optional cooling system to cure build material powders, minimizing manual handling and ensuring safe processing by controlling temperature, atmosphere, and motion to alter powder attributes for improved binder jetting performance.

Post-Processing Integration with Traditional Machining Methods

The integration of Binder Jetting (BJ) with traditional machining methods represents a significant advancement in additive manufacturing post-processing strategies. This synergistic approach leverages the strengths of both manufacturing paradigms to overcome the inherent limitations of BJ technology, particularly regarding surface integrity and dimensional accuracy.

Traditional machining processes such as milling, turning, grinding, and polishing can be strategically applied to BJ-produced components to achieve superior surface quality that would be unattainable through BJ alone. Research indicates that hybrid manufacturing approaches combining BJ with CNC machining can reduce surface roughness values from typical as-printed Ra values of 15-25 μm down to 0.8-3 μm, depending on the material system and machining parameters employed.

A key consideration in this integration is the determination of appropriate machining allowances during the design phase. Studies suggest that optimal machining stock for BJ parts typically ranges from 0.3 to 0.8 mm, balancing material removal requirements with manufacturing efficiency. This predetermined allowance must account for the inherent porosity and material heterogeneity characteristic of BJ components.

The machinability of BJ parts presents unique challenges compared to traditionally manufactured components. The residual porosity in green or partially sintered BJ parts can lead to inconsistent cutting forces and tool wear patterns. Research has demonstrated that tailored cutting parameters—including reduced cutting speeds (typically 30-50% lower than those used for wrought materials) and modified feed rates—can significantly improve machining outcomes for BJ components.

Emerging research focuses on process chain optimization, where BJ and machining operations are sequenced to maximize efficiency and quality outcomes. One promising approach involves performing intermediate machining operations on green or partially sintered parts, followed by final sintering and precision finishing operations. This methodology has shown potential for reducing overall processing time by up to 40% while simultaneously improving dimensional accuracy and surface quality.

The development of specialized fixturing systems represents another critical area of innovation in BJ-machining integration. Custom-designed fixtures that accommodate the unique geometries and material properties of BJ parts have demonstrated significant improvements in machining precision, with positional accuracies approaching ±0.025 mm for complex geometrical features.

Advanced monitoring systems incorporating acoustic emission and cutting force sensors are being developed to provide real-time feedback during the machining of BJ components. These systems enable adaptive control of machining parameters based on the local material conditions encountered during processing, further enhancing the robustness and reliability of the integrated manufacturing approach.

Traditional machining processes such as milling, turning, grinding, and polishing can be strategically applied to BJ-produced components to achieve superior surface quality that would be unattainable through BJ alone. Research indicates that hybrid manufacturing approaches combining BJ with CNC machining can reduce surface roughness values from typical as-printed Ra values of 15-25 μm down to 0.8-3 μm, depending on the material system and machining parameters employed.

A key consideration in this integration is the determination of appropriate machining allowances during the design phase. Studies suggest that optimal machining stock for BJ parts typically ranges from 0.3 to 0.8 mm, balancing material removal requirements with manufacturing efficiency. This predetermined allowance must account for the inherent porosity and material heterogeneity characteristic of BJ components.

The machinability of BJ parts presents unique challenges compared to traditionally manufactured components. The residual porosity in green or partially sintered BJ parts can lead to inconsistent cutting forces and tool wear patterns. Research has demonstrated that tailored cutting parameters—including reduced cutting speeds (typically 30-50% lower than those used for wrought materials) and modified feed rates—can significantly improve machining outcomes for BJ components.

Emerging research focuses on process chain optimization, where BJ and machining operations are sequenced to maximize efficiency and quality outcomes. One promising approach involves performing intermediate machining operations on green or partially sintered parts, followed by final sintering and precision finishing operations. This methodology has shown potential for reducing overall processing time by up to 40% while simultaneously improving dimensional accuracy and surface quality.

The development of specialized fixturing systems represents another critical area of innovation in BJ-machining integration. Custom-designed fixtures that accommodate the unique geometries and material properties of BJ parts have demonstrated significant improvements in machining precision, with positional accuracies approaching ±0.025 mm for complex geometrical features.

Advanced monitoring systems incorporating acoustic emission and cutting force sensors are being developed to provide real-time feedback during the machining of BJ components. These systems enable adaptive control of machining parameters based on the local material conditions encountered during processing, further enhancing the robustness and reliability of the integrated manufacturing approach.

Material-Process Relationship in Surface Integrity Optimization

The optimization of surface integrity in binder jetting processes requires a comprehensive understanding of the intricate relationships between material properties and process parameters. Different materials exhibit unique behaviors during the printing, curing, and post-processing stages, significantly influencing the final surface quality.

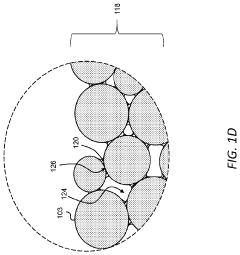

Powder characteristics play a fundamental role in determining surface integrity outcomes. Particle size distribution, morphology, and flowability directly impact the layer formation process. Finer powders generally yield smoother surfaces but may present challenges in spreading uniformity. Materials with irregular particle shapes tend to create more surface defects compared to spherical particles that promote better packing density.

The binder-material interaction constitutes another critical factor affecting surface quality. Chemical compatibility between the binder and powder material influences infiltration dynamics, which subsequently affects edge definition and surface roughness. Hydrophilic materials may experience different wetting behaviors compared to hydrophobic ones, necessitating tailored binder formulations to achieve optimal surface integrity.

Thermal properties of materials significantly impact post-processing outcomes. Materials with high thermal conductivity distribute heat more evenly during sintering or curing processes, resulting in more consistent surface characteristics. Conversely, materials with poor thermal properties may develop localized overheating, leading to surface irregularities and compromised edge fidelity.

Process parameters must be calibrated according to specific material properties. Layer thickness optimization depends on particle size distribution, with thinner layers generally producing better surface quality but potentially increasing build time. Binder saturation levels require adjustment based on material porosity and absorption characteristics to prevent oversaturation that leads to bleeding and poor edge definition.

Post-processing techniques demonstrate varying effectiveness depending on material properties. Infiltration processes work differently with porous versus dense materials, while machining responses vary significantly based on material hardness and microstructure. Materials with higher ductility typically achieve better surface finish through conventional machining compared to brittle materials that may require specialized approaches.

The synergistic relationship between material selection and process optimization creates opportunities for tailored manufacturing strategies. By understanding these material-process interactions, manufacturers can develop predictive models that anticipate surface integrity outcomes and implement adaptive processing parameters to achieve desired quality metrics across diverse material systems.

Powder characteristics play a fundamental role in determining surface integrity outcomes. Particle size distribution, morphology, and flowability directly impact the layer formation process. Finer powders generally yield smoother surfaces but may present challenges in spreading uniformity. Materials with irregular particle shapes tend to create more surface defects compared to spherical particles that promote better packing density.

The binder-material interaction constitutes another critical factor affecting surface quality. Chemical compatibility between the binder and powder material influences infiltration dynamics, which subsequently affects edge definition and surface roughness. Hydrophilic materials may experience different wetting behaviors compared to hydrophobic ones, necessitating tailored binder formulations to achieve optimal surface integrity.

Thermal properties of materials significantly impact post-processing outcomes. Materials with high thermal conductivity distribute heat more evenly during sintering or curing processes, resulting in more consistent surface characteristics. Conversely, materials with poor thermal properties may develop localized overheating, leading to surface irregularities and compromised edge fidelity.

Process parameters must be calibrated according to specific material properties. Layer thickness optimization depends on particle size distribution, with thinner layers generally producing better surface quality but potentially increasing build time. Binder saturation levels require adjustment based on material porosity and absorption characteristics to prevent oversaturation that leads to bleeding and poor edge definition.

Post-processing techniques demonstrate varying effectiveness depending on material properties. Infiltration processes work differently with porous versus dense materials, while machining responses vary significantly based on material hardness and microstructure. Materials with higher ductility typically achieve better surface finish through conventional machining compared to brittle materials that may require specialized approaches.

The synergistic relationship between material selection and process optimization creates opportunities for tailored manufacturing strategies. By understanding these material-process interactions, manufacturers can develop predictive models that anticipate surface integrity outcomes and implement adaptive processing parameters to achieve desired quality metrics across diverse material systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!