Binder Jetting Vs LPBF: Density, Fatigue And Surface Integrity

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal AM Technology Evolution and Objectives

Metal additive manufacturing (AM) has evolved significantly over the past three decades, transforming from experimental prototyping techniques to viable production methods for critical components. The journey began in the 1990s with rudimentary powder bed systems that produced parts with limited mechanical properties and considerable porosity issues. By the early 2000s, laser-based systems had improved substantially, though they remained primarily focused on prototyping applications rather than end-use parts.

The technological evolution accelerated dramatically between 2010-2020, with the emergence of two distinct metal AM pathways: powder bed fusion technologies like Laser Powder Bed Fusion (LPBF) and binder-based approaches such as Binder Jetting. LPBF systems evolved to incorporate multiple lasers, sophisticated monitoring systems, and improved powder handling capabilities, enabling the production of components with densities exceeding 99.5% of theoretical maximum.

Concurrently, Binder Jetting technology underwent significant refinement, moving from primarily sand-casting applications to direct metal part production. The separation of printing and sintering processes in Binder Jetting created new possibilities for scalability and cost reduction, though density achievement remained a persistent challenge compared to LPBF processes.

The primary objectives driving metal AM development have consistently centered around achieving material properties comparable to conventionally manufactured parts. Density has emerged as a critical factor, directly influencing mechanical performance, particularly fatigue resistance. Surface integrity represents another crucial objective, as both technologies produce distinct surface characteristics that impact post-processing requirements and final part performance.

Current technological objectives focus on addressing the fundamental trade-offs between these two approaches. LPBF aims to maintain its superior density while reducing residual stresses, improving surface finish, and increasing build rates. Binder Jetting development targets enhanced sintering protocols to achieve densities comparable to LPBF while preserving its inherent advantages in scalability and cost-effectiveness.

The evolution trajectory suggests convergence toward hybrid approaches that leverage the strengths of both technologies. Research increasingly focuses on tailored process parameters that optimize density, fatigue performance, and surface integrity for specific applications rather than pursuing universal solutions. This application-specific optimization represents the next frontier in metal AM development, with particular emphasis on high-performance sectors like aerospace, medical, and energy production.

The technological evolution accelerated dramatically between 2010-2020, with the emergence of two distinct metal AM pathways: powder bed fusion technologies like Laser Powder Bed Fusion (LPBF) and binder-based approaches such as Binder Jetting. LPBF systems evolved to incorporate multiple lasers, sophisticated monitoring systems, and improved powder handling capabilities, enabling the production of components with densities exceeding 99.5% of theoretical maximum.

Concurrently, Binder Jetting technology underwent significant refinement, moving from primarily sand-casting applications to direct metal part production. The separation of printing and sintering processes in Binder Jetting created new possibilities for scalability and cost reduction, though density achievement remained a persistent challenge compared to LPBF processes.

The primary objectives driving metal AM development have consistently centered around achieving material properties comparable to conventionally manufactured parts. Density has emerged as a critical factor, directly influencing mechanical performance, particularly fatigue resistance. Surface integrity represents another crucial objective, as both technologies produce distinct surface characteristics that impact post-processing requirements and final part performance.

Current technological objectives focus on addressing the fundamental trade-offs between these two approaches. LPBF aims to maintain its superior density while reducing residual stresses, improving surface finish, and increasing build rates. Binder Jetting development targets enhanced sintering protocols to achieve densities comparable to LPBF while preserving its inherent advantages in scalability and cost-effectiveness.

The evolution trajectory suggests convergence toward hybrid approaches that leverage the strengths of both technologies. Research increasingly focuses on tailored process parameters that optimize density, fatigue performance, and surface integrity for specific applications rather than pursuing universal solutions. This application-specific optimization represents the next frontier in metal AM development, with particular emphasis on high-performance sectors like aerospace, medical, and energy production.

Market Analysis for Binder Jetting and LPBF Applications

The additive manufacturing market has witnessed significant growth in recent years, with Binder Jetting and Laser Powder Bed Fusion (LPBF) emerging as two prominent technologies. The global additive manufacturing market reached approximately $13.7 billion in 2021 and is projected to grow at a CAGR of 20.8% through 2030, according to SmarTech Analysis.

Metal additive manufacturing specifically has seen accelerated adoption across aerospace, automotive, healthcare, and industrial sectors. LPBF currently dominates this segment, accounting for roughly 80% of metal AM systems sold globally, while Binder Jetting represents a rapidly growing alternative with 15% market share that continues to expand.

The aerospace industry remains the largest consumer of these technologies, valuing the high-density parts produced by LPBF for critical components. Boeing, GE Aviation, and Airbus have invested heavily in LPBF technology for producing complex engine components and structural parts. Meanwhile, Binder Jetting has gained traction in automotive applications, where HP and Desktop Metal have secured significant contracts with major manufacturers like BMW and Ford.

Healthcare represents another substantial market, with medical device manufacturers increasingly adopting both technologies. LPBF dominates in patient-specific implants requiring high density and excellent fatigue resistance, while Binder Jetting shows promise for non-implantable devices and anatomical models where production speed outweighs density requirements.

Regional analysis reveals North America leading with approximately 40% market share, followed by Europe (35%) and Asia-Pacific (20%). China has emerged as the fastest-growing market, investing heavily in both technologies as part of its "Made in China 2025" initiative.

Price sensitivity varies significantly across applications. High-value, low-volume industries like aerospace and medical implants prioritize the superior density and fatigue performance of LPBF despite its higher costs. Conversely, automotive, consumer goods, and general industrial applications increasingly favor Binder Jetting's cost advantages and higher throughput capabilities.

Market forecasts indicate Binder Jetting will experience faster growth (30% CAGR) compared to LPBF (18% CAGR) through 2028, driven by improving material properties and significant cost advantages. However, LPBF will maintain dominance in high-performance applications where mechanical properties remain paramount.

The service bureau market has evolved to accommodate both technologies, with companies like Materialise, Protolabs, and Shapeways expanding their offerings to include both processes, allowing customers to select based on specific application requirements for density, surface finish, and fatigue performance.

Metal additive manufacturing specifically has seen accelerated adoption across aerospace, automotive, healthcare, and industrial sectors. LPBF currently dominates this segment, accounting for roughly 80% of metal AM systems sold globally, while Binder Jetting represents a rapidly growing alternative with 15% market share that continues to expand.

The aerospace industry remains the largest consumer of these technologies, valuing the high-density parts produced by LPBF for critical components. Boeing, GE Aviation, and Airbus have invested heavily in LPBF technology for producing complex engine components and structural parts. Meanwhile, Binder Jetting has gained traction in automotive applications, where HP and Desktop Metal have secured significant contracts with major manufacturers like BMW and Ford.

Healthcare represents another substantial market, with medical device manufacturers increasingly adopting both technologies. LPBF dominates in patient-specific implants requiring high density and excellent fatigue resistance, while Binder Jetting shows promise for non-implantable devices and anatomical models where production speed outweighs density requirements.

Regional analysis reveals North America leading with approximately 40% market share, followed by Europe (35%) and Asia-Pacific (20%). China has emerged as the fastest-growing market, investing heavily in both technologies as part of its "Made in China 2025" initiative.

Price sensitivity varies significantly across applications. High-value, low-volume industries like aerospace and medical implants prioritize the superior density and fatigue performance of LPBF despite its higher costs. Conversely, automotive, consumer goods, and general industrial applications increasingly favor Binder Jetting's cost advantages and higher throughput capabilities.

Market forecasts indicate Binder Jetting will experience faster growth (30% CAGR) compared to LPBF (18% CAGR) through 2028, driven by improving material properties and significant cost advantages. However, LPBF will maintain dominance in high-performance applications where mechanical properties remain paramount.

The service bureau market has evolved to accommodate both technologies, with companies like Materialise, Protolabs, and Shapeways expanding their offerings to include both processes, allowing customers to select based on specific application requirements for density, surface finish, and fatigue performance.

Technical Comparison and Limitations Assessment

When comparing Binder Jetting (BJ) and Laser Powder Bed Fusion (LPBF) technologies, significant differences emerge in their fundamental capabilities and limitations. LPBF typically achieves superior density levels, commonly reaching 99.5-99.9% of theoretical density due to its complete melting process. In contrast, BJ parts often exhibit lower densities ranging from 60-96% without post-processing, necessitating infiltration or sintering to improve density.

Surface integrity characteristics differ substantially between these technologies. LPBF produces surfaces with roughness values (Ra) typically between 5-20 μm, with the potential for localized thermal stress concentrations and occasional spatter particles. BJ generally yields rougher surfaces with Ra values of 15-30 μm, though it avoids thermal stress-related defects and offers more consistent surface texture across complex geometries.

Fatigue performance represents a critical differentiator between these technologies. LPBF components demonstrate superior fatigue resistance, achieving 70-90% of wrought material properties after proper heat treatment. This performance stems from their high density and strong metallurgical bonding. BJ parts typically exhibit 40-70% of wrought material fatigue properties, primarily limited by residual porosity that serves as crack initiation sites.

Technical limitations of LPBF include significant residual stresses requiring support structures and post-process heat treatment, size constraints (typically under 500mm in any dimension), and challenges with certain high-reflectivity or crack-susceptible materials. BJ's limitations center on lower mechanical properties, dimensional accuracy challenges during sintering (±0.2-0.5% compared to LPBF's ±0.1%), and more extensive post-processing requirements.

Material compatibility also differs markedly. LPBF excels with titanium alloys, nickel superalloys, and tool steels, but struggles with copper, aluminum, and refractory metals. BJ offers broader material flexibility, including ceramics and composites, though achieving optimal properties remains challenging with high-performance alloys.

Production economics reveal that LPBF becomes cost-prohibitive for larger volumes due to slow build rates (15-120 cm³/hour) and high energy consumption. BJ offers significantly faster build rates (300-3000 cm³/hour) and lower energy requirements, making it more economical for higher production volumes despite additional post-processing costs.

Surface integrity characteristics differ substantially between these technologies. LPBF produces surfaces with roughness values (Ra) typically between 5-20 μm, with the potential for localized thermal stress concentrations and occasional spatter particles. BJ generally yields rougher surfaces with Ra values of 15-30 μm, though it avoids thermal stress-related defects and offers more consistent surface texture across complex geometries.

Fatigue performance represents a critical differentiator between these technologies. LPBF components demonstrate superior fatigue resistance, achieving 70-90% of wrought material properties after proper heat treatment. This performance stems from their high density and strong metallurgical bonding. BJ parts typically exhibit 40-70% of wrought material fatigue properties, primarily limited by residual porosity that serves as crack initiation sites.

Technical limitations of LPBF include significant residual stresses requiring support structures and post-process heat treatment, size constraints (typically under 500mm in any dimension), and challenges with certain high-reflectivity or crack-susceptible materials. BJ's limitations center on lower mechanical properties, dimensional accuracy challenges during sintering (±0.2-0.5% compared to LPBF's ±0.1%), and more extensive post-processing requirements.

Material compatibility also differs markedly. LPBF excels with titanium alloys, nickel superalloys, and tool steels, but struggles with copper, aluminum, and refractory metals. BJ offers broader material flexibility, including ceramics and composites, though achieving optimal properties remains challenging with high-performance alloys.

Production economics reveal that LPBF becomes cost-prohibitive for larger volumes due to slow build rates (15-120 cm³/hour) and high energy consumption. BJ offers significantly faster build rates (300-3000 cm³/hour) and lower energy requirements, making it more economical for higher production volumes despite additional post-processing costs.

Current Solutions for Density and Integrity Challenges

01 Density optimization in additive manufacturing processes

Various techniques can be employed to optimize density in both Binder Jetting and LPBF processes. For Binder Jetting, controlling binder saturation levels and post-processing sintering parameters significantly affects final part density. In LPBF, laser power, scanning speed, and hatch spacing are critical parameters that determine energy density and consequently part density. Advanced process monitoring and control systems can be implemented to ensure consistent density throughout complex geometries, reducing porosity and improving mechanical properties.- Density optimization in additive manufacturing processes: Density is a critical parameter in both Binder Jetting and LPBF processes that affects the mechanical properties of the final parts. Various techniques can be employed to optimize density, including process parameter optimization, powder characteristics control, and post-processing treatments. Higher density typically correlates with improved mechanical properties, reduced porosity, and enhanced performance in functional applications. Optimization strategies may include adjusting laser power and scan speed in LPBF or binder saturation and curing parameters in Binder Jetting.

- Fatigue performance comparison between Binder Jetting and LPBF: Fatigue performance differs significantly between parts produced via Binder Jetting and LPBF due to their inherent process characteristics. LPBF typically produces parts with higher density and better fatigue resistance due to the complete melting of powder particles. Binder Jetting parts often require additional post-processing steps like infiltration or sintering to achieve comparable fatigue properties. Factors affecting fatigue performance include microstructural features, residual stresses, surface roughness, and internal defects such as pores or lack-of-fusion defects.

- Surface integrity enhancement techniques: Surface integrity is crucial for both aesthetic and functional properties of additively manufactured parts. Various post-processing techniques can be applied to enhance surface integrity, including mechanical finishing (polishing, shot peening, machining), chemical treatments, and thermal processes. For LPBF, laser re-melting of the surface layer can significantly improve surface quality. For Binder Jetting, infiltration processes and careful control of sintering parameters can enhance surface characteristics. Improved surface integrity typically leads to better fatigue performance and dimensional accuracy.

- Process parameter optimization for improved mechanical properties: Optimizing process parameters in both Binder Jetting and LPBF is essential for achieving desired mechanical properties. For LPBF, key parameters include laser power, scan speed, hatch spacing, and layer thickness. In Binder Jetting, critical parameters include binder saturation, layer thickness, curing conditions, and sintering profiles. Advanced optimization approaches may involve machine learning algorithms, design of experiments, and in-process monitoring systems to establish correlations between process parameters and resulting material properties such as density, strength, and fatigue resistance.

- Post-processing treatments for density and performance enhancement: Post-processing treatments play a crucial role in enhancing the density, mechanical properties, and surface integrity of parts produced by both Binder Jetting and LPBF. Common treatments include hot isostatic pressing (HIP) to eliminate internal porosity, heat treatments to relieve residual stresses and modify microstructure, infiltration with secondary materials for Binder Jetted parts, and surface treatments like shot peening or laser polishing. These post-processing steps can significantly improve fatigue performance, density, and overall part quality, bridging the gap between the two manufacturing methods.

02 Fatigue performance enhancement strategies

Fatigue performance of additively manufactured parts can be enhanced through various strategies specific to each process. For LPBF, heat treatment protocols can relieve residual stresses and modify microstructure to improve fatigue resistance. In Binder Jetting, infiltration techniques and specialized sintering profiles can strengthen parts against cyclic loading. Surface treatments such as shot peening or hot isostatic pressing (HIP) can be applied to both processes to eliminate surface defects that act as fatigue crack initiation sites, thereby extending component life under dynamic loading conditions.Expand Specific Solutions03 Surface integrity improvement methods

Surface integrity of additively manufactured components can be significantly improved through post-processing techniques. For LPBF parts, laser polishing can reduce surface roughness while maintaining dimensional accuracy. Chemical treatments and electropolishing are effective for complex geometries in both processes. For Binder Jetted parts, media tumbling and abrasive flow machining can enhance surface finish. Advanced hybrid manufacturing approaches that combine additive processes with in-situ machining operations can produce components with superior surface integrity directly from the build process.Expand Specific Solutions04 Process parameter optimization for material properties

Optimizing process parameters is crucial for achieving desired material properties in both Binder Jetting and LPBF. Machine learning algorithms can be employed to identify optimal parameter combinations for specific materials and geometries. For LPBF, laser scan strategies including contour scanning and island scanning can be tailored to control microstructure development. In Binder Jetting, binder formulation and curing parameters significantly impact green part strength and subsequent sintering behavior. Multi-objective optimization approaches can balance density, mechanical properties, and production efficiency.Expand Specific Solutions05 Comparative analysis between Binder Jetting and LPBF

Comparative studies between Binder Jetting and LPBF reveal distinct advantages for specific applications. LPBF typically produces parts with higher density and superior mechanical properties but with higher residual stresses and limited material compatibility. Binder Jetting offers larger build volumes, faster production rates, and lower costs but generally yields lower density parts requiring extensive post-processing. Hybrid approaches combining aspects of both technologies are emerging to leverage their complementary strengths. Material-specific considerations guide process selection, with certain alloys performing better in one process versus the other.Expand Specific Solutions

Leading Companies in Metal AM Technologies

Binder Jetting and Laser Powder Bed Fusion (LPBF) technologies are currently at different maturity stages in the additive manufacturing landscape. The market is experiencing rapid growth, projected to reach $35 billion by 2027, with a CAGR of approximately 20%. While LPBF has achieved greater industrial adoption due to superior density and mechanical properties, Binder Jetting is gaining momentum for its cost-effectiveness and higher production rates. Key players shaping this competitive landscape include Desktop Metal and ExOne (now part of Nano Dimension) pioneering Binder Jetting advancements, while established manufacturers like GE Additive, EOS, and newer entrants such as Xerox are developing LPBF technologies. Research institutions including The University of Liverpool, Politecnico di Milano, and Yale University are contributing significant innovations in material science and process optimization for both technologies.

ExOne Operating LLC

Technical Solution: ExOne specializes in industrial binder jetting technology with their Triple Advanced Compaction Technology (Triple ACT) system that significantly improves powder packing density during the printing process. Their approach utilizes specialized binders and controlled powder spreading techniques to achieve green part densities up to 65%, which translates to final sintered densities exceeding 97% for most metal alloys. ExOne's research has demonstrated that their binder jetted parts, when subjected to optimized sintering protocols, can achieve surface roughness values of Ra 6-10 μm without additional finishing, compared to typical LPBF surface roughness of Ra 10-15 μm. Their patented CleanFuse binder system addresses oxygen contamination issues during sintering, resulting in improved microstructural integrity and fatigue performance. ExOne has documented that properly sintered 316L stainless steel parts can achieve 95-98% of the fatigue strength of equivalent LPBF parts while offering significant cost advantages for complex geometries.

Strengths: Lower equipment and operational costs compared to LPBF, ability to process larger build volumes, excellent material versatility including ceramics and composites, and superior surface finish potential. Weaknesses: Lower green part strength requiring careful handling before sintering, longer overall processing time due to debinding and sintering requirements, and more complex process parameter optimization for achieving maximum density.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed a proprietary Single Pass Jetting (SPJ) binder jetting technology that achieves up to 100 times faster production speeds compared to LPBF systems. Their Production System P-50 utilizes bi-directional printing and advanced powder spreading mechanisms to achieve part densities exceeding 98% without the need for lengthy sintering cycles. The company's Bound Metal Deposition process combines the accessibility of binder jetting with enhanced surface finish capabilities. Desktop Metal has also pioneered the Live Sinter simulation software that predicts and compensates for sintering deformation, addressing one of binder jetting's key challenges in maintaining dimensional accuracy and surface integrity. Their research indicates that binder jetted parts, when properly sintered, can achieve comparable fatigue performance to LPBF parts in certain applications while offering significant cost advantages.

Strengths: Superior production speed (up to 100x faster than LPBF), lower operational costs, ability to process a wider range of materials including ceramics and composites, and excellent scalability for mass production. Weaknesses: Generally lower as-printed densities requiring post-processing sintering steps, more limited mechanical properties for certain high-stress applications, and greater dimensional variability compared to LPBF processes.

Critical Patents and Research in AM Material Properties

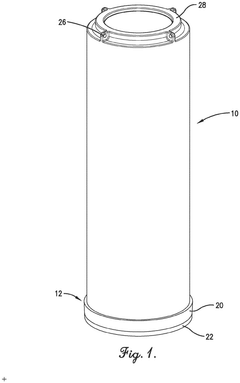

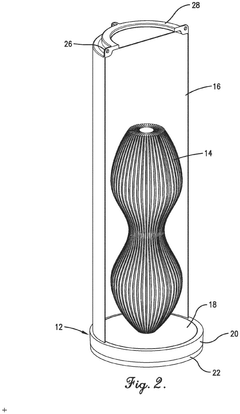

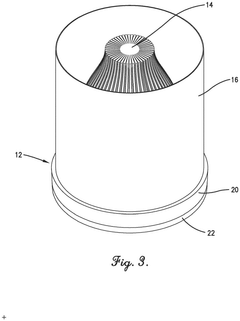

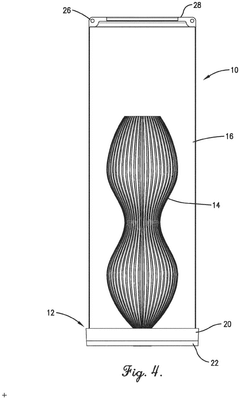

Method for three-dimensional printed powder containment

PatentPendingEP4509249A2

Innovation

- A method involving the simultaneous 3D printing of a canister with the printed part using a single additive manufacturing process, allowing for the containment of powder within the canister, which can then be transported and processed separately for powder removal and recycling.

Material Science Considerations for AM Technologies

Material selection for additive manufacturing (AM) technologies requires careful consideration of the unique processing conditions and their effects on final part properties. When comparing Binder Jetting and Laser Powder Bed Fusion (LPBF) technologies, material science factors significantly influence the achievable density, fatigue performance, and surface integrity of manufactured components.

Powder characteristics play a crucial role in both processes but with different requirements. LPBF typically demands spherical powders with specific size distributions (20-63 μm) to ensure optimal laser absorption and melt pool dynamics. Binder Jetting can accommodate wider particle size distributions and less spherical morphologies, though these factors directly impact green part density and subsequent sintering behavior.

The thermal history experienced by materials differs dramatically between these technologies. LPBF subjects materials to extreme thermal gradients (10^3-10^6 K/s) and rapid solidification, leading to unique microstructures often characterized by columnar grains growing in the build direction. Binder Jetting involves a more gradual thermal process during sintering, resulting in more equiaxed grain structures but potentially higher porosity.

Porosity formation mechanisms are fundamentally different between these processes. In LPBF, porosity typically results from lack-of-fusion defects, keyhole formation, or gas entrapment during rapid solidification. Binder Jetting porosity stems primarily from incomplete sintering and initial powder packing density limitations. These different porosity types significantly impact fatigue performance, with LPBF parts generally achieving higher density (>99.5%) compared to Binder Jetting (95-99%).

Surface integrity considerations also vary substantially. LPBF surfaces typically exhibit partially melted powder particles and laser scan track patterns, with roughness values (Ra) ranging from 5-20 μm depending on orientation. Binder Jetting produces surfaces with characteristic sintering-related features and generally higher roughness values unless post-processing is applied.

Material compatibility presents another important distinction. LPBF has been successfully applied to numerous alloys including titanium, nickel-based superalloys, and aluminum, though weldability is a prerequisite. Binder Jetting offers broader material flexibility including ceramics and composites, but requires careful binder-powder compatibility assessment and sintering profile optimization.

These material science considerations directly translate to mechanical property differences, particularly in fatigue performance where LPBF's higher density typically yields superior high-cycle fatigue resistance despite residual stress challenges. Understanding these fundamental material science aspects is essential for appropriate technology selection based on specific application requirements.

Powder characteristics play a crucial role in both processes but with different requirements. LPBF typically demands spherical powders with specific size distributions (20-63 μm) to ensure optimal laser absorption and melt pool dynamics. Binder Jetting can accommodate wider particle size distributions and less spherical morphologies, though these factors directly impact green part density and subsequent sintering behavior.

The thermal history experienced by materials differs dramatically between these technologies. LPBF subjects materials to extreme thermal gradients (10^3-10^6 K/s) and rapid solidification, leading to unique microstructures often characterized by columnar grains growing in the build direction. Binder Jetting involves a more gradual thermal process during sintering, resulting in more equiaxed grain structures but potentially higher porosity.

Porosity formation mechanisms are fundamentally different between these processes. In LPBF, porosity typically results from lack-of-fusion defects, keyhole formation, or gas entrapment during rapid solidification. Binder Jetting porosity stems primarily from incomplete sintering and initial powder packing density limitations. These different porosity types significantly impact fatigue performance, with LPBF parts generally achieving higher density (>99.5%) compared to Binder Jetting (95-99%).

Surface integrity considerations also vary substantially. LPBF surfaces typically exhibit partially melted powder particles and laser scan track patterns, with roughness values (Ra) ranging from 5-20 μm depending on orientation. Binder Jetting produces surfaces with characteristic sintering-related features and generally higher roughness values unless post-processing is applied.

Material compatibility presents another important distinction. LPBF has been successfully applied to numerous alloys including titanium, nickel-based superalloys, and aluminum, though weldability is a prerequisite. Binder Jetting offers broader material flexibility including ceramics and composites, but requires careful binder-powder compatibility assessment and sintering profile optimization.

These material science considerations directly translate to mechanical property differences, particularly in fatigue performance where LPBF's higher density typically yields superior high-cycle fatigue resistance despite residual stress challenges. Understanding these fundamental material science aspects is essential for appropriate technology selection based on specific application requirements.

Cost-Benefit Analysis of Competing AM Methods

When comparing Binder Jetting (BJ) and Laser Powder Bed Fusion (LPBF) additive manufacturing technologies, cost-benefit analysis reveals significant economic and operational differences that impact manufacturing decisions.

Initial equipment investment presents a stark contrast, with BJ systems typically ranging from $200,000 to $500,000, while LPBF systems command higher capital expenditure between $400,000 and $1.5 million. This substantial difference in upfront costs makes BJ more accessible for smaller operations or companies entering the additive manufacturing space.

Material costs also favor BJ, which can utilize standard metal powders without specialized requirements for flowability or laser absorption characteristics. LPBF requires specially designed powders with specific particle size distributions and optical properties, often commanding a 30-50% price premium over standard powders used in BJ processes.

Production speed analysis demonstrates BJ's advantage in high-volume scenarios. BJ can simultaneously produce multiple parts across the entire build platform, while LPBF processes parts sequentially as the laser traces each layer. For large production runs, BJ may achieve 3-5x higher throughput rates, significantly reducing per-part costs.

Energy consumption metrics further differentiate these technologies. LPBF's high-powered lasers (typically 200-1000W) consume substantially more energy than BJ's printheads and curing systems. Studies indicate LPBF processes require approximately 80-120 kWh per kilogram of processed material, whereas BJ systems operate at 15-30 kWh per kilogram.

Post-processing requirements introduce additional cost considerations. BJ parts require debinding and sintering steps that add processing time and equipment costs. Conversely, LPBF parts often need support removal, heat treatment, and surface finishing. The total post-processing costs typically represent 20-40% of total part cost for BJ and 15-30% for LPBF, depending on geometry complexity.

Maintenance and operational expenses also differ significantly. LPBF systems require regular laser maintenance, filter replacements, and specialized operator training. BJ systems generally have lower maintenance costs but may require more frequent printhead replacements and sintering furnace maintenance.

When analyzing total cost of ownership over a five-year period, BJ demonstrates advantages for high-volume production of less structurally demanding components, while LPBF proves more economical for lower-volume, high-performance applications where material properties are paramount.

Initial equipment investment presents a stark contrast, with BJ systems typically ranging from $200,000 to $500,000, while LPBF systems command higher capital expenditure between $400,000 and $1.5 million. This substantial difference in upfront costs makes BJ more accessible for smaller operations or companies entering the additive manufacturing space.

Material costs also favor BJ, which can utilize standard metal powders without specialized requirements for flowability or laser absorption characteristics. LPBF requires specially designed powders with specific particle size distributions and optical properties, often commanding a 30-50% price premium over standard powders used in BJ processes.

Production speed analysis demonstrates BJ's advantage in high-volume scenarios. BJ can simultaneously produce multiple parts across the entire build platform, while LPBF processes parts sequentially as the laser traces each layer. For large production runs, BJ may achieve 3-5x higher throughput rates, significantly reducing per-part costs.

Energy consumption metrics further differentiate these technologies. LPBF's high-powered lasers (typically 200-1000W) consume substantially more energy than BJ's printheads and curing systems. Studies indicate LPBF processes require approximately 80-120 kWh per kilogram of processed material, whereas BJ systems operate at 15-30 kWh per kilogram.

Post-processing requirements introduce additional cost considerations. BJ parts require debinding and sintering steps that add processing time and equipment costs. Conversely, LPBF parts often need support removal, heat treatment, and surface finishing. The total post-processing costs typically represent 20-40% of total part cost for BJ and 15-30% for LPBF, depending on geometry complexity.

Maintenance and operational expenses also differ significantly. LPBF systems require regular laser maintenance, filter replacements, and specialized operator training. BJ systems generally have lower maintenance costs but may require more frequent printhead replacements and sintering furnace maintenance.

When analyzing total cost of ownership over a five-year period, BJ demonstrates advantages for high-volume production of less structurally demanding components, while LPBF proves more economical for lower-volume, high-performance applications where material properties are paramount.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!