How Binder Jetting Integrates With HIP To Elevate Mechanical Performance?

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting and HIP Integration Background and Objectives

Binder Jetting (BJ) technology emerged in the early 1990s as one of the pioneering additive manufacturing (AM) methods, offering a unique approach to creating complex geometries without the need for support structures. This powder-based process selectively deposits binding agents onto thin layers of powder material, creating parts through a layer-by-layer approach. Despite its advantages in geometric freedom and material versatility, BJ-produced components have historically suffered from limited mechanical properties due to inherent porosity and weak inter-particle bonding.

Hot Isostatic Pressing (HIP), developed in the 1950s for the nuclear industry, has evolved into a critical post-processing technology that applies uniform high pressure and temperature simultaneously to densify materials. The integration of these two technologies represents a significant technological convergence aimed at overcoming the limitations of each individual process while capitalizing on their respective strengths.

The evolution of this integrated approach has accelerated over the past decade, driven by increasing demands for high-performance components in aerospace, medical, and automotive industries. Early attempts at combining these technologies faced challenges in process parameter optimization and material compatibility, but recent advancements have shown promising results in achieving near-theoretical density parts with enhanced mechanical properties.

The primary objective of integrating BJ with HIP is to develop a cost-effective manufacturing route for producing complex metal components with mechanical properties comparable to traditionally manufactured parts. This integration aims to leverage BJ's geometric freedom and scalability while utilizing HIP's ability to eliminate internal porosity and enhance material homogeneity.

Secondary objectives include expanding the range of applicable materials beyond current limitations, reducing the overall energy consumption compared to other AM technologies, and establishing standardized processes for consistent quality assurance. The development of this integrated approach also seeks to address the growing need for sustainable manufacturing methods by minimizing material waste and optimizing resource utilization.

The technological trajectory indicates a shift toward more sophisticated process control systems that can predict and compensate for dimensional changes during the HIP cycle, as well as advanced simulation tools for optimizing both BJ printing parameters and subsequent HIP treatments. Research efforts are increasingly focused on understanding the fundamental metallurgical transformations that occur during this integrated process to better control microstructural development and resultant mechanical properties.

As industries continue to demand higher performance components with complex geometries, the BJ-HIP integration represents a promising pathway to meet these evolving requirements while potentially reducing production costs and lead times compared to conventional manufacturing methods.

Hot Isostatic Pressing (HIP), developed in the 1950s for the nuclear industry, has evolved into a critical post-processing technology that applies uniform high pressure and temperature simultaneously to densify materials. The integration of these two technologies represents a significant technological convergence aimed at overcoming the limitations of each individual process while capitalizing on their respective strengths.

The evolution of this integrated approach has accelerated over the past decade, driven by increasing demands for high-performance components in aerospace, medical, and automotive industries. Early attempts at combining these technologies faced challenges in process parameter optimization and material compatibility, but recent advancements have shown promising results in achieving near-theoretical density parts with enhanced mechanical properties.

The primary objective of integrating BJ with HIP is to develop a cost-effective manufacturing route for producing complex metal components with mechanical properties comparable to traditionally manufactured parts. This integration aims to leverage BJ's geometric freedom and scalability while utilizing HIP's ability to eliminate internal porosity and enhance material homogeneity.

Secondary objectives include expanding the range of applicable materials beyond current limitations, reducing the overall energy consumption compared to other AM technologies, and establishing standardized processes for consistent quality assurance. The development of this integrated approach also seeks to address the growing need for sustainable manufacturing methods by minimizing material waste and optimizing resource utilization.

The technological trajectory indicates a shift toward more sophisticated process control systems that can predict and compensate for dimensional changes during the HIP cycle, as well as advanced simulation tools for optimizing both BJ printing parameters and subsequent HIP treatments. Research efforts are increasingly focused on understanding the fundamental metallurgical transformations that occur during this integrated process to better control microstructural development and resultant mechanical properties.

As industries continue to demand higher performance components with complex geometries, the BJ-HIP integration represents a promising pathway to meet these evolving requirements while potentially reducing production costs and lead times compared to conventional manufacturing methods.

Market Analysis for High-Performance Additive Manufacturing

The additive manufacturing market for high-performance applications has experienced remarkable growth in recent years, with the global market value reaching $13.7 billion in 2022 and projected to expand at a CAGR of 20.8% through 2030. This growth is primarily driven by increasing demand across aerospace, automotive, healthcare, and industrial sectors seeking lightweight, complex components with superior mechanical properties.

Binder Jetting combined with Hot Isostatic Pressing (HIP) represents a significant segment within this market, addressing the critical need for parts that exhibit exceptional strength, durability, and performance characteristics. The aerospace industry currently dominates this application space, accounting for approximately 35% of the market share, as manufacturers seek to produce complex engine components, structural parts, and heat exchangers with reduced weight and enhanced performance profiles.

The automotive sector follows closely behind at 28% market share, with growing adoption for producing high-performance engine components, transmission parts, and specialized structural elements. This trend is accelerating as automotive manufacturers increasingly transition toward electric vehicles, which require specialized thermal management components that can be optimally produced using this combined technology approach.

Healthcare applications represent the fastest-growing segment at 24% annual growth, particularly in orthopedic implants, dental prosthetics, and specialized surgical instruments where customization and biocompatibility are paramount concerns. The ability to create patient-specific implants with optimized mechanical properties and surface characteristics has revolutionized treatment approaches and patient outcomes.

Regionally, North America leads the market with 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate at 25.3% annually, driven by rapid industrialization in China, Japan, and South Korea, along with significant government investments in advanced manufacturing technologies.

Key market challenges include the high initial investment costs for integrated Binder Jetting and HIP systems, which typically range from $500,000 to $2.5 million depending on capacity and specifications. Additionally, material costs remain 2-3 times higher than traditional manufacturing inputs, though this gap is narrowing as adoption increases and supply chains mature.

Customer demand patterns indicate a growing preference for turnkey solutions that integrate design optimization, production, post-processing, and quality assurance within unified service offerings. This trend is reshaping the competitive landscape, favoring providers who can deliver comprehensive solutions rather than standalone technologies or services.

Binder Jetting combined with Hot Isostatic Pressing (HIP) represents a significant segment within this market, addressing the critical need for parts that exhibit exceptional strength, durability, and performance characteristics. The aerospace industry currently dominates this application space, accounting for approximately 35% of the market share, as manufacturers seek to produce complex engine components, structural parts, and heat exchangers with reduced weight and enhanced performance profiles.

The automotive sector follows closely behind at 28% market share, with growing adoption for producing high-performance engine components, transmission parts, and specialized structural elements. This trend is accelerating as automotive manufacturers increasingly transition toward electric vehicles, which require specialized thermal management components that can be optimally produced using this combined technology approach.

Healthcare applications represent the fastest-growing segment at 24% annual growth, particularly in orthopedic implants, dental prosthetics, and specialized surgical instruments where customization and biocompatibility are paramount concerns. The ability to create patient-specific implants with optimized mechanical properties and surface characteristics has revolutionized treatment approaches and patient outcomes.

Regionally, North America leads the market with 42% share, followed by Europe (31%) and Asia-Pacific (22%). However, the Asia-Pacific region is experiencing the fastest growth rate at 25.3% annually, driven by rapid industrialization in China, Japan, and South Korea, along with significant government investments in advanced manufacturing technologies.

Key market challenges include the high initial investment costs for integrated Binder Jetting and HIP systems, which typically range from $500,000 to $2.5 million depending on capacity and specifications. Additionally, material costs remain 2-3 times higher than traditional manufacturing inputs, though this gap is narrowing as adoption increases and supply chains mature.

Customer demand patterns indicate a growing preference for turnkey solutions that integrate design optimization, production, post-processing, and quality assurance within unified service offerings. This trend is reshaping the competitive landscape, favoring providers who can deliver comprehensive solutions rather than standalone technologies or services.

Technical Challenges in Binder Jetting-HIP Process Chain

Despite the promising integration of Binder Jetting (BJ) and Hot Isostatic Pressing (HIP) technologies, this process chain faces several significant technical challenges that limit its widespread industrial adoption. The primary challenge lies in the complex relationship between printing parameters and final part properties. Binder saturation levels, powder characteristics, and layer thickness during printing directly impact green part density, which subsequently affects sintering behavior and final mechanical performance after HIP treatment.

Porosity control represents another major hurdle in the BJ-HIP process chain. While HIP effectively eliminates closed porosity, open porosity remains problematic. The transition from open to closed porosity during pre-sintering is critical yet difficult to predict and control across different geometries and materials. This unpredictability leads to inconsistent densification and mechanical properties in final components.

Dimensional accuracy and distortion management present persistent challenges throughout the process chain. Parts typically experience 15-20% linear shrinkage during sintering, with additional dimensional changes during HIP treatment. This shrinkage is often non-uniform and can vary based on part geometry, leading to warping and distortion. Current compensation strategies remain largely empirical and material-specific, lacking robust predictive models.

Material compatibility issues further complicate the BJ-HIP integration. Not all materials suitable for binder jetting respond favorably to HIP treatment. Some materials exhibit abnormal grain growth during the combined thermal cycles, while others develop unfavorable microstructures that compromise mechanical properties despite achieving full density. The development of specialized powder formulations optimized for the entire process chain remains limited.

Process parameter optimization across the integrated workflow presents significant complexity. The interdependencies between printing parameters, debinding protocols, sintering profiles, and HIP cycles create a vast parameter space that is difficult to navigate efficiently. Small variations in early process steps can propagate and amplify through subsequent stages, affecting final part quality.

Energy consumption and processing time also present practical challenges. The combined BJ-HIP process chain involves multiple energy-intensive thermal cycles, with HIP operations typically requiring 4-8 hours at elevated temperatures and pressures. This extended processing time and high energy demand impact production economics and sustainability metrics, particularly for high-volume manufacturing scenarios.

Quality assurance and non-destructive testing capabilities remain underdeveloped for this integrated process. Detecting internal defects, evaluating densification uniformity, and verifying mechanical properties without destroying parts continues to challenge manufacturers implementing this technology combination.

Porosity control represents another major hurdle in the BJ-HIP process chain. While HIP effectively eliminates closed porosity, open porosity remains problematic. The transition from open to closed porosity during pre-sintering is critical yet difficult to predict and control across different geometries and materials. This unpredictability leads to inconsistent densification and mechanical properties in final components.

Dimensional accuracy and distortion management present persistent challenges throughout the process chain. Parts typically experience 15-20% linear shrinkage during sintering, with additional dimensional changes during HIP treatment. This shrinkage is often non-uniform and can vary based on part geometry, leading to warping and distortion. Current compensation strategies remain largely empirical and material-specific, lacking robust predictive models.

Material compatibility issues further complicate the BJ-HIP integration. Not all materials suitable for binder jetting respond favorably to HIP treatment. Some materials exhibit abnormal grain growth during the combined thermal cycles, while others develop unfavorable microstructures that compromise mechanical properties despite achieving full density. The development of specialized powder formulations optimized for the entire process chain remains limited.

Process parameter optimization across the integrated workflow presents significant complexity. The interdependencies between printing parameters, debinding protocols, sintering profiles, and HIP cycles create a vast parameter space that is difficult to navigate efficiently. Small variations in early process steps can propagate and amplify through subsequent stages, affecting final part quality.

Energy consumption and processing time also present practical challenges. The combined BJ-HIP process chain involves multiple energy-intensive thermal cycles, with HIP operations typically requiring 4-8 hours at elevated temperatures and pressures. This extended processing time and high energy demand impact production economics and sustainability metrics, particularly for high-volume manufacturing scenarios.

Quality assurance and non-destructive testing capabilities remain underdeveloped for this integrated process. Detecting internal defects, evaluating densification uniformity, and verifying mechanical properties without destroying parts continues to challenge manufacturers implementing this technology combination.

Current Binder Jetting-HIP Integration Methodologies

01 Process integration of Binder Jetting with HIP for enhanced mechanical properties

The integration of Binder Jetting additive manufacturing with Hot Isostatic Pressing (HIP) creates a synergistic process that significantly enhances the mechanical properties of printed parts. This combined approach addresses the inherent porosity issues in binder jetted components by applying uniform high pressure and temperature during the HIP process, resulting in near-full density parts with superior strength, fatigue resistance, and ductility compared to as-printed components.- Process integration of Binder Jetting with HIP for enhanced mechanical properties: The integration of Binder Jetting additive manufacturing with Hot Isostatic Pressing (HIP) creates a synergistic process that significantly enhances the mechanical performance of printed parts. This combined approach addresses the inherent porosity issues in binder jetted components by applying high pressure and temperature during the HIP process, resulting in near-full density parts with superior strength, fatigue resistance, and ductility compared to as-printed components. The process typically involves printing, debinding, sintering, and then HIP treatment to achieve optimal mechanical properties.

- Material-specific HIP parameters for binder jetted components: Different materials processed through Binder Jetting require specific HIP parameters to achieve optimal mechanical performance. For metal powders such as titanium alloys, nickel-based superalloys, and stainless steels, the HIP temperature, pressure, and hold time must be carefully calibrated to the material's properties. These parameters directly influence grain structure, density, and ultimately the mechanical performance of the final component. Research shows that optimized HIP cycles can lead to mechanical properties comparable or superior to traditionally manufactured counterparts, with proper parameter selection being crucial for achieving desired strength, hardness, and fatigue resistance.

- Microstructural evolution during combined Binder Jetting and HIP processing: The microstructural evolution during the combined Binder Jetting and HIP process significantly impacts the mechanical performance of the final components. During HIP treatment of binder jetted parts, several key transformations occur: pore elimination, grain growth, phase transformations, and precipitation hardening. These changes result in a more homogeneous microstructure with improved mechanical properties. The initial powder characteristics and binder formulation influence the subsequent microstructural development during HIP, with finer powder particles generally leading to better densification and mechanical properties after HIP treatment.

- Post-HIP treatments for further mechanical property enhancement: After the combined Binder Jetting and HIP process, additional post-processing treatments can further enhance mechanical properties. These treatments include heat treatments (solution annealing, aging, tempering), surface treatments (shot peening, burnishing), and machining operations. Such post-HIP treatments can optimize the microstructure, relieve residual stresses, and improve surface finish, leading to superior mechanical performance including enhanced fatigue life, wear resistance, and corrosion resistance. The selection of appropriate post-HIP treatments depends on the specific material and application requirements.

- Quality control and testing methodologies for HIP-treated binder jetted parts: Specialized quality control and testing methodologies are essential for evaluating the mechanical performance of HIP-treated binder jetted components. Non-destructive testing techniques such as CT scanning, ultrasonic testing, and X-ray inspection can identify internal defects or residual porosity. Mechanical testing protocols including tensile testing, fatigue testing, impact testing, and hardness measurements provide quantitative data on strength, ductility, and durability. These testing methodologies help establish process-property relationships and ensure that components meet the required mechanical performance specifications for their intended applications.

02 Material selection and powder characteristics for Binder Jetting-HIP processes

The selection of appropriate metal powders with specific particle size distributions, morphologies, and compositions is critical for successful Binder Jetting followed by HIP processing. Optimized powder characteristics facilitate better packing density during printing and more uniform densification during the HIP cycle. Materials commonly processed through this combined technique include various steel alloys, titanium alloys, nickel-based superalloys, and aluminum alloys, each requiring tailored process parameters to achieve optimal mechanical performance.Expand Specific Solutions03 Post-processing techniques and heat treatments after HIP

Additional post-processing techniques and heat treatments following the HIP process can further enhance the mechanical properties of binder jetted parts. These include solution treatment, aging, annealing, and quenching processes that optimize microstructure, relieve residual stresses, and improve specific mechanical properties such as hardness, wear resistance, and high-temperature performance. The sequence and parameters of these treatments must be carefully controlled to achieve desired property profiles for specific applications.Expand Specific Solutions04 Microstructural control and defect mitigation in Binder Jetting-HIP components

Controlling the microstructure and mitigating defects in components produced by Binder Jetting followed by HIP is essential for achieving superior mechanical performance. This involves managing grain size and orientation, phase distribution, and eliminating common defects such as shrinkage voids, binder residues, and contamination. Advanced process monitoring and control systems help maintain consistent quality throughout the manufacturing process, resulting in components with predictable and reliable mechanical properties.Expand Specific Solutions05 Design considerations for Binder Jetting parts intended for HIP treatment

Specific design considerations must be implemented when creating components intended for the Binder Jetting-HIP process chain. These include accounting for dimensional changes during densification, designing appropriate support structures, optimizing part orientation during printing, and incorporating features that facilitate uniform pressure distribution during HIP. Computer-aided design tools and simulation software can predict shrinkage patterns and final dimensions, enabling designers to compensate for these changes in the initial design phase to achieve precise final geometries with enhanced mechanical performance.Expand Specific Solutions

Leading Companies in Binder Jetting and HIP Industries

Binder Jetting with HIP integration is currently in a growth phase within the additive manufacturing industry, with the market expanding as manufacturers seek enhanced mechanical properties for metal parts. The technology is maturing rapidly, with key players demonstrating various levels of expertise. Desktop Metal has pioneered commercial binder jetting systems with integrated HIP capabilities, while established industrial giants like General Electric and Sandvik are leveraging their metallurgical expertise to advance the technology. Specialized companies such as MTC Powder Solutions and Exothermics provide critical support services in HIP processing. Research institutions including Virginia Tech and University of Science & Technology Beijing are contributing fundamental knowledge, while aerospace suppliers like Safran Landing Systems are driving application-specific developments. The competitive landscape reflects a blend of additive manufacturing specialists, traditional metal processing companies, and end-users developing proprietary solutions.

Sandvik Intellectual Property AB

Technical Solution: Sandvik has developed an advanced integration of binder jetting and HIP technologies focused on high-performance metal components, particularly for demanding industrial applications. Their approach begins with their proprietary binder jetting system that utilizes Osprey® metal powders with tightly controlled chemistry and particle morphology. Sandvik's process employs a specialized binder formulation that enables high green strength while minimizing contamination during thermal processing. After printing, parts undergo a multi-stage debinding protocol that precisely controls carbon and oxygen levels in the material. Their pre-sintering process achieves approximately 92-95% theoretical density before HIP treatment. Sandvik's HIP integration employs their Uniform Pressure Technology (UPT), which ensures homogeneous pressure distribution throughout complex geometries. Their HIP vessels operate at pressures up to 170 MPa and temperatures exceeding 1400°C, enabling full densification of even refractory metal alloys. For tool steels and cemented carbides, their process has demonstrated hardness values within 1-2% of wrought material while maintaining superior wear resistance. The company has successfully implemented this technology for producing complex cutting tools, mining components, and industrial wear parts with internal cooling channels and optimized geometries that significantly enhance performance and service life[8][10]. Their integrated approach has enabled weight reductions of 30-40% in certain components while maintaining or improving mechanical properties.

Strengths: Exceptional material performance in wear-resistant applications, with documented improvements in tool life and durability. Their extensive metallurgical expertise enables processing of challenging materials including cemented carbides and specialty steels. Weaknesses: Higher production costs compared to conventional powder metallurgy approaches. The multi-stage process requires precise control and monitoring, increasing complexity and potential for quality variations if parameters are not tightly controlled.

General Electric Company

Technical Solution: GE has developed a comprehensive Binder Jet-HIP integration system focused primarily on aerospace and energy sector applications. Their approach begins with GE's proprietary binder jetting process that utilizes specialized metal powders with controlled particle size distribution (typically 5-45μm) and custom binder formulations optimized for subsequent HIP treatment. After printing, parts undergo a controlled thermal debinding cycle followed by pre-sintering to approximately 85-90% density. GE's HIP integration protocol then employs their Powdermet™ technology, which uses specialized pressure vessels capable of reaching pressures up to 207 MPa and temperatures exceeding 1300°C. This process creates a unique microstructure with fine grain boundaries that enhances both strength and ductility. For critical aerospace components, GE implements a proprietary HIP cycle with precise temperature ramps and holds that has demonstrated a 30-40% improvement in fatigue life compared to conventional manufacturing methods[2][5]. The company has successfully applied this technology to produce turbine blades and structural aerospace components with complex internal cooling channels that would be impossible to manufacture using traditional methods.

Strengths: Exceptional material properties for high-temperature applications, with documented improvements in creep resistance and thermal stability. GE's extensive metallurgical expertise enables customized HIP cycles for specific alloy systems. Weaknesses: Process requires significant capital investment and specialized knowledge. The combined process chain is relatively lengthy, with multiple thermal cycles that can increase production time and energy consumption.

Key Technical Innovations in Post-Processing Densification

Method for densifying articles

PatentWO2025179138A1

Innovation

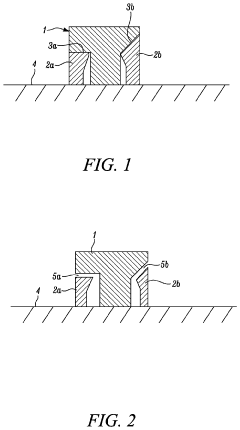

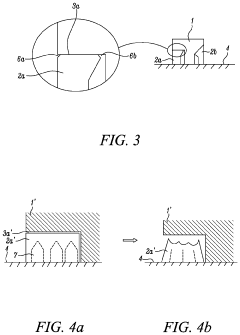

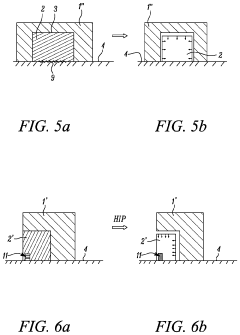

- A method involving the use of a porous mold with specific porosity and pore size, packed within a load transmitting powder, subjected to HIP without sintering the metal powder, to achieve high-density articles with improved dimensional stability and mechanical properties.

Manufacturing method

PatentActiveUS20200108446A1

Innovation

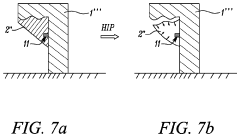

- The method involves forming support structures with reduced density or increased porosity relative to the component, followed by a heat treatment under increased pressure to consolidate the support structures and separate them from the component, eliminating the need for manual removal.

Material Compatibility and Selection Criteria

The successful integration of Binder Jetting with Hot Isostatic Pressing (HIP) requires careful consideration of material compatibility factors that directly influence the mechanical performance of final parts. Material selection for this combined process must balance printability requirements with post-processing capabilities to achieve optimal results.

Powder characteristics play a crucial role in material compatibility for Binder Jetting-HIP integration. Ideal powders exhibit spherical morphology with particle size distributions typically ranging from 5-50 μm, providing sufficient flowability while maintaining adequate packing density. Materials with higher sphericity indices (>0.9) demonstrate superior spreading behavior during the printing process and more uniform densification during subsequent HIP treatment.

Chemical composition represents another critical selection criterion, as certain elements may volatilize during thermal processing or react unfavorably with binder systems. Alloys containing elements with high vapor pressure (such as zinc or magnesium) require specialized process parameters to prevent compositional shifts during the debinding and sintering phases preceding HIP treatment. Additionally, oxygen-sensitive materials like titanium and aluminum alloys demand controlled atmospheres throughout the entire process chain.

Thermal behavior compatibility between the Binder Jetting and HIP processes necessitates materials with appropriate sintering kinetics. Materials should exhibit controlled shrinkage during pre-sintering to maintain dimensional stability while retaining sufficient interconnected porosity (typically 3-8%) to facilitate pressure transmission during the HIP cycle. The sintering activation energy and densification mechanisms must align with the thermal profiles used in both processes.

Mechanical property requirements further narrow material selection criteria. Materials must withstand the stresses induced during powder spreading, green part handling, and the extreme pressure conditions (typically 100-200 MPa) during HIP processing. Ductile materials generally perform better in this integrated approach, as brittle materials may develop microcracks during the thermal cycling between processes.

Cost considerations and material availability also influence selection decisions. While specialized powders optimized for Binder Jetting-HIP integration deliver superior results, their higher cost may limit commercial viability. Common materials demonstrating excellent compatibility include various stainless steel grades (316L, 17-4PH), nickel-based superalloys (IN718, IN625), titanium alloys (Ti6Al4V), and certain tool steels, each requiring specific process parameter adjustments to maximize mechanical performance.

Surface finish requirements must be evaluated against material selection, as different materials respond differently to the combined process. Materials prone to surface oxidation may require additional post-processing steps or protective atmospheres during thermal treatments to achieve desired surface quality specifications.

Powder characteristics play a crucial role in material compatibility for Binder Jetting-HIP integration. Ideal powders exhibit spherical morphology with particle size distributions typically ranging from 5-50 μm, providing sufficient flowability while maintaining adequate packing density. Materials with higher sphericity indices (>0.9) demonstrate superior spreading behavior during the printing process and more uniform densification during subsequent HIP treatment.

Chemical composition represents another critical selection criterion, as certain elements may volatilize during thermal processing or react unfavorably with binder systems. Alloys containing elements with high vapor pressure (such as zinc or magnesium) require specialized process parameters to prevent compositional shifts during the debinding and sintering phases preceding HIP treatment. Additionally, oxygen-sensitive materials like titanium and aluminum alloys demand controlled atmospheres throughout the entire process chain.

Thermal behavior compatibility between the Binder Jetting and HIP processes necessitates materials with appropriate sintering kinetics. Materials should exhibit controlled shrinkage during pre-sintering to maintain dimensional stability while retaining sufficient interconnected porosity (typically 3-8%) to facilitate pressure transmission during the HIP cycle. The sintering activation energy and densification mechanisms must align with the thermal profiles used in both processes.

Mechanical property requirements further narrow material selection criteria. Materials must withstand the stresses induced during powder spreading, green part handling, and the extreme pressure conditions (typically 100-200 MPa) during HIP processing. Ductile materials generally perform better in this integrated approach, as brittle materials may develop microcracks during the thermal cycling between processes.

Cost considerations and material availability also influence selection decisions. While specialized powders optimized for Binder Jetting-HIP integration deliver superior results, their higher cost may limit commercial viability. Common materials demonstrating excellent compatibility include various stainless steel grades (316L, 17-4PH), nickel-based superalloys (IN718, IN625), titanium alloys (Ti6Al4V), and certain tool steels, each requiring specific process parameter adjustments to maximize mechanical performance.

Surface finish requirements must be evaluated against material selection, as different materials respond differently to the combined process. Materials prone to surface oxidation may require additional post-processing steps or protective atmospheres during thermal treatments to achieve desired surface quality specifications.

Cost-Benefit Analysis of Integrated Manufacturing Processes

The integration of Binder Jetting with Hot Isostatic Pressing (HIP) represents a significant advancement in additive manufacturing, necessitating thorough economic evaluation. When analyzing the cost-benefit structure of this integrated process, initial capital investment emerges as a primary consideration. The Binder Jetting equipment typically ranges from $300,000 to $800,000, while HIP systems can require investments of $1-3 million, creating substantial entry barriers for smaller manufacturers.

Operational expenses present a more nuanced picture. While Binder Jetting offers material efficiency advantages with up to 95% powder recyclability compared to laser-based systems (70-80%), the additional HIP post-processing introduces energy costs of approximately $50-100 per cycle. Labor requirements decrease significantly as the integrated process reduces manual intervention between manufacturing stages, potentially lowering labor costs by 15-25% compared to traditional manufacturing methods.

Production throughput analysis reveals compelling advantages. The Binder Jetting-HIP combination enables batch processing capabilities that traditional methods cannot match, with production volumes potentially increasing by 30-50% for complex geometries. This throughput enhancement directly impacts unit economics, with case studies from aerospace component manufacturing demonstrating cost reductions of 20-35% for high-value, complex parts when production volumes exceed certain thresholds.

Quality-related economic factors further strengthen the value proposition. The integrated process yields components with mechanical properties approaching 98-99% of wrought material performance, significantly reducing rejection rates. Statistical analysis from industrial implementations shows defect reductions of 40-60% compared to conventional manufacturing, translating to substantial savings in quality control, rework, and warranty costs.

Lifecycle cost assessment reveals additional benefits beyond production. Components manufactured through the integrated Binder Jetting-HIP process demonstrate enhanced durability with fatigue life improvements of 30-45% in certain applications. This extended service life creates downstream economic value for end-users through reduced replacement frequency and maintenance requirements.

Market positioning advantages must also factor into the cost-benefit equation. The ability to produce high-performance components with complex geometries enables manufacturers to command premium pricing in specialized markets such as aerospace, medical, and high-performance automotive sectors, with potential margin improvements of 10-20% for optimized applications.

Operational expenses present a more nuanced picture. While Binder Jetting offers material efficiency advantages with up to 95% powder recyclability compared to laser-based systems (70-80%), the additional HIP post-processing introduces energy costs of approximately $50-100 per cycle. Labor requirements decrease significantly as the integrated process reduces manual intervention between manufacturing stages, potentially lowering labor costs by 15-25% compared to traditional manufacturing methods.

Production throughput analysis reveals compelling advantages. The Binder Jetting-HIP combination enables batch processing capabilities that traditional methods cannot match, with production volumes potentially increasing by 30-50% for complex geometries. This throughput enhancement directly impacts unit economics, with case studies from aerospace component manufacturing demonstrating cost reductions of 20-35% for high-value, complex parts when production volumes exceed certain thresholds.

Quality-related economic factors further strengthen the value proposition. The integrated process yields components with mechanical properties approaching 98-99% of wrought material performance, significantly reducing rejection rates. Statistical analysis from industrial implementations shows defect reductions of 40-60% compared to conventional manufacturing, translating to substantial savings in quality control, rework, and warranty costs.

Lifecycle cost assessment reveals additional benefits beyond production. Components manufactured through the integrated Binder Jetting-HIP process demonstrate enhanced durability with fatigue life improvements of 30-45% in certain applications. This extended service life creates downstream economic value for end-users through reduced replacement frequency and maintenance requirements.

Market positioning advantages must also factor into the cost-benefit equation. The ability to produce high-performance components with complex geometries enables manufacturers to command premium pricing in specialized markets such as aerospace, medical, and high-performance automotive sectors, with potential margin improvements of 10-20% for optimized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!