Binder Jetting For Aerospace Hardware: Certification, Traceability And Quality Assurance

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Aerospace Applications

Binder Jetting technology has evolved significantly since its inception in the early 1990s at Massachusetts Institute of Technology. Initially developed as a rapid prototyping method, the technology has undergone substantial refinement in terms of material compatibility, precision, and production speed. The evolution trajectory shows a clear shift from prototype development to functional part production, with aerospace applications emerging as a key focus area in the last decade.

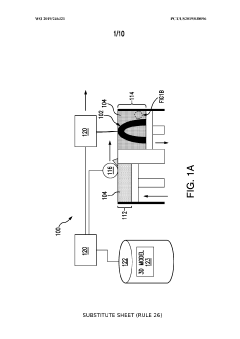

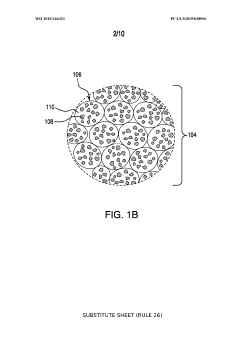

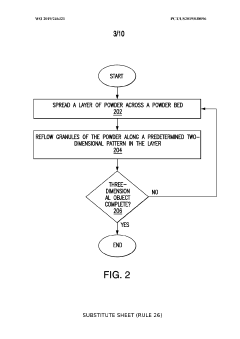

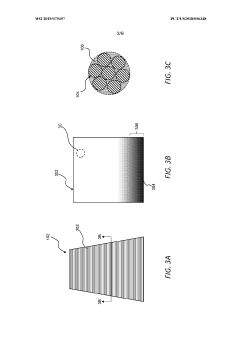

The fundamental process of Binder Jetting involves selectively depositing a liquid binding agent onto a powder bed, layer by layer, to create three-dimensional structures. Early iterations were limited by material constraints and dimensional accuracy issues, but advancements in printhead technology, binder formulations, and powder characteristics have dramatically improved capabilities.

Between 2010 and 2015, a significant technological leap occurred with the introduction of metal Binder Jetting systems capable of producing parts with mechanical properties approaching those of traditionally manufactured components. This breakthrough opened doors for aerospace applications, where weight reduction and complex geometries offer substantial performance benefits.

The aerospace industry's adoption of Binder Jetting has followed a cautious but progressive path. Initial applications focused on non-critical components and tooling, gradually expanding to include more demanding applications as technology matured. Current aerospace applications include lightweight structural components, heat exchangers, fluid distribution systems, and custom brackets.

Material development has been particularly crucial for aerospace adoption. The introduction of high-performance alloys compatible with Binder Jetting processes, including titanium alloys, nickel-based superalloys, and specialized aluminum formulations, has enabled applications in increasingly demanding environments. These developments have been complemented by post-processing innovations, particularly sintering techniques that achieve near-full density in final parts.

Recent technological advancements have focused on addressing aerospace-specific challenges, including dimensional stability, surface finish quality, and internal feature resolution. Software developments have improved build preparation and process simulation, allowing for better prediction of sintering shrinkage and distortion—critical factors for aerospace tolerance requirements.

The integration of in-process monitoring systems represents the latest evolutionary step, enabling real-time quality control and establishing the foundation for certification pathways. These systems combine optical, thermal, and mechanical sensors to detect anomalies during the build process, creating digital records essential for traceability and quality assurance in aerospace applications.

Looking forward, the technology evolution is trending toward larger build volumes, faster production rates, and enhanced material properties, positioning Binder Jetting as an increasingly viable manufacturing method for critical aerospace hardware where certification requirements are stringent.

The fundamental process of Binder Jetting involves selectively depositing a liquid binding agent onto a powder bed, layer by layer, to create three-dimensional structures. Early iterations were limited by material constraints and dimensional accuracy issues, but advancements in printhead technology, binder formulations, and powder characteristics have dramatically improved capabilities.

Between 2010 and 2015, a significant technological leap occurred with the introduction of metal Binder Jetting systems capable of producing parts with mechanical properties approaching those of traditionally manufactured components. This breakthrough opened doors for aerospace applications, where weight reduction and complex geometries offer substantial performance benefits.

The aerospace industry's adoption of Binder Jetting has followed a cautious but progressive path. Initial applications focused on non-critical components and tooling, gradually expanding to include more demanding applications as technology matured. Current aerospace applications include lightweight structural components, heat exchangers, fluid distribution systems, and custom brackets.

Material development has been particularly crucial for aerospace adoption. The introduction of high-performance alloys compatible with Binder Jetting processes, including titanium alloys, nickel-based superalloys, and specialized aluminum formulations, has enabled applications in increasingly demanding environments. These developments have been complemented by post-processing innovations, particularly sintering techniques that achieve near-full density in final parts.

Recent technological advancements have focused on addressing aerospace-specific challenges, including dimensional stability, surface finish quality, and internal feature resolution. Software developments have improved build preparation and process simulation, allowing for better prediction of sintering shrinkage and distortion—critical factors for aerospace tolerance requirements.

The integration of in-process monitoring systems represents the latest evolutionary step, enabling real-time quality control and establishing the foundation for certification pathways. These systems combine optical, thermal, and mechanical sensors to detect anomalies during the build process, creating digital records essential for traceability and quality assurance in aerospace applications.

Looking forward, the technology evolution is trending toward larger build volumes, faster production rates, and enhanced material properties, positioning Binder Jetting as an increasingly viable manufacturing method for critical aerospace hardware where certification requirements are stringent.

Aerospace Market Demand for Additive Manufacturing Solutions

The aerospace industry is experiencing a significant shift towards additive manufacturing technologies, with the global aerospace additive manufacturing market projected to reach $5.2 billion by 2026, growing at a CAGR of 15.7%. This growth is driven by the industry's continuous pursuit of lightweight components, complex geometries, and reduced lead times in production processes.

Binder Jetting technology specifically addresses several critical aerospace manufacturing challenges. The sector demands materials with exceptional strength-to-weight ratios, heat resistance, and durability under extreme conditions. Traditional manufacturing methods often result in material waste of up to 80% when creating complex aerospace components, while Binder Jetting can reduce this waste to less than 10%.

Commercial aviation represents the largest market segment, accounting for approximately 42% of aerospace additive manufacturing applications. Major airlines and aircraft manufacturers are seeking solutions that can reduce fuel consumption through lightweight components while maintaining or improving safety standards. Each 1% reduction in aircraft weight translates to approximately 0.75% fuel savings, creating substantial economic incentives for adoption.

Military and defense applications constitute the fastest-growing segment, with a 17.3% annual growth rate. These applications require rapid prototyping capabilities and the ability to produce replacement parts on demand, particularly in remote locations or during deployment. Binder Jetting's ability to create complex internal structures without tooling makes it particularly valuable for missile components, drone parts, and specialized hardware.

Space exploration presents another expanding market, with private space companies increasing their launch frequency by 300% over the past decade. These organizations require manufacturing technologies that can produce highly specialized, one-off components with precise specifications. The reduced lead time offered by Binder Jetting (often 65-80% faster than traditional methods) provides significant competitive advantages.

The aftermarket and maintenance sectors also demonstrate substantial demand, as airlines seek to reduce aircraft downtime and inventory costs. The ability to produce replacement parts on demand rather than maintaining extensive inventories could reduce inventory carrying costs by up to 30% for aerospace maintenance operations.

Despite these opportunities, aerospace manufacturers express concerns regarding certification processes, quality assurance, and traceability systems for additively manufactured parts. Industry surveys indicate that 78% of aerospace executives consider certification challenges as the primary barrier to wider adoption of technologies like Binder Jetting, highlighting the critical need for standardized quality assurance protocols.

Binder Jetting technology specifically addresses several critical aerospace manufacturing challenges. The sector demands materials with exceptional strength-to-weight ratios, heat resistance, and durability under extreme conditions. Traditional manufacturing methods often result in material waste of up to 80% when creating complex aerospace components, while Binder Jetting can reduce this waste to less than 10%.

Commercial aviation represents the largest market segment, accounting for approximately 42% of aerospace additive manufacturing applications. Major airlines and aircraft manufacturers are seeking solutions that can reduce fuel consumption through lightweight components while maintaining or improving safety standards. Each 1% reduction in aircraft weight translates to approximately 0.75% fuel savings, creating substantial economic incentives for adoption.

Military and defense applications constitute the fastest-growing segment, with a 17.3% annual growth rate. These applications require rapid prototyping capabilities and the ability to produce replacement parts on demand, particularly in remote locations or during deployment. Binder Jetting's ability to create complex internal structures without tooling makes it particularly valuable for missile components, drone parts, and specialized hardware.

Space exploration presents another expanding market, with private space companies increasing their launch frequency by 300% over the past decade. These organizations require manufacturing technologies that can produce highly specialized, one-off components with precise specifications. The reduced lead time offered by Binder Jetting (often 65-80% faster than traditional methods) provides significant competitive advantages.

The aftermarket and maintenance sectors also demonstrate substantial demand, as airlines seek to reduce aircraft downtime and inventory costs. The ability to produce replacement parts on demand rather than maintaining extensive inventories could reduce inventory carrying costs by up to 30% for aerospace maintenance operations.

Despite these opportunities, aerospace manufacturers express concerns regarding certification processes, quality assurance, and traceability systems for additively manufactured parts. Industry surveys indicate that 78% of aerospace executives consider certification challenges as the primary barrier to wider adoption of technologies like Binder Jetting, highlighting the critical need for standardized quality assurance protocols.

Current Challenges in Binder Jetting for Aerospace Components

Binder Jetting technology faces significant challenges in aerospace applications, particularly concerning certification, traceability, and quality assurance. The aerospace industry's stringent regulatory environment demands exceptionally high standards for component performance and reliability, creating substantial barriers for additive manufacturing technologies like Binder Jetting.

Material qualification represents one of the most formidable obstacles. Aerospace-grade materials processed through Binder Jetting must demonstrate consistent mechanical properties, thermal stability, and resistance to environmental factors. Current challenges include achieving uniform density throughout complex geometries and ensuring repeatable material properties across production batches. The sintering process, critical for final part properties, introduces variability that must be precisely controlled and documented.

Certification pathways remain underdeveloped for Binder Jetting in aerospace applications. Unlike traditional manufacturing methods with established certification frameworks, Binder Jetting lacks standardized testing protocols and acceptance criteria. Regulatory bodies such as the FAA, EASA, and military standards organizations are still developing comprehensive guidelines for additively manufactured aerospace components, creating uncertainty for manufacturers and end-users.

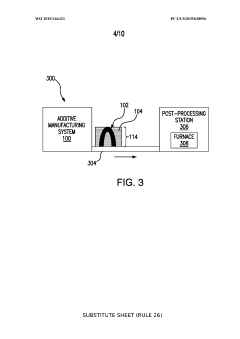

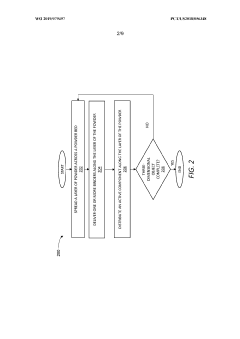

Process validation presents another significant hurdle. The multi-step nature of Binder Jetting—including powder preparation, printing, curing, sintering, and post-processing—introduces numerous variables that must be monitored and controlled. Each step requires robust validation protocols to ensure consistency and repeatability. Current systems struggle with real-time monitoring capabilities necessary for aerospace-grade quality assurance.

Traceability requirements pose particular challenges for Binder Jetting processes. Aerospace applications demand complete documentation of material provenance, process parameters, and quality checks throughout the manufacturing workflow. Existing Binder Jetting systems often lack integrated data collection and management capabilities needed to maintain this comprehensive digital thread.

Non-destructive testing (NDT) methods for Binder Jetting parts remain limited in their ability to detect internal defects such as voids, cracks, or insufficient sintering. Traditional NDT techniques like X-ray and CT scanning face difficulties with complex internal geometries typical of additively manufactured components. This creates uncertainty in quality verification processes critical for aerospace applications.

Surface finish and dimensional accuracy continue to challenge Binder Jetting adoption. Aerospace components often require precise tolerances and specific surface characteristics that current Binder Jetting processes struggle to achieve without extensive post-processing, adding cost and complexity to the manufacturing workflow.

Material qualification represents one of the most formidable obstacles. Aerospace-grade materials processed through Binder Jetting must demonstrate consistent mechanical properties, thermal stability, and resistance to environmental factors. Current challenges include achieving uniform density throughout complex geometries and ensuring repeatable material properties across production batches. The sintering process, critical for final part properties, introduces variability that must be precisely controlled and documented.

Certification pathways remain underdeveloped for Binder Jetting in aerospace applications. Unlike traditional manufacturing methods with established certification frameworks, Binder Jetting lacks standardized testing protocols and acceptance criteria. Regulatory bodies such as the FAA, EASA, and military standards organizations are still developing comprehensive guidelines for additively manufactured aerospace components, creating uncertainty for manufacturers and end-users.

Process validation presents another significant hurdle. The multi-step nature of Binder Jetting—including powder preparation, printing, curing, sintering, and post-processing—introduces numerous variables that must be monitored and controlled. Each step requires robust validation protocols to ensure consistency and repeatability. Current systems struggle with real-time monitoring capabilities necessary for aerospace-grade quality assurance.

Traceability requirements pose particular challenges for Binder Jetting processes. Aerospace applications demand complete documentation of material provenance, process parameters, and quality checks throughout the manufacturing workflow. Existing Binder Jetting systems often lack integrated data collection and management capabilities needed to maintain this comprehensive digital thread.

Non-destructive testing (NDT) methods for Binder Jetting parts remain limited in their ability to detect internal defects such as voids, cracks, or insufficient sintering. Traditional NDT techniques like X-ray and CT scanning face difficulties with complex internal geometries typical of additively manufactured components. This creates uncertainty in quality verification processes critical for aerospace applications.

Surface finish and dimensional accuracy continue to challenge Binder Jetting adoption. Aerospace components often require precise tolerances and specific surface characteristics that current Binder Jetting processes struggle to achieve without extensive post-processing, adding cost and complexity to the manufacturing workflow.

Existing Certification Frameworks for Aerospace Additive Manufacturing

01 Quality control systems for binder jetting processes

Quality control systems for binder jetting processes involve monitoring and verification of various parameters during the manufacturing process. These systems can include real-time monitoring of printing parameters, material properties, and environmental conditions to ensure consistent quality. Advanced systems may incorporate machine learning algorithms to predict potential defects and adjust process parameters accordingly, ensuring that the final products meet certification requirements.- Quality control systems for binder jetting processes: Quality control systems for binder jetting processes involve monitoring and verification of various parameters during the manufacturing process. These systems can include real-time monitoring of printing parameters, material properties, and environmental conditions to ensure consistent quality. Advanced systems may incorporate machine learning algorithms to detect anomalies and predict potential defects before they occur, thereby maintaining high standards in additive manufacturing processes.

- Traceability methods in additive manufacturing: Traceability methods in additive manufacturing, particularly binder jetting, involve tracking materials, processes, and products throughout the manufacturing lifecycle. These methods can include unique identifiers, digital signatures, and blockchain technology to create an unbroken chain of custody from raw materials to finished products. Comprehensive traceability systems enable manufacturers to verify the origin of materials, document process parameters, and validate compliance with industry standards.

- Certification protocols for binder jetting technology: Certification protocols for binder jetting technology establish standardized procedures for validating the quality and reliability of printed parts. These protocols typically include material testing, process validation, and performance verification against established benchmarks. Certification may involve third-party assessment, documentation of manufacturing processes, and demonstration of compliance with industry-specific requirements to ensure that binder jetted components meet necessary safety and performance standards.

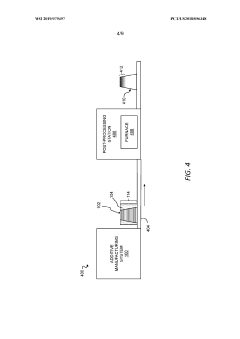

- Data management systems for quality assurance: Data management systems for quality assurance in binder jetting processes focus on collecting, analyzing, and storing critical manufacturing data. These systems can integrate with production equipment to capture process parameters, test results, and inspection data in a centralized database. Advanced analytics tools can be used to identify trends, correlations, and potential quality issues, enabling manufacturers to implement continuous improvement initiatives and maintain comprehensive quality records for regulatory compliance.

- Testing and validation methods for binder jetted parts: Testing and validation methods for binder jetted parts encompass various techniques to verify dimensional accuracy, mechanical properties, and functional performance. These methods may include non-destructive testing, such as CT scanning and ultrasonic inspection, as well as destructive testing to evaluate material strength and durability. Standardized testing protocols help ensure that binder jetted components meet design specifications and perform reliably under intended operating conditions.

02 Traceability methods in additive manufacturing

Traceability methods in additive manufacturing, including binder jetting, involve tracking the entire production process from raw materials to finished products. These methods can include unique identifiers for each component, digital signatures, and blockchain technology to create an immutable record of the manufacturing process. Comprehensive documentation of material sources, process parameters, and quality test results enables full traceability required for certification and regulatory compliance.Expand Specific Solutions03 Certification standards and compliance for binder jetting

Certification standards for binder jetting processes establish the requirements for quality, safety, and performance of additively manufactured parts. These standards may include material specifications, process parameters, testing protocols, and documentation requirements. Compliance with industry-specific standards such as those for aerospace, medical, or automotive applications is essential for product certification and market acceptance. Certification processes typically involve third-party verification and regular audits to maintain compliance.Expand Specific Solutions04 Testing and validation methodologies for binder jetted parts

Testing and validation methodologies for binder jetted parts include non-destructive testing techniques, mechanical property assessments, and dimensional accuracy verification. These methodologies may involve optical scanning, X-ray computed tomography, tensile testing, and fatigue analysis to ensure that parts meet design specifications and quality requirements. Standardized testing protocols help establish consistency in quality assurance processes and provide objective evidence for certification purposes.Expand Specific Solutions05 Digital quality assurance frameworks for additive manufacturing

Digital quality assurance frameworks for additive manufacturing integrate various digital tools and technologies to ensure comprehensive quality management throughout the binder jetting process. These frameworks may include digital twins, simulation software, automated inspection systems, and data analytics platforms that collect, analyze, and visualize quality-related data. By implementing such frameworks, manufacturers can achieve real-time quality monitoring, predictive maintenance, and continuous process improvement, ultimately enhancing product reliability and certification compliance.Expand Specific Solutions

Leading Companies in Aerospace Binder Jetting Manufacturing

Binder Jetting for aerospace hardware is currently in a transitional phase from early adoption to mainstream implementation, with the market expected to grow significantly as certification processes mature. The global market for aerospace additive manufacturing is expanding rapidly, driven by demands for lightweight components and supply chain efficiency. Technologically, companies like Desktop Metal, GE, and Boeing are leading innovation in binder jetting processes specifically tailored for aerospace applications, while organizations such as Thales and 3M are advancing quality assurance methodologies. The technology's maturity varies across applications, with structural components requiring more rigorous certification pathways than non-critical parts. Key challenges remain in standardizing traceability protocols and establishing consistent quality assurance frameworks that satisfy stringent aerospace regulatory requirements.

Desktop Metal, Inc.

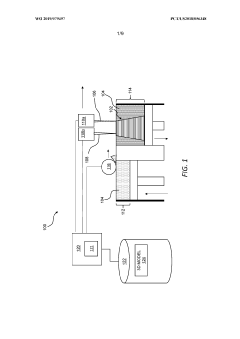

Technical Solution: Desktop Metal has developed a comprehensive Binder Jetting solution specifically tailored for aerospace applications called Production System™. This platform utilizes their patented Single Pass Jetting™ technology that delivers speeds up to 100 times faster than laser-based systems while maintaining aerospace-grade quality. Their approach incorporates a closed-loop quality control system with in-process monitoring that captures over 20 million data points per second to ensure part consistency and traceability. For aerospace certification, Desktop Metal has implemented a rigorous material qualification program that follows ASTM and SAE standards, with documented process parameters for various aerospace alloys including titanium, Inconel, and aluminum. Their system includes comprehensive digital thread capabilities that track each part from powder characterization through post-processing, generating detailed documentation required for aerospace certification[1][3]. The company has also developed specialized software tools that enable real-time quality assurance and facilitate FAA and EASA certification processes.

Strengths: Industry-leading print speeds while maintaining high precision; comprehensive digital traceability system integrated throughout the manufacturing process; extensive material qualification program specifically for aerospace alloys. Weaknesses: Relatively higher initial investment costs compared to traditional manufacturing; still requires industry-specific certification processes that can be time-consuming; post-processing requirements can add complexity to the overall manufacturing workflow.

General Electric Company

Technical Solution: GE has pioneered an advanced Binder Jetting technology platform specifically engineered for aerospace hardware production. Their system incorporates proprietary binder chemistry optimized for high-temperature aerospace alloys and features a multi-stage quality assurance framework. GE's approach includes a comprehensive digital twin methodology that creates a virtual replica of each physical part, allowing for predictive quality analysis before manufacturing begins. Their Binder Jetting process utilizes high-resolution imaging systems that perform layer-by-layer inspection during printing, with automated defect detection algorithms that can identify anomalies as small as 50 microns. For aerospace certification, GE has developed a standardized qualification pathway that aligns with FAA, EASA, and military standards, including detailed material property databases for common aerospace alloys. The company's traceability system incorporates blockchain technology to create immutable records of the entire manufacturing process, from powder characterization to final inspection[2][5]. GE has successfully implemented this technology in producing certified components for their own jet engines, demonstrating the viability of Binder Jetting for flight-critical applications.

Strengths: Extensive aerospace industry experience and established relationships with certification authorities; integrated approach combining materials science, process engineering, and digital technologies; demonstrated success with flight-critical components. Weaknesses: System may be optimized primarily for GE's own aerospace applications rather than as a general-purpose solution; higher operational costs compared to some competing technologies; complex implementation requiring specialized expertise.

Critical Patents and Research in Aerospace-grade Binder Jetting

Methods and compositions for the preparation of powders for binder-based three-dimensional additive metal manufacturing

PatentWO2019246321A1

Innovation

- The use of coated powders where each granule has a core of one material overlaid with a coating of another material, reducing segregation and enhancing homogeneity and physicochemical properties of the finished parts.

Binder jetting in additive manufacturing of inhomogeneous three-dimensional parts

PatentWO2019079497A1

Innovation

- The method involves forming layers of a powder bed with inorganic particles, delivering binders, and depositing additives with active components in controlled patterns, followed by thermal processing to create gradients of physicochemical properties in the resulting three-dimensional part.

Material Traceability Systems for Aerospace Additive Manufacturing

In the aerospace industry, material traceability systems for additive manufacturing represent a critical infrastructure component that ensures compliance with stringent regulatory requirements. These systems track materials throughout the entire manufacturing process, from raw powder acquisition to final component installation. For Binder Jetting technology specifically, traceability begins with powder characterization and batch identification, where each powder lot receives unique identifiers linked to supplier certificates and internal testing results.

Digital material passports have emerged as a cornerstone of modern traceability systems, containing comprehensive data on chemical composition, particle size distribution, flowability, and other critical parameters. These passports follow materials through each processing step, accumulating process parameters and quality check results to create an unbroken chain of documentation.

Real-time monitoring technologies integrate with traceability systems to capture process variations during Binder Jetting operations. Sensors track binder saturation levels, spreading uniformity, and curing conditions, with data automatically linked to specific part identifiers and material batches. This integration enables immediate detection of process deviations that might compromise part integrity.

Blockchain technology has recently been implemented in aerospace material traceability systems, providing tamper-proof documentation of the entire manufacturing history. This distributed ledger approach ensures that material data cannot be altered retroactively, addressing concerns about data security and authenticity in certification processes.

Post-processing traceability represents another crucial element, as Binder Jetted aerospace components typically undergo infiltration, sintering, and surface treatments. Each treatment step must maintain material identity and process parameter documentation to preserve the traceability chain through to final inspection.

Machine learning algorithms now enhance traceability systems by identifying patterns in material behavior across different batches and processing conditions. These predictive capabilities help manufacturers anticipate potential quality issues based on historical material performance data, improving first-time yield rates.

Regulatory frameworks from FAA, EASA, and other aviation authorities increasingly recognize digital traceability systems as acceptable means of compliance for material control requirements. However, these systems must demonstrate robust data integrity controls, access restrictions, and long-term data preservation capabilities to meet aerospace standards.

Digital material passports have emerged as a cornerstone of modern traceability systems, containing comprehensive data on chemical composition, particle size distribution, flowability, and other critical parameters. These passports follow materials through each processing step, accumulating process parameters and quality check results to create an unbroken chain of documentation.

Real-time monitoring technologies integrate with traceability systems to capture process variations during Binder Jetting operations. Sensors track binder saturation levels, spreading uniformity, and curing conditions, with data automatically linked to specific part identifiers and material batches. This integration enables immediate detection of process deviations that might compromise part integrity.

Blockchain technology has recently been implemented in aerospace material traceability systems, providing tamper-proof documentation of the entire manufacturing history. This distributed ledger approach ensures that material data cannot be altered retroactively, addressing concerns about data security and authenticity in certification processes.

Post-processing traceability represents another crucial element, as Binder Jetted aerospace components typically undergo infiltration, sintering, and surface treatments. Each treatment step must maintain material identity and process parameter documentation to preserve the traceability chain through to final inspection.

Machine learning algorithms now enhance traceability systems by identifying patterns in material behavior across different batches and processing conditions. These predictive capabilities help manufacturers anticipate potential quality issues based on historical material performance data, improving first-time yield rates.

Regulatory frameworks from FAA, EASA, and other aviation authorities increasingly recognize digital traceability systems as acceptable means of compliance for material control requirements. However, these systems must demonstrate robust data integrity controls, access restrictions, and long-term data preservation capabilities to meet aerospace standards.

Regulatory Compliance and Industry Standards for Aerospace AM

The aerospace industry operates under stringent regulatory frameworks that govern the adoption of new manufacturing technologies. For Binder Jetting additive manufacturing to gain widespread acceptance in aerospace hardware production, compliance with established standards is non-negotiable. Currently, several key regulatory bodies oversee this domain, including the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and the International Organization for Standardization (ISO).

These organizations have developed specific standards addressing additive manufacturing processes. Notable among these are the ASTM F42 committee standards, which provide guidelines for terminology, test methods, materials, and processes in additive manufacturing. For aerospace applications, the SAE AMS7000 series specifically addresses metal additive manufacturing requirements, covering process control, material properties, and quality assurance protocols.

Certification pathways for Binder Jetting technology in aerospace applications typically follow a multi-tiered approach. Initially, material qualification must be established through extensive testing to demonstrate consistent mechanical properties. Subsequently, process qualification validates that the manufacturing method produces parts meeting predetermined specifications with statistical reliability.

Traceability requirements present unique challenges for Binder Jetting technology. Current standards mandate comprehensive documentation of the entire manufacturing process, from powder characteristics to post-processing treatments. This includes detailed records of build parameters, thermal history, and quality control measurements at each production stage.

Quality assurance standards for aerospace AM emphasize non-destructive testing (NDT) methodologies. However, conventional NDT techniques often require adaptation for the complex geometries and material characteristics inherent to Binder Jetting parts. The industry is actively developing specialized inspection protocols, including advanced CT scanning and in-situ monitoring systems tailored to powder bed fusion processes.

Recent regulatory developments show a trend toward performance-based certification approaches rather than prescriptive requirements. This shift potentially benefits Binder Jetting technology by allowing manufacturers to demonstrate equivalent safety and reliability through alternative means, rather than adhering to standards originally developed for conventional manufacturing methods.

Industry consortia like America Makes and the Aerospace Technology Institute are collaborating with regulatory bodies to develop standardized qualification methodologies specifically for Binder Jetting processes. These initiatives aim to establish clear certification pathways that maintain safety standards while accommodating the unique characteristics of additive manufacturing technologies.

These organizations have developed specific standards addressing additive manufacturing processes. Notable among these are the ASTM F42 committee standards, which provide guidelines for terminology, test methods, materials, and processes in additive manufacturing. For aerospace applications, the SAE AMS7000 series specifically addresses metal additive manufacturing requirements, covering process control, material properties, and quality assurance protocols.

Certification pathways for Binder Jetting technology in aerospace applications typically follow a multi-tiered approach. Initially, material qualification must be established through extensive testing to demonstrate consistent mechanical properties. Subsequently, process qualification validates that the manufacturing method produces parts meeting predetermined specifications with statistical reliability.

Traceability requirements present unique challenges for Binder Jetting technology. Current standards mandate comprehensive documentation of the entire manufacturing process, from powder characteristics to post-processing treatments. This includes detailed records of build parameters, thermal history, and quality control measurements at each production stage.

Quality assurance standards for aerospace AM emphasize non-destructive testing (NDT) methodologies. However, conventional NDT techniques often require adaptation for the complex geometries and material characteristics inherent to Binder Jetting parts. The industry is actively developing specialized inspection protocols, including advanced CT scanning and in-situ monitoring systems tailored to powder bed fusion processes.

Recent regulatory developments show a trend toward performance-based certification approaches rather than prescriptive requirements. This shift potentially benefits Binder Jetting technology by allowing manufacturers to demonstrate equivalent safety and reliability through alternative means, rather than adhering to standards originally developed for conventional manufacturing methods.

Industry consortia like America Makes and the Aerospace Technology Institute are collaborating with regulatory bodies to develop standardized qualification methodologies specifically for Binder Jetting processes. These initiatives aim to establish clear certification pathways that maintain safety standards while accommodating the unique characteristics of additive manufacturing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!