Binder Jetting Lifecycle Assessment For Industrial Adoption

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting technology emerged in the early 1990s at the Massachusetts Institute of Technology, representing a significant advancement in additive manufacturing. This powder-bed based process selectively deposits binding agents onto powder materials, creating complex geometries without the need for support structures. The evolution of this technology has been marked by continuous improvements in resolution, material compatibility, and production speed.

The initial development focused primarily on prototyping applications, with limited material options and relatively low mechanical properties. By the early 2000s, advancements in printhead technology and binder formulations enabled higher resolution printing and improved part quality. The mid-2010s witnessed a pivotal shift toward industrial applications, with major manufacturers developing systems capable of higher throughput and better repeatability.

Recent technological developments have significantly expanded the material portfolio beyond traditional ceramics and metals to include advanced composites and functional materials. Modern Binder Jetting systems incorporate sophisticated process monitoring capabilities, automated powder handling, and integrated post-processing solutions, addressing previous limitations in surface finish and dimensional accuracy.

The primary objective of Binder Jetting technology assessment is to evaluate its viability for full-scale industrial adoption across diverse manufacturing sectors. This includes analyzing the complete lifecycle implications, from raw material sourcing to end-of-life considerations. Specific technical objectives encompass improving part density and mechanical properties through optimized sintering protocols, enhancing dimensional accuracy through better binder-powder interactions, and developing closed-loop quality control systems.

Economic objectives focus on reducing the total cost of ownership through increased build rates, minimized material waste, and streamlined post-processing requirements. Environmental sustainability represents another critical objective, with emphasis on energy consumption patterns, material efficiency, and recyclability potential compared to conventional manufacturing methods.

The technology roadmap aims to address current limitations in surface quality, build chamber size, and process repeatability. Future development trajectories point toward multi-material capabilities, functionally graded structures, and integration with existing manufacturing workflows. Industry standardization efforts are underway to establish consistent quality metrics, testing protocols, and certification pathways for Binder Jetted components in regulated industries.

As industrial adoption accelerates, research priorities include developing specialized materials optimized for the Binder Jetting process, improving process modeling capabilities to predict part properties, and creating robust design guidelines that leverage the unique capabilities of this manufacturing approach.

The initial development focused primarily on prototyping applications, with limited material options and relatively low mechanical properties. By the early 2000s, advancements in printhead technology and binder formulations enabled higher resolution printing and improved part quality. The mid-2010s witnessed a pivotal shift toward industrial applications, with major manufacturers developing systems capable of higher throughput and better repeatability.

Recent technological developments have significantly expanded the material portfolio beyond traditional ceramics and metals to include advanced composites and functional materials. Modern Binder Jetting systems incorporate sophisticated process monitoring capabilities, automated powder handling, and integrated post-processing solutions, addressing previous limitations in surface finish and dimensional accuracy.

The primary objective of Binder Jetting technology assessment is to evaluate its viability for full-scale industrial adoption across diverse manufacturing sectors. This includes analyzing the complete lifecycle implications, from raw material sourcing to end-of-life considerations. Specific technical objectives encompass improving part density and mechanical properties through optimized sintering protocols, enhancing dimensional accuracy through better binder-powder interactions, and developing closed-loop quality control systems.

Economic objectives focus on reducing the total cost of ownership through increased build rates, minimized material waste, and streamlined post-processing requirements. Environmental sustainability represents another critical objective, with emphasis on energy consumption patterns, material efficiency, and recyclability potential compared to conventional manufacturing methods.

The technology roadmap aims to address current limitations in surface quality, build chamber size, and process repeatability. Future development trajectories point toward multi-material capabilities, functionally graded structures, and integration with existing manufacturing workflows. Industry standardization efforts are underway to establish consistent quality metrics, testing protocols, and certification pathways for Binder Jetted components in regulated industries.

As industrial adoption accelerates, research priorities include developing specialized materials optimized for the Binder Jetting process, improving process modeling capabilities to predict part properties, and creating robust design guidelines that leverage the unique capabilities of this manufacturing approach.

Market Analysis for Industrial Binder Jetting Applications

The global market for binder jetting technology has experienced significant growth in recent years, with an estimated market value reaching $300 million in 2022 and projected to exceed $1.3 billion by 2028. This growth trajectory is primarily driven by increasing industrial adoption across multiple sectors, including automotive, aerospace, healthcare, and consumer goods manufacturing.

Industrial adoption of binder jetting technology is particularly strong in the automotive sector, where manufacturers are leveraging its capabilities for rapid prototyping, tooling, and increasingly for end-use parts production. The aerospace industry represents another major market segment, with companies utilizing binder jetting for complex components that benefit from the technology's design freedom and material efficiency.

Market analysis reveals that North America currently holds the largest market share at approximately 40%, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the highest compound annual growth rate over the next five years due to increasing industrialization and government initiatives supporting advanced manufacturing technologies.

From a materials perspective, metal binder jetting applications dominate the industrial market, accounting for roughly 65% of total applications. This is followed by sand (20%) and ceramic (15%) applications. Within the metal segment, stainless steel, tool steels, and copper alloys represent the most commonly processed materials, though aluminum alloys are gaining traction as process parameters continue to improve.

The competitive landscape features established players like Desktop Metal, ExOne (now part of Desktop Metal), HP, and Digital Metal, alongside emerging companies introducing innovative solutions. Market consolidation through mergers and acquisitions has been a notable trend, as evidenced by Desktop Metal's acquisition of ExOne in 2021.

Key market drivers include increasing demand for complex geometries that traditional manufacturing methods cannot produce cost-effectively, growing emphasis on supply chain resilience through on-demand manufacturing capabilities, and sustainability considerations as binder jetting typically generates less material waste compared to subtractive manufacturing processes.

Barriers to wider industrial adoption include concerns about part quality consistency, limited material options compared to traditional manufacturing, and the need for post-processing steps that impact overall production costs and lead times. Additionally, the total cost of ownership remains a significant consideration for industrial users evaluating binder jetting against conventional manufacturing methods.

Industrial adoption of binder jetting technology is particularly strong in the automotive sector, where manufacturers are leveraging its capabilities for rapid prototyping, tooling, and increasingly for end-use parts production. The aerospace industry represents another major market segment, with companies utilizing binder jetting for complex components that benefit from the technology's design freedom and material efficiency.

Market analysis reveals that North America currently holds the largest market share at approximately 40%, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the highest compound annual growth rate over the next five years due to increasing industrialization and government initiatives supporting advanced manufacturing technologies.

From a materials perspective, metal binder jetting applications dominate the industrial market, accounting for roughly 65% of total applications. This is followed by sand (20%) and ceramic (15%) applications. Within the metal segment, stainless steel, tool steels, and copper alloys represent the most commonly processed materials, though aluminum alloys are gaining traction as process parameters continue to improve.

The competitive landscape features established players like Desktop Metal, ExOne (now part of Desktop Metal), HP, and Digital Metal, alongside emerging companies introducing innovative solutions. Market consolidation through mergers and acquisitions has been a notable trend, as evidenced by Desktop Metal's acquisition of ExOne in 2021.

Key market drivers include increasing demand for complex geometries that traditional manufacturing methods cannot produce cost-effectively, growing emphasis on supply chain resilience through on-demand manufacturing capabilities, and sustainability considerations as binder jetting typically generates less material waste compared to subtractive manufacturing processes.

Barriers to wider industrial adoption include concerns about part quality consistency, limited material options compared to traditional manufacturing, and the need for post-processing steps that impact overall production costs and lead times. Additionally, the total cost of ownership remains a significant consideration for industrial users evaluating binder jetting against conventional manufacturing methods.

Current Limitations and Technical Barriers in Binder Jetting

Despite the promising potential of binder jetting technology in additive manufacturing, several significant technical barriers currently limit its widespread industrial adoption. Material compatibility remains a primary challenge, as not all powders respond optimally to binding agents. Certain materials exhibit poor flowability characteristics or inconsistent particle size distribution, leading to density variations and structural weaknesses in final parts. The binder-powder interaction chemistry is still not fully understood across diverse material systems, resulting in unpredictable binding quality and mechanical properties.

Resolution limitations present another substantial barrier. Current binder jetting systems typically achieve dimensional accuracies of ±0.2 mm, which falls short of requirements for high-precision industrial applications. The droplet placement precision and control over binder spreading mechanisms need significant improvement to compete with traditional manufacturing methods in terms of dimensional stability and surface finish quality.

Post-processing complexity substantially increases production costs and time requirements. Most binder jetted parts require extensive post-processing, including de-powdering, curing, sintering, and infiltration. These additional steps introduce variability in final part properties and dimensional accuracy. The sintering process, in particular, can cause unpredictable shrinkage ranging from 1-20% depending on material composition and geometry, making it difficult to achieve consistent results across production batches.

Production speed and scalability issues further hinder industrial adoption. While binder jetting offers theoretical advantages in build speed compared to other additive manufacturing technologies, the actual production throughput is limited by post-processing bottlenecks. Current systems struggle to maintain consistent quality at higher production volumes, with defect rates increasing as production scales up.

Quality control and process monitoring capabilities remain inadequate for industrial standards. The lack of robust in-situ monitoring systems makes it difficult to detect defects during the build process, resulting in material waste and reduced production efficiency. Non-destructive testing methods for binder jetted parts are still evolving, creating challenges for quality assurance in critical applications.

Sustainability concerns also present barriers to adoption. The environmental impact of binder materials, particularly solvent-based systems, raises regulatory compliance issues in certain industries. Additionally, powder recycling efficiency is lower than ideal, with material degradation occurring after multiple reuse cycles, affecting both economics and environmental footprint of the technology.

Resolution limitations present another substantial barrier. Current binder jetting systems typically achieve dimensional accuracies of ±0.2 mm, which falls short of requirements for high-precision industrial applications. The droplet placement precision and control over binder spreading mechanisms need significant improvement to compete with traditional manufacturing methods in terms of dimensional stability and surface finish quality.

Post-processing complexity substantially increases production costs and time requirements. Most binder jetted parts require extensive post-processing, including de-powdering, curing, sintering, and infiltration. These additional steps introduce variability in final part properties and dimensional accuracy. The sintering process, in particular, can cause unpredictable shrinkage ranging from 1-20% depending on material composition and geometry, making it difficult to achieve consistent results across production batches.

Production speed and scalability issues further hinder industrial adoption. While binder jetting offers theoretical advantages in build speed compared to other additive manufacturing technologies, the actual production throughput is limited by post-processing bottlenecks. Current systems struggle to maintain consistent quality at higher production volumes, with defect rates increasing as production scales up.

Quality control and process monitoring capabilities remain inadequate for industrial standards. The lack of robust in-situ monitoring systems makes it difficult to detect defects during the build process, resulting in material waste and reduced production efficiency. Non-destructive testing methods for binder jetted parts are still evolving, creating challenges for quality assurance in critical applications.

Sustainability concerns also present barriers to adoption. The environmental impact of binder materials, particularly solvent-based systems, raises regulatory compliance issues in certain industries. Additionally, powder recycling efficiency is lower than ideal, with material degradation occurring after multiple reuse cycles, affecting both economics and environmental footprint of the technology.

Current Industrial Implementation Solutions for Binder Jetting

01 Environmental impact assessment of binder jetting processes

Lifecycle assessment methodologies specifically designed for binder jetting additive manufacturing processes that evaluate environmental impacts throughout the entire product lifecycle. These assessments consider factors such as material consumption, energy usage, waste generation, and emissions during raw material extraction, manufacturing, use, and end-of-life stages. The methodologies help in identifying environmental hotspots and opportunities for sustainability improvements in binder jetting operations.- Environmental impact assessment of binder jetting processes: Lifecycle assessment methodologies are applied to evaluate the environmental impacts of binder jetting additive manufacturing processes. These assessments consider factors such as energy consumption, material usage efficiency, waste generation, and carbon footprint throughout the entire manufacturing process. The analysis helps in identifying environmental hotspots and opportunities for sustainability improvements in binder jetting technology compared to traditional manufacturing methods.

- Material optimization for sustainable binder jetting: Research focuses on developing and optimizing materials for binder jetting processes that minimize environmental impact throughout the product lifecycle. This includes biodegradable binders, recyclable powders, and materials with reduced toxicity. The selection and formulation of these materials aim to decrease resource consumption, enable easier recycling, and reduce end-of-life environmental impacts while maintaining required mechanical properties and performance characteristics.

- Process efficiency and waste reduction in binder jetting: Innovations in binder jetting technology focus on improving process efficiency and reducing waste generation throughout the manufacturing lifecycle. These advancements include optimized printing parameters, powder recycling systems, and improved binder application methods. By enhancing material utilization rates and minimizing waste, these technologies contribute to more sustainable manufacturing practices and reduced environmental footprint of binder jetting operations.

- Digital twins and simulation for lifecycle optimization: Digital twin technology and simulation tools are employed to model and optimize the entire lifecycle of binder jetting processes. These digital representations enable virtual testing and validation of design modifications, process parameters, and material selections before physical implementation. By predicting performance and environmental impacts throughout the product lifecycle, these tools help manufacturers make informed decisions that balance technical requirements with sustainability goals.

- End-of-life considerations and circular economy approaches: Lifecycle assessment of binder jetted products includes analysis of end-of-life scenarios and implementation of circular economy principles. This involves designing products for disassembly, reuse, or recycling, as well as developing processes for material recovery from used parts. The approach aims to close material loops, extend product lifespans, and minimize waste disposal, thereby reducing the overall environmental impact of binder jetting manufacturing throughout the complete product lifecycle.

02 Material efficiency and recycling in binder jetting processes

Techniques for improving material efficiency and implementing recycling strategies in binder jetting processes to reduce environmental footprint. These include methods for powder reclamation and reuse, minimizing binder consumption, and utilizing recycled or bio-based materials as feedstock. The approaches focus on creating closed-loop systems that maximize resource utilization while maintaining product quality and performance throughout the lifecycle.Expand Specific Solutions03 Energy optimization and carbon footprint reduction

Methods for optimizing energy consumption and reducing the carbon footprint of binder jetting manufacturing processes. These include energy-efficient machine designs, process parameter optimization, and integration of renewable energy sources. The approaches also encompass strategies for quantifying and minimizing greenhouse gas emissions throughout the product lifecycle, from raw material production to end-of-life management.Expand Specific Solutions04 Digital tools for lifecycle assessment and sustainability optimization

Digital platforms and software tools specifically designed for conducting lifecycle assessments and optimizing sustainability parameters in binder jetting processes. These tools enable real-time monitoring, simulation, and analysis of environmental impacts throughout the manufacturing process and product lifecycle. They incorporate data analytics and artificial intelligence to identify optimization opportunities and support decision-making for sustainable manufacturing.Expand Specific Solutions05 Sustainable binder formulations and post-processing methods

Development of environmentally friendly binder formulations and post-processing techniques that reduce the ecological footprint of binder jetting processes. These include water-based and bio-derived binders with lower toxicity, as well as energy-efficient curing and sintering methods. The innovations focus on minimizing harmful emissions, reducing resource consumption, and improving the overall sustainability profile of the manufacturing process while maintaining or enhancing product performance.Expand Specific Solutions

Leading Companies and Competitive Landscape in Binder Jetting

Binder Jetting Lifecycle Assessment for industrial adoption is currently in a growth phase, with the market expected to expand significantly due to increasing demand for sustainable manufacturing solutions. The global market size for binder jetting technology is projected to reach substantial value as industries seek cost-effective additive manufacturing alternatives. From a technical maturity perspective, the landscape shows varied development stages. Desktop Metal leads commercial implementation with production-ready systems, while General Electric has integrated binder jetting into industrial workflows. Academic institutions like University of Science & Technology Beijing and Central South University are advancing fundamental research. Companies including Evove, Meta Additive, and DuPont are developing specialized materials and applications, indicating the technology is transitioning from experimental to practical industrial implementation, though challenges in standardization and lifecycle assessment methodologies remain.

Desktop Metal, Inc.

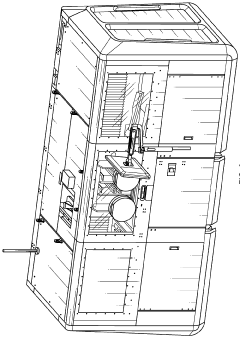

Technical Solution: Desktop Metal has developed a comprehensive lifecycle assessment framework for their Binder Jetting technology that evaluates environmental impacts across the entire production process. Their Production System™ utilizes a proprietary Single Pass Jetting™ technology that deposits binding agents onto a powder bed at high speeds, achieving print speeds up to 12,000 cm³/hour[1]. Their approach includes detailed analysis of raw material extraction, powder production, printing process energy consumption, debinding and sintering phases, and end-of-life considerations. Desktop Metal has implemented closed-loop powder recycling systems that can reclaim up to 98% of unused powder[2], significantly reducing material waste. Their lifecycle assessment methodology incorporates ISO 14040/14044 standards and quantifies carbon footprint, energy consumption, water usage, and waste generation across the manufacturing process, enabling industrial adopters to make data-driven sustainability decisions.

Strengths: Industry-leading print speeds and throughput capabilities make their technology economically viable for mass production. Their comprehensive powder recycling systems significantly reduce material waste and environmental impact. Weaknesses: The multi-step process (printing, debinding, sintering) requires substantial energy consumption, particularly during the thermal processing stages, which impacts the overall environmental footprint.

General Electric Company

Technical Solution: GE has developed an integrated lifecycle assessment framework for Binder Jetting that focuses on industrial-scale implementation across their aerospace and energy divisions. Their approach centers on a "Design for Additive" methodology that optimizes components specifically for binder jetting processes, reducing material usage by up to 30% compared to traditional manufacturing[3]. GE's lifecycle assessment includes detailed analysis of powder production energy requirements, binding agent environmental impacts, and post-processing energy consumption. Their H2 binder system uses environmentally-optimized binders that reduce harmful emissions during debinding by approximately 40%[4]. GE has also pioneered hybrid manufacturing approaches that combine binder jetting with conventional techniques to optimize both environmental impact and mechanical properties. Their assessment framework includes specialized tools for calculating total lifecycle carbon emissions, enabling industrial adopters to quantify sustainability improvements against conventional manufacturing baselines.

Strengths: Extensive experience implementing binder jetting in regulated industries like aerospace provides valuable compliance insights. Their hybrid manufacturing approaches offer practical pathways for industrial adoption that balance performance and sustainability. Weaknesses: Their solutions often require significant capital investment and specialized expertise, creating barriers to adoption for smaller manufacturers. Some of their proprietary binder systems still contain components with environmental concerns.

Key Patents and Technical Innovations in Binder Jetting

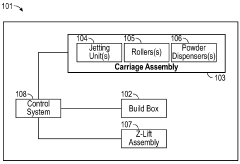

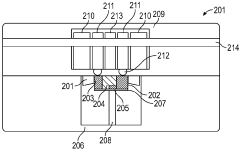

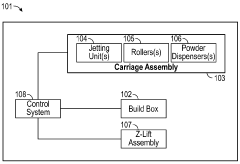

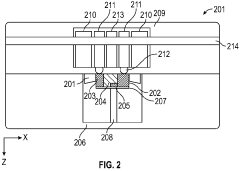

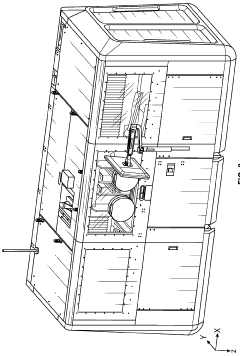

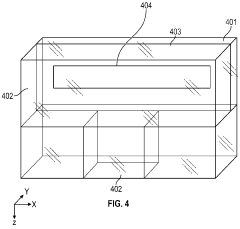

Downdraft system for binder jetting additive manufacturing

PatentWO2023158669A1

Innovation

- A downdraft system with powder collection chutes and a pneumatic conveyance system, utilizing a gas management system to convey and separate excess powder from the process gas, ensuring safe collection and reuse within the printer.

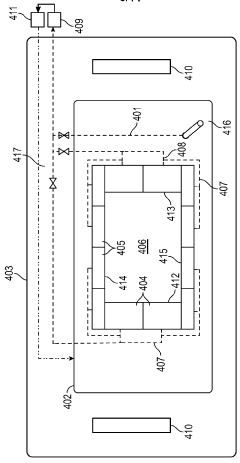

Gas management system for binder jetting additive manufacturing

PatentWO2023158667A1

Innovation

- A gas management system is implemented within the binder jet printer to control the gaseous atmosphere by using partitions, baffle systems, and process gas flow to separate and manage gaseous volumes, maintaining specific oxygen concentrations and preventing powder migration, thereby ensuring a safe and inert environment for printing.

Environmental Impact and Sustainability Considerations

Binder Jetting technology, while offering significant advantages in manufacturing flexibility and material efficiency, presents important environmental considerations that must be addressed for sustainable industrial adoption. The lifecycle assessment of this additive manufacturing process reveals both positive and negative environmental impacts that require careful evaluation.

From a resource consumption perspective, Binder Jetting demonstrates notable advantages over traditional manufacturing methods. The process utilizes up to 95% of input materials, significantly reducing waste compared to subtractive manufacturing techniques. Additionally, the ability to produce complex geometries without tooling eliminates the environmental footprint associated with tool production and disposal.

Energy consumption patterns in Binder Jetting present a mixed environmental profile. While the printing process itself consumes relatively low energy compared to laser-based additive manufacturing technologies, the post-processing steps—particularly sintering—can be energy-intensive. Recent studies indicate that sintering accounts for approximately 60-70% of the total energy consumption in the Binder Jetting lifecycle, highlighting an area for potential optimization.

Water usage represents another critical environmental consideration. The binder solutions used in the process often contain water-based components, and cleaning operations throughout the manufacturing cycle require additional water resources. Closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 80%, though implementation remains inconsistent across the industry.

Chemical safety concerns arise from the binders and processing agents used in Binder Jetting. Many commercial binders contain volatile organic compounds (VOCs) and other potentially hazardous substances that require proper handling and disposal. The development of bio-based and environmentally benign binder alternatives has progressed significantly, with several manufacturers now offering formulations that reduce harmful emissions by 40-60% compared to conventional options.

End-of-life considerations for Binder Jetted products present both challenges and opportunities. The multi-material nature of some components can complicate recycling efforts, while metal parts produced through this process can generally be recycled through conventional metal recycling streams. Research into design-for-disassembly approaches specific to Binder Jetted products shows promise for improving end-of-life recovery rates.

Carbon footprint analyses comparing Binder Jetting to conventional manufacturing methods indicate potential CO2 emission reductions of 25-40% for appropriate applications, primarily due to material efficiency and supply chain simplification through on-demand, localized production. However, these benefits are highly application-specific and require case-by-case assessment for accurate environmental impact determination.

From a resource consumption perspective, Binder Jetting demonstrates notable advantages over traditional manufacturing methods. The process utilizes up to 95% of input materials, significantly reducing waste compared to subtractive manufacturing techniques. Additionally, the ability to produce complex geometries without tooling eliminates the environmental footprint associated with tool production and disposal.

Energy consumption patterns in Binder Jetting present a mixed environmental profile. While the printing process itself consumes relatively low energy compared to laser-based additive manufacturing technologies, the post-processing steps—particularly sintering—can be energy-intensive. Recent studies indicate that sintering accounts for approximately 60-70% of the total energy consumption in the Binder Jetting lifecycle, highlighting an area for potential optimization.

Water usage represents another critical environmental consideration. The binder solutions used in the process often contain water-based components, and cleaning operations throughout the manufacturing cycle require additional water resources. Closed-loop water recycling systems have demonstrated potential to reduce freshwater consumption by up to 80%, though implementation remains inconsistent across the industry.

Chemical safety concerns arise from the binders and processing agents used in Binder Jetting. Many commercial binders contain volatile organic compounds (VOCs) and other potentially hazardous substances that require proper handling and disposal. The development of bio-based and environmentally benign binder alternatives has progressed significantly, with several manufacturers now offering formulations that reduce harmful emissions by 40-60% compared to conventional options.

End-of-life considerations for Binder Jetted products present both challenges and opportunities. The multi-material nature of some components can complicate recycling efforts, while metal parts produced through this process can generally be recycled through conventional metal recycling streams. Research into design-for-disassembly approaches specific to Binder Jetted products shows promise for improving end-of-life recovery rates.

Carbon footprint analyses comparing Binder Jetting to conventional manufacturing methods indicate potential CO2 emission reductions of 25-40% for appropriate applications, primarily due to material efficiency and supply chain simplification through on-demand, localized production. However, these benefits are highly application-specific and require case-by-case assessment for accurate environmental impact determination.

Cost-Benefit Analysis for Industrial Adoption

The economic viability of Binder Jetting technology requires thorough cost-benefit analysis across the entire production lifecycle. Initial capital investment for Binder Jetting systems ranges from $200,000 to $1.5 million, significantly lower than comparable metal additive manufacturing technologies like Selective Laser Melting (SLM) or Electron Beam Melting (EBM). This reduced entry barrier makes it particularly attractive for small to medium enterprises seeking to adopt additive manufacturing capabilities.

Operational costs present a complex calculation involving material consumption, energy usage, post-processing requirements, and maintenance expenses. Material costs for Binder Jetting powders typically range between $80-200 per kilogram, with binder costs adding approximately $0.10-0.30 per cubic centimeter of printed volume. Energy consumption averages 5-8 kWh per kilogram of processed material, substantially lower than laser-based systems that consume 25-30 kWh for equivalent output.

Post-processing represents a significant portion of total production costs, accounting for 30-40% of the overall expense. This includes debinding, sintering, and finishing operations that require additional equipment and energy inputs. Maintenance costs typically range from 8-12% of the initial machine cost annually, with consumable parts replacement adding further expenses.

The benefits side of the equation reveals compelling advantages. Production speed improvements of 5-10x compared to laser-based systems translate to higher throughput and reduced per-part costs for medium to high volume production runs. Design freedom enables complex geometries that reduce part count by 30-50% in many applications, decreasing assembly costs and improving reliability.

Material efficiency reaches 95-98% with powder recycling systems, significantly higher than subtractive manufacturing methods that typically achieve only 20-40% material utilization. This efficiency becomes particularly valuable when working with expensive alloys or materials with complex supply chains.

Return on investment (ROI) calculations indicate breakeven periods of 18-36 months for industries with appropriate applications, particularly in automotive, aerospace, and medical device manufacturing. Companies report cost reductions of 20-60% for specific components when transitioning from traditional manufacturing to optimized Binder Jetting processes.

Long-term economic benefits include reduced inventory costs through on-demand manufacturing capabilities, decreased tooling expenses, and enhanced product customization opportunities that command premium pricing. These factors contribute to the technology's growing adoption despite the learning curve and process optimization challenges that organizations must overcome during implementation.

Operational costs present a complex calculation involving material consumption, energy usage, post-processing requirements, and maintenance expenses. Material costs for Binder Jetting powders typically range between $80-200 per kilogram, with binder costs adding approximately $0.10-0.30 per cubic centimeter of printed volume. Energy consumption averages 5-8 kWh per kilogram of processed material, substantially lower than laser-based systems that consume 25-30 kWh for equivalent output.

Post-processing represents a significant portion of total production costs, accounting for 30-40% of the overall expense. This includes debinding, sintering, and finishing operations that require additional equipment and energy inputs. Maintenance costs typically range from 8-12% of the initial machine cost annually, with consumable parts replacement adding further expenses.

The benefits side of the equation reveals compelling advantages. Production speed improvements of 5-10x compared to laser-based systems translate to higher throughput and reduced per-part costs for medium to high volume production runs. Design freedom enables complex geometries that reduce part count by 30-50% in many applications, decreasing assembly costs and improving reliability.

Material efficiency reaches 95-98% with powder recycling systems, significantly higher than subtractive manufacturing methods that typically achieve only 20-40% material utilization. This efficiency becomes particularly valuable when working with expensive alloys or materials with complex supply chains.

Return on investment (ROI) calculations indicate breakeven periods of 18-36 months for industries with appropriate applications, particularly in automotive, aerospace, and medical device manufacturing. Companies report cost reductions of 20-60% for specific components when transitioning from traditional manufacturing to optimized Binder Jetting processes.

Long-term economic benefits include reduced inventory costs through on-demand manufacturing capabilities, decreased tooling expenses, and enhanced product customization opportunities that command premium pricing. These factors contribute to the technology's growing adoption despite the learning curve and process optimization challenges that organizations must overcome during implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!