Binder Jetting For Automotive Components: Lightweight Structures And Qualification Paths

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting technology emerged in the early 1990s as an additive manufacturing process developed at the Massachusetts Institute of Technology. Initially conceived as a rapid prototyping method, the technology has evolved significantly over three decades to become a viable production technique for complex metal and ceramic components. The fundamental principle—selectively depositing a liquid binding agent onto powder materials to create three-dimensional structures—has remained consistent, while the supporting technologies have advanced dramatically.

The evolution of Binder Jetting can be characterized by several distinct phases. The first generation (1990-2005) focused primarily on sand casting applications and non-functional prototypes, with limited material options and relatively poor mechanical properties. The second generation (2005-2015) saw improvements in binder chemistry and powder characteristics, enabling the production of functional prototypes and limited production parts, though still with significant limitations in density and strength.

The current third generation (2015-present) represents a transformative period for Binder Jetting technology, with substantial advancements in machine precision, process control, and material science. Modern systems feature high-resolution printheads (achieving droplet sizes below 30 microns), advanced thermal management, and sophisticated software controls that enable the production of components with dimensional accuracies approaching ±0.2% and relative densities exceeding 99% after sintering.

For automotive applications specifically, Binder Jetting technology aims to address several critical objectives. Primary among these is the development of lightweight structural components that can contribute to vehicle weight reduction without compromising safety or performance. The technology targets a 20-40% weight reduction compared to conventional manufacturing methods for specific components, particularly those with complex internal geometries that benefit from the design freedom of additive manufacturing.

Another key objective is establishing qualification pathways that enable the integration of Binder Jetted components into automotive supply chains. This includes developing standardized testing protocols, material property databases, and process monitoring systems that can ensure consistent quality and reliability across production runs. The technology seeks to achieve repeatability metrics with coefficient of variation below 3% for critical mechanical properties.

Cost-effectiveness represents another crucial objective, with current efforts focused on reducing the total cost of ownership through increased build speeds (targeting >100 cm³/hour), improved powder recycling rates (>95%), and reduced post-processing requirements. The ultimate goal is to achieve cost parity with conventional manufacturing methods for medium-volume production runs (5,000-20,000 units annually) by 2025.

The evolution of Binder Jetting can be characterized by several distinct phases. The first generation (1990-2005) focused primarily on sand casting applications and non-functional prototypes, with limited material options and relatively poor mechanical properties. The second generation (2005-2015) saw improvements in binder chemistry and powder characteristics, enabling the production of functional prototypes and limited production parts, though still with significant limitations in density and strength.

The current third generation (2015-present) represents a transformative period for Binder Jetting technology, with substantial advancements in machine precision, process control, and material science. Modern systems feature high-resolution printheads (achieving droplet sizes below 30 microns), advanced thermal management, and sophisticated software controls that enable the production of components with dimensional accuracies approaching ±0.2% and relative densities exceeding 99% after sintering.

For automotive applications specifically, Binder Jetting technology aims to address several critical objectives. Primary among these is the development of lightweight structural components that can contribute to vehicle weight reduction without compromising safety or performance. The technology targets a 20-40% weight reduction compared to conventional manufacturing methods for specific components, particularly those with complex internal geometries that benefit from the design freedom of additive manufacturing.

Another key objective is establishing qualification pathways that enable the integration of Binder Jetted components into automotive supply chains. This includes developing standardized testing protocols, material property databases, and process monitoring systems that can ensure consistent quality and reliability across production runs. The technology seeks to achieve repeatability metrics with coefficient of variation below 3% for critical mechanical properties.

Cost-effectiveness represents another crucial objective, with current efforts focused on reducing the total cost of ownership through increased build speeds (targeting >100 cm³/hour), improved powder recycling rates (>95%), and reduced post-processing requirements. The ultimate goal is to achieve cost parity with conventional manufacturing methods for medium-volume production runs (5,000-20,000 units annually) by 2025.

Automotive Market Demand for Lightweight Components

The automotive industry is experiencing a significant shift towards lightweight components, driven primarily by stringent global emissions regulations and the increasing consumer demand for fuel-efficient vehicles. According to recent industry analyses, reducing vehicle weight by 10% can improve fuel efficiency by approximately 6-8%, making lightweight components a critical factor in meeting corporate average fuel economy (CAFE) standards and European CO2 emission targets.

The global market for automotive lightweight materials was valued at $88.5 billion in 2022 and is projected to reach $126.8 billion by 2027, growing at a CAGR of 7.4%. This growth is particularly pronounced in premium and electric vehicle segments, where weight reduction directly correlates with extended range capabilities and enhanced performance metrics.

Original Equipment Manufacturers (OEMs) are increasingly focusing on structural components that can be redesigned using advanced manufacturing techniques like Binder Jetting. Engine brackets, suspension components, chassis parts, and heat exchangers represent high-value targets for weight reduction without compromising structural integrity or safety standards.

Electric vehicles present a particularly compelling case for lightweight components. Despite the elimination of traditional internal combustion engines, EVs typically weigh 20-30% more than their conventional counterparts due to battery systems. This weight penalty creates an even greater imperative for lightweight solutions in non-battery components to maximize range efficiency.

Regional market analysis reveals varying adoption rates of lightweight technologies. European manufacturers, facing the most stringent emissions regulations, lead in lightweight innovation, followed closely by North American and Japanese OEMs. The Chinese automotive market, while still developing in this area, is showing accelerated adoption rates, particularly in their rapidly expanding electric vehicle sector.

Consumer willingness to pay premiums for fuel efficiency has created a favorable market environment for lightweight technologies. Studies indicate that consumers are willing to pay approximately $2,000 more for vehicles that offer a 10% improvement in fuel economy, creating a viable commercial pathway for technologies that may initially command higher production costs.

The demand for lightweight components is further amplified by the autonomous vehicle trend, where additional weight from sensors and computing systems creates new challenges for vehicle designers. Industry forecasts suggest that by 2030, over 60% of new vehicles will incorporate some level of autonomous capability, further driving the need for advanced lightweight structural solutions across the automotive value chain.

The global market for automotive lightweight materials was valued at $88.5 billion in 2022 and is projected to reach $126.8 billion by 2027, growing at a CAGR of 7.4%. This growth is particularly pronounced in premium and electric vehicle segments, where weight reduction directly correlates with extended range capabilities and enhanced performance metrics.

Original Equipment Manufacturers (OEMs) are increasingly focusing on structural components that can be redesigned using advanced manufacturing techniques like Binder Jetting. Engine brackets, suspension components, chassis parts, and heat exchangers represent high-value targets for weight reduction without compromising structural integrity or safety standards.

Electric vehicles present a particularly compelling case for lightweight components. Despite the elimination of traditional internal combustion engines, EVs typically weigh 20-30% more than their conventional counterparts due to battery systems. This weight penalty creates an even greater imperative for lightweight solutions in non-battery components to maximize range efficiency.

Regional market analysis reveals varying adoption rates of lightweight technologies. European manufacturers, facing the most stringent emissions regulations, lead in lightweight innovation, followed closely by North American and Japanese OEMs. The Chinese automotive market, while still developing in this area, is showing accelerated adoption rates, particularly in their rapidly expanding electric vehicle sector.

Consumer willingness to pay premiums for fuel efficiency has created a favorable market environment for lightweight technologies. Studies indicate that consumers are willing to pay approximately $2,000 more for vehicles that offer a 10% improvement in fuel economy, creating a viable commercial pathway for technologies that may initially command higher production costs.

The demand for lightweight components is further amplified by the autonomous vehicle trend, where additional weight from sensors and computing systems creates new challenges for vehicle designers. Industry forecasts suggest that by 2030, over 60% of new vehicles will incorporate some level of autonomous capability, further driving the need for advanced lightweight structural solutions across the automotive value chain.

Current Capabilities and Barriers in Binder Jetting

Binder jetting technology has evolved significantly over the past decade, establishing itself as a viable additive manufacturing method for automotive applications. Current capabilities include the ability to produce complex geometries with internal channels and lattice structures that would be impossible with traditional manufacturing methods. The technology can process a wide range of materials including stainless steel, tool steel, copper, tungsten, and various ceramic materials, offering automotive manufacturers flexibility in component design and material selection.

Production volumes have increased substantially, with modern binder jetting systems capable of manufacturing hundreds to thousands of parts per day, depending on component size. This throughput makes binder jetting increasingly attractive for automotive production environments where scale is critical. Resolution capabilities have also improved, with layer thicknesses now commonly available between 20-100 microns, allowing for finer detail in automotive components.

Despite these advancements, significant barriers remain. Material property consistency presents a major challenge, as parts often exhibit anisotropic behavior with mechanical properties varying based on build orientation. This inconsistency complicates qualification processes for safety-critical automotive components. Post-processing requirements also present bottlenecks, as green parts require debinding and sintering, which can introduce dimensional changes of 15-20% that must be accurately predicted and compensated for during design.

Surface finish quality remains inferior to traditional manufacturing methods, often requiring additional post-processing for components with strict surface requirements. This adds cost and time to the production process. Size limitations also persist, with most commercial binder jetting systems restricted to build volumes under 800 x 500 x 400 mm, constraining the production of larger automotive components.

Perhaps most critically for automotive applications, qualification and certification pathways remain underdeveloped. The industry lacks standardized testing protocols and acceptance criteria specifically for binder jetted automotive components. This regulatory gap creates uncertainty in implementation timelines and increases validation costs for manufacturers.

Material costs continue to be higher than those for traditional manufacturing, with specialized powders for binder jetting typically costing 3-10 times more than conventional materials. This cost differential impacts the economic viability of the technology for mass-market automotive applications, particularly for price-sensitive components.

Energy consumption during the sintering phase presents another barrier, with high-temperature furnaces requiring significant power input and contributing to the overall carbon footprint of the manufacturing process. This contradicts sustainability goals that many automotive manufacturers have established.

Production volumes have increased substantially, with modern binder jetting systems capable of manufacturing hundreds to thousands of parts per day, depending on component size. This throughput makes binder jetting increasingly attractive for automotive production environments where scale is critical. Resolution capabilities have also improved, with layer thicknesses now commonly available between 20-100 microns, allowing for finer detail in automotive components.

Despite these advancements, significant barriers remain. Material property consistency presents a major challenge, as parts often exhibit anisotropic behavior with mechanical properties varying based on build orientation. This inconsistency complicates qualification processes for safety-critical automotive components. Post-processing requirements also present bottlenecks, as green parts require debinding and sintering, which can introduce dimensional changes of 15-20% that must be accurately predicted and compensated for during design.

Surface finish quality remains inferior to traditional manufacturing methods, often requiring additional post-processing for components with strict surface requirements. This adds cost and time to the production process. Size limitations also persist, with most commercial binder jetting systems restricted to build volumes under 800 x 500 x 400 mm, constraining the production of larger automotive components.

Perhaps most critically for automotive applications, qualification and certification pathways remain underdeveloped. The industry lacks standardized testing protocols and acceptance criteria specifically for binder jetted automotive components. This regulatory gap creates uncertainty in implementation timelines and increases validation costs for manufacturers.

Material costs continue to be higher than those for traditional manufacturing, with specialized powders for binder jetting typically costing 3-10 times more than conventional materials. This cost differential impacts the economic viability of the technology for mass-market automotive applications, particularly for price-sensitive components.

Energy consumption during the sintering phase presents another barrier, with high-temperature furnaces requiring significant power input and contributing to the overall carbon footprint of the manufacturing process. This contradicts sustainability goals that many automotive manufacturers have established.

Existing Binder Jetting Solutions for Vehicle Components

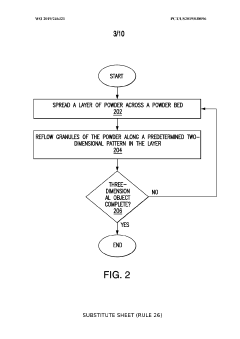

01 Binder jetting processes for lightweight structures

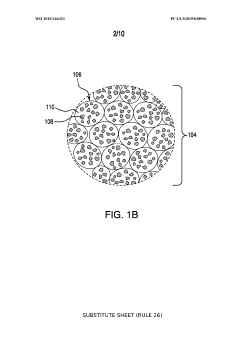

Binder jetting is an additive manufacturing process that can be used to create lightweight structures by selectively depositing a binding agent onto a powder bed. This process allows for the creation of complex geometries with controlled porosity, resulting in lightweight yet strong structures. The process typically involves layering powder material, applying binder in specific patterns, and then post-processing to achieve the desired mechanical properties. This approach enables the production of components with optimized weight-to-strength ratios for various applications.- Binder jetting processes for lightweight cellular structures: Binder jetting techniques can be used to create lightweight cellular structures with controlled porosity. These processes involve selectively depositing a binding agent onto powder material to create complex geometries with internal voids. The resulting structures feature high strength-to-weight ratios while maintaining structural integrity. Various powder materials can be used, including metals, ceramics, and polymers, allowing for customization based on specific application requirements.

- Material compositions for lightweight binder jetted parts: Specialized material compositions have been developed for binder jetting lightweight structures. These compositions include modified powders with specific particle size distributions and morphologies, as well as binder formulations that provide optimal green strength and final part properties. Some compositions incorporate hollow microspheres, foaming agents, or other lightweight fillers to further reduce density while maintaining structural performance. Post-processing treatments can enhance the mechanical properties of these lightweight materials.

- Lattice and honeycomb design optimization for binder jetted structures: Advanced design methodologies for lattice and honeycomb structures enable the creation of optimized lightweight components through binder jetting. These designs incorporate variable cell sizes, wall thicknesses, and geometries based on load requirements and stress distribution analysis. Topology optimization algorithms can be employed to determine the optimal material distribution within a given design space, resulting in structures that maximize strength while minimizing weight. These designs often feature gradient porosity to address specific performance requirements in different regions of the part.

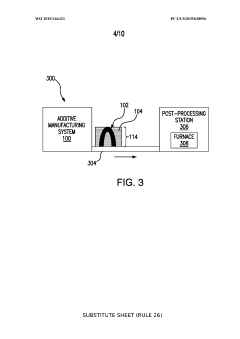

- Post-processing techniques for binder jetted lightweight structures: Various post-processing methods can be applied to binder jetted lightweight structures to enhance their properties. These include sintering protocols optimized for cellular structures, infiltration with secondary materials to improve strength without significantly increasing weight, and surface treatments to improve finish quality and durability. Controlled heat treatment processes can be used to achieve desired microstructural characteristics while maintaining dimensional accuracy. Some techniques involve the removal of sacrificial materials to create complex internal channels or voids.

- Applications of binder jetted lightweight structures: Binder jetted lightweight structures find applications across various industries due to their unique combination of low weight and customizable properties. In aerospace and automotive sectors, these structures are used for components requiring high strength-to-weight ratios. Medical applications include customized implants with controlled porosity for tissue integration. Energy sector applications include lightweight heat exchangers and thermal management systems. Consumer products benefit from reduced material usage while maintaining functionality. These structures also enable novel designs that would be impossible to manufacture using conventional methods.

02 Materials for lightweight binder jetted structures

Various materials can be used in binder jetting to create lightweight structures, including metal powders, ceramics, polymers, and composites. The selection of materials significantly impacts the final properties of the structure, such as strength, weight, and durability. Advanced material formulations may incorporate hollow microspheres, foaming agents, or cellular structures to further reduce weight while maintaining structural integrity. The combination of specialized powders with tailored binders enables the creation of structures with gradient densities and optimized mechanical properties.Expand Specific Solutions03 Lattice and cellular designs for weight reduction

Binder jetting technology enables the fabrication of complex lattice and cellular structures that significantly reduce weight while maintaining mechanical strength. These designs feature interconnected networks of struts or walls that distribute loads efficiently while minimizing material usage. Various lattice types, including octet, gyroid, and honeycomb structures, can be implemented based on specific application requirements. The ability to create these intricate internal architectures allows for optimization of strength-to-weight ratios that would be impossible with conventional manufacturing methods.Expand Specific Solutions04 Post-processing techniques for lightweight structures

After the initial binder jetting process, various post-processing techniques can be applied to enhance the properties of lightweight structures. These include sintering, infiltration, heat treatment, and surface finishing. Sintering consolidates the powder particles, while infiltration with secondary materials can fill voids to improve strength. Heat treatments can optimize microstructure and mechanical properties. These post-processing steps are crucial for achieving the desired combination of lightweight characteristics and structural performance, enabling the production of components with tailored properties for specific applications.Expand Specific Solutions05 Applications of binder jetted lightweight structures

Binder jetted lightweight structures find applications across various industries including aerospace, automotive, medical, and consumer products. In aerospace and automotive sectors, these structures help reduce fuel consumption and emissions while maintaining safety standards. In medical applications, customized implants with controlled porosity can promote tissue integration. The ability to create complex geometries with optimized weight distribution makes binder jetted components ideal for performance-critical applications where weight reduction provides significant advantages, such as in electric vehicles, drones, and portable electronic devices.Expand Specific Solutions

Leading Companies in Automotive Binder Jetting Technology

Binder Jetting for automotive components is currently in the early growth phase, with the market expected to expand significantly as the technology matures. The global market for this technology is projected to reach approximately $300-400 million by 2025, driven by increasing demand for lightweight automotive structures. Desktop Metal leads the technological advancement with their Production System, while established automotive manufacturers like Mercedes-Benz, BMW, and Ford are actively integrating binder jetting into their production processes. Airbus Operations and Fraunhofer-Gesellschaft are contributing to qualification standards development, while materials suppliers such as Materion Corp and Henkel are developing specialized powders and binders. The technology is approaching mainstream adoption, with qualification paths being established through collaborations between automotive OEMs and research institutions.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed a comprehensive Binder Jetting technology specifically optimized for automotive components called Production System™. This platform utilizes Single Pass Jetting™ technology that deposits binding agents onto a powder bed at high speeds, enabling the creation of complex lightweight structures with superior dimensional accuracy. Their proprietary binder formulations are specifically engineered for automotive-grade metals including aluminum alloys and steel variants commonly used in vehicle manufacturing. The system incorporates advanced thermal processing techniques for debinding and sintering that maintain tight tolerances critical for automotive applications. Desktop Metal has established qualification protocols aligned with IATF 16949 automotive quality standards, providing a clear path for parts certification. Their technology enables the production of components with optimized internal lattice structures that reduce weight while maintaining structural integrity, addressing the automotive industry's push for lightweighting.

Strengths: Industry-leading print speeds (up to 12,000 cm³/hr) enable cost-effective mass production; proprietary binder systems compatible with wide range of metal powders; established qualification pathways aligned with automotive standards. Weaknesses: Higher initial capital investment compared to traditional manufacturing; limited maximum part size compared to some competing technologies; requires specialized knowledge for design optimization.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a specialized approach to Binder Jetting for automotive applications focused on lightweight structural components. Their technology integrates with their "Bionic Design" philosophy, allowing for the creation of components that mimic natural structures for optimal strength-to-weight ratios. Mercedes has established a comprehensive qualification framework specifically for additive manufactured parts that includes extensive material testing, process validation, and performance verification under automotive-specific conditions. Their approach includes proprietary post-processing techniques that enhance the surface finish and mechanical properties of binder jetted components. Mercedes has successfully implemented this technology for producing complex structural brackets, cooling components, and interior elements that meet stringent automotive requirements. Their qualification path includes specialized testing protocols for vibration resistance, thermal cycling, and crash performance that exceed standard industry requirements, ensuring parts meet Mercedes-Benz's premium quality standards.

Strengths: Comprehensive integration with existing automotive design and manufacturing workflows; extensive in-house material science expertise; established qualification protocols specific to luxury vehicle requirements. Weaknesses: Technology primarily optimized for premium vehicle applications where cost is less critical; limited to smaller components rather than large structural elements; requires significant post-processing to achieve desired surface finish.

Critical Patents and Research in Automotive Binder Jetting

Methods and compositions for the preparation of powders for binder-based three-dimensional additive metal manufacturing

PatentWO2019246321A1

Innovation

- The use of coated powders where each granule has a core of one material overlaid with a coating of another material, reducing segregation and enhancing homogeneity and physicochemical properties of the finished parts.

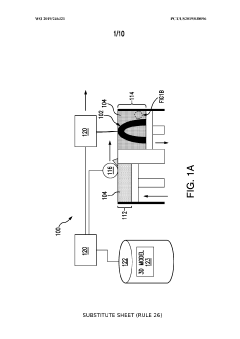

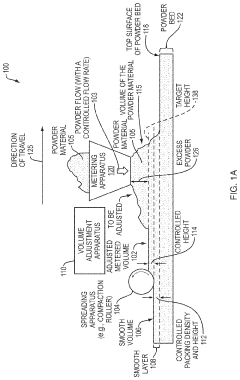

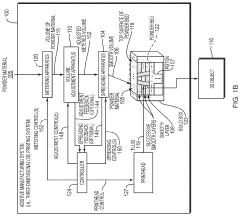

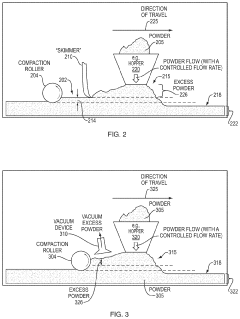

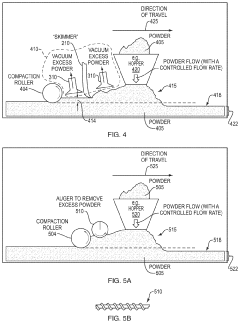

System and method for controlling powder bed density for 3D printing

PatentActiveUS11998982B2

Innovation

- A system comprising a metering apparatus, volume adjustment apparatus, and spreading apparatus that controls the height and packing density of powder layers, using a skimmer, vacuum, or compaction rollers to ensure a smooth, uniform layer formation across the powder bed, with a controller to manage the process and maintain consistent packing density.

Qualification Standards and Testing Protocols

The qualification of Binder Jetting processes for automotive components requires adherence to rigorous standards and testing protocols to ensure consistent quality, reliability, and performance. Currently, the industry follows a multi-tiered approach to qualification, with standards from organizations such as ASTM International, ISO, and automotive-specific bodies like the Automotive Industry Action Group (AIAG).

Material qualification represents the first critical step, with standards such as ASTM F3049 providing guidelines for characterizing metal powders used in additive manufacturing. For automotive applications, additional testing for thermal stability, corrosion resistance, and long-term durability under varying environmental conditions is essential. These tests must be conducted according to established protocols such as ASTM G85 for accelerated corrosion testing and ISO 11357 for thermal analysis.

Process qualification follows material validation, focusing on the repeatability and reliability of the Binder Jetting process itself. This includes establishing process parameter windows that consistently produce parts meeting specifications. The automotive industry typically requires Statistical Process Control (SPC) methodologies as outlined in IATF 16949, with Capability Process Index (Cpk) values exceeding 1.33 for critical dimensions and properties.

Part qualification represents the most comprehensive testing phase, involving both non-destructive and destructive testing protocols. Non-destructive techniques include CT scanning (ASTM E1570), ultrasonic testing (ASTM E494), and dimensional metrology (ISO 10360). Destructive testing encompasses mechanical property evaluation according to ASTM E8 for tensile properties, ASTM E399 for fracture toughness, and SAE J1099 for fatigue performance.

For lightweight automotive structures specifically, additional qualification protocols address the unique requirements of these components. These include vibration testing (ISO 16750-3), impact resistance evaluation (ASTM D3763), and thermal cycling (USCAR-2). The testing must verify that the lightweight structures maintain their integrity under the full range of automotive operating conditions, from extreme temperatures (-40°C to 125°C) to high-vibration environments.

Emerging qualification standards are beginning to address the specific characteristics of Binder Jetted parts, including the effects of post-processing treatments like sintering and infiltration on final part properties. The SAE AMS7032 standard, currently under development, will provide specific guidelines for the qualification of metal parts produced via Binder Jetting for safety-critical applications, including automotive components.

Material qualification represents the first critical step, with standards such as ASTM F3049 providing guidelines for characterizing metal powders used in additive manufacturing. For automotive applications, additional testing for thermal stability, corrosion resistance, and long-term durability under varying environmental conditions is essential. These tests must be conducted according to established protocols such as ASTM G85 for accelerated corrosion testing and ISO 11357 for thermal analysis.

Process qualification follows material validation, focusing on the repeatability and reliability of the Binder Jetting process itself. This includes establishing process parameter windows that consistently produce parts meeting specifications. The automotive industry typically requires Statistical Process Control (SPC) methodologies as outlined in IATF 16949, with Capability Process Index (Cpk) values exceeding 1.33 for critical dimensions and properties.

Part qualification represents the most comprehensive testing phase, involving both non-destructive and destructive testing protocols. Non-destructive techniques include CT scanning (ASTM E1570), ultrasonic testing (ASTM E494), and dimensional metrology (ISO 10360). Destructive testing encompasses mechanical property evaluation according to ASTM E8 for tensile properties, ASTM E399 for fracture toughness, and SAE J1099 for fatigue performance.

For lightweight automotive structures specifically, additional qualification protocols address the unique requirements of these components. These include vibration testing (ISO 16750-3), impact resistance evaluation (ASTM D3763), and thermal cycling (USCAR-2). The testing must verify that the lightweight structures maintain their integrity under the full range of automotive operating conditions, from extreme temperatures (-40°C to 125°C) to high-vibration environments.

Emerging qualification standards are beginning to address the specific characteristics of Binder Jetted parts, including the effects of post-processing treatments like sintering and infiltration on final part properties. The SAE AMS7032 standard, currently under development, will provide specific guidelines for the qualification of metal parts produced via Binder Jetting for safety-critical applications, including automotive components.

Sustainability Impact of Binder Jetting in Automotive Manufacturing

The implementation of binder jetting technology in automotive manufacturing represents a significant advancement in sustainable production practices. By utilizing additive manufacturing processes that selectively deposit binding agents onto powder beds, binder jetting offers substantial environmental benefits compared to traditional manufacturing methods.

The primary sustainability advantage lies in material efficiency. Binder jetting creates components with optimized geometries that maintain structural integrity while using significantly less material—typically reducing material consumption by 30-45% compared to conventional casting or machining processes. This reduction directly translates to decreased resource extraction and associated environmental impacts throughout the supply chain.

Energy consumption patterns also demonstrate notable improvements. Studies comparing binder jetting to traditional manufacturing show energy reductions of 25-60% depending on component complexity and production volume. This efficiency stems from eliminating energy-intensive steps like tooling production, machining operations, and reduced heating requirements during processing.

Carbon footprint analysis reveals that lightweight automotive components produced via binder jetting contribute to sustainability in two distinct phases. During manufacturing, the process generates approximately 40% fewer carbon emissions than conventional methods. More significantly, when implemented in vehicles, these lightweight components improve fuel efficiency by reducing overall vehicle weight, with estimates suggesting that a 10% weight reduction can improve fuel economy by 6-8% over a vehicle's operational lifetime.

Waste reduction represents another critical sustainability dimension. Binder jetting achieves near-net-shape production with minimal post-processing requirements. The powder-based process allows for up to 98% of unused material to be recycled directly back into production, creating a closed-loop manufacturing system that dramatically reduces landfill contributions.

Water usage in binder jetting operations is substantially lower than in traditional manufacturing processes that often require coolants and cleaning solutions. Comparative analyses indicate water consumption reductions of 70-85% across the production lifecycle, contributing to conservation of this increasingly scarce resource.

The technology also enables localized production capabilities, reducing transportation-related emissions in global supply chains. By enabling on-demand manufacturing closer to assembly facilities, binder jetting can reduce logistics-related carbon emissions by an estimated 35-50% for complex components that would otherwise require international shipping.

The primary sustainability advantage lies in material efficiency. Binder jetting creates components with optimized geometries that maintain structural integrity while using significantly less material—typically reducing material consumption by 30-45% compared to conventional casting or machining processes. This reduction directly translates to decreased resource extraction and associated environmental impacts throughout the supply chain.

Energy consumption patterns also demonstrate notable improvements. Studies comparing binder jetting to traditional manufacturing show energy reductions of 25-60% depending on component complexity and production volume. This efficiency stems from eliminating energy-intensive steps like tooling production, machining operations, and reduced heating requirements during processing.

Carbon footprint analysis reveals that lightweight automotive components produced via binder jetting contribute to sustainability in two distinct phases. During manufacturing, the process generates approximately 40% fewer carbon emissions than conventional methods. More significantly, when implemented in vehicles, these lightweight components improve fuel efficiency by reducing overall vehicle weight, with estimates suggesting that a 10% weight reduction can improve fuel economy by 6-8% over a vehicle's operational lifetime.

Waste reduction represents another critical sustainability dimension. Binder jetting achieves near-net-shape production with minimal post-processing requirements. The powder-based process allows for up to 98% of unused material to be recycled directly back into production, creating a closed-loop manufacturing system that dramatically reduces landfill contributions.

Water usage in binder jetting operations is substantially lower than in traditional manufacturing processes that often require coolants and cleaning solutions. Comparative analyses indicate water consumption reductions of 70-85% across the production lifecycle, contributing to conservation of this increasingly scarce resource.

The technology also enables localized production capabilities, reducing transportation-related emissions in global supply chains. By enabling on-demand manufacturing closer to assembly facilities, binder jetting can reduce logistics-related carbon emissions by an estimated 35-50% for complex components that would otherwise require international shipping.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!