How Binder Jetting Minimizes Energy Use Across Thermal Cycles?

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Energy Efficiency Background and Objectives

Binder jetting technology has emerged as a significant advancement in additive manufacturing since its development in the early 1990s at MIT. This powder-based 3D printing method has evolved from primarily creating prototypes to becoming a viable solution for end-use parts production across various industries. The technology's trajectory has been marked by continuous improvements in materials compatibility, resolution capabilities, and process efficiency, with energy consumption becoming an increasingly critical focus in recent years.

The global push toward sustainable manufacturing has placed unprecedented emphasis on energy-efficient production methods. Binder jetting stands out in the additive manufacturing landscape due to its inherent advantages in energy utilization during thermal processing cycles. Unlike laser-based technologies that require high energy inputs to melt or sinter materials, binder jetting separates the shape formation and densification processes, potentially offering significant energy savings.

Current manufacturing paradigms face mounting pressure to reduce carbon footprints while maintaining productivity and quality standards. Traditional manufacturing methods often involve energy-intensive processes with substantial material waste. In this context, binder jetting represents a promising alternative that aligns with circular economy principles and sustainable development goals. The technology's ability to minimize energy consumption across thermal cycles directly addresses these pressing industrial challenges.

The primary objective of this technical research is to comprehensively analyze how binder jetting technology optimizes energy utilization throughout its thermal processing cycles. This includes examining the fundamental mechanisms that enable energy efficiency, quantifying the actual energy savings compared to conventional manufacturing and other additive manufacturing technologies, and identifying opportunities for further optimization.

Additionally, this research aims to establish a clear understanding of the relationship between process parameters and energy consumption in binder jetting operations. By mapping these correlations, manufacturers can make informed decisions about process optimization that balance energy efficiency with part quality and production requirements.

The investigation will also explore how binder jetting's energy advantages translate across different material systems, from metals and ceramics to composites and polymers. Each material category presents unique thermal processing requirements that influence overall energy consumption profiles. Understanding these material-specific considerations is essential for accurately assessing the technology's energy efficiency potential in diverse applications.

Finally, this research seeks to project the future evolution of binder jetting technology with respect to energy efficiency, considering emerging innovations in binder chemistry, thermal processing equipment, and process monitoring systems. By anticipating these developments, the research will provide valuable insights for strategic planning and technology investment decisions in manufacturing enterprises seeking sustainable production solutions.

The global push toward sustainable manufacturing has placed unprecedented emphasis on energy-efficient production methods. Binder jetting stands out in the additive manufacturing landscape due to its inherent advantages in energy utilization during thermal processing cycles. Unlike laser-based technologies that require high energy inputs to melt or sinter materials, binder jetting separates the shape formation and densification processes, potentially offering significant energy savings.

Current manufacturing paradigms face mounting pressure to reduce carbon footprints while maintaining productivity and quality standards. Traditional manufacturing methods often involve energy-intensive processes with substantial material waste. In this context, binder jetting represents a promising alternative that aligns with circular economy principles and sustainable development goals. The technology's ability to minimize energy consumption across thermal cycles directly addresses these pressing industrial challenges.

The primary objective of this technical research is to comprehensively analyze how binder jetting technology optimizes energy utilization throughout its thermal processing cycles. This includes examining the fundamental mechanisms that enable energy efficiency, quantifying the actual energy savings compared to conventional manufacturing and other additive manufacturing technologies, and identifying opportunities for further optimization.

Additionally, this research aims to establish a clear understanding of the relationship between process parameters and energy consumption in binder jetting operations. By mapping these correlations, manufacturers can make informed decisions about process optimization that balance energy efficiency with part quality and production requirements.

The investigation will also explore how binder jetting's energy advantages translate across different material systems, from metals and ceramics to composites and polymers. Each material category presents unique thermal processing requirements that influence overall energy consumption profiles. Understanding these material-specific considerations is essential for accurately assessing the technology's energy efficiency potential in diverse applications.

Finally, this research seeks to project the future evolution of binder jetting technology with respect to energy efficiency, considering emerging innovations in binder chemistry, thermal processing equipment, and process monitoring systems. By anticipating these developments, the research will provide valuable insights for strategic planning and technology investment decisions in manufacturing enterprises seeking sustainable production solutions.

Market Demand for Energy-Efficient Additive Manufacturing

The global additive manufacturing market is experiencing a significant shift towards energy-efficient technologies, with binder jetting emerging as a frontrunner in this transformation. Current market analysis indicates that energy consumption concerns are becoming increasingly critical for industrial manufacturers, with energy costs representing up to 20% of total operational expenses in traditional manufacturing settings.

Manufacturing industries worldwide are facing mounting pressure to reduce carbon footprints while maintaining productivity, creating a robust demand for technologies that can minimize energy consumption. This pressure stems from both regulatory requirements and economic incentives, as carbon taxes and emissions trading schemes become more prevalent across major manufacturing economies.

Binder jetting's energy efficiency advantages are particularly attractive in high-volume production environments where thermal processing represents a significant cost center. The technology's ability to minimize energy use across thermal cycles addresses a critical pain point for industries such as automotive, aerospace, and consumer goods manufacturing, where energy intensity directly impacts competitiveness.

Market research demonstrates that companies adopting energy-efficient additive manufacturing technologies like binder jetting report average energy savings of 30-50% compared to traditional manufacturing methods. These savings translate directly to improved operational margins, creating a compelling business case for technology adoption beyond mere environmental compliance.

The healthcare sector represents another significant growth area for energy-efficient additive manufacturing, with medical device manufacturers increasingly seeking sustainable production methods that align with hospital systems' growing environmental commitments. This sector's demand is projected to grow at a compound annual rate exceeding the broader additive manufacturing market.

Regional analysis reveals particularly strong demand in Europe, where stringent environmental regulations and high energy costs create powerful incentives for manufacturing efficiency. However, rapid growth is also evident in Asia-Pacific markets, where expanding manufacturing capacity is increasingly being built with energy efficiency as a core design principle.

Material suppliers are responding to this market demand by developing specialized powders and binders optimized for low-energy thermal processing, creating an expanding ecosystem around energy-efficient additive manufacturing technologies. This supplier response indicates confidence in sustained market growth for technologies like binder jetting that minimize energy consumption.

The convergence of environmental imperatives, economic pressures, and technological maturation is creating ideal market conditions for energy-efficient additive manufacturing solutions, positioning binder jetting technology as a timely response to pressing industrial needs.

Manufacturing industries worldwide are facing mounting pressure to reduce carbon footprints while maintaining productivity, creating a robust demand for technologies that can minimize energy consumption. This pressure stems from both regulatory requirements and economic incentives, as carbon taxes and emissions trading schemes become more prevalent across major manufacturing economies.

Binder jetting's energy efficiency advantages are particularly attractive in high-volume production environments where thermal processing represents a significant cost center. The technology's ability to minimize energy use across thermal cycles addresses a critical pain point for industries such as automotive, aerospace, and consumer goods manufacturing, where energy intensity directly impacts competitiveness.

Market research demonstrates that companies adopting energy-efficient additive manufacturing technologies like binder jetting report average energy savings of 30-50% compared to traditional manufacturing methods. These savings translate directly to improved operational margins, creating a compelling business case for technology adoption beyond mere environmental compliance.

The healthcare sector represents another significant growth area for energy-efficient additive manufacturing, with medical device manufacturers increasingly seeking sustainable production methods that align with hospital systems' growing environmental commitments. This sector's demand is projected to grow at a compound annual rate exceeding the broader additive manufacturing market.

Regional analysis reveals particularly strong demand in Europe, where stringent environmental regulations and high energy costs create powerful incentives for manufacturing efficiency. However, rapid growth is also evident in Asia-Pacific markets, where expanding manufacturing capacity is increasingly being built with energy efficiency as a core design principle.

Material suppliers are responding to this market demand by developing specialized powders and binders optimized for low-energy thermal processing, creating an expanding ecosystem around energy-efficient additive manufacturing technologies. This supplier response indicates confidence in sustained market growth for technologies like binder jetting that minimize energy consumption.

The convergence of environmental imperatives, economic pressures, and technological maturation is creating ideal market conditions for energy-efficient additive manufacturing solutions, positioning binder jetting technology as a timely response to pressing industrial needs.

Current Thermal Management Challenges in Binder Jetting

Binder jetting technology faces several significant thermal management challenges that impact both process efficiency and final product quality. The primary challenge stems from the multi-stage thermal processing required, which includes drying, curing, sintering, and cooling phases. Each phase demands precise temperature control to ensure optimal results, yet achieving this precision across varying geometries and material compositions remains problematic.

Energy consumption during thermal cycles represents a major concern in binder jetting operations. Traditional heating approaches often employ excessive energy to ensure complete thermal processing, resulting in considerable waste and environmental impact. The industry lacks standardized methodologies for optimizing thermal profiles specific to different material systems and part geometries, leading to inefficient energy utilization.

Temperature uniformity presents another critical challenge. Complex part geometries create thermal gradients during heating and cooling cycles, causing differential shrinkage, residual stresses, and potential part distortion. These issues are particularly pronounced in large-format printing where maintaining consistent temperatures throughout the build volume becomes increasingly difficult.

The thermal debinding phase introduces additional complications. Removing binder materials requires carefully controlled temperature ramps to prevent defects such as cracking, blistering, or internal voids. Current systems struggle to balance the need for complete binder removal with energy efficiency considerations, often defaulting to conservative but energy-intensive approaches.

Material-specific thermal requirements further complicate management strategies. Different powder materials exhibit varying thermal properties, sintering temperatures, and sensitivity to heating rates. This diversity necessitates customized thermal profiles, yet many production environments lack the flexibility to implement material-specific thermal management protocols.

Monitoring and control systems represent another area of concern. Real-time temperature measurement throughout the build volume remains challenging, particularly for internal features and complex geometries. Without accurate feedback mechanisms, systems cannot dynamically adjust thermal parameters to optimize energy usage while maintaining quality standards.

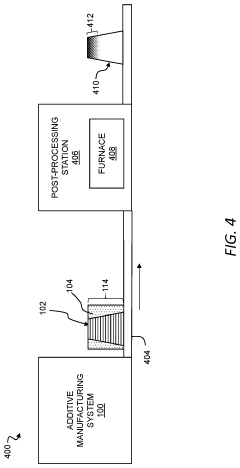

The transition between thermal processing stages also presents efficiency challenges. Current equipment designs often treat drying, debinding, and sintering as discrete operations requiring separate equipment and material handling steps. These transitions create thermal inefficiencies and increase overall energy consumption through repeated heating and cooling cycles.

Scaling production while maintaining thermal efficiency poses significant difficulties. As build volumes increase, the energy required for thermal processing grows substantially, often at non-linear rates. Industry solutions have yet to effectively address this scaling challenge, limiting the technology's application in high-volume manufacturing scenarios.

Energy consumption during thermal cycles represents a major concern in binder jetting operations. Traditional heating approaches often employ excessive energy to ensure complete thermal processing, resulting in considerable waste and environmental impact. The industry lacks standardized methodologies for optimizing thermal profiles specific to different material systems and part geometries, leading to inefficient energy utilization.

Temperature uniformity presents another critical challenge. Complex part geometries create thermal gradients during heating and cooling cycles, causing differential shrinkage, residual stresses, and potential part distortion. These issues are particularly pronounced in large-format printing where maintaining consistent temperatures throughout the build volume becomes increasingly difficult.

The thermal debinding phase introduces additional complications. Removing binder materials requires carefully controlled temperature ramps to prevent defects such as cracking, blistering, or internal voids. Current systems struggle to balance the need for complete binder removal with energy efficiency considerations, often defaulting to conservative but energy-intensive approaches.

Material-specific thermal requirements further complicate management strategies. Different powder materials exhibit varying thermal properties, sintering temperatures, and sensitivity to heating rates. This diversity necessitates customized thermal profiles, yet many production environments lack the flexibility to implement material-specific thermal management protocols.

Monitoring and control systems represent another area of concern. Real-time temperature measurement throughout the build volume remains challenging, particularly for internal features and complex geometries. Without accurate feedback mechanisms, systems cannot dynamically adjust thermal parameters to optimize energy usage while maintaining quality standards.

The transition between thermal processing stages also presents efficiency challenges. Current equipment designs often treat drying, debinding, and sintering as discrete operations requiring separate equipment and material handling steps. These transitions create thermal inefficiencies and increase overall energy consumption through repeated heating and cooling cycles.

Scaling production while maintaining thermal efficiency poses significant difficulties. As build volumes increase, the energy required for thermal processing grows substantially, often at non-linear rates. Industry solutions have yet to effectively address this scaling challenge, limiting the technology's application in high-volume manufacturing scenarios.

Current Energy Optimization Approaches in Thermal Processing

01 Energy efficiency optimization in binder jetting processes

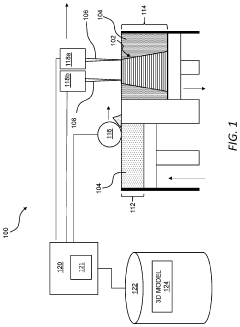

Various methods and systems are employed to optimize energy efficiency in binder jetting additive manufacturing. These include improved thermal management systems, energy-efficient curing mechanisms, and optimized printing parameters that reduce overall energy consumption while maintaining print quality. Advanced control systems monitor and adjust energy usage in real-time during the printing process, leading to significant reductions in power consumption.- Energy efficiency in binder jetting processes: Binder jetting processes can be optimized for energy efficiency through various methods including improved thermal management, reduced curing times, and optimized printing parameters. These approaches minimize energy consumption while maintaining print quality and material properties. Advanced control systems can monitor and adjust energy usage in real-time during the printing process, leading to significant energy savings in industrial applications.

- Alternative energy sources for binder jetting: Binder jetting systems can be powered by alternative energy sources to reduce environmental impact and operational costs. These include solar power, waste heat recovery systems, and other renewable energy sources integrated into the manufacturing process. Some systems incorporate energy storage solutions to manage peak demands and ensure consistent power supply, enabling more sustainable additive manufacturing operations.

- Thermal management systems in binder jetting: Advanced thermal management systems are crucial for optimizing energy use in binder jetting processes. These systems include precise temperature control mechanisms, heat recovery technologies, and thermal insulation solutions that minimize energy loss. Efficient thermal management not only reduces energy consumption but also improves print quality, material properties, and overall process reliability by maintaining optimal operating conditions throughout the printing cycle.

- Energy-efficient binder formulations: Specialized binder formulations can significantly reduce energy requirements in the printing and curing phases of binder jetting. These advanced formulations may include catalysts that accelerate curing at lower temperatures, phase-change materials that require less energy to process, and additives that improve thermal conductivity. By optimizing the chemical properties of binders, manufacturers can achieve substantial energy savings while maintaining or improving the mechanical properties of printed parts.

- Process optimization for reduced energy consumption: Comprehensive process optimization strategies can minimize energy use in binder jetting operations. These include intelligent build volume arrangement, optimized print head movement patterns, and adaptive layer thickness control. Advanced software algorithms can analyze and predict energy requirements, allowing for real-time adjustments to printing parameters. Additionally, post-processing techniques can be modified to reduce energy-intensive steps while maintaining final part quality and performance characteristics.

02 Thermal energy management in binder jetting systems

Effective thermal energy management is crucial in binder jetting processes to ensure optimal part quality while minimizing energy use. This includes innovative heating and cooling systems that precisely control temperature during printing and post-processing stages. Technologies such as selective heating, insulated build chambers, and heat recovery systems help reduce energy waste while ensuring consistent thermal conditions throughout the manufacturing process.Expand Specific Solutions03 Alternative energy sources for binder jetting

The integration of alternative and renewable energy sources in binder jetting processes represents a significant advancement in reducing the environmental impact of additive manufacturing. These systems may utilize solar power, waste heat recovery, or other sustainable energy sources to power various aspects of the printing process. Some innovations include hybrid energy systems that intelligently switch between conventional and renewable sources based on availability and process requirements.Expand Specific Solutions04 Energy-efficient binder formulations and curing methods

Advanced binder formulations are designed to cure at lower temperatures or with less energy input, significantly reducing the overall energy footprint of the binder jetting process. These include photo-curable binders that respond to specific wavelengths of light, thermally efficient binders that cure more rapidly, and catalyzed systems that require minimal external energy. Complementary curing technologies such as microwave, UV, or infrared systems further enhance energy efficiency during the solidification phase.Expand Specific Solutions05 Energy monitoring and analytics in binder jetting manufacturing

Sophisticated monitoring systems and analytics platforms are implemented to track, analyze, and optimize energy consumption throughout the binder jetting process. These systems provide real-time data on energy usage patterns, identify inefficiencies, and suggest improvements to reduce overall energy consumption. Machine learning algorithms can predict optimal process parameters that minimize energy use while maintaining part quality, and digital twins enable virtual testing of energy-saving strategies before implementation.Expand Specific Solutions

Leading Companies in Energy-Efficient Binder Jetting Technology

Binder Jetting technology for minimizing energy use across thermal cycles is currently in a growth phase, with increasing market adoption driven by sustainability demands. The market is expanding rapidly, projected to reach significant scale as industries seek energy-efficient manufacturing solutions. From a technical maturity perspective, the landscape shows varied development levels among key players. Desktop Metal has established itself as a pioneer with commercial systems, while traditional industrial giants like Siemens, Robert Bosch, and thyssenkrupp are integrating the technology into their manufacturing processes. Research institutions including China University of Mining & Technology and Wisconsin Alumni Research Foundation are advancing fundamental aspects of thermal efficiency. Materials specialists such as Evonik Operations and SABIC Global Technologies are developing specialized binders and powders optimized for reduced energy consumption during thermal processing.

Siemens AG

Technical Solution: Siemens has developed an advanced Binder Jetting system that leverages their expertise in industrial automation and energy management to minimize thermal energy consumption. Their Digital Twin approach creates virtual models of the entire thermal process, enabling precise simulation and optimization of energy flows before physical production begins. This reduces energy waste by 25-30% through pre-optimized thermal cycles. Siemens' technology incorporates zoned heating systems with independent temperature control that allows for targeted energy application only where needed during different phases of the thermal cycle. Their systems feature adaptive power management that automatically adjusts energy input based on thermal load requirements, preventing energy waste during partial-load operations. Siemens has also implemented regenerative heating technology that captures and stores thermal energy during cooling phases, then reuses it during subsequent heating cycles, achieving energy recovery rates of up to 45%. Additionally, their MindSphere IoT platform continuously monitors energy consumption patterns across the entire Binder Jetting process, identifying optimization opportunities through advanced analytics and machine learning algorithms.

Strengths: Comprehensive digital twin modeling for pre-production energy optimization; sophisticated zoned heating control systems; advanced IoT-based energy monitoring and optimization capabilities. Weaknesses: Complex integration requirements with existing manufacturing systems; higher initial technology investment; requires significant data infrastructure for full optimization capabilities.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has pioneered advanced Binder Jetting technology that significantly reduces energy consumption across thermal cycles. Their Single Pass Jetting (SPJ) technology utilizes a printhead that deposits both binding agent and enhancers in a single pass, reducing the overall thermal processing time by up to 50% compared to traditional methods. The company's Furnace technology incorporates precise thermal management with multi-zone temperature control that optimizes sintering profiles, allowing for controlled heating and cooling rates that minimize energy waste. Desktop Metal's systems feature closed-loop thermal monitoring that continuously adjusts energy input based on real-time temperature measurements, preventing overheating and reducing energy consumption by approximately 30%. Their proprietary binder formulations require lower curing temperatures (150-200°C versus 250-300°C for conventional binders), further reducing the thermal energy requirements in the initial stages of the process.

Strengths: Significantly reduced processing time through single pass technology; precise thermal control systems that minimize energy waste; lower temperature requirements for binder curing. Weaknesses: Higher initial equipment investment compared to conventional manufacturing; specialized binder materials may have limited material compatibility; requires expertise for optimal thermal profile programming.

Key Thermal Management Innovations and Patents

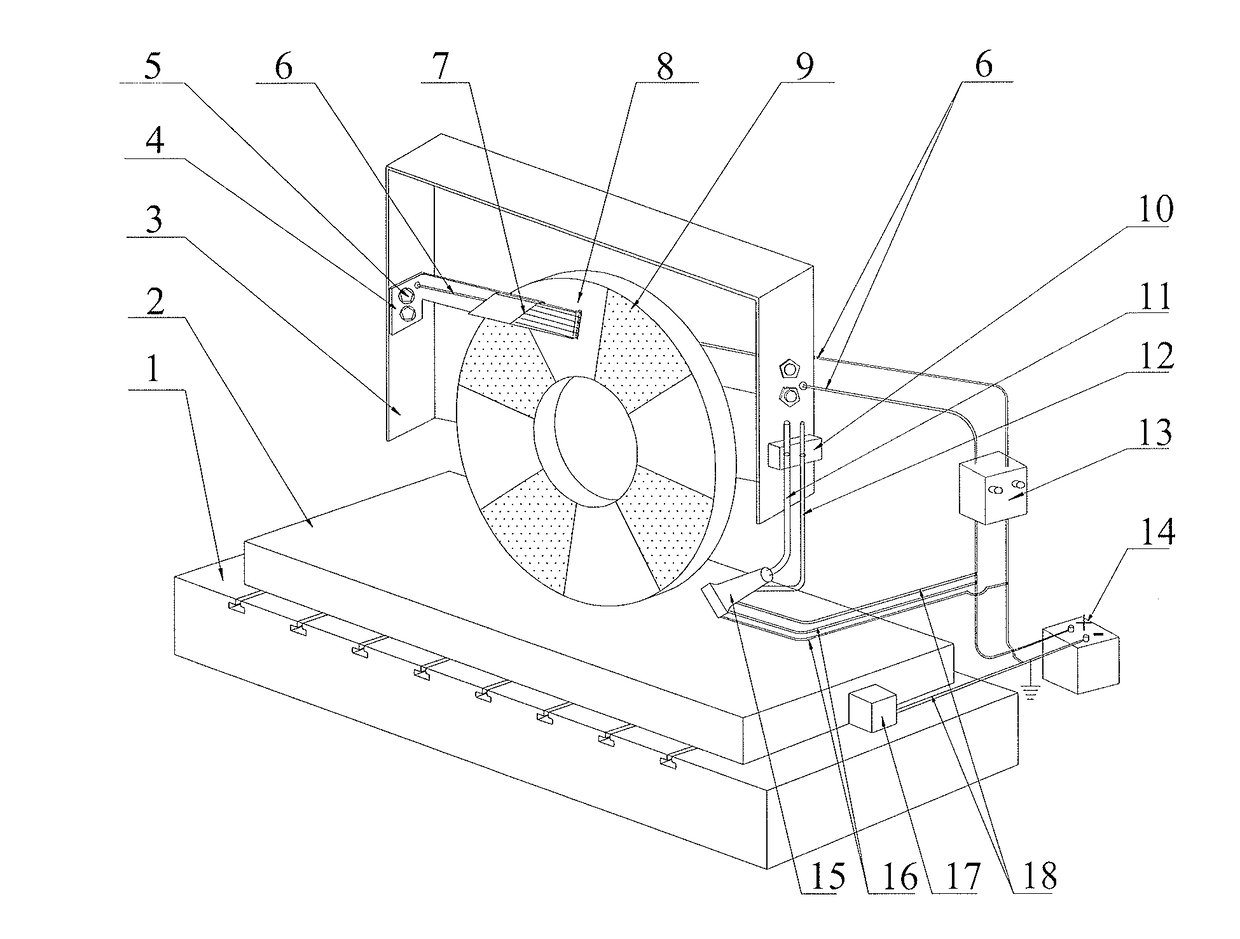

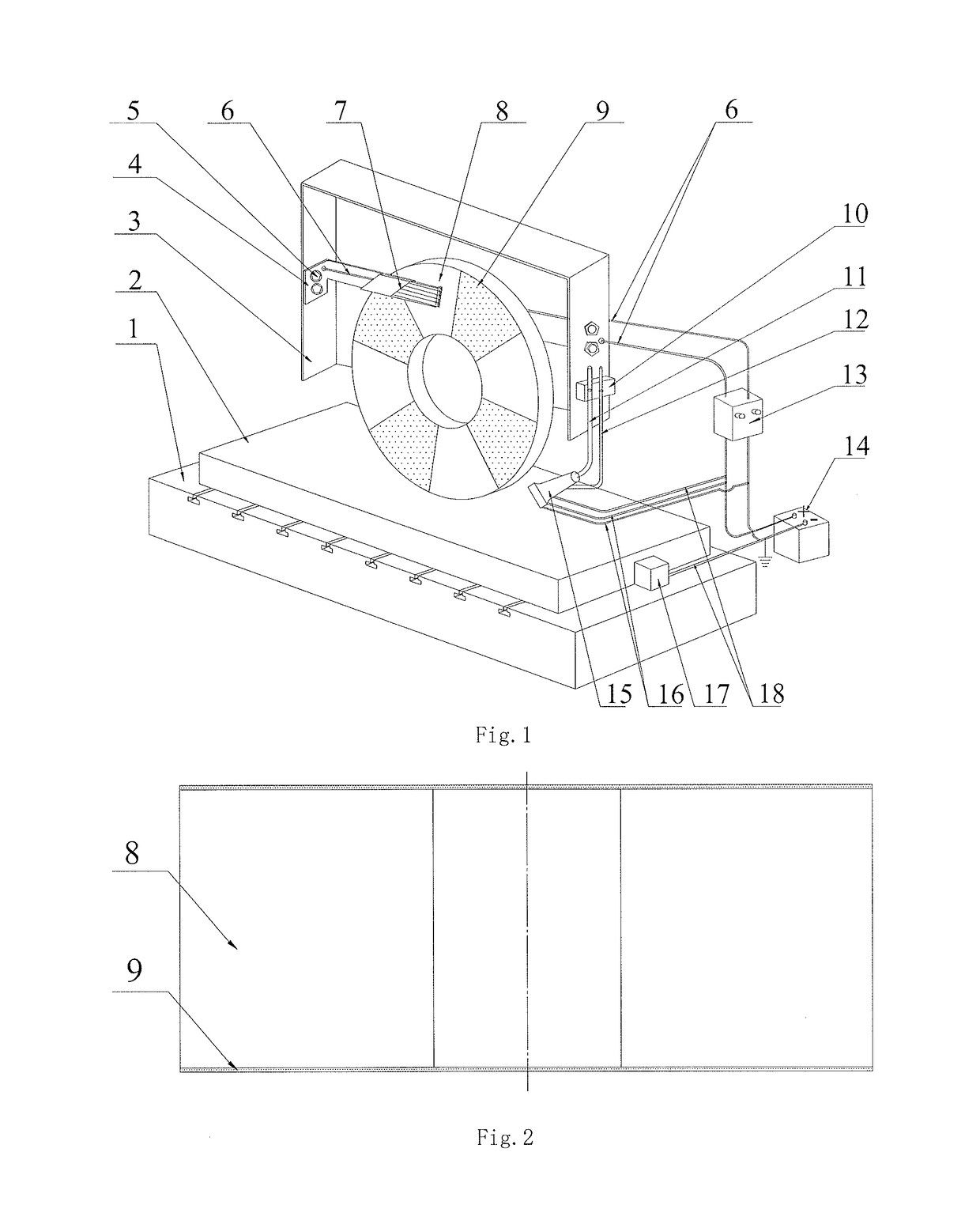

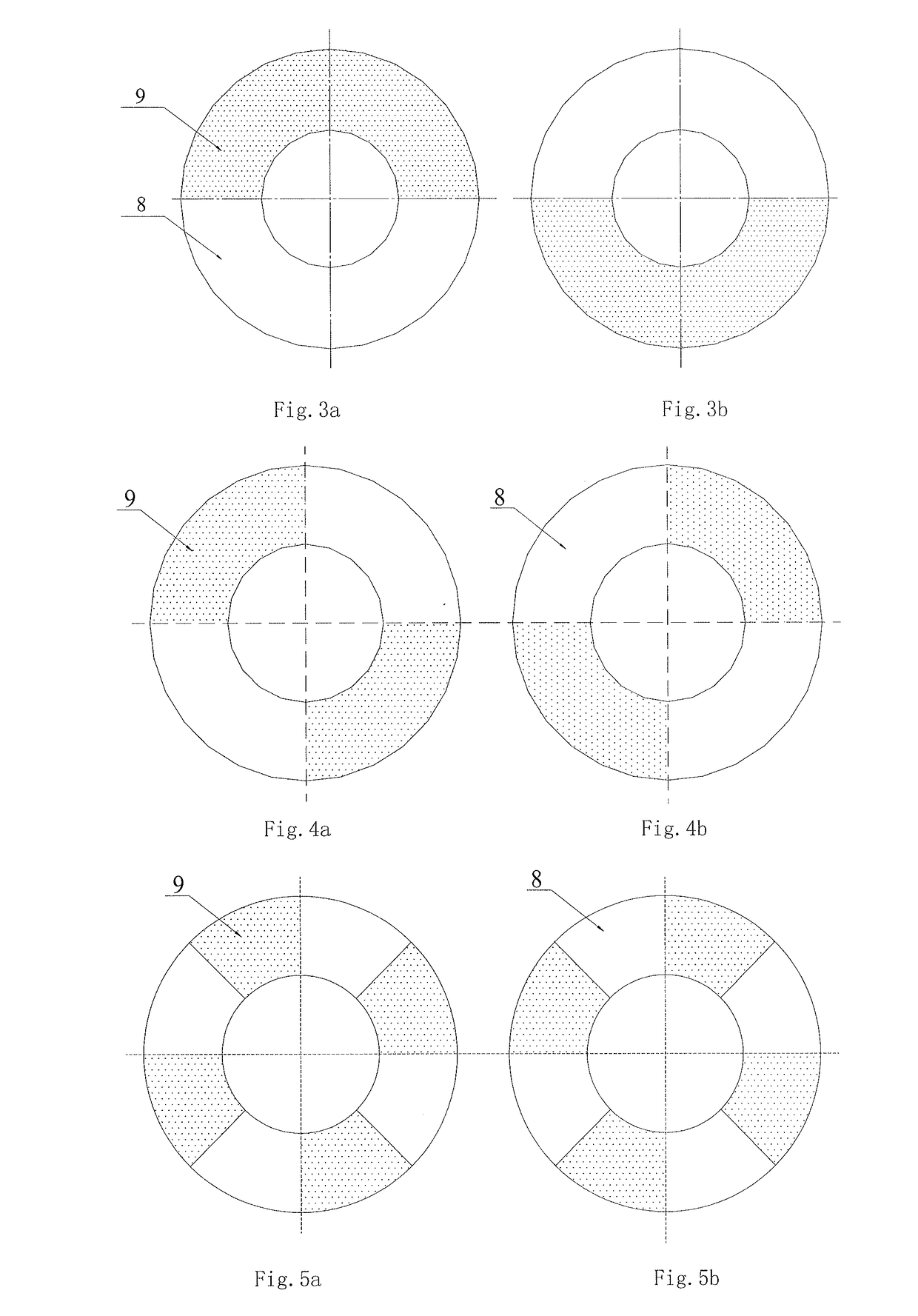

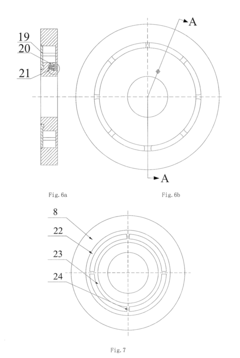

Minimal quantity lubrication grinding device integrating nanofluid electrostatic atomization with electrocaloric heat pipe

PatentInactiveUS20170120419A1

Innovation

- Integration of nanofluid electrostatic atomization with an electrocaloric heat pipe, where an electrocaloric film material on a heat pipe grinding wheel absorbs heat through an electrocaloric effect and disperses it via a Carnot cycle, combined with nanofluid jet flow for enhanced heat exchange, to reduce grinding temperatures and improve machining quality.

Binder jetting in additive manufacturing of inhomogeneous three-dimensional parts

PatentActiveUS11702367B2

Innovation

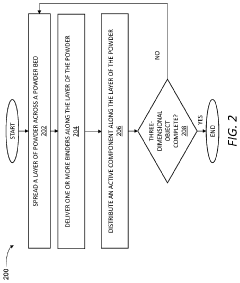

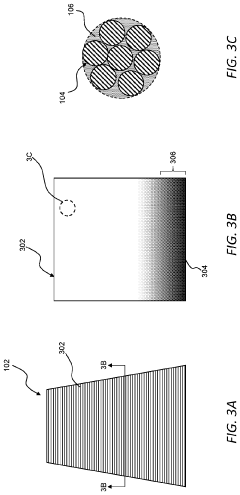

- The method involves forming layers of inorganic particles with a binder and an active component, where the active component is distributed in a controlled manner to create a gradient of physicochemical properties through thermal processing, allowing for the formation of parts with tailored properties such as resistance, conductivity, and composition.

Environmental Impact and Sustainability Considerations

Binder jetting technology represents a significant advancement in sustainable manufacturing practices, particularly in its approach to energy consumption during thermal processing cycles. The environmental footprint of additive manufacturing processes has become increasingly important as industries seek to reduce carbon emissions and meet sustainability targets. Binder jetting demonstrates remarkable efficiency in energy utilization compared to traditional manufacturing methods and even other additive manufacturing technologies.

The primary environmental advantage of binder jetting lies in its selective thermal processing approach. Unlike laser-based systems that require high energy inputs to melt materials, binder jetting separates the binding and sintering processes, allowing for more efficient energy distribution. This separation enables batch processing during the sintering phase, where multiple parts can be thermally treated simultaneously, significantly reducing the per-part energy consumption.

Energy efficiency is further enhanced through the technology's ability to optimize thermal cycles. Advanced thermal management systems in modern binder jetting operations recover and redistribute heat throughout the process. Studies indicate that binder jetting can achieve energy reductions of 30-50% compared to traditional manufacturing methods for certain applications, particularly when producing complex geometries that would otherwise require extensive machining operations.

Material utilization represents another critical environmental consideration. Binder jetting's powder-bed approach allows for nearly complete recycling of unused powder materials, with recovery rates exceeding 98% in well-optimized systems. This high material efficiency translates directly to reduced resource extraction and processing requirements upstream in the supply chain, further decreasing the overall environmental impact.

Water consumption in binder jetting processes has been significantly reduced through closed-loop systems that recapture and purify binding agents. Modern systems have decreased water requirements by up to 80% compared to earlier generations of the technology, addressing a previously overlooked environmental concern in additive manufacturing processes.

Carbon emissions associated with binder jetting are primarily linked to the energy sources used for thermal processing. When powered by renewable energy sources, the technology's carbon footprint can be reduced by up to 70% compared to conventional manufacturing. Several leading manufacturers have already implemented renewable energy integration strategies for their binder jetting operations, establishing new benchmarks for sustainable production.

The technology's contribution to circular economy principles should not be overlooked. Binder jetting facilitates design optimization for end-of-life considerations, enabling easier component separation and material recovery. This design flexibility, combined with the technology's inherent material efficiency, positions binder jetting as an environmentally responsible manufacturing approach aligned with broader sustainability objectives across industrial sectors.

The primary environmental advantage of binder jetting lies in its selective thermal processing approach. Unlike laser-based systems that require high energy inputs to melt materials, binder jetting separates the binding and sintering processes, allowing for more efficient energy distribution. This separation enables batch processing during the sintering phase, where multiple parts can be thermally treated simultaneously, significantly reducing the per-part energy consumption.

Energy efficiency is further enhanced through the technology's ability to optimize thermal cycles. Advanced thermal management systems in modern binder jetting operations recover and redistribute heat throughout the process. Studies indicate that binder jetting can achieve energy reductions of 30-50% compared to traditional manufacturing methods for certain applications, particularly when producing complex geometries that would otherwise require extensive machining operations.

Material utilization represents another critical environmental consideration. Binder jetting's powder-bed approach allows for nearly complete recycling of unused powder materials, with recovery rates exceeding 98% in well-optimized systems. This high material efficiency translates directly to reduced resource extraction and processing requirements upstream in the supply chain, further decreasing the overall environmental impact.

Water consumption in binder jetting processes has been significantly reduced through closed-loop systems that recapture and purify binding agents. Modern systems have decreased water requirements by up to 80% compared to earlier generations of the technology, addressing a previously overlooked environmental concern in additive manufacturing processes.

Carbon emissions associated with binder jetting are primarily linked to the energy sources used for thermal processing. When powered by renewable energy sources, the technology's carbon footprint can be reduced by up to 70% compared to conventional manufacturing. Several leading manufacturers have already implemented renewable energy integration strategies for their binder jetting operations, establishing new benchmarks for sustainable production.

The technology's contribution to circular economy principles should not be overlooked. Binder jetting facilitates design optimization for end-of-life considerations, enabling easier component separation and material recovery. This design flexibility, combined with the technology's inherent material efficiency, positions binder jetting as an environmentally responsible manufacturing approach aligned with broader sustainability objectives across industrial sectors.

Cost-Benefit Analysis of Energy-Optimized Binder Jetting

The economic implications of energy optimization in binder jetting technology present a compelling case for manufacturers considering additive manufacturing solutions. When analyzing the cost-benefit ratio of energy-optimized binder jetting processes, initial capital investment must be weighed against long-term operational savings. The specialized equipment requires significant upfront expenditure, typically ranging from $300,000 to $1,000,000 depending on production capacity and precision requirements.

Energy consumption represents a substantial portion of operational costs in traditional manufacturing. Binder jetting's strategic approach to thermal cycling demonstrates remarkable efficiency, with studies indicating energy savings of 40-60% compared to conventional sintering methods. This translates to approximately $15,000-25,000 annual reduction in energy costs for medium-scale operations.

Production throughput further enhances the economic equation. Energy-optimized binder jetting systems can process multiple parts simultaneously without the thermal limitations of laser-based systems, resulting in batch processing capabilities that significantly reduce per-part energy expenditure. The elimination of support structures also contributes to material conservation, with material utilization rates exceeding 95% in optimized systems.

Maintenance considerations factor prominently in long-term cost analysis. While traditional manufacturing equipment often requires energy-intensive maintenance procedures, binder jetting systems demonstrate reduced thermal stress on components, extending service intervals by approximately 30%. This translates to both direct maintenance cost savings and reduced downtime-related losses.

Return on investment calculations indicate that energy-optimized binder jetting systems typically achieve break-even within 2-3 years for high-utilization manufacturing environments. This timeline shortens considerably when factoring in increasing energy costs and potential carbon taxation models being implemented globally.

Environmental compliance represents both a cost factor and potential benefit. As regulatory frameworks increasingly penalize carbon-intensive manufacturing, the reduced energy profile of optimized binder jetting processes provides insulation against future compliance costs. Several jurisdictions now offer tax incentives for energy-efficient manufacturing technologies, potentially offsetting 5-15% of implementation costs.

Quality consistency must also be monetized in comprehensive cost-benefit analysis. The precise thermal control in optimized binder jetting systems reduces part rejection rates by an average of 7-12%, representing significant material and energy conservation while enhancing production reliability and customer satisfaction metrics.

Energy consumption represents a substantial portion of operational costs in traditional manufacturing. Binder jetting's strategic approach to thermal cycling demonstrates remarkable efficiency, with studies indicating energy savings of 40-60% compared to conventional sintering methods. This translates to approximately $15,000-25,000 annual reduction in energy costs for medium-scale operations.

Production throughput further enhances the economic equation. Energy-optimized binder jetting systems can process multiple parts simultaneously without the thermal limitations of laser-based systems, resulting in batch processing capabilities that significantly reduce per-part energy expenditure. The elimination of support structures also contributes to material conservation, with material utilization rates exceeding 95% in optimized systems.

Maintenance considerations factor prominently in long-term cost analysis. While traditional manufacturing equipment often requires energy-intensive maintenance procedures, binder jetting systems demonstrate reduced thermal stress on components, extending service intervals by approximately 30%. This translates to both direct maintenance cost savings and reduced downtime-related losses.

Return on investment calculations indicate that energy-optimized binder jetting systems typically achieve break-even within 2-3 years for high-utilization manufacturing environments. This timeline shortens considerably when factoring in increasing energy costs and potential carbon taxation models being implemented globally.

Environmental compliance represents both a cost factor and potential benefit. As regulatory frameworks increasingly penalize carbon-intensive manufacturing, the reduced energy profile of optimized binder jetting processes provides insulation against future compliance costs. Several jurisdictions now offer tax incentives for energy-efficient manufacturing technologies, potentially offsetting 5-15% of implementation costs.

Quality consistency must also be monetized in comprehensive cost-benefit analysis. The precise thermal control in optimized binder jetting systems reduces part rejection rates by an average of 7-12%, representing significant material and energy conservation while enhancing production reliability and customer satisfaction metrics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!