Binder Jetting Non-Destructive Evaluation: CT, Ultrasonic And Acoustic Methods

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting NDE Technology Background and Objectives

Binder Jetting technology has emerged as a significant additive manufacturing process over the past two decades, offering unique capabilities for producing complex geometries with a variety of materials. The technology originated in the early 1990s at MIT and has since evolved from primarily creating prototypes to manufacturing functional end-use parts. This evolution has been marked by continuous improvements in resolution, material compatibility, and process reliability.

The fundamental principle of Binder Jetting involves selectively depositing a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures layer by layer. As the technology has matured, its applications have expanded across industries including aerospace, automotive, healthcare, and consumer products, driving the need for more sophisticated quality assurance methods.

Non-Destructive Evaluation (NDE) techniques have become increasingly critical in the Binder Jetting ecosystem as the technology transitions from prototyping to production of functional components. Traditional manufacturing quality control methods often prove inadequate for additively manufactured parts due to their complex internal geometries and unique material properties resulting from the layer-by-layer building process.

The primary NDE methods currently employed for Binder Jetting evaluation include Computed Tomography (CT), ultrasonic testing, and acoustic methods. CT scanning has emerged as particularly valuable due to its ability to visualize internal structures without destroying the part. Ultrasonic techniques offer advantages in detecting subsurface defects, while acoustic methods provide insights into material consistency and structural integrity.

Recent technological advancements have focused on improving the resolution, speed, and accessibility of these NDE techniques. The integration of machine learning algorithms has enhanced defect detection capabilities, while in-situ monitoring systems are being developed to identify issues during the printing process rather than post-production.

The primary objective of current research in Binder Jetting NDE is to develop comprehensive, reliable, and cost-effective evaluation protocols that can be integrated into production workflows. This includes establishing standardized testing procedures, defining acceptance criteria for different applications, and creating correlations between NDE results and mechanical performance.

Another critical goal is to transition from purely defect detection to predictive quality assurance, where NDE data can be used to forecast part performance and longevity. This shift requires deeper understanding of how detected anomalies impact functional properties and how process parameters influence defect formation. The ultimate aim is to enable real-time quality control decisions during the manufacturing process, reducing waste and improving overall production efficiency.

The fundamental principle of Binder Jetting involves selectively depositing a liquid binding agent onto thin layers of powder materials, creating complex three-dimensional structures layer by layer. As the technology has matured, its applications have expanded across industries including aerospace, automotive, healthcare, and consumer products, driving the need for more sophisticated quality assurance methods.

Non-Destructive Evaluation (NDE) techniques have become increasingly critical in the Binder Jetting ecosystem as the technology transitions from prototyping to production of functional components. Traditional manufacturing quality control methods often prove inadequate for additively manufactured parts due to their complex internal geometries and unique material properties resulting from the layer-by-layer building process.

The primary NDE methods currently employed for Binder Jetting evaluation include Computed Tomography (CT), ultrasonic testing, and acoustic methods. CT scanning has emerged as particularly valuable due to its ability to visualize internal structures without destroying the part. Ultrasonic techniques offer advantages in detecting subsurface defects, while acoustic methods provide insights into material consistency and structural integrity.

Recent technological advancements have focused on improving the resolution, speed, and accessibility of these NDE techniques. The integration of machine learning algorithms has enhanced defect detection capabilities, while in-situ monitoring systems are being developed to identify issues during the printing process rather than post-production.

The primary objective of current research in Binder Jetting NDE is to develop comprehensive, reliable, and cost-effective evaluation protocols that can be integrated into production workflows. This includes establishing standardized testing procedures, defining acceptance criteria for different applications, and creating correlations between NDE results and mechanical performance.

Another critical goal is to transition from purely defect detection to predictive quality assurance, where NDE data can be used to forecast part performance and longevity. This shift requires deeper understanding of how detected anomalies impact functional properties and how process parameters influence defect formation. The ultimate aim is to enable real-time quality control decisions during the manufacturing process, reducing waste and improving overall production efficiency.

Market Demand Analysis for Binder Jetting Quality Control

The market for quality control solutions in binder jetting additive manufacturing has experienced significant growth as the technology transitions from prototyping to production of functional parts. Current market analysis indicates that the global non-destructive testing market for additive manufacturing is valued at approximately $340 million, with a projected compound annual growth rate of 14.3% through 2028. Within this segment, solutions specifically tailored for binder jetting quality control represent a rapidly expanding niche.

Manufacturing industries, particularly aerospace, automotive, medical, and energy sectors, are driving demand for advanced quality control methods for binder jetting processes. These industries require 100% inspection capabilities for critical components to ensure structural integrity and performance reliability. The aerospace industry alone has increased investment in non-destructive evaluation technologies by 22% over the past three years, with particular emphasis on methods compatible with complex geometries produced through binder jetting.

Healthcare and medical device manufacturers represent another significant market segment, with regulatory requirements mandating comprehensive quality assurance protocols. The FDA and other regulatory bodies have established increasingly stringent guidelines for additive manufactured medical devices, creating substantial demand for non-destructive evaluation methods that can verify internal structures without compromising part integrity.

Market research indicates that end-users are willing to invest substantially in quality control solutions that can reduce scrap rates and prevent costly failures. A recent industry survey revealed that manufacturers using binder jetting technology report average scrap rates of 15-20% due to undetected internal defects, representing millions in lost production value annually.

The integration of artificial intelligence and machine learning with non-destructive evaluation methods represents a high-growth market opportunity. Solutions that combine CT scanning, ultrasonic testing, or acoustic methods with automated defect recognition systems command premium pricing and are experiencing adoption rates 2.5 times higher than conventional inspection systems.

Regional analysis shows North America and Europe currently dominating the market for advanced binder jetting quality control solutions, accounting for approximately 65% of global market share. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization and increasing adoption of additive manufacturing technologies in countries like China, Japan, and South Korea.

Customer feedback indicates growing demand for in-line and real-time monitoring capabilities rather than post-production inspection. This shift is creating new market opportunities for integrated sensor systems that can detect defects during the binder jetting process, potentially preventing defective parts from completing production cycles.

Manufacturing industries, particularly aerospace, automotive, medical, and energy sectors, are driving demand for advanced quality control methods for binder jetting processes. These industries require 100% inspection capabilities for critical components to ensure structural integrity and performance reliability. The aerospace industry alone has increased investment in non-destructive evaluation technologies by 22% over the past three years, with particular emphasis on methods compatible with complex geometries produced through binder jetting.

Healthcare and medical device manufacturers represent another significant market segment, with regulatory requirements mandating comprehensive quality assurance protocols. The FDA and other regulatory bodies have established increasingly stringent guidelines for additive manufactured medical devices, creating substantial demand for non-destructive evaluation methods that can verify internal structures without compromising part integrity.

Market research indicates that end-users are willing to invest substantially in quality control solutions that can reduce scrap rates and prevent costly failures. A recent industry survey revealed that manufacturers using binder jetting technology report average scrap rates of 15-20% due to undetected internal defects, representing millions in lost production value annually.

The integration of artificial intelligence and machine learning with non-destructive evaluation methods represents a high-growth market opportunity. Solutions that combine CT scanning, ultrasonic testing, or acoustic methods with automated defect recognition systems command premium pricing and are experiencing adoption rates 2.5 times higher than conventional inspection systems.

Regional analysis shows North America and Europe currently dominating the market for advanced binder jetting quality control solutions, accounting for approximately 65% of global market share. However, the Asia-Pacific region is expected to witness the fastest growth rate, driven by rapid industrialization and increasing adoption of additive manufacturing technologies in countries like China, Japan, and South Korea.

Customer feedback indicates growing demand for in-line and real-time monitoring capabilities rather than post-production inspection. This shift is creating new market opportunities for integrated sensor systems that can detect defects during the binder jetting process, potentially preventing defective parts from completing production cycles.

Current State and Challenges in Additive Manufacturing Inspection

Additive Manufacturing (AM) inspection technologies have evolved significantly over the past decade, yet numerous challenges persist in ensuring consistent quality and reliability of printed parts. Current inspection methods for Binder Jetting technology can be broadly categorized into in-process monitoring and post-process evaluation techniques, each with distinct capabilities and limitations.

In-process monitoring systems for Binder Jetting primarily focus on layer-by-layer inspection, utilizing optical cameras, thermal imaging, and acoustic emission sensors. These systems can detect gross defects such as powder bed irregularities, binder saturation issues, and major layer delamination. However, they often lack the resolution to identify micro-scale defects that can significantly impact mechanical properties.

Post-process evaluation techniques currently dominate the industry, with Computed Tomography (CT) scanning representing the gold standard for internal defect detection in Binder Jetted parts. CT technology offers comprehensive volumetric inspection but faces significant limitations including high equipment costs, slow scanning speeds, and size constraints for larger components. Additionally, the massive datasets generated require sophisticated analysis algorithms and substantial computing resources.

Ultrasonic testing methods have gained traction for Binder Jetting inspection, particularly for detecting internal voids, cracks, and bonding issues. Conventional ultrasonic techniques struggle with the inherent porosity of Binder Jetted parts, which causes significant signal attenuation and scattering. Advanced techniques like phased array ultrasonics show promise but require further development for reliable application to complex geometries.

Acoustic methods, including resonant ultrasound spectroscopy and acoustic emission monitoring, are emerging as complementary approaches. These techniques can detect structural anomalies by analyzing vibrational responses but currently lack the spatial resolution to precisely locate defects within complex parts.

A significant challenge across all inspection methodologies is the establishment of standardized acceptance criteria. Unlike traditional manufacturing, where decades of empirical data inform quality standards, AM processes like Binder Jetting lack comprehensive defect-property correlation databases. This gap complicates the interpretation of inspection results and hinders quality assurance efforts.

Integration of inspection data with process parameters represents another frontier challenge. Current systems typically operate in isolation, with limited feedback mechanisms between inspection results and process adjustments. This disconnect impedes the development of closed-loop control systems that could potentially correct defects during the build process.

The computational demands of processing inspection data present additional hurdles. Real-time analysis of high-resolution CT or ultrasonic data requires advanced algorithms and substantial computing resources, creating bottlenecks in production environments where rapid quality decisions are essential.

In-process monitoring systems for Binder Jetting primarily focus on layer-by-layer inspection, utilizing optical cameras, thermal imaging, and acoustic emission sensors. These systems can detect gross defects such as powder bed irregularities, binder saturation issues, and major layer delamination. However, they often lack the resolution to identify micro-scale defects that can significantly impact mechanical properties.

Post-process evaluation techniques currently dominate the industry, with Computed Tomography (CT) scanning representing the gold standard for internal defect detection in Binder Jetted parts. CT technology offers comprehensive volumetric inspection but faces significant limitations including high equipment costs, slow scanning speeds, and size constraints for larger components. Additionally, the massive datasets generated require sophisticated analysis algorithms and substantial computing resources.

Ultrasonic testing methods have gained traction for Binder Jetting inspection, particularly for detecting internal voids, cracks, and bonding issues. Conventional ultrasonic techniques struggle with the inherent porosity of Binder Jetted parts, which causes significant signal attenuation and scattering. Advanced techniques like phased array ultrasonics show promise but require further development for reliable application to complex geometries.

Acoustic methods, including resonant ultrasound spectroscopy and acoustic emission monitoring, are emerging as complementary approaches. These techniques can detect structural anomalies by analyzing vibrational responses but currently lack the spatial resolution to precisely locate defects within complex parts.

A significant challenge across all inspection methodologies is the establishment of standardized acceptance criteria. Unlike traditional manufacturing, where decades of empirical data inform quality standards, AM processes like Binder Jetting lack comprehensive defect-property correlation databases. This gap complicates the interpretation of inspection results and hinders quality assurance efforts.

Integration of inspection data with process parameters represents another frontier challenge. Current systems typically operate in isolation, with limited feedback mechanisms between inspection results and process adjustments. This disconnect impedes the development of closed-loop control systems that could potentially correct defects during the build process.

The computational demands of processing inspection data present additional hurdles. Real-time analysis of high-resolution CT or ultrasonic data requires advanced algorithms and substantial computing resources, creating bottlenecks in production environments where rapid quality decisions are essential.

Current CT, Ultrasonic and Acoustic Inspection Solutions

01 X-ray and CT scanning techniques for binder jetting quality evaluation

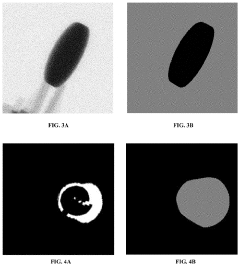

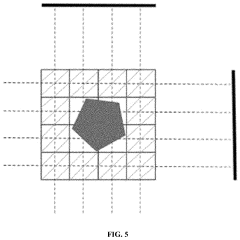

X-ray and computed tomography (CT) scanning techniques are used for non-destructive evaluation of binder jetted parts. These methods allow for internal inspection of complex geometries without damaging the parts, enabling detection of defects such as porosity, cracks, and internal voids. Advanced CT scanning can provide three-dimensional visualization of the internal structure, helping to assess the quality of binder jetted components throughout the manufacturing process.- X-ray and CT scanning techniques for binder jetting quality evaluation: X-ray and computed tomography (CT) scanning techniques are used for non-destructive evaluation of binder jetted parts. These methods allow for internal inspection of complex geometries without damaging the parts, enabling detection of defects such as voids, cracks, and density variations. Advanced image processing algorithms can be applied to the scan data to create 3D visualizations of internal structures and quantify defect characteristics, providing comprehensive quality assessment of binder jetted components.

- Ultrasonic testing methods for binder jetting quality control: Ultrasonic testing provides a non-destructive method for evaluating the quality of binder jetted parts by measuring the propagation of sound waves through the material. This technique can detect internal defects, layer adhesion issues, and variations in material density. Advanced ultrasonic systems can create detailed maps of internal structures and identify microscopic flaws that might affect part performance. The method is particularly valuable for evaluating the integrity of complex geometries and thick-walled components produced through binder jetting processes.

- In-process monitoring systems for binder jetting quality assurance: In-process monitoring systems integrate sensors and cameras directly into binder jetting equipment to evaluate part quality during fabrication. These systems can detect issues in real-time by monitoring parameters such as powder bed uniformity, binder deposition accuracy, and layer consolidation. Machine learning algorithms analyze the collected data to identify anomalies and predict potential defects before they become critical. This approach allows for immediate corrective actions during the manufacturing process, reducing waste and improving overall part quality.

- Optical and laser-based inspection techniques for surface quality assessment: Optical and laser-based inspection techniques provide high-resolution evaluation of surface characteristics in binder jetted parts. These methods use structured light, laser scanning, or digital image correlation to create detailed surface maps that can identify defects such as warping, roughness variations, and dimensional inaccuracies. The non-contact nature of these techniques makes them ideal for inspecting delicate or complex geometries without risking damage to the parts. Advanced image processing algorithms can automatically identify and classify surface defects according to predefined quality criteria.

- Material characterization methods for binder jetted part evaluation: Material characterization methods assess the physical and mechanical properties of binder jetted parts without destroying them. These techniques include resonant frequency analysis, eddy current testing, and thermal imaging to evaluate material homogeneity, density variations, and internal structure. By comparing the measured properties against established standards, these methods can verify if parts meet design specifications and performance requirements. This approach is particularly valuable for evaluating how post-processing treatments affect the final quality of binder jetted components.

02 Ultrasonic testing methods for binder jetted parts

Ultrasonic testing provides a non-destructive method for evaluating the quality of binder jetted components. By transmitting high-frequency sound waves through the material and analyzing the reflected signals, this technique can detect internal defects, measure thickness, and assess material properties. Ultrasonic methods are particularly valuable for identifying delamination, voids, and inconsistencies in material density that may affect the structural integrity of binder jetted parts.Expand Specific Solutions03 In-process monitoring systems for binder jetting quality control

In-process monitoring systems integrate sensors and data analysis tools directly into the binder jetting manufacturing process. These systems collect real-time data on various parameters such as binder deposition, powder spreading uniformity, and curing conditions. By continuously monitoring these factors, manufacturers can detect anomalies immediately, make process adjustments, and ensure consistent quality throughout production, reducing the need for post-production inspection and minimizing waste.Expand Specific Solutions04 Machine learning and AI for defect detection in binder jetted components

Machine learning and artificial intelligence algorithms are being applied to analyze data from various non-destructive evaluation techniques for binder jetted parts. These computational methods can identify patterns and anomalies that might be missed by human inspectors or traditional analysis methods. By training on datasets of known defects, AI systems can automatically classify and quantify defects, predict part quality, and provide recommendations for process improvements, enhancing the reliability of quality evaluation.Expand Specific Solutions05 Optical and laser-based inspection techniques for surface quality assessment

Optical and laser-based inspection techniques provide non-destructive methods for evaluating the surface quality of binder jetted parts. These methods use light reflection, scattering, or interferometry to detect surface defects, measure roughness, and assess dimensional accuracy. High-resolution cameras and structured light systems can create detailed surface maps, while laser scanning can provide precise measurements of surface features. These techniques are particularly valuable for evaluating the external quality of binder jetted components before post-processing.Expand Specific Solutions

Key Industry Players in AM Inspection Technologies

Binder Jetting Non-Destructive Evaluation is currently in a growth phase, with the market expanding as additive manufacturing adoption increases across industries. The global market for non-destructive testing in additive manufacturing is projected to reach significant scale as quality assurance becomes critical for industrial applications. Technologically, the field shows varying maturity levels across different evaluation methods. Leading organizations like Baker Hughes, Fraunhofer-Gesellschaft, and NASA are advancing CT scanning technologies, while companies such as Siemens AG and General Electric are developing integrated ultrasonic solutions. Academic institutions including Huazhong University of Science & Technology and Nanjing University are contributing fundamental research in acoustic methods, creating a competitive landscape balanced between established industrial players and research organizations driving innovation.

Edison Welding Institute, Inc.

Technical Solution: Edison Welding Institute (EWI) has pioneered a multi-modal approach to non-destructive evaluation of binder jetted parts that combines ultrasonic testing with CT scanning. Their system employs phased array ultrasonic technology (PAUT) with customized transducers designed specifically for the unique material properties of binder jetted components. EWI's solution features automated scanning systems that can map internal structures and identify defects such as voids, cracks, and binding inconsistencies with high precision. The institute has developed specialized coupling techniques to overcome the challenges of ultrasonic transmission in porous binder jetted materials, including the use of custom-formulated coupling gels and immersion testing methodologies. Their approach incorporates real-time data processing that allows for immediate feedback during manufacturing, enabling process adjustments before completion of production runs.[2][5]

Strengths: Complementary multi-modal approach provides more comprehensive defect detection; specialized expertise in materials joining and testing; solutions adaptable to various material systems. Weaknesses: Implementation complexity due to multiple technologies; requires careful calibration for different material compositions; higher operational complexity compared to single-method approaches.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed advanced CT (Computed Tomography) scanning systems specifically optimized for Binder Jetting additive manufacturing processes. Their technology utilizes high-resolution industrial CT scanners with specialized algorithms to detect internal defects, porosity, and dimensional accuracy in binder jetted parts. The company's approach combines multi-angle X-ray projections with proprietary reconstruction software that can identify sub-millimeter defects even in complex geometries. Baker Hughes has integrated machine learning capabilities into their evaluation system, allowing for automated defect recognition and classification based on extensive training datasets from oil and gas component manufacturing. Their solution provides comprehensive volumetric analysis with resolution capabilities down to 5 microns, enabling quality control throughout the production process rather than just end-product verification.[1][3]

Strengths: Superior defect detection in complex geometries; integration with production workflows; extensive experience with demanding oil and gas industry requirements. Weaknesses: Systems typically require significant capital investment; specialized training needed for operators; evaluation speed may be limited for high-volume production environments.

Critical Technical Analysis of NDE Methods for Binder Jetting

Computed tomography for non-destructive evaluation of manufactured parts

PatentActiveUS20200393823A1

Innovation

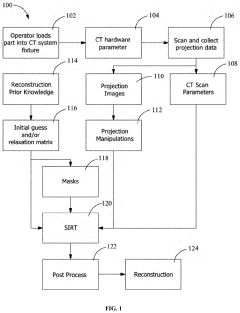

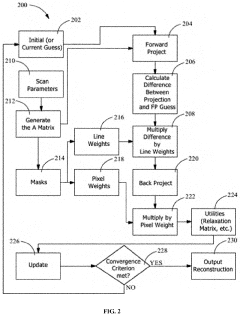

- The use of an iterative algebraic reconstruction technique, such as the Simultaneous Iterative Reconstruction Technique (SIRT), which integrates prior knowledge data to reduce the number of scan images needed, thereby decreasing scan time and maintaining reconstruction quality, is implemented. This method processes projection data, aligns prior knowledge data, generates masks and a relaxation matrix, and iteratively updates the reconstruction until convergence, allowing for faster CT scan times.

Ultrasonic non-destructive evaluation of thin specimens

PatentInactiveUS5305239A

Innovation

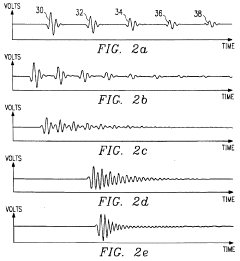

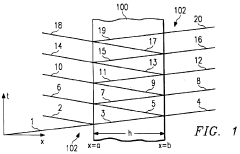

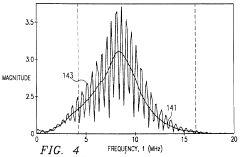

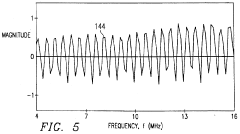

- A method involving the transmission and reception of ultrasonic waves within a predetermined frequency range, followed by analysis in the frequency domain to determine frequency-dependent normalized wavenumbers, which provide information on wavespeed and attenuation, allowing for the evaluation of both thick and thin specimens.

Standards and Certification Requirements for AM NDE

The standardization landscape for Non-Destructive Evaluation (NDE) in Additive Manufacturing (AM), particularly for Binder Jetting processes, is rapidly evolving to address the unique challenges presented by this technology. Currently, several international organizations are developing comprehensive standards specifically for AM NDE methods, including CT scanning, ultrasonic testing, and acoustic techniques.

ASTM International's Committee F42 on Additive Manufacturing Technologies has established the F42.07 subcommittee dedicated to NDE of AM parts. This group has published guidelines such as ASTM F3122, which provides standard guidance for evaluating mechanical properties of AM parts using various NDE methods. For Binder Jetting specifically, standards are being developed to address the unique porosity characteristics and material interfaces that affect inspection reliability.

ISO/TC 261 has also contributed significantly to the standardization framework through ISO/ASTM 52900 series, which includes terminology and general principles for AM processes. However, specific standards for NDE methods applied to Binder Jetted components are still under development, with working groups focusing on adapting traditional NDE techniques to the unique characteristics of powder bed fusion processes.

Certification requirements for AM NDE practitioners represent another critical aspect of the ecosystem. The American Society for Nondestructive Testing (ASNT) has begun developing certification programs specifically for AM inspection specialists. These programs require demonstrable knowledge of both traditional NDE principles and the unique considerations for AM parts, including understanding of build orientation effects on defect detection and interpretation of CT data for powder-based processes.

Regulatory bodies such as the FDA for medical devices and the FAA for aerospace components have established guidance documents that outline NDE requirements for AM parts in critical applications. These typically mandate validation studies to demonstrate that selected NDE methods can reliably detect critical defects in Binder Jetted components, with particular emphasis on internal voids, binding agent distribution, and interlayer adhesion quality.

For CT scanning specifically, ASTM E1570 provides guidelines for computed tomographic examination, though adaptations for the unique characteristics of Binder Jetted parts are still evolving. Similarly, ultrasonic testing standards such as ASTM E2375 require modification to account for the anisotropic acoustic properties of Binder Jetted materials, which can vary significantly based on printing parameters and post-processing treatments.

Industry consortia like America Makes are actively working to bridge standardization gaps by funding research projects focused on establishing correlation between NDE results and mechanical performance of AM parts, which will ultimately inform future certification requirements and inspection protocols for Binder Jetting technology.

ASTM International's Committee F42 on Additive Manufacturing Technologies has established the F42.07 subcommittee dedicated to NDE of AM parts. This group has published guidelines such as ASTM F3122, which provides standard guidance for evaluating mechanical properties of AM parts using various NDE methods. For Binder Jetting specifically, standards are being developed to address the unique porosity characteristics and material interfaces that affect inspection reliability.

ISO/TC 261 has also contributed significantly to the standardization framework through ISO/ASTM 52900 series, which includes terminology and general principles for AM processes. However, specific standards for NDE methods applied to Binder Jetted components are still under development, with working groups focusing on adapting traditional NDE techniques to the unique characteristics of powder bed fusion processes.

Certification requirements for AM NDE practitioners represent another critical aspect of the ecosystem. The American Society for Nondestructive Testing (ASNT) has begun developing certification programs specifically for AM inspection specialists. These programs require demonstrable knowledge of both traditional NDE principles and the unique considerations for AM parts, including understanding of build orientation effects on defect detection and interpretation of CT data for powder-based processes.

Regulatory bodies such as the FDA for medical devices and the FAA for aerospace components have established guidance documents that outline NDE requirements for AM parts in critical applications. These typically mandate validation studies to demonstrate that selected NDE methods can reliably detect critical defects in Binder Jetted components, with particular emphasis on internal voids, binding agent distribution, and interlayer adhesion quality.

For CT scanning specifically, ASTM E1570 provides guidelines for computed tomographic examination, though adaptations for the unique characteristics of Binder Jetted parts are still evolving. Similarly, ultrasonic testing standards such as ASTM E2375 require modification to account for the anisotropic acoustic properties of Binder Jetted materials, which can vary significantly based on printing parameters and post-processing treatments.

Industry consortia like America Makes are actively working to bridge standardization gaps by funding research projects focused on establishing correlation between NDE results and mechanical performance of AM parts, which will ultimately inform future certification requirements and inspection protocols for Binder Jetting technology.

Cost-Benefit Analysis of NDE Implementation in Production

Implementing non-destructive evaluation (NDE) methods for Binder Jetting additive manufacturing processes requires careful consideration of financial implications. The initial investment in CT scanning equipment represents a significant capital expenditure, typically ranging from $150,000 to $500,000 depending on resolution capabilities and scanning volume. However, this cost must be weighed against the potential savings from reduced material waste and prevention of downstream manufacturing failures.

Ultrasonic testing systems present a more economical alternative, with equipment costs between $30,000 and $100,000, though they require specialized transducers optimized for porous binder jetted materials. The return on investment typically materializes within 12-24 months through improved part qualification rates and reduced scrap.

Acoustic methods, particularly resonance testing, offer the most cost-effective entry point at $15,000-$50,000, but with more limited detection capabilities. These systems excel at high-throughput screening applications where complete volumetric data is not required.

Labor costs constitute another significant consideration, with trained NDE technicians commanding salaries of $60,000-$90,000 annually. Automation can mitigate these expenses, though it requires additional upfront investment. Training existing staff on NDE techniques typically requires 40-80 hours per employee, representing a temporary productivity loss that must be factored into implementation planning.

Production integration costs vary significantly based on manufacturing volume. High-volume operations benefit from in-line NDE systems that, while expensive initially, reduce per-part inspection costs to under $5. Low-volume, high-value production may justify batch inspection approaches with per-part costs of $20-$100 depending on complexity.

Quality improvement metrics demonstrate that effective NDE implementation can reduce field failures by 30-60% and warranty claims by 25-45%. For critical applications in aerospace and medical sectors, these improvements justify premium NDE approaches despite higher costs.

Time-to-market advantages must also be quantified, as NDE can accelerate design iteration cycles by providing rapid feedback on internal features without destructive testing. This acceleration typically reduces development cycles by 15-30%, creating significant competitive advantages that may outweigh direct implementation costs.

Finally, regulatory compliance requirements in regulated industries may mandate specific NDE protocols regardless of cost considerations, making implementation a necessary business expense rather than an optional investment decision.

Ultrasonic testing systems present a more economical alternative, with equipment costs between $30,000 and $100,000, though they require specialized transducers optimized for porous binder jetted materials. The return on investment typically materializes within 12-24 months through improved part qualification rates and reduced scrap.

Acoustic methods, particularly resonance testing, offer the most cost-effective entry point at $15,000-$50,000, but with more limited detection capabilities. These systems excel at high-throughput screening applications where complete volumetric data is not required.

Labor costs constitute another significant consideration, with trained NDE technicians commanding salaries of $60,000-$90,000 annually. Automation can mitigate these expenses, though it requires additional upfront investment. Training existing staff on NDE techniques typically requires 40-80 hours per employee, representing a temporary productivity loss that must be factored into implementation planning.

Production integration costs vary significantly based on manufacturing volume. High-volume operations benefit from in-line NDE systems that, while expensive initially, reduce per-part inspection costs to under $5. Low-volume, high-value production may justify batch inspection approaches with per-part costs of $20-$100 depending on complexity.

Quality improvement metrics demonstrate that effective NDE implementation can reduce field failures by 30-60% and warranty claims by 25-45%. For critical applications in aerospace and medical sectors, these improvements justify premium NDE approaches despite higher costs.

Time-to-market advantages must also be quantified, as NDE can accelerate design iteration cycles by providing rapid feedback on internal features without destructive testing. This acceleration typically reduces development cycles by 15-30%, creating significant competitive advantages that may outweigh direct implementation costs.

Finally, regulatory compliance requirements in regulated industries may mandate specific NDE protocols regardless of cost considerations, making implementation a necessary business expense rather than an optional investment decision.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!