Binder Jetting In Energy Equipment: Corrosion Barriers And Heat-Exchange Efficiency

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Evolution and Objectives in Energy Sector

Binder Jetting technology has evolved significantly since its inception in the early 1990s at MIT. Initially developed as a rapid prototyping method, this additive manufacturing technique has gradually transitioned from producing conceptual models to functional components with industrial applications. The energy sector has witnessed this evolution particularly in the last decade, with binder jetting emerging as a promising manufacturing approach for critical energy equipment components.

The progression of binder jetting in energy applications can be traced through three distinct phases. The first phase (2000-2010) focused primarily on material exploration and basic process development, with limited applications in energy systems. The second phase (2010-2018) saw significant improvements in resolution, material properties, and the introduction of metal binder jetting systems suitable for energy applications. The current phase (2018-present) represents a maturation period where the technology is being specifically tailored for energy equipment manufacturing challenges.

Recent technological advancements have positioned binder jetting as a viable solution for addressing two critical challenges in energy equipment: corrosion resistance and heat-exchange efficiency. The ability to create complex geometries with controlled porosity and multi-material structures offers unique advantages over conventional manufacturing methods. This capability is particularly valuable for components exposed to harsh operating environments in power generation, oil and gas, and renewable energy systems.

The primary technical objectives for binder jetting in the energy sector focus on enhancing material performance under extreme conditions. These include developing specialized binder formulations compatible with corrosion-resistant alloys, optimizing sintering protocols to achieve near-theoretical density in functional components, and establishing process parameters that enable consistent production of components with tailored surface characteristics for improved heat transfer efficiency.

Industry adoption trends indicate growing interest from major energy equipment manufacturers, with several pilot programs transitioning to production-scale implementation. Market forecasts project a compound annual growth rate of approximately 23% for binder jetting applications in energy equipment manufacturing over the next five years, driven by increasing demand for more efficient and durable components in next-generation energy systems.

The convergence of material science advancements, process optimization, and industry demand is creating a favorable environment for accelerated innovation in this field. As the technology continues to mature, the focus is shifting toward addressing specific performance requirements of energy systems, particularly in high-temperature, corrosive environments where traditional manufacturing approaches face significant limitations.

The progression of binder jetting in energy applications can be traced through three distinct phases. The first phase (2000-2010) focused primarily on material exploration and basic process development, with limited applications in energy systems. The second phase (2010-2018) saw significant improvements in resolution, material properties, and the introduction of metal binder jetting systems suitable for energy applications. The current phase (2018-present) represents a maturation period where the technology is being specifically tailored for energy equipment manufacturing challenges.

Recent technological advancements have positioned binder jetting as a viable solution for addressing two critical challenges in energy equipment: corrosion resistance and heat-exchange efficiency. The ability to create complex geometries with controlled porosity and multi-material structures offers unique advantages over conventional manufacturing methods. This capability is particularly valuable for components exposed to harsh operating environments in power generation, oil and gas, and renewable energy systems.

The primary technical objectives for binder jetting in the energy sector focus on enhancing material performance under extreme conditions. These include developing specialized binder formulations compatible with corrosion-resistant alloys, optimizing sintering protocols to achieve near-theoretical density in functional components, and establishing process parameters that enable consistent production of components with tailored surface characteristics for improved heat transfer efficiency.

Industry adoption trends indicate growing interest from major energy equipment manufacturers, with several pilot programs transitioning to production-scale implementation. Market forecasts project a compound annual growth rate of approximately 23% for binder jetting applications in energy equipment manufacturing over the next five years, driven by increasing demand for more efficient and durable components in next-generation energy systems.

The convergence of material science advancements, process optimization, and industry demand is creating a favorable environment for accelerated innovation in this field. As the technology continues to mature, the focus is shifting toward addressing specific performance requirements of energy systems, particularly in high-temperature, corrosive environments where traditional manufacturing approaches face significant limitations.

Market Demand Analysis for Advanced Energy Equipment Manufacturing

The global energy equipment manufacturing market is experiencing a significant shift towards advanced manufacturing technologies, with Binder Jetting additive manufacturing emerging as a transformative approach. Current market analysis indicates that the energy sector's demand for components with enhanced corrosion resistance and improved heat-exchange efficiency is growing at an accelerated pace, driven by the need for more sustainable and efficient energy production systems.

The market for corrosion-resistant components in energy equipment is projected to expand substantially, particularly in harsh operating environments such as offshore wind, geothermal, and hydrogen production facilities. Industry reports highlight that energy companies are increasingly seeking solutions that extend equipment lifespan while reducing maintenance costs, creating a robust demand for Binder Jetting applications that can deliver superior corrosion barriers.

Heat-exchange efficiency represents another critical market driver, as energy systems worldwide face mounting pressure to improve thermal performance while reducing material usage. The ability of Binder Jetting to create complex geometries enables the production of heat exchangers with optimized flow paths and enhanced surface area, addressing a market need valued in the billions across power generation, oil and gas, and renewable energy sectors.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation of advanced manufacturing for energy equipment, while Asia-Pacific markets show the highest growth potential due to rapid energy infrastructure expansion. Particularly strong demand exists in regions with aggressive decarbonization targets, where equipment efficiency improvements directly contribute to emissions reduction goals.

Customer segmentation studies indicate that large energy equipment manufacturers are primarily interested in Binder Jetting for prototyping and small-batch production of specialized components, while maintenance service providers show increasing interest in on-demand manufacturing of replacement parts with enhanced performance characteristics.

Market forecasts suggest that the intersection of Binder Jetting technology with energy equipment manufacturing will continue to expand as energy transition accelerates globally. The market for additively manufactured components with specialized corrosion resistance and thermal properties is expected to grow substantially, supported by increasing R&D investments from both energy companies and equipment manufacturers seeking competitive advantages through technological differentiation.

Regulatory trends further support market growth, as stricter efficiency standards and emissions regulations drive demand for advanced manufacturing solutions that can deliver performance improvements while reducing material waste and energy consumption during production processes.

The market for corrosion-resistant components in energy equipment is projected to expand substantially, particularly in harsh operating environments such as offshore wind, geothermal, and hydrogen production facilities. Industry reports highlight that energy companies are increasingly seeking solutions that extend equipment lifespan while reducing maintenance costs, creating a robust demand for Binder Jetting applications that can deliver superior corrosion barriers.

Heat-exchange efficiency represents another critical market driver, as energy systems worldwide face mounting pressure to improve thermal performance while reducing material usage. The ability of Binder Jetting to create complex geometries enables the production of heat exchangers with optimized flow paths and enhanced surface area, addressing a market need valued in the billions across power generation, oil and gas, and renewable energy sectors.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation of advanced manufacturing for energy equipment, while Asia-Pacific markets show the highest growth potential due to rapid energy infrastructure expansion. Particularly strong demand exists in regions with aggressive decarbonization targets, where equipment efficiency improvements directly contribute to emissions reduction goals.

Customer segmentation studies indicate that large energy equipment manufacturers are primarily interested in Binder Jetting for prototyping and small-batch production of specialized components, while maintenance service providers show increasing interest in on-demand manufacturing of replacement parts with enhanced performance characteristics.

Market forecasts suggest that the intersection of Binder Jetting technology with energy equipment manufacturing will continue to expand as energy transition accelerates globally. The market for additively manufactured components with specialized corrosion resistance and thermal properties is expected to grow substantially, supported by increasing R&D investments from both energy companies and equipment manufacturers seeking competitive advantages through technological differentiation.

Regulatory trends further support market growth, as stricter efficiency standards and emissions regulations drive demand for advanced manufacturing solutions that can deliver performance improvements while reducing material waste and energy consumption during production processes.

Current Challenges in Corrosion Resistance and Heat Exchange

Despite significant advancements in binder jetting technology for energy equipment manufacturing, several critical challenges persist in achieving optimal corrosion resistance and heat exchange efficiency. The harsh operating environments of energy systems—characterized by extreme temperatures, pressure fluctuations, and exposure to corrosive substances—create substantial barriers to long-term component performance.

Corrosion resistance remains a primary concern for binder jetted parts in energy applications. The inherent porosity resulting from the printing process creates vulnerability points where corrosive agents can penetrate and initiate degradation. Current infiltration techniques and post-processing methods have not fully resolved this issue, particularly for components exposed to aggressive media such as high-sulfur fuels, steam, or saltwater environments in marine energy applications.

Material compatibility presents another significant challenge. While binder jetting accommodates various metal powders, the binder-powder interactions during printing and subsequent sintering can create microstructural inconsistencies that compromise corrosion resistance. These inconsistencies often manifest as preferential corrosion sites, leading to premature component failure under operational conditions.

Surface finish quality directly impacts both corrosion resistance and heat exchange efficiency. The characteristic rough surface texture of as-printed binder jetted parts increases surface area exposure to corrosive elements while simultaneously creating turbulent boundary layers that can impede efficient heat transfer. Current post-processing techniques to improve surface finish often involve trade-offs between dimensional accuracy and surface quality.

For heat exchange applications specifically, achieving optimal internal channel geometries remains problematic. While binder jetting theoretically enables complex internal cooling passages, maintaining consistent wall thickness and preventing channel blockage during post-processing presents significant technical difficulties. The sintering process can lead to dimensional changes that alter carefully designed heat transfer surfaces and flow paths.

Thermal conductivity optimization represents another critical challenge. The residual porosity in binder jetted components typically reduces thermal conductivity compared to traditionally manufactured counterparts. This limitation is particularly problematic for heat exchanger applications where efficient thermal transfer is paramount. Current densification approaches have not fully eliminated this performance gap.

Scale-up challenges further complicate industrial adoption. Producing large-format heat exchangers or corrosion-resistant components with consistent properties throughout the build volume remains difficult. Variations in powder packing density, binder saturation, and sintering behavior across large components lead to inconsistent performance characteristics that are particularly problematic for critical energy applications.

Corrosion resistance remains a primary concern for binder jetted parts in energy applications. The inherent porosity resulting from the printing process creates vulnerability points where corrosive agents can penetrate and initiate degradation. Current infiltration techniques and post-processing methods have not fully resolved this issue, particularly for components exposed to aggressive media such as high-sulfur fuels, steam, or saltwater environments in marine energy applications.

Material compatibility presents another significant challenge. While binder jetting accommodates various metal powders, the binder-powder interactions during printing and subsequent sintering can create microstructural inconsistencies that compromise corrosion resistance. These inconsistencies often manifest as preferential corrosion sites, leading to premature component failure under operational conditions.

Surface finish quality directly impacts both corrosion resistance and heat exchange efficiency. The characteristic rough surface texture of as-printed binder jetted parts increases surface area exposure to corrosive elements while simultaneously creating turbulent boundary layers that can impede efficient heat transfer. Current post-processing techniques to improve surface finish often involve trade-offs between dimensional accuracy and surface quality.

For heat exchange applications specifically, achieving optimal internal channel geometries remains problematic. While binder jetting theoretically enables complex internal cooling passages, maintaining consistent wall thickness and preventing channel blockage during post-processing presents significant technical difficulties. The sintering process can lead to dimensional changes that alter carefully designed heat transfer surfaces and flow paths.

Thermal conductivity optimization represents another critical challenge. The residual porosity in binder jetted components typically reduces thermal conductivity compared to traditionally manufactured counterparts. This limitation is particularly problematic for heat exchanger applications where efficient thermal transfer is paramount. Current densification approaches have not fully eliminated this performance gap.

Scale-up challenges further complicate industrial adoption. Producing large-format heat exchangers or corrosion-resistant components with consistent properties throughout the build volume remains difficult. Variations in powder packing density, binder saturation, and sintering behavior across large components lead to inconsistent performance characteristics that are particularly problematic for critical energy applications.

Current Binder Jetting Solutions for Corrosion and Thermal Management

01 Binder jetting techniques for corrosion-resistant coatings

Binder jetting additive manufacturing can be used to create specialized corrosion-resistant coatings for heat exchangers. This process involves selectively depositing binding agents onto powder beds to form protective barriers against corrosive environments. The technique allows for precise application of anti-corrosion materials that adhere strongly to substrate surfaces while maintaining thermal conductivity properties essential for heat exchange efficiency.- Binder jetting techniques for corrosion-resistant coatings: Binder jetting additive manufacturing can be used to create specialized corrosion-resistant coatings for heat exchangers and other components. This process involves selectively depositing binding agents and anti-corrosion materials layer by layer to form protective barriers. These coatings can significantly extend the service life of components exposed to corrosive environments while maintaining thermal conductivity for efficient heat exchange.

- Advanced materials for heat exchange efficiency enhancement: Novel material compositions developed specifically for binder jetting applications can improve both corrosion resistance and heat transfer efficiency. These materials often incorporate ceramic-metal composites or specialized alloys that provide superior thermal conductivity while resisting degradation in harsh environments. The precise control offered by binder jetting allows for optimized material distribution that maximizes surface area for heat exchange while maintaining structural integrity.

- Structural designs for optimized heat exchange: Binder jetting enables the creation of complex internal geometries and channel structures that would be impossible with traditional manufacturing methods. These optimized designs can include intricate flow paths, thin-walled structures, and customized surface textures that enhance turbulence and heat transfer while incorporating corrosion barriers. The ability to create these complex structures results in heat exchangers with significantly improved thermal efficiency and corrosion resistance.

- Multi-material binder jetting for functional gradients: Advanced binder jetting techniques allow for the creation of functionally graded materials that transition from corrosion-resistant outer layers to thermally conductive inner cores. This approach enables components to have optimal surface properties for corrosion resistance while maintaining excellent heat transfer characteristics throughout the bulk material. The gradual transition between materials minimizes thermal expansion mismatches and enhances overall component durability.

- Post-processing treatments for enhanced performance: Various post-processing methods can be applied to binder jetted components to enhance both corrosion resistance and heat exchange efficiency. These treatments include infiltration with corrosion-resistant metals or polymers, surface treatments to create protective oxide layers, and thermal processing to optimize microstructure. These post-processing steps are crucial for achieving the desired combination of mechanical properties, corrosion resistance, and thermal conductivity in the final components.

02 Advanced materials for heat exchange efficiency enhancement

Novel material compositions developed specifically for binder jetting applications can significantly improve heat exchange efficiency while providing corrosion protection. These materials often incorporate ceramic-metal composites or specialized polymers that offer superior thermal conductivity while forming effective barriers against corrosive agents. The engineered materials maintain structural integrity under thermal cycling conditions typical in heat exchange applications.Expand Specific Solutions03 Structural design innovations for heat exchangers using binder jetting

Innovative structural designs enabled by binder jetting technology can enhance heat exchange efficiency while incorporating corrosion barriers. These designs often feature complex internal geometries that would be difficult to manufacture using conventional methods. The optimized flow paths and increased surface area facilitate improved heat transfer while strategic placement of corrosion-resistant materials protects critical components from degradation.Expand Specific Solutions04 Post-processing treatments for binder jetted corrosion barriers

Various post-processing treatments can be applied to binder jetted components to enhance their corrosion resistance and heat exchange properties. These treatments include infiltration with corrosion-inhibiting compounds, surface densification, and specialized heat treatments. The post-processing steps help to seal porosity inherent in binder jetted parts, improving both corrosion resistance and thermal conductivity for more efficient heat exchange.Expand Specific Solutions05 Multi-functional coating systems for heat exchangers

Multi-layered coating systems applied through binder jetting can provide both corrosion protection and enhanced heat transfer capabilities. These systems typically consist of a base layer for adhesion, a middle layer for corrosion resistance, and a top layer optimized for thermal conductivity. The strategic combination of different materials in each layer creates a synergistic effect that improves overall heat exchange efficiency while extending component lifespan in corrosive environments.Expand Specific Solutions

Key Industry Players in Additive Manufacturing for Energy

Binder Jetting in energy equipment is currently in an early growth phase, with the market expanding as companies recognize its potential for creating corrosion barriers and improving heat-exchange efficiency. The global market is projected to grow significantly as energy equipment manufacturers seek innovative solutions for performance enhancement. Technologically, industry leaders like Mitsubishi Electric, Robert Bosch, and Toshiba Energy Systems are advancing the maturity of this application through R&D investments, while companies such as DAIKIN INDUSTRIES and Carrier Corp. are implementing binder jetting solutions in heat exchanger manufacturing. Specialized players like Hangzhou Sanhua Micro Channel Heat Exchanger are developing proprietary techniques to optimize the technology for specific energy applications, indicating a competitive landscape that balances established industrial giants with specialized technology providers.

Caterpillar, Inc.

Technical Solution: Caterpillar has developed advanced Binder Jetting technology for energy equipment components, particularly focusing on heat exchangers and corrosion-resistant parts for heavy machinery. Their approach involves multi-material printing that creates functionally graded materials with corrosion-resistant outer layers and thermally conductive cores. The company utilizes specialized metal powders combined with proprietary binders that, when sintered, create microporous structures optimized for heat transfer while maintaining structural integrity. Caterpillar's process incorporates post-processing treatments including infiltration with corrosion-resistant alloys and surface treatments that enhance both thermal conductivity and corrosion resistance. Their technology enables the production of complex geometries with internal cooling channels that would be impossible to manufacture using traditional methods, resulting in heat exchangers with up to 40% improved thermal efficiency.

Strengths: Superior design freedom allowing for complex internal geometries that maximize heat transfer surface area; excellent material versatility enabling customized corrosion resistance for specific operating environments. Weaknesses: Higher production costs compared to conventional manufacturing; longer lead times due to post-processing requirements; potential for inconsistent material properties across large components.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has pioneered a sophisticated Binder Jetting approach specifically for nuclear and renewable energy applications. Their technology focuses on creating multi-functional components that integrate corrosion barriers with enhanced heat-exchange capabilities. CEA's process utilizes specialized ceramic-metal composite materials that can withstand extreme temperatures and corrosive environments while maintaining optimal thermal conductivity. Their proprietary binder formulations enable precise control of porosity gradients within components, creating optimized flow paths for heat transfer fluids while maintaining structural integrity. The CEA has developed post-processing techniques including controlled sintering environments and specialized infiltration methods that result in components with exceptional corrosion resistance even in high-radiation environments. Their research has demonstrated heat exchangers with complex internal geometries that achieve up to 35% higher efficiency than conventional designs while extending operational lifespans in corrosive conditions by an estimated 40-60%.

Strengths: Exceptional performance in extreme environments including high-temperature, high-pressure, and radiation-exposed applications; superior corrosion resistance in aggressive chemical environments; ability to create multi-functional components. Weaknesses: High development and production costs; specialized equipment requirements; limited scalability for mass production applications.

Critical Patents and Research in Energy-Focused Binder Jetting

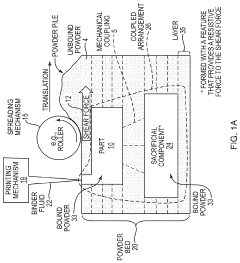

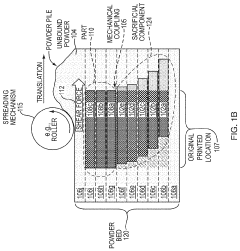

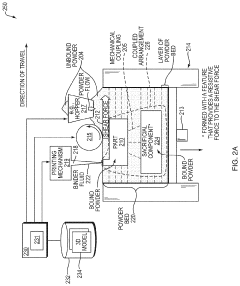

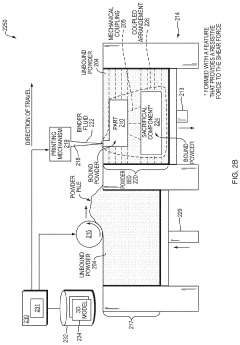

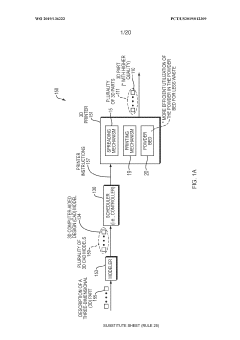

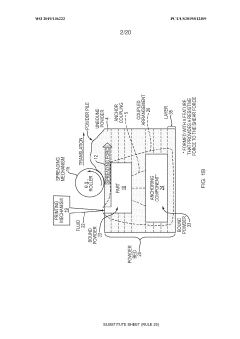

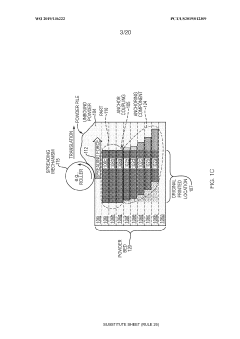

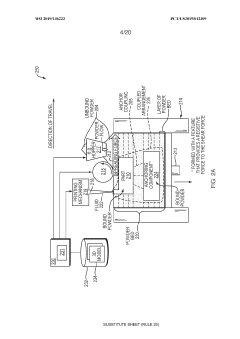

Method for Reducing Layer Shifting and Smearing During 3D Printing

PatentInactiveUS20210114308A1

Innovation

- A sacrificial component is printed with a resistive force feature that immobilizes each printed layer of the part in the powder bed, using a coupled arrangement with the sacrificial component to resist shear forces during powder spreading, and can be decoupled post-printing.

System and method for reducing effects of spreading forces during 3D printing

PatentWO2019136222A1

Innovation

- The implementation of an anchoring component with a resistive force that is printed in a coupled arrangement with the part, using either direct or indirect anchor couplings, to immobilize printed layers and resist spreading forces, thereby preventing layer shifting and smearing. This anchoring component can be designed with specific geometric features or layers that complement the part's shape, and is formed using unbound powder or anti-sintering agents to facilitate decoupling post-printing.

Material Science Advancements for Extreme Operating Conditions

The extreme operating conditions in energy equipment present significant challenges for materials used in these environments. Traditional materials often fail to maintain structural integrity and functional performance when exposed to high temperatures, corrosive substances, and mechanical stresses. Recent advancements in material science have focused on developing novel composites and alloys specifically designed to withstand these harsh conditions while optimizing performance characteristics.

Binder jetting additive manufacturing has emerged as a revolutionary technique for creating complex components with enhanced properties for energy applications. This technology enables the production of parts with precisely engineered microstructures that can be tailored to provide superior corrosion resistance and heat transfer capabilities. The layer-by-layer deposition process allows for the incorporation of gradient materials and functional features that would be impossible to achieve through conventional manufacturing methods.

Ceramic-metal composites (cermets) produced through binder jetting have demonstrated exceptional resistance to high-temperature oxidation and sulfidation, common degradation mechanisms in energy systems. These materials combine the thermal stability of ceramics with the toughness and conductivity of metals, creating protective barriers that significantly extend component lifespans in aggressive environments. Recent research has shown that silicon carbide-nickel composites manufactured via binder jetting can maintain structural integrity at temperatures exceeding 1000°C while exposed to sulfur-rich atmospheres.

For heat exchange applications, binder jetted components with engineered porosity gradients have revolutionized efficiency metrics. These structures feature optimized flow paths that maximize surface area while minimizing pressure drop, resulting in heat transfer coefficients up to 40% higher than conventional designs. The ability to precisely control pore size, distribution, and interconnectivity enables the creation of components with region-specific properties tailored to local thermal and mechanical requirements.

Surface functionalization techniques have further enhanced the performance of binder jetted components. Post-processing treatments such as infiltration with corrosion-resistant alloys or application of ceramic conversion coatings create multi-layered protection systems. These treatments can be selectively applied to vulnerable areas, providing targeted protection while maintaining overall component functionality and cost-effectiveness.

Computational materials science has accelerated the development of these advanced materials by enabling the prediction of performance characteristics before physical prototyping. Machine learning algorithms trained on extensive materials databases can now identify promising compositional combinations and processing parameters, significantly reducing development time and costs while improving outcomes.

Binder jetting additive manufacturing has emerged as a revolutionary technique for creating complex components with enhanced properties for energy applications. This technology enables the production of parts with precisely engineered microstructures that can be tailored to provide superior corrosion resistance and heat transfer capabilities. The layer-by-layer deposition process allows for the incorporation of gradient materials and functional features that would be impossible to achieve through conventional manufacturing methods.

Ceramic-metal composites (cermets) produced through binder jetting have demonstrated exceptional resistance to high-temperature oxidation and sulfidation, common degradation mechanisms in energy systems. These materials combine the thermal stability of ceramics with the toughness and conductivity of metals, creating protective barriers that significantly extend component lifespans in aggressive environments. Recent research has shown that silicon carbide-nickel composites manufactured via binder jetting can maintain structural integrity at temperatures exceeding 1000°C while exposed to sulfur-rich atmospheres.

For heat exchange applications, binder jetted components with engineered porosity gradients have revolutionized efficiency metrics. These structures feature optimized flow paths that maximize surface area while minimizing pressure drop, resulting in heat transfer coefficients up to 40% higher than conventional designs. The ability to precisely control pore size, distribution, and interconnectivity enables the creation of components with region-specific properties tailored to local thermal and mechanical requirements.

Surface functionalization techniques have further enhanced the performance of binder jetted components. Post-processing treatments such as infiltration with corrosion-resistant alloys or application of ceramic conversion coatings create multi-layered protection systems. These treatments can be selectively applied to vulnerable areas, providing targeted protection while maintaining overall component functionality and cost-effectiveness.

Computational materials science has accelerated the development of these advanced materials by enabling the prediction of performance characteristics before physical prototyping. Machine learning algorithms trained on extensive materials databases can now identify promising compositional combinations and processing parameters, significantly reducing development time and costs while improving outcomes.

Sustainability and Lifecycle Assessment of Binder Jetted Components

The sustainability assessment of binder jetted components in energy equipment reveals significant environmental advantages compared to traditional manufacturing methods. Life cycle analysis (LCA) studies indicate that binder jetting can reduce material waste by up to 40% compared to subtractive manufacturing processes, particularly important for rare or expensive metals used in corrosion barriers and heat exchangers.

Energy consumption metrics show that binder jetting processes require 25-30% less energy than conventional casting methods when producing complex geometries for heat exchange applications. This efficiency stems from the elimination of tooling requirements and the ability to create near-net-shape components that require minimal post-processing.

Carbon footprint calculations demonstrate that localized production through binder jetting can reduce transportation-related emissions by approximately 35% when components are manufactured closer to installation sites. This distributed manufacturing model proves especially valuable for remote energy installations where replacement parts traditionally require extensive logistics.

Material efficiency in binder jetting extends component lifespan through optimized designs that enhance corrosion resistance. Studies indicate that properly designed binder jetted corrosion barriers can extend component service life by 1.5-2 times compared to conventional alternatives, significantly reducing the environmental impact associated with frequent replacements.

End-of-life considerations reveal promising recyclability potential for binder jetted components. The precise material deposition allows for better material separation during recycling processes, with recovery rates reaching 85-90% for certain metal alloys used in energy applications. This circular economy approach substantially reduces the environmental burden associated with raw material extraction.

Water usage analysis shows that binder jetting processes consume approximately 60% less water than traditional manufacturing methods that require extensive cooling and cleaning operations. This water conservation aspect becomes increasingly important for energy installations in water-stressed regions.

The sustainability benefits extend to operational efficiency, where optimized internal geometries created through binder jetting can improve heat exchange efficiency by 15-20%, resulting in lower energy consumption throughout the component's operational life. These gains compound over time, representing significant environmental savings beyond the manufacturing phase.

Energy consumption metrics show that binder jetting processes require 25-30% less energy than conventional casting methods when producing complex geometries for heat exchange applications. This efficiency stems from the elimination of tooling requirements and the ability to create near-net-shape components that require minimal post-processing.

Carbon footprint calculations demonstrate that localized production through binder jetting can reduce transportation-related emissions by approximately 35% when components are manufactured closer to installation sites. This distributed manufacturing model proves especially valuable for remote energy installations where replacement parts traditionally require extensive logistics.

Material efficiency in binder jetting extends component lifespan through optimized designs that enhance corrosion resistance. Studies indicate that properly designed binder jetted corrosion barriers can extend component service life by 1.5-2 times compared to conventional alternatives, significantly reducing the environmental impact associated with frequent replacements.

End-of-life considerations reveal promising recyclability potential for binder jetted components. The precise material deposition allows for better material separation during recycling processes, with recovery rates reaching 85-90% for certain metal alloys used in energy applications. This circular economy approach substantially reduces the environmental burden associated with raw material extraction.

Water usage analysis shows that binder jetting processes consume approximately 60% less water than traditional manufacturing methods that require extensive cooling and cleaning operations. This water conservation aspect becomes increasingly important for energy installations in water-stressed regions.

The sustainability benefits extend to operational efficiency, where optimized internal geometries created through binder jetting can improve heat exchange efficiency by 15-20%, resulting in lower energy consumption throughout the component's operational life. These gains compound over time, representing significant environmental savings beyond the manufacturing phase.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!