How Binder Jetting Enhances Reliability With Real-Time Process Monitoring?

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Background and Objectives

Binder Jetting technology emerged in the early 1990s as one of the pioneering additive manufacturing (AM) processes, initially developed at the Massachusetts Institute of Technology. This powder-bed-based technology selectively deposits binding agents onto thin layers of powder materials, creating complex three-dimensional structures through a layer-by-layer approach. Over the past three decades, the technology has evolved from producing primarily conceptual prototypes to manufacturing functional end-use parts across various industries.

The evolution of Binder Jetting has been marked by significant improvements in material compatibility, dimensional accuracy, and production speed. Initially limited to ceramics and metals with relatively low density, modern systems can now process a wide range of materials including metals, ceramics, polymers, and composites with enhanced mechanical properties. This expansion in material versatility has been a critical factor in broadening the technology's application scope.

Recent technological trends in Binder Jetting focus on process reliability and repeatability, which are essential for industrial-scale production. The integration of real-time monitoring systems represents a paradigm shift from traditional quality control methods that relied heavily on post-production inspection. This transition aligns with Industry 4.0 principles, emphasizing smart manufacturing through data-driven process optimization.

The primary objective of implementing real-time process monitoring in Binder Jetting is to enhance production reliability by identifying and addressing process anomalies as they occur. This proactive approach aims to minimize defects, reduce material waste, and ultimately lower production costs while maintaining consistent part quality. Additionally, the continuous data collection enables the development of predictive models that can anticipate potential failures before they manifest.

Another critical goal is to establish closed-loop feedback systems that automatically adjust process parameters based on real-time observations. Such systems promise to compensate for variations in material properties, environmental conditions, and machine performance, thereby ensuring consistent output quality regardless of external factors. This capability is particularly valuable for industries with stringent quality requirements, such as aerospace, medical devices, and automotive components.

From a technological development perspective, the integration of advanced sensors, machine learning algorithms, and high-speed data processing capabilities represents the convergence of additive manufacturing with digital technologies. This convergence is expected to accelerate the industrialization of Binder Jetting by addressing key barriers to adoption, including concerns about process stability and part-to-part consistency.

Looking forward, the technology roadmap for Binder Jetting includes further refinement of monitoring systems to capture increasingly subtle process variations, development of standardized quality metrics specific to the technology, and establishment of certification protocols that leverage real-time data to validate part integrity.

The evolution of Binder Jetting has been marked by significant improvements in material compatibility, dimensional accuracy, and production speed. Initially limited to ceramics and metals with relatively low density, modern systems can now process a wide range of materials including metals, ceramics, polymers, and composites with enhanced mechanical properties. This expansion in material versatility has been a critical factor in broadening the technology's application scope.

Recent technological trends in Binder Jetting focus on process reliability and repeatability, which are essential for industrial-scale production. The integration of real-time monitoring systems represents a paradigm shift from traditional quality control methods that relied heavily on post-production inspection. This transition aligns with Industry 4.0 principles, emphasizing smart manufacturing through data-driven process optimization.

The primary objective of implementing real-time process monitoring in Binder Jetting is to enhance production reliability by identifying and addressing process anomalies as they occur. This proactive approach aims to minimize defects, reduce material waste, and ultimately lower production costs while maintaining consistent part quality. Additionally, the continuous data collection enables the development of predictive models that can anticipate potential failures before they manifest.

Another critical goal is to establish closed-loop feedback systems that automatically adjust process parameters based on real-time observations. Such systems promise to compensate for variations in material properties, environmental conditions, and machine performance, thereby ensuring consistent output quality regardless of external factors. This capability is particularly valuable for industries with stringent quality requirements, such as aerospace, medical devices, and automotive components.

From a technological development perspective, the integration of advanced sensors, machine learning algorithms, and high-speed data processing capabilities represents the convergence of additive manufacturing with digital technologies. This convergence is expected to accelerate the industrialization of Binder Jetting by addressing key barriers to adoption, including concerns about process stability and part-to-part consistency.

Looking forward, the technology roadmap for Binder Jetting includes further refinement of monitoring systems to capture increasingly subtle process variations, development of standardized quality metrics specific to the technology, and establishment of certification protocols that leverage real-time data to validate part integrity.

Market Demand Analysis for Reliable Additive Manufacturing

The additive manufacturing (AM) market is experiencing significant growth, with the global market value projected to reach $51 billion by 2030, representing a compound annual growth rate of approximately 20%. Within this expanding landscape, reliability has emerged as a critical factor driving adoption across industries. Manufacturing sectors including aerospace, automotive, medical devices, and industrial equipment are increasingly demanding AM solutions that can deliver consistent, high-quality parts with documented reliability.

Binder jetting technology with real-time process monitoring addresses several key market demands that traditional manufacturing and earlier AM technologies have struggled to fulfill. Primary among these is the need for repeatable quality in production environments. A recent industry survey revealed that 78% of potential industrial AM adopters cite quality consistency as their top concern when considering implementation.

The aerospace sector represents one of the most promising markets for reliable binder jetting technology. With stringent certification requirements and zero-tolerance for part failure, aerospace manufacturers require comprehensive process validation. The market for qualified AM parts in aerospace is growing at 25% annually, outpacing the overall AM market growth.

Similarly, the medical device industry demands manufacturing processes with exceptional reliability for implantable and patient-specific devices. The market for AM-produced medical devices is expected to grow from $1.1 billion in 2020 to $5.8 billion by 2027, with reliability-focused technologies capturing the largest share of this growth.

Real-time process monitoring capabilities align perfectly with the growing industrial trend toward smart manufacturing and Industry 4.0 integration. Manufacturing facilities are increasingly implementing digital twins and connected production systems, creating a natural environment for monitored binder jetting technology to thrive. The market for Industry 4.0-compatible AM systems is growing at 32% annually.

Cost considerations also drive market demand for reliable binder jetting. While traditional manufacturing processes may achieve reliability through extensive post-production testing and high scrap rates, this approach is economically unsustainable. Real-time monitored binder jetting reduces waste by identifying issues during production, addressing the market need for sustainable and cost-effective manufacturing solutions.

Geographically, North America currently represents the largest market for reliability-focused AM technologies (38% of global demand), followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate as manufacturing hubs in China, Japan, and South Korea increasingly adopt advanced AM technologies to maintain competitive advantages in global supply chains.

Binder jetting technology with real-time process monitoring addresses several key market demands that traditional manufacturing and earlier AM technologies have struggled to fulfill. Primary among these is the need for repeatable quality in production environments. A recent industry survey revealed that 78% of potential industrial AM adopters cite quality consistency as their top concern when considering implementation.

The aerospace sector represents one of the most promising markets for reliable binder jetting technology. With stringent certification requirements and zero-tolerance for part failure, aerospace manufacturers require comprehensive process validation. The market for qualified AM parts in aerospace is growing at 25% annually, outpacing the overall AM market growth.

Similarly, the medical device industry demands manufacturing processes with exceptional reliability for implantable and patient-specific devices. The market for AM-produced medical devices is expected to grow from $1.1 billion in 2020 to $5.8 billion by 2027, with reliability-focused technologies capturing the largest share of this growth.

Real-time process monitoring capabilities align perfectly with the growing industrial trend toward smart manufacturing and Industry 4.0 integration. Manufacturing facilities are increasingly implementing digital twins and connected production systems, creating a natural environment for monitored binder jetting technology to thrive. The market for Industry 4.0-compatible AM systems is growing at 32% annually.

Cost considerations also drive market demand for reliable binder jetting. While traditional manufacturing processes may achieve reliability through extensive post-production testing and high scrap rates, this approach is economically unsustainable. Real-time monitored binder jetting reduces waste by identifying issues during production, addressing the market need for sustainable and cost-effective manufacturing solutions.

Geographically, North America currently represents the largest market for reliability-focused AM technologies (38% of global demand), followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the fastest growth rate as manufacturing hubs in China, Japan, and South Korea increasingly adopt advanced AM technologies to maintain competitive advantages in global supply chains.

Current State and Challenges in Binder Jetting Monitoring

Binder jetting technology has evolved significantly over the past decade, with real-time process monitoring emerging as a critical component for ensuring reliability and quality in additive manufacturing. Currently, the global landscape of binder jetting monitoring systems demonstrates varying levels of sophistication, with leading industrial nations like the United States, Germany, and Japan spearheading advancements in this domain.

The state-of-the-art monitoring systems in binder jetting primarily focus on four key parameters: droplet formation, powder bed characteristics, binder-powder interaction, and layer consolidation. Advanced optical systems utilizing high-speed cameras can capture droplet ejection at rates exceeding 10,000 frames per second, allowing for real-time analysis of droplet volume, velocity, and trajectory. However, these systems often struggle with the dense printing environment, limiting visibility and data accuracy.

Powder bed monitoring technologies have incorporated thermal imaging and optical coherence tomography to assess powder distribution uniformity and layer thickness consistency. Despite these advances, current systems face significant challenges in detecting sub-surface anomalies and predicting potential failure points before they manifest in the final part.

A major technical hurdle remains in the integration of multi-modal sensing technologies. While individual sensors can monitor specific aspects of the process, comprehensive systems that synchronize data from multiple sensors and provide actionable insights in real-time are still in developmental stages. The computational demands for processing this multi-sensor data stream present substantial challenges, particularly for high-throughput production environments.

Material-specific monitoring also presents unique challenges. Different powder materials interact distinctively with binders, requiring calibrated monitoring approaches. Current systems lack the adaptability to automatically adjust monitoring parameters based on material properties, necessitating time-consuming manual calibration processes that impede production efficiency.

Data interpretation represents another significant bottleneck. The correlation between monitored parameters and final part quality remains partially understood, with many manufacturers relying on empirical testing rather than predictive models. Machine learning approaches show promise but require extensive training datasets that are not yet widely available across the industry.

Standardization issues further complicate the landscape. The absence of universally accepted monitoring protocols and quality metrics makes cross-platform comparisons difficult and hinders widespread adoption of monitoring technologies. Regulatory frameworks for validating monitoring systems in critical applications like aerospace and medical devices remain underdeveloped, creating uncertainty for manufacturers in these sectors.

Cost considerations also present barriers to implementation, particularly for small and medium enterprises. High-end monitoring systems can represent 15-30% of the total equipment cost, creating adoption challenges despite their potential for reducing waste and improving part quality.

The state-of-the-art monitoring systems in binder jetting primarily focus on four key parameters: droplet formation, powder bed characteristics, binder-powder interaction, and layer consolidation. Advanced optical systems utilizing high-speed cameras can capture droplet ejection at rates exceeding 10,000 frames per second, allowing for real-time analysis of droplet volume, velocity, and trajectory. However, these systems often struggle with the dense printing environment, limiting visibility and data accuracy.

Powder bed monitoring technologies have incorporated thermal imaging and optical coherence tomography to assess powder distribution uniformity and layer thickness consistency. Despite these advances, current systems face significant challenges in detecting sub-surface anomalies and predicting potential failure points before they manifest in the final part.

A major technical hurdle remains in the integration of multi-modal sensing technologies. While individual sensors can monitor specific aspects of the process, comprehensive systems that synchronize data from multiple sensors and provide actionable insights in real-time are still in developmental stages. The computational demands for processing this multi-sensor data stream present substantial challenges, particularly for high-throughput production environments.

Material-specific monitoring also presents unique challenges. Different powder materials interact distinctively with binders, requiring calibrated monitoring approaches. Current systems lack the adaptability to automatically adjust monitoring parameters based on material properties, necessitating time-consuming manual calibration processes that impede production efficiency.

Data interpretation represents another significant bottleneck. The correlation between monitored parameters and final part quality remains partially understood, with many manufacturers relying on empirical testing rather than predictive models. Machine learning approaches show promise but require extensive training datasets that are not yet widely available across the industry.

Standardization issues further complicate the landscape. The absence of universally accepted monitoring protocols and quality metrics makes cross-platform comparisons difficult and hinders widespread adoption of monitoring technologies. Regulatory frameworks for validating monitoring systems in critical applications like aerospace and medical devices remain underdeveloped, creating uncertainty for manufacturers in these sectors.

Cost considerations also present barriers to implementation, particularly for small and medium enterprises. High-end monitoring systems can represent 15-30% of the total equipment cost, creating adoption challenges despite their potential for reducing waste and improving part quality.

Real-Time Monitoring Solutions for Binder Jetting

01 Binder composition optimization for reliability

Optimizing binder compositions can significantly improve the reliability of binder jetting processes. This includes developing specialized formulations with enhanced rheological properties, improved adhesion characteristics, and controlled curing behavior. Advanced binders may incorporate additives that prevent nozzle clogging, ensure consistent droplet formation, and maintain stability during storage. These optimized compositions contribute to more uniform powder binding, reduced part defects, and improved overall process reliability.- Binder formulation optimization for reliability: The reliability of binder jetting processes can be significantly improved through optimization of binder formulations. This includes developing specialized binders with enhanced rheological properties, controlled viscosity, and improved surface tension characteristics. Advanced formulations may incorporate additives that prevent nozzle clogging and ensure consistent droplet formation. These optimized binders contribute to more uniform powder wetting, better green part strength, and ultimately more reliable printed components with consistent dimensional accuracy and mechanical properties.

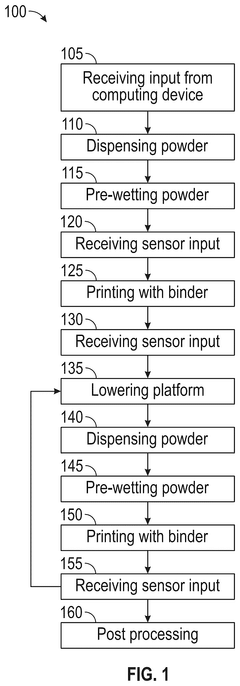

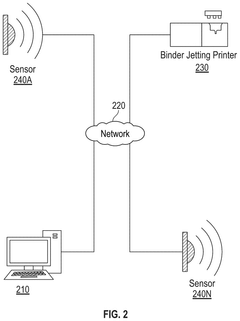

- Process parameter control systems: Automated control systems that monitor and adjust critical process parameters in real-time significantly enhance binder jetting reliability. These systems utilize sensors and feedback mechanisms to maintain optimal printing conditions by regulating parameters such as binder saturation levels, spreading uniformity, layer thickness, and environmental conditions within the build chamber. Advanced algorithms can detect anomalies during printing and make immediate adjustments to prevent defects, ensuring consistent part quality across production runs and reducing variability between builds.

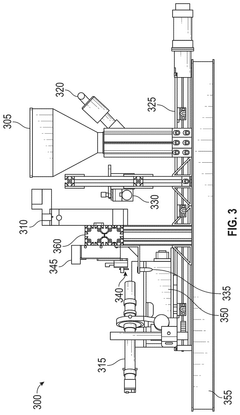

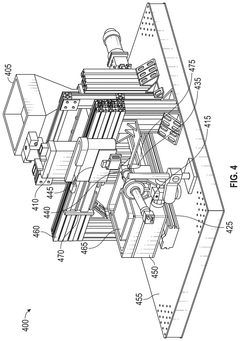

- Powder characteristics and spreading mechanisms: The reliability of binder jetting processes is heavily influenced by powder characteristics and spreading mechanisms. Optimized powder properties including particle size distribution, flowability, packing density, and surface morphology are essential for consistent layer formation. Advanced spreading mechanisms that ensure uniform powder bed density without compaction or disturbance of previous layers contribute significantly to print reliability. Innovations in recoater designs and powder handling systems help minimize variations in powder bed characteristics that could lead to defects in the final parts.

- Post-processing techniques for enhanced reliability: Specialized post-processing techniques have been developed to enhance the reliability of binder jetted parts. These include optimized curing protocols, controlled drying processes, and advanced sintering profiles that minimize distortion and maximize density. Infiltration methods that improve mechanical properties while maintaining dimensional accuracy are also critical. These post-processing approaches address the inherent challenges of green part handling and conversion to final parts, ensuring consistent results even with variations in the initial printing process.

- In-process monitoring and quality control: Advanced in-process monitoring systems significantly improve binder jetting reliability by enabling real-time quality control. These systems utilize various sensing technologies including optical cameras, thermal sensors, and layer imaging to detect defects as they occur. Machine learning algorithms analyze the collected data to identify patterns and predict potential failures before they happen. This approach allows for immediate corrective actions during the build process, reducing waste and ensuring consistent part quality across production runs.

02 Process parameter control and monitoring systems

Implementing sophisticated control and monitoring systems for binder jetting parameters enhances process reliability. These systems continuously track critical variables such as printhead temperature, binder viscosity, droplet volume, and powder bed characteristics. Real-time feedback mechanisms allow for automatic adjustments to maintain optimal printing conditions. Advanced monitoring technologies may include optical systems for layer inspection, thermal sensors for curing verification, and predictive algorithms that anticipate potential failures before they occur, resulting in more consistent part quality.Expand Specific Solutions03 Powder characteristics and handling improvements

The reliability of binder jetting processes is significantly influenced by powder characteristics and handling methods. Innovations in this area include developing powders with optimized particle size distribution, flowability, and packing density. Advanced powder handling systems incorporate humidity control, electrostatic discharge prevention, and precise recoating mechanisms. Specialized treatments for powders can improve their interaction with binders, resulting in more uniform layer formation, reduced porosity, and enhanced mechanical properties of the final parts.Expand Specific Solutions04 Post-processing techniques for enhanced reliability

Advanced post-processing techniques play a crucial role in ensuring the reliability of binder jetted parts. These include optimized curing protocols, controlled sintering processes, and infiltration methods that enhance mechanical properties. Novel approaches to remove residual binders without causing deformation or cracking have been developed. Post-processing treatments can also address surface finish issues, dimensional accuracy, and internal defects, resulting in more consistent and reliable final products with improved performance characteristics.Expand Specific Solutions05 Quality assurance and defect detection systems

Implementing comprehensive quality assurance and defect detection systems significantly improves binder jetting reliability. These systems incorporate in-process monitoring tools such as high-resolution cameras, layer-by-layer inspection algorithms, and non-destructive testing methods. Advanced techniques include machine learning approaches for identifying patterns associated with potential defects, predictive maintenance systems for equipment, and closed-loop feedback mechanisms that automatically adjust process parameters based on detected anomalies. These systems ensure consistent part quality and reduce rejection rates.Expand Specific Solutions

Leading Companies in Binder Jetting Technology Ecosystem

Binder Jetting technology with real-time process monitoring is currently in a growth phase, with the market expected to expand significantly as additive manufacturing adoption increases. The global market for this technology is projected to reach several billion dollars by 2028, driven by increasing demand for reliable, high-volume production parts. Desktop Metal leads technological innovation with advanced monitoring systems that enhance part quality and reproducibility, while HP Development and ExOne (now part of Desktop Metal) have developed proprietary monitoring solutions for industrial applications. Academic institutions like Brigham Young University and South China University of Technology are contributing fundamental research on process parameters and monitoring algorithms. The technology is approaching maturity for certain applications but continues to evolve with companies like Nordson and General Electric investing in sensor integration and data analytics capabilities to further improve reliability.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed an advanced binder jetting platform called Production System™ that incorporates comprehensive real-time process monitoring capabilities. Their system utilizes a network of sensors and high-speed cameras that continuously monitor critical parameters including powder spreading uniformity, binder droplet formation, layer thickness, and thermal conditions. The company's Single Pass Jetting™ technology integrates these monitoring systems with automated feedback loops that can make real-time adjustments to printing parameters when deviations are detected. Desktop Metal's monitoring system captures over 800 data points per second across multiple process variables, enabling detailed part traceability and quality documentation. Their Live Sinter™ simulation software works in conjunction with the monitoring system to predict and compensate for sintering deformations before they occur, significantly enhancing final part reliability.

Strengths: Industry-leading print speeds (up to 12,000 cm³/hr) while maintaining comprehensive monitoring; closed-loop feedback system enables automatic parameter adjustments; extensive data collection supports advanced analytics and part certification. Weaknesses: Higher initial investment cost compared to conventional systems; complex monitoring systems require specialized technical knowledge for maintenance and optimization.

HP Development Co. LP

Technical Solution: HP's Multi Jet Fusion technology, while primarily known as a powder bed fusion process, incorporates binder jetting principles with advanced real-time monitoring capabilities. Their system employs a multi-agent printing process where a detailing agent and fusing agent are selectively deposited, followed by energy application. HP's real-time monitoring system utilizes thermal imaging cameras that capture layer-by-layer thermal profiles with micrometer precision. Their proprietary voxel-level control technology enables monitoring and control at the individual voxel scale (21 microns), allowing for unprecedented quality control. The system incorporates machine learning algorithms that analyze thermal signature patterns to detect anomalies and predict potential defects before they manifest in the final part. HP's monitoring technology includes automated calibration systems that continuously verify printer performance and material consistency, ensuring reliability across production runs.

Strengths: Exceptional resolution in monitoring (voxel-level precision); integrated machine learning capabilities for predictive quality control; comprehensive thermal mapping provides detailed insight into fusion process. Weaknesses: System complexity requires significant technical expertise; primarily optimized for HP's own materials ecosystem; higher energy consumption compared to some competing technologies.

Key Sensor Technologies and Data Analytics Innovations

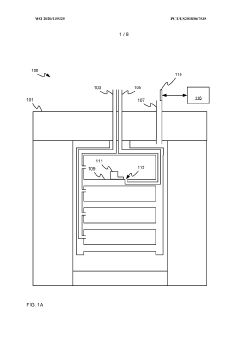

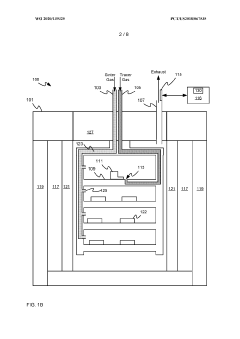

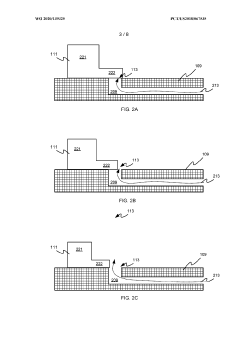

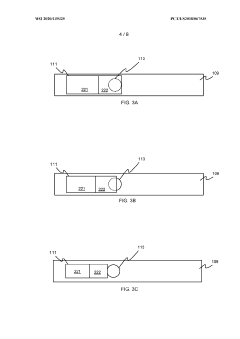

Tracer gas endpoint-monitored sinter systems

PatentWO2020139325A1

Innovation

- A sinter system incorporating a tracer gas inlet and detector to monitor the sinter process endpoint, where a sample green object changes shape relative to an opening, modifying the tracer gas flow, allowing the controller to determine when to stop the process based on tracer gas concentration or amount, thereby accurately controlling sinter cycle times.

Method for improving absorption of droplets on powder

PatentPendingUS20250074005A1

Innovation

- A method and system that improve the absorption of droplets on powder by using a combination of pre-wetting techniques, precise binder deposition, and real-time sensor feedback to optimize the interaction between binder and powder, thereby enhancing the mechanical properties and printability of binder jetting parts.

Material Compatibility and Process Parameter Optimization

Material compatibility represents a critical factor in binder jetting technology's reliability when enhanced with real-time process monitoring. The interaction between powdered materials and binding agents significantly influences print quality, structural integrity, and final part performance. Current research indicates that metal powders (including stainless steel, titanium alloys, and copper) demonstrate varying degrees of compatibility with different binder formulations, necessitating specific parameter adjustments for optimal results.

Process parameter optimization becomes increasingly sophisticated when integrated with real-time monitoring systems. The key parameters requiring precise calibration include binder saturation levels (typically ranging from 60-120% depending on material), layer thickness (20-100 microns), drying time between layers (3-15 seconds), and print head speed (200-600 mm/s). These parameters must be dynamically adjusted based on feedback from monitoring systems to maintain consistent quality.

Advanced monitoring technologies enable the development of material-specific parameter libraries that can automatically adjust settings based on environmental conditions and material batch variations. For instance, humidity fluctuations of merely 5% can necessitate binder saturation adjustments of up to 15% to maintain dimensional accuracy in final parts. This adaptive approach represents a significant advancement over traditional fixed-parameter methodologies.

Material-specific challenges require tailored monitoring approaches. Highly reactive metal powders demand oxygen level monitoring and parameter adjustments to prevent oxidation during processing. Meanwhile, ceramic materials often require modified binder formulations with higher viscosity ranges (15-25 cP) and adjusted droplet spacing to accommodate their unique absorption characteristics.

The correlation between material properties and optimal process parameters has been systematically documented through extensive testing. Research indicates that particle size distribution significantly impacts powder bed density, with D50 values between 15-45 μm generally yielding optimal results for most metal applications. Real-time monitoring of powder bed density variations allows for immediate adjustment of binder delivery rates, maintaining consistent part quality despite material inconsistencies.

Temperature gradient monitoring during the printing process has emerged as a crucial factor in parameter optimization. Thermal sensors integrated into modern binder jetting systems can detect localized temperature variations as small as 0.5°C, triggering compensatory adjustments in drying parameters to prevent warping or cracking in sensitive materials. This capability is particularly valuable when processing temperature-sensitive alloys or composites with varying thermal expansion coefficients.

Process parameter optimization becomes increasingly sophisticated when integrated with real-time monitoring systems. The key parameters requiring precise calibration include binder saturation levels (typically ranging from 60-120% depending on material), layer thickness (20-100 microns), drying time between layers (3-15 seconds), and print head speed (200-600 mm/s). These parameters must be dynamically adjusted based on feedback from monitoring systems to maintain consistent quality.

Advanced monitoring technologies enable the development of material-specific parameter libraries that can automatically adjust settings based on environmental conditions and material batch variations. For instance, humidity fluctuations of merely 5% can necessitate binder saturation adjustments of up to 15% to maintain dimensional accuracy in final parts. This adaptive approach represents a significant advancement over traditional fixed-parameter methodologies.

Material-specific challenges require tailored monitoring approaches. Highly reactive metal powders demand oxygen level monitoring and parameter adjustments to prevent oxidation during processing. Meanwhile, ceramic materials often require modified binder formulations with higher viscosity ranges (15-25 cP) and adjusted droplet spacing to accommodate their unique absorption characteristics.

The correlation between material properties and optimal process parameters has been systematically documented through extensive testing. Research indicates that particle size distribution significantly impacts powder bed density, with D50 values between 15-45 μm generally yielding optimal results for most metal applications. Real-time monitoring of powder bed density variations allows for immediate adjustment of binder delivery rates, maintaining consistent part quality despite material inconsistencies.

Temperature gradient monitoring during the printing process has emerged as a crucial factor in parameter optimization. Thermal sensors integrated into modern binder jetting systems can detect localized temperature variations as small as 0.5°C, triggering compensatory adjustments in drying parameters to prevent warping or cracking in sensitive materials. This capability is particularly valuable when processing temperature-sensitive alloys or composites with varying thermal expansion coefficients.

Industry Standards and Certification Requirements

The additive manufacturing industry has established several standards and certification frameworks to ensure the quality, safety, and reliability of binder jetting processes. ASTM International's Committee F42 on Additive Manufacturing Technologies has developed key standards specifically addressing binder jetting processes, including ASTM F3301 for terminology and ASTM F3374 for process qualification. These standards provide essential guidelines for manufacturers implementing real-time monitoring systems in their binder jetting operations.

ISO/TC 261 complements these efforts with standards such as ISO/ASTM 52901:2021, which outlines requirements for purchased AM parts, and ISO/ASTM 52904:2019, which specifies process characteristics and performance metrics. For binder jetting systems incorporating real-time monitoring capabilities, compliance with these standards is crucial for market acceptance and regulatory approval.

The National Institute of Standards and Technology (NIST) has established measurement science standards specifically for in-process monitoring of additive manufacturing, providing reference methodologies for calibrating sensors and validating monitoring systems. These standards ensure that real-time data collected during binder jetting processes can be reliably interpreted and compared across different manufacturing environments.

Industry-specific certification requirements vary by application sector. In aerospace, the AS9100 quality management system incorporates specific provisions for additive manufacturing processes, including requirements for process monitoring and validation. Similarly, medical device manufacturers utilizing binder jetting must comply with FDA regulations and ISO 13485, which mandate comprehensive process validation and monitoring protocols.

The UL 3400 certification specifically addresses safety considerations for additive manufacturing facilities, including requirements for monitoring systems that detect process anomalies and prevent hazardous conditions. This certification is increasingly important for manufacturers implementing binder jetting in production environments.

Material-specific standards are also emerging, with organizations like MMPDS (Metallic Materials Properties Development and Standardization) developing guidelines for qualifying metal powders used in binder jetting processes. These standards often specify requirements for real-time monitoring of material properties and process parameters to ensure consistent part quality.

Certification bodies like TÜV SÜD and DNV GL have developed specialized programs for additive manufacturing qualification, which include assessment of monitoring capabilities and data management systems. These certifications provide third-party validation of a manufacturer's ability to consistently produce reliable parts using binder jetting technology with appropriate process controls.

ISO/TC 261 complements these efforts with standards such as ISO/ASTM 52901:2021, which outlines requirements for purchased AM parts, and ISO/ASTM 52904:2019, which specifies process characteristics and performance metrics. For binder jetting systems incorporating real-time monitoring capabilities, compliance with these standards is crucial for market acceptance and regulatory approval.

The National Institute of Standards and Technology (NIST) has established measurement science standards specifically for in-process monitoring of additive manufacturing, providing reference methodologies for calibrating sensors and validating monitoring systems. These standards ensure that real-time data collected during binder jetting processes can be reliably interpreted and compared across different manufacturing environments.

Industry-specific certification requirements vary by application sector. In aerospace, the AS9100 quality management system incorporates specific provisions for additive manufacturing processes, including requirements for process monitoring and validation. Similarly, medical device manufacturers utilizing binder jetting must comply with FDA regulations and ISO 13485, which mandate comprehensive process validation and monitoring protocols.

The UL 3400 certification specifically addresses safety considerations for additive manufacturing facilities, including requirements for monitoring systems that detect process anomalies and prevent hazardous conditions. This certification is increasingly important for manufacturers implementing binder jetting in production environments.

Material-specific standards are also emerging, with organizations like MMPDS (Metallic Materials Properties Development and Standardization) developing guidelines for qualifying metal powders used in binder jetting processes. These standards often specify requirements for real-time monitoring of material properties and process parameters to ensure consistent part quality.

Certification bodies like TÜV SÜD and DNV GL have developed specialized programs for additive manufacturing qualification, which include assessment of monitoring capabilities and data management systems. These certifications provide third-party validation of a manufacturer's ability to consistently produce reliable parts using binder jetting technology with appropriate process controls.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!