Binder Jetting Porosity Distribution And Its Effect On Fatigue And Leak-Tightness

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Porosity Background and Objectives

Binder Jetting (BJ) technology has emerged as a significant additive manufacturing process since its inception in the early 1990s at MIT. This powder bed-based technique selectively deposits a liquid binding agent onto powder particles, creating complex geometries layer by layer without the need for high-energy sources like lasers or electron beams. The technology has evolved from primarily producing prototypes and casting patterns to manufacturing functional metal components across aerospace, automotive, and medical industries.

The inherent nature of the BJ process introduces porosity into manufactured parts, which has historically been viewed as a limitation. However, recent research has shifted toward understanding porosity distribution patterns and their predictability, recognizing that controlled porosity can be advantageous for specific applications such as filters or lightweight structures. The evolution of BJ technology has seen significant improvements in resolution, material compatibility, and process control, yet porosity management remains a critical challenge.

Current market trends indicate growing adoption of BJ for metal parts production, with a compound annual growth rate exceeding 20% in the industrial manufacturing sector. This growth is driving increased attention to the relationship between porosity characteristics and mechanical performance, particularly fatigue resistance and leak-tightness properties that are essential for functional components.

The scientific understanding of porosity in BJ has progressed from basic characterization to sophisticated modeling of pore formation mechanisms. Research has revealed that porosity distribution is influenced by multiple factors including powder characteristics, binder properties, printing parameters, and post-processing conditions. These interactions create complex patterns that significantly impact mechanical behavior and fluid permeability of the final parts.

This technical research aims to comprehensively investigate the relationship between BJ process parameters and resultant porosity distributions, with particular focus on how these distributions affect fatigue performance and leak-tightness properties. The primary objectives include: developing predictive models for porosity formation based on process parameters; establishing correlations between porosity characteristics (size, distribution, morphology) and mechanical failure modes; and formulating strategies to optimize porosity profiles for specific performance requirements.

Additionally, this research seeks to establish standardized methodologies for porosity characterization in BJ components, addressing the current lack of industry-wide metrics. By advancing the fundamental understanding of these relationships, we aim to enable more precise control over component properties, expanding the application range of BJ technology into more demanding sectors requiring high reliability and performance predictability.

The inherent nature of the BJ process introduces porosity into manufactured parts, which has historically been viewed as a limitation. However, recent research has shifted toward understanding porosity distribution patterns and their predictability, recognizing that controlled porosity can be advantageous for specific applications such as filters or lightweight structures. The evolution of BJ technology has seen significant improvements in resolution, material compatibility, and process control, yet porosity management remains a critical challenge.

Current market trends indicate growing adoption of BJ for metal parts production, with a compound annual growth rate exceeding 20% in the industrial manufacturing sector. This growth is driving increased attention to the relationship between porosity characteristics and mechanical performance, particularly fatigue resistance and leak-tightness properties that are essential for functional components.

The scientific understanding of porosity in BJ has progressed from basic characterization to sophisticated modeling of pore formation mechanisms. Research has revealed that porosity distribution is influenced by multiple factors including powder characteristics, binder properties, printing parameters, and post-processing conditions. These interactions create complex patterns that significantly impact mechanical behavior and fluid permeability of the final parts.

This technical research aims to comprehensively investigate the relationship between BJ process parameters and resultant porosity distributions, with particular focus on how these distributions affect fatigue performance and leak-tightness properties. The primary objectives include: developing predictive models for porosity formation based on process parameters; establishing correlations between porosity characteristics (size, distribution, morphology) and mechanical failure modes; and formulating strategies to optimize porosity profiles for specific performance requirements.

Additionally, this research seeks to establish standardized methodologies for porosity characterization in BJ components, addressing the current lack of industry-wide metrics. By advancing the fundamental understanding of these relationships, we aim to enable more precise control over component properties, expanding the application range of BJ technology into more demanding sectors requiring high reliability and performance predictability.

Market Analysis for Binder Jetting Applications

The global market for binder jetting technology has experienced significant growth in recent years, with an estimated market value reaching $1.3 billion in 2022 and projected to grow at a CAGR of 21.5% through 2028. This growth is primarily driven by increasing adoption across aerospace, automotive, medical, and industrial sectors where complex geometries and internal features are required.

The aerospace industry represents the largest application segment for binder jetting, accounting for approximately 32% of the total market share. This dominance stems from the technology's ability to produce lightweight components with complex internal structures that enhance fuel efficiency while maintaining structural integrity. However, concerns regarding porosity distribution and its impact on fatigue life and leak-tightness remain significant barriers to wider adoption in critical applications.

Automotive manufacturers have begun integrating binder jetted components into production vehicles, particularly for non-structural components and fluid management systems. The market penetration in this sector has grown by 27% annually since 2019, though applications remain limited to parts where porosity-related issues do not compromise safety or performance. The potential market expansion hinges on technological advancements that address current porosity control limitations.

The medical device industry represents the fastest-growing application segment with 29% annual growth, particularly for customized implants and surgical instruments. However, regulatory concerns regarding material porosity and its effect on biocompatibility and mechanical performance have restricted widespread implementation in permanent implants.

Industrial equipment manufacturers have embraced binder jetting for tooling applications, where the technology's cost advantages outweigh concerns about porosity-related performance limitations. This segment accounts for approximately 24% of the current market.

Regional analysis indicates North America leads the market with 41% share, followed by Europe (32%) and Asia-Pacific (21%). China has demonstrated the most aggressive growth trajectory, with domestic binder jetting installations increasing by 35% annually since 2020.

Market forecasts suggest that technological advancements specifically addressing porosity distribution control could unlock an additional $2.7 billion market opportunity by 2030, particularly in high-value applications requiring pressure-tight components or those subject to cyclic loading. Industries most likely to benefit from these advancements include aerospace propulsion systems, automotive fluid handling components, and medical implant technologies.

Consumer demand increasingly favors sustainable manufacturing methods, positioning binder jetting favorably against traditional subtractive manufacturing due to its material efficiency and reduced waste generation. This trend is expected to drive further market expansion as porosity-related technical challenges are overcome.

The aerospace industry represents the largest application segment for binder jetting, accounting for approximately 32% of the total market share. This dominance stems from the technology's ability to produce lightweight components with complex internal structures that enhance fuel efficiency while maintaining structural integrity. However, concerns regarding porosity distribution and its impact on fatigue life and leak-tightness remain significant barriers to wider adoption in critical applications.

Automotive manufacturers have begun integrating binder jetted components into production vehicles, particularly for non-structural components and fluid management systems. The market penetration in this sector has grown by 27% annually since 2019, though applications remain limited to parts where porosity-related issues do not compromise safety or performance. The potential market expansion hinges on technological advancements that address current porosity control limitations.

The medical device industry represents the fastest-growing application segment with 29% annual growth, particularly for customized implants and surgical instruments. However, regulatory concerns regarding material porosity and its effect on biocompatibility and mechanical performance have restricted widespread implementation in permanent implants.

Industrial equipment manufacturers have embraced binder jetting for tooling applications, where the technology's cost advantages outweigh concerns about porosity-related performance limitations. This segment accounts for approximately 24% of the current market.

Regional analysis indicates North America leads the market with 41% share, followed by Europe (32%) and Asia-Pacific (21%). China has demonstrated the most aggressive growth trajectory, with domestic binder jetting installations increasing by 35% annually since 2020.

Market forecasts suggest that technological advancements specifically addressing porosity distribution control could unlock an additional $2.7 billion market opportunity by 2030, particularly in high-value applications requiring pressure-tight components or those subject to cyclic loading. Industries most likely to benefit from these advancements include aerospace propulsion systems, automotive fluid handling components, and medical implant technologies.

Consumer demand increasingly favors sustainable manufacturing methods, positioning binder jetting favorably against traditional subtractive manufacturing due to its material efficiency and reduced waste generation. This trend is expected to drive further market expansion as porosity-related technical challenges are overcome.

Current Challenges in Porosity Control

Despite significant advancements in binder jetting technology, controlling porosity distribution remains one of the most challenging aspects of the process. The inherent nature of binder jetting, which involves selective deposition of a liquid binding agent onto powder particles, creates unavoidable porosity in the final parts. This porosity varies significantly across different regions of the printed component, leading to inconsistent mechanical properties and performance characteristics.

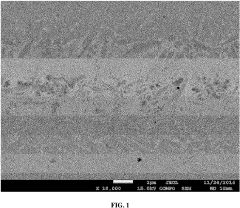

The primary challenge lies in the unpredictable distribution of pores throughout the printed structure. Current research indicates that porosity tends to concentrate at layer interfaces and in regions with complex geometries, creating potential failure points under cyclic loading conditions. These non-uniform porosity distributions significantly impact fatigue life, with studies showing up to 40% reduction in fatigue strength compared to conventionally manufactured counterparts.

For applications requiring leak-tightness, such as fluid containment systems or pressure vessels, the interconnected nature of pores presents a critical challenge. Even when overall porosity is reduced to acceptable levels (typically below 3-5%), the presence of connected pore networks can still create leak paths that compromise the functional integrity of components. Current post-processing techniques, including infiltration and hot isostatic pressing, have shown limited success in completely eliminating these interconnected pore networks.

Another significant challenge is the trade-off between printing speed and porosity control. Higher printing speeds, which are desirable for production efficiency, often result in inadequate powder bed saturation and increased porosity. Conversely, slower printing speeds with higher binder saturation can lead to dimensional inaccuracies and surface defects due to excessive binder migration.

The relationship between process parameters and resultant porosity remains incompletely understood. Variables such as powder characteristics (particle size distribution, morphology, and packing density), binder properties (viscosity, surface tension), and process settings (layer thickness, print head speed) interact in complex ways that current predictive models cannot fully capture. This makes it difficult to establish reliable process windows for achieving target porosity levels.

Material-specific challenges further complicate porosity control. Different materials exhibit varying wetting behaviors, sintering characteristics, and thermal expansion properties, all of which influence pore formation and distribution. For instance, high-temperature alloys commonly show different porosity patterns compared to stainless steels when processed under similar conditions, necessitating material-specific process optimization.

The primary challenge lies in the unpredictable distribution of pores throughout the printed structure. Current research indicates that porosity tends to concentrate at layer interfaces and in regions with complex geometries, creating potential failure points under cyclic loading conditions. These non-uniform porosity distributions significantly impact fatigue life, with studies showing up to 40% reduction in fatigue strength compared to conventionally manufactured counterparts.

For applications requiring leak-tightness, such as fluid containment systems or pressure vessels, the interconnected nature of pores presents a critical challenge. Even when overall porosity is reduced to acceptable levels (typically below 3-5%), the presence of connected pore networks can still create leak paths that compromise the functional integrity of components. Current post-processing techniques, including infiltration and hot isostatic pressing, have shown limited success in completely eliminating these interconnected pore networks.

Another significant challenge is the trade-off between printing speed and porosity control. Higher printing speeds, which are desirable for production efficiency, often result in inadequate powder bed saturation and increased porosity. Conversely, slower printing speeds with higher binder saturation can lead to dimensional inaccuracies and surface defects due to excessive binder migration.

The relationship between process parameters and resultant porosity remains incompletely understood. Variables such as powder characteristics (particle size distribution, morphology, and packing density), binder properties (viscosity, surface tension), and process settings (layer thickness, print head speed) interact in complex ways that current predictive models cannot fully capture. This makes it difficult to establish reliable process windows for achieving target porosity levels.

Material-specific challenges further complicate porosity control. Different materials exhibit varying wetting behaviors, sintering characteristics, and thermal expansion properties, all of which influence pore formation and distribution. For instance, high-temperature alloys commonly show different porosity patterns compared to stainless steels when processed under similar conditions, necessitating material-specific process optimization.

Existing Porosity Mitigation Strategies

01 Porosity control in binder jetting processes

Controlling porosity distribution in binder jetting additive manufacturing is crucial for producing parts with desired mechanical properties. Various techniques can be employed to manipulate and control porosity, including adjusting binder saturation levels, powder particle size distribution, and post-processing treatments. These methods help achieve specific porosity gradients or uniform porosity distribution throughout the printed part, which directly impacts the structural integrity and performance characteristics of the final component.- Porosity control in binder jetting processes: Controlling porosity distribution in binder jetting additive manufacturing is crucial for producing parts with desired mechanical properties. Various techniques can be employed to manipulate and control porosity, including adjusting binder saturation levels, powder particle size distribution, and post-processing treatments. These methods help achieve specific porosity distributions that can be tailored for different applications, balancing strength requirements with weight considerations.

- Fatigue resistance enhancement in binder jetted components: Improving fatigue resistance in components manufactured through binder jetting involves several approaches. These include thermal treatments to reduce internal stresses, infiltration techniques to fill pores with secondary materials, and surface treatments to minimize crack initiation sites. The relationship between porosity distribution and fatigue performance is particularly important, as controlled porosity can sometimes be beneficial for crack propagation resistance while maintaining structural integrity under cyclic loading conditions.

- Leak-tightness solutions for binder jetted parts: Achieving leak-tightness in binder jetted components is essential for fluid-handling applications. Various sealing methods can be applied, including impregnation with polymers or metals, surface densification techniques, and specialized post-processing treatments. These approaches aim to close interconnected pores that would otherwise create leak paths. The balance between maintaining desired mechanical properties while ensuring fluid impermeability presents a significant challenge in binder jetting technology.

- Post-processing techniques for porosity modification: Post-processing treatments play a crucial role in modifying the porosity distribution of binder jetted parts. These include sintering at various temperatures and durations, hot isostatic pressing, infiltration with secondary materials, and surface treatments. Each technique offers different advantages in terms of porosity reduction, strength enhancement, and dimensional control. The selection of appropriate post-processing methods depends on the specific requirements of the final component and its intended application.

- Testing and characterization methods for porosity and leak-tightness: Various testing and characterization techniques are employed to evaluate porosity distribution, fatigue performance, and leak-tightness of binder jetted components. These include computed tomography scanning, mercury intrusion porosimetry, pressure decay testing, and cyclic loading tests. Advanced imaging and analytical methods help in understanding the relationship between manufacturing parameters, resulting microstructure, and component performance. These testing approaches are essential for quality control and process optimization in binder jetting manufacturing.

02 Fatigue resistance enhancement in binder jetted components

Improving fatigue resistance in components manufactured through binder jetting involves several strategies. These include optimizing the sintering process to strengthen particle bonds, applying infiltration techniques to fill voids, and implementing heat treatments to relieve internal stresses. The relationship between porosity distribution and fatigue performance is particularly important, as controlled porosity can be used to create components with enhanced fatigue life by managing stress distribution and crack propagation pathways.Expand Specific Solutions03 Leak-tightness solutions for binder jetted parts

Achieving leak-tightness in binder jetted components presents unique challenges due to inherent porosity. Various approaches can be implemented to enhance the hermetic properties of these parts, including post-processing sealing treatments, infiltration with secondary materials like polymers or metals, and surface treatments that close surface-connected pores. These techniques are essential for applications requiring pressure containment or fluid handling, where even microscopic leakage paths can lead to functional failure.Expand Specific Solutions04 Post-processing techniques to modify porosity characteristics

Post-processing methods play a critical role in modifying the porosity characteristics of binder jetted parts. Techniques such as hot isostatic pressing, infiltration with secondary materials, and various sintering protocols can significantly alter the porosity distribution. These processes can be tailored to either reduce overall porosity for improved mechanical properties or to create specific porosity gradients for functional applications. The selection of appropriate post-processing techniques depends on the desired final properties and application requirements of the component.Expand Specific Solutions05 Testing and characterization methods for porosity and leak-tightness

Accurate testing and characterization of porosity distribution and leak-tightness in binder jetted components is essential for quality control and performance prediction. Various methods are employed, including computed tomography scanning for non-destructive 3D porosity mapping, mercury intrusion porosimetry for pore size distribution analysis, and pressure decay testing for leak detection. These techniques provide critical data on the relationship between manufacturing parameters, resulting porosity characteristics, and functional performance metrics such as fatigue resistance and hermetic sealing capabilities.Expand Specific Solutions

Leading Companies and Research Institutions

The binder jetting porosity distribution market is currently in a growth phase, with increasing adoption across aerospace, automotive, and industrial sectors. The market size is estimated to reach $2-3 billion by 2025, driven by demand for complex metal parts with controlled porosity. Technologically, the field is advancing rapidly but still maturing, with companies at different development stages. Leading players include Desktop Metal, which has pioneered accessible binder jetting solutions, Robert Bosch GmbH leveraging the technology for automotive applications, and Airbus Operations GmbH exploring aerospace implementations. Other significant contributors include Michelin Recherche et Technique SA, Sandvik Manufacturing & Machining Solutions, and HP Development Co., which are advancing fatigue resistance and leak-tightness solutions critical for industrial applications.

HP Development Co. LP

Technical Solution: HP has developed Multi Jet Fusion technology that, while not traditional binder jetting, addresses similar porosity challenges through their proprietary Multi Jet Fusion (MJF) process. Their approach combines a detailing agent with the binding agent to precisely control fusion at the voxel level, resulting in more consistent density distribution throughout parts. HP's systems utilize thermal management technologies that maintain optimal temperature profiles during printing to prevent uneven porosity formation. Their latest research has focused on developing specialized algorithms that predict potential porosity clusters based on part geometry and adaptively modify printing parameters to mitigate these issues. HP has also introduced advanced post-processing techniques that specifically target leak-tightness improvement through controlled infiltration of secondary materials into the residual porous network, effectively sealing potential leak paths while maintaining mechanical integrity.

Strengths: Superior thermal management during printing results in more consistent material properties and reduced porosity variation. Their predictive algorithms provide preventative porosity control. Weaknesses: Limited material compatibility compared to some dedicated binder jetting systems, and their solutions are primarily optimized for polymer-based applications rather than metals.

Safran Ceramics SA

Technical Solution: Safran Ceramics has developed specialized binder jetting techniques for ceramic components that address the unique porosity challenges in high-temperature applications. Their approach utilizes gradient binder saturation profiles that are precisely tailored to component geometry and anticipated stress distributions, resulting in controlled porosity gradients that enhance both mechanical performance and thermal shock resistance. Safran has pioneered multi-material binder jetting processes that strategically combine different ceramic formulations within a single component to create engineered porosity transitions that mitigate crack propagation and enhance fatigue resistance. Their research has established quantitative relationships between specific porosity characteristics (size, distribution, interconnectivity) and leak-tightness in high-pressure gas applications, enabling predictive design for hermetic components. Safran's latest innovation involves specialized infiltration techniques that selectively target and seal porosity networks in critical regions while maintaining beneficial porosity in non-critical areas, optimizing both weight and performance.

Strengths: Unparalleled expertise in high-temperature ceramic applications with specialized knowledge of how porosity affects thermal-mechanical performance. Their multi-material approach offers unique capabilities for engineered porosity gradients. Weaknesses: Their solutions are primarily optimized for aerospace and defense applications, potentially limiting applicability in consumer or general industrial contexts. The specialized ceramic formulations often require extremely high sintering temperatures, increasing energy costs.

Critical Patents in Porosity Distribution Management

Infiltrated ferrous materials

PatentInactiveUS20230249250A1

Innovation

- A layer-by-layer construction method using iron-based alloys with spherical powders and infiltration with a suitable liquid phase to form a strong, wear-resistant metallic structure that is stable at high temperatures, eliminating the need for thermal hardening processes like quenching and tempering.

Spray-dried soft-phase emulsion polymer for filling the gussets in bead polymer layers in a binder jetting method

PatentActiveEP3442783A1

Innovation

- A method involving a powder bed with a mixture of polymer particles and spray-dried or precipitated coagulated emulsion polymers, which increases bulk density and improves binder distribution, allowing for higher mechanical stability and reduced porosity by filling gaps between particles.

Material-Process Interaction Effects

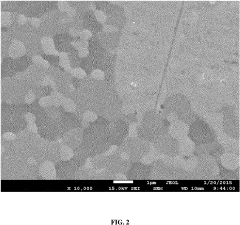

The interaction between material properties and binder jetting process parameters creates a complex relationship that significantly influences porosity distribution patterns. Materials with different particle size distributions, morphologies, and chemical compositions respond uniquely to binder saturation levels, drying rates, and sintering protocols. Fine powders typically result in higher green part density but may cause spreading challenges, while coarser powders improve flowability at the expense of increased inter-particle voids.

Powder characteristics such as wettability directly impact binder-powder interactions, determining how effectively the binder penetrates the powder bed. Hydrophilic materials facilitate better binder spread but may require adjusted saturation levels to prevent excessive bleeding, whereas hydrophobic materials might need specialized binders or surface treatments to achieve adequate adhesion between layers.

The thermal properties of materials play a crucial role during post-processing stages. Materials with higher thermal conductivity distribute heat more uniformly during sintering, potentially leading to more homogeneous porosity distribution. Conversely, materials with poor thermal conductivity may develop thermal gradients that create uneven densification patterns, resulting in localized porosity clusters that become potential failure initiation sites under fatigue loading.

Binder chemistry and material compatibility represent another critical interaction factor. Chemical reactions between binders and certain alloys can introduce impurities or precipitates at particle boundaries, affecting both the sintering kinetics and the resulting microstructure. These reactions may create regions with distinct mechanical properties that influence crack propagation paths during fatigue testing and compromise leak-tightness performance.

The sintering behavior of different materials under identical process conditions varies substantially, with some materials achieving near-full densification while others retain significant residual porosity. This variability necessitates material-specific process parameter optimization to achieve desired porosity distributions. For instance, materials with higher sintering activation energy require modified temperature profiles to achieve comparable densification to more easily sintered materials.

Particle packing efficiency, determined by both material characteristics and spreading parameters, establishes the initial porosity distribution before sintering. Materials with broader particle size distributions typically achieve higher packing densities when appropriate spreading parameters are employed, resulting in more uniform post-sintering porosity distributions that enhance both fatigue resistance and leak-tightness properties.

Powder characteristics such as wettability directly impact binder-powder interactions, determining how effectively the binder penetrates the powder bed. Hydrophilic materials facilitate better binder spread but may require adjusted saturation levels to prevent excessive bleeding, whereas hydrophobic materials might need specialized binders or surface treatments to achieve adequate adhesion between layers.

The thermal properties of materials play a crucial role during post-processing stages. Materials with higher thermal conductivity distribute heat more uniformly during sintering, potentially leading to more homogeneous porosity distribution. Conversely, materials with poor thermal conductivity may develop thermal gradients that create uneven densification patterns, resulting in localized porosity clusters that become potential failure initiation sites under fatigue loading.

Binder chemistry and material compatibility represent another critical interaction factor. Chemical reactions between binders and certain alloys can introduce impurities or precipitates at particle boundaries, affecting both the sintering kinetics and the resulting microstructure. These reactions may create regions with distinct mechanical properties that influence crack propagation paths during fatigue testing and compromise leak-tightness performance.

The sintering behavior of different materials under identical process conditions varies substantially, with some materials achieving near-full densification while others retain significant residual porosity. This variability necessitates material-specific process parameter optimization to achieve desired porosity distributions. For instance, materials with higher sintering activation energy require modified temperature profiles to achieve comparable densification to more easily sintered materials.

Particle packing efficiency, determined by both material characteristics and spreading parameters, establishes the initial porosity distribution before sintering. Materials with broader particle size distributions typically achieve higher packing densities when appropriate spreading parameters are employed, resulting in more uniform post-sintering porosity distributions that enhance both fatigue resistance and leak-tightness properties.

Quality Assurance and Testing Methodologies

Quality assurance and testing methodologies for Binder Jetting processes require comprehensive approaches to evaluate porosity distribution and its effects on critical mechanical properties. Non-destructive testing (NDT) techniques have emerged as essential tools in this domain, with X-ray computed tomography (CT) standing out as the gold standard for porosity characterization. CT scanning enables three-dimensional visualization of internal structures without destroying the specimen, providing crucial data on pore size, distribution, and interconnectivity.

Mechanical testing protocols specifically designed for additively manufactured components have been developed to correlate porosity patterns with fatigue performance. These include specialized cyclic loading tests that account for the unique microstructural characteristics of binder jetted parts. The standardization of these tests has progressed significantly, with organizations like ASTM International and ISO developing dedicated testing frameworks for additive manufacturing processes.

Leak-tightness assessment methodologies have evolved to address the specific challenges posed by binder jetted components. Pressure decay testing and helium mass spectrometry have been adapted to detect microscopic leakage pathways that may form due to interconnected porosity networks. These techniques are particularly valuable for components intended for fluid-handling applications where impermeability is critical.

In-process monitoring systems represent a significant advancement in quality assurance for binder jetting. Real-time data collection during the printing process enables early detection of anomalies that might lead to problematic porosity formation. Advanced systems incorporate machine learning algorithms to predict potential defect zones based on process parameters and material behavior patterns.

Post-processing quality verification has become increasingly sophisticated, with standardized protocols for evaluating the effectiveness of infiltration, sintering, and other densification treatments. These protocols typically include density measurements via Archimedes method, microhardness mapping, and surface roughness analysis to ensure consistent material properties throughout the component.

Statistical process control methodologies have been adapted specifically for binder jetting operations, enabling manufacturers to establish correlations between process parameters and resultant porosity characteristics. These approaches facilitate the development of process windows that minimize detrimental porosity while maintaining production efficiency.

Digital twin technology is emerging as a powerful quality assurance tool, allowing for virtual testing and validation of components before physical production. By simulating the entire manufacturing process and predicting potential porosity-related issues, manufacturers can optimize designs and process parameters to achieve desired mechanical properties and leak-tightness specifications.

Mechanical testing protocols specifically designed for additively manufactured components have been developed to correlate porosity patterns with fatigue performance. These include specialized cyclic loading tests that account for the unique microstructural characteristics of binder jetted parts. The standardization of these tests has progressed significantly, with organizations like ASTM International and ISO developing dedicated testing frameworks for additive manufacturing processes.

Leak-tightness assessment methodologies have evolved to address the specific challenges posed by binder jetted components. Pressure decay testing and helium mass spectrometry have been adapted to detect microscopic leakage pathways that may form due to interconnected porosity networks. These techniques are particularly valuable for components intended for fluid-handling applications where impermeability is critical.

In-process monitoring systems represent a significant advancement in quality assurance for binder jetting. Real-time data collection during the printing process enables early detection of anomalies that might lead to problematic porosity formation. Advanced systems incorporate machine learning algorithms to predict potential defect zones based on process parameters and material behavior patterns.

Post-processing quality verification has become increasingly sophisticated, with standardized protocols for evaluating the effectiveness of infiltration, sintering, and other densification treatments. These protocols typically include density measurements via Archimedes method, microhardness mapping, and surface roughness analysis to ensure consistent material properties throughout the component.

Statistical process control methodologies have been adapted specifically for binder jetting operations, enabling manufacturers to establish correlations between process parameters and resultant porosity characteristics. These approaches facilitate the development of process windows that minimize detrimental porosity while maintaining production efficiency.

Digital twin technology is emerging as a powerful quality assurance tool, allowing for virtual testing and validation of components before physical production. By simulating the entire manufacturing process and predicting potential porosity-related issues, manufacturers can optimize designs and process parameters to achieve desired mechanical properties and leak-tightness specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!