Binder Jetting Material Families: Ferrous, Non-Ferrous And Ceramic Use Cases

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Background and Objectives

Binder Jetting (BJ) technology emerged in the early 1990s at the Massachusetts Institute of Technology as a powder-based additive manufacturing process. Unlike other 3D printing methods that use heat or lasers to fuse materials, BJ selectively deposits a liquid binding agent onto powder particles, creating complex three-dimensional structures layer by layer. This approach offers distinct advantages in terms of material versatility, production speed, and cost-effectiveness compared to alternative additive manufacturing technologies.

The evolution of BJ technology has been marked by significant improvements in binder formulations, print head technology, and post-processing techniques. Early systems were limited by low resolution, poor mechanical properties, and restricted material options. However, recent advancements have dramatically expanded the range of compatible materials to include various metal alloys, ceramics, and composites, making BJ increasingly relevant across multiple industries.

Current technological trends in BJ focus on enhancing print resolution, improving material density, reducing shrinkage during sintering, and developing specialized binders for specific material families. The integration of machine learning algorithms for process optimization and real-time quality control represents another important direction in the field's development.

The primary objective of this research is to comprehensively evaluate the current state and future potential of BJ technology across three major material families: ferrous metals, non-ferrous metals, and ceramics. By examining these distinct material categories, we aim to identify the unique challenges, opportunities, and applications associated with each material type in the context of BJ manufacturing.

For ferrous materials, the research seeks to address challenges related to porosity control, dimensional accuracy, and mechanical properties comparable to traditionally manufactured parts. With non-ferrous metals, the focus shifts to exploring the expanded design possibilities, particularly for lightweight structures and complex geometries in aerospace and automotive applications.

In the ceramic domain, the research aims to investigate how BJ can overcome traditional manufacturing limitations, enabling the production of complex geometries with controlled porosity for applications in medical implants, filtration systems, and high-temperature components.

The ultimate goal is to establish a comprehensive understanding of material-process relationships in BJ technology, providing a foundation for future innovation and industrial implementation. This includes identifying optimal process parameters for each material family, developing predictive models for part quality, and establishing design guidelines that leverage the unique capabilities of BJ across diverse application domains.

The evolution of BJ technology has been marked by significant improvements in binder formulations, print head technology, and post-processing techniques. Early systems were limited by low resolution, poor mechanical properties, and restricted material options. However, recent advancements have dramatically expanded the range of compatible materials to include various metal alloys, ceramics, and composites, making BJ increasingly relevant across multiple industries.

Current technological trends in BJ focus on enhancing print resolution, improving material density, reducing shrinkage during sintering, and developing specialized binders for specific material families. The integration of machine learning algorithms for process optimization and real-time quality control represents another important direction in the field's development.

The primary objective of this research is to comprehensively evaluate the current state and future potential of BJ technology across three major material families: ferrous metals, non-ferrous metals, and ceramics. By examining these distinct material categories, we aim to identify the unique challenges, opportunities, and applications associated with each material type in the context of BJ manufacturing.

For ferrous materials, the research seeks to address challenges related to porosity control, dimensional accuracy, and mechanical properties comparable to traditionally manufactured parts. With non-ferrous metals, the focus shifts to exploring the expanded design possibilities, particularly for lightweight structures and complex geometries in aerospace and automotive applications.

In the ceramic domain, the research aims to investigate how BJ can overcome traditional manufacturing limitations, enabling the production of complex geometries with controlled porosity for applications in medical implants, filtration systems, and high-temperature components.

The ultimate goal is to establish a comprehensive understanding of material-process relationships in BJ technology, providing a foundation for future innovation and industrial implementation. This includes identifying optimal process parameters for each material family, developing predictive models for part quality, and establishing design guidelines that leverage the unique capabilities of BJ across diverse application domains.

Market Analysis for Binder Jetting Materials

The global binder jetting materials market is experiencing significant growth, driven by increasing adoption across various industrial sectors. Current market valuations indicate that the binder jetting segment of the additive manufacturing industry is expanding at a compound annual growth rate of approximately 20%, outpacing several other 3D printing technologies. This acceleration is primarily attributed to binder jetting's ability to process a diverse range of materials while offering cost advantages for medium to high-volume production runs.

Material consumption patterns reveal distinct market preferences across different regions. North America currently leads in ferrous material applications, particularly in automotive and heavy machinery sectors, while European markets show stronger demand for specialized ceramic applications in medical and aerospace industries. The Asia-Pacific region demonstrates the fastest growth rate, with significant investments in non-ferrous metal applications for consumer electronics and industrial components.

The ferrous materials segment, including various steel alloys and iron-based composites, represents the largest market share at approximately 45% of the total binder jetting materials market. This dominance stems from established industrial applications and the material's favorable cost-to-performance ratio. Non-ferrous materials, particularly aluminum, copper, and titanium alloys, account for roughly 30% of the market, with demand increasing due to their application in lightweight components for aerospace and automotive industries.

Ceramic materials constitute about 25% of the market but show the highest growth potential, with projected increases in market share over the next five years. This growth is driven by expanding applications in medical implants, electronics, and high-temperature industrial components where ceramics offer unique performance advantages.

End-user industry analysis reveals that automotive manufacturing represents the largest consumer of binder jetting materials, followed by aerospace, medical, and general industrial applications. The automotive sector's dominance is attributed to the technology's ability to produce complex geometries for functional prototypes and end-use parts while reducing assembly requirements and overall component weight.

Price sensitivity varies significantly across material families, with specialized ceramics and high-performance metal alloys commanding premium pricing. Material suppliers are increasingly focusing on developing cost-effective formulations that maintain performance characteristics while improving process reliability and part quality. This trend is expected to drive further market expansion by making binder jetting more accessible to medium-sized manufacturers and new industrial applications.

Material consumption patterns reveal distinct market preferences across different regions. North America currently leads in ferrous material applications, particularly in automotive and heavy machinery sectors, while European markets show stronger demand for specialized ceramic applications in medical and aerospace industries. The Asia-Pacific region demonstrates the fastest growth rate, with significant investments in non-ferrous metal applications for consumer electronics and industrial components.

The ferrous materials segment, including various steel alloys and iron-based composites, represents the largest market share at approximately 45% of the total binder jetting materials market. This dominance stems from established industrial applications and the material's favorable cost-to-performance ratio. Non-ferrous materials, particularly aluminum, copper, and titanium alloys, account for roughly 30% of the market, with demand increasing due to their application in lightweight components for aerospace and automotive industries.

Ceramic materials constitute about 25% of the market but show the highest growth potential, with projected increases in market share over the next five years. This growth is driven by expanding applications in medical implants, electronics, and high-temperature industrial components where ceramics offer unique performance advantages.

End-user industry analysis reveals that automotive manufacturing represents the largest consumer of binder jetting materials, followed by aerospace, medical, and general industrial applications. The automotive sector's dominance is attributed to the technology's ability to produce complex geometries for functional prototypes and end-use parts while reducing assembly requirements and overall component weight.

Price sensitivity varies significantly across material families, with specialized ceramics and high-performance metal alloys commanding premium pricing. Material suppliers are increasingly focusing on developing cost-effective formulations that maintain performance characteristics while improving process reliability and part quality. This trend is expected to drive further market expansion by making binder jetting more accessible to medium-sized manufacturers and new industrial applications.

Current Challenges in Multi-Material Binder Jetting

Despite significant advancements in binder jetting technology, multi-material processing remains one of the most challenging frontiers in this field. The fundamental challenge stems from the inherent complexity of managing different material properties within a single build process. Materials with varying particle sizes, densities, and binding characteristics require precise calibration of process parameters that often conflict when attempting to process them simultaneously.

Powder bed management presents a significant hurdle, as different materials exhibit distinct flow behaviors and packing densities. Ferrous materials typically require higher sintering temperatures than non-ferrous alternatives, creating thermal processing incompatibilities when attempting to co-process these materials. Similarly, ceramics demand entirely different thermal profiles compared to metals, making unified post-processing nearly impossible without compromising material integrity.

Binder-material interactions vary dramatically across material families. A binder formulation optimized for steel powders may perform poorly with aluminum or ceramic materials due to differences in surface chemistry and wettability. This necessitates either compromise in binding performance or the development of specialized multi-binder systems, adding complexity to machine design and process control.

Interface quality between dissimilar materials represents another critical challenge. The formation of brittle intermetallic compounds at ferrous/non-ferrous interfaces or weak bonding between metals and ceramics can create failure points in final parts. Differential shrinkage during sintering further exacerbates these interface issues, often resulting in cracking, warping, or delamination at material boundaries.

Resolution limitations of current binder jetting systems restrict the precision with which different materials can be deposited, limiting applications requiring fine material transitions. Most commercial systems lack the capability to effectively manage material cross-contamination, which becomes increasingly problematic as material complexity increases.

Post-processing compatibility remains perhaps the most significant barrier to widespread multi-material binder jetting adoption. The vastly different sintering requirements between ferrous alloys (typically >1200°C), non-ferrous metals like aluminum (550-650°C), and ceramics (often >1400°C with different atmospheres) make unified thermal processing exceptionally difficult. Infiltration processes further complicate matters, as infiltrants suitable for one material family may be incompatible with others.

These technical challenges are compounded by economic considerations. The increased complexity of multi-material systems drives up equipment costs, processing times, and quality control requirements. Current market applications have not yet demonstrated sufficient value to justify these increased costs for most industrial applications, limiting research investment and commercial development in this area.

Powder bed management presents a significant hurdle, as different materials exhibit distinct flow behaviors and packing densities. Ferrous materials typically require higher sintering temperatures than non-ferrous alternatives, creating thermal processing incompatibilities when attempting to co-process these materials. Similarly, ceramics demand entirely different thermal profiles compared to metals, making unified post-processing nearly impossible without compromising material integrity.

Binder-material interactions vary dramatically across material families. A binder formulation optimized for steel powders may perform poorly with aluminum or ceramic materials due to differences in surface chemistry and wettability. This necessitates either compromise in binding performance or the development of specialized multi-binder systems, adding complexity to machine design and process control.

Interface quality between dissimilar materials represents another critical challenge. The formation of brittle intermetallic compounds at ferrous/non-ferrous interfaces or weak bonding between metals and ceramics can create failure points in final parts. Differential shrinkage during sintering further exacerbates these interface issues, often resulting in cracking, warping, or delamination at material boundaries.

Resolution limitations of current binder jetting systems restrict the precision with which different materials can be deposited, limiting applications requiring fine material transitions. Most commercial systems lack the capability to effectively manage material cross-contamination, which becomes increasingly problematic as material complexity increases.

Post-processing compatibility remains perhaps the most significant barrier to widespread multi-material binder jetting adoption. The vastly different sintering requirements between ferrous alloys (typically >1200°C), non-ferrous metals like aluminum (550-650°C), and ceramics (often >1400°C with different atmospheres) make unified thermal processing exceptionally difficult. Infiltration processes further complicate matters, as infiltrants suitable for one material family may be incompatible with others.

These technical challenges are compounded by economic considerations. The increased complexity of multi-material systems drives up equipment costs, processing times, and quality control requirements. Current market applications have not yet demonstrated sufficient value to justify these increased costs for most industrial applications, limiting research investment and commercial development in this area.

Material-Specific Binder Jetting Solutions

01 Ferrous Material Families for Binder Jetting

Ferrous materials such as steel, iron, and their alloys are commonly used in binder jetting processes. These materials offer high strength, durability, and heat resistance, making them suitable for industrial applications. The binder jetting process for ferrous materials typically involves the deposition of metal powder layers followed by selective application of a binding agent. After printing, the parts undergo sintering to achieve the desired mechanical properties. Ferrous materials in binder jetting are particularly valuable for producing complex components for automotive, aerospace, and manufacturing industries.- Ferrous Material Families for Binder Jetting: Ferrous materials such as steel, iron, and their alloys are commonly used in binder jetting processes. These materials offer high strength, durability, and heat resistance, making them suitable for industrial applications. The binder jetting process for ferrous materials typically involves the deposition of metal powder layers followed by selective application of a binding agent. After printing, the parts undergo sintering to achieve the desired mechanical properties. Ferrous materials in binder jetting are particularly valuable for producing complex components for automotive, aerospace, and manufacturing industries.

- Non-Ferrous Material Families for Binder Jetting: Non-ferrous materials including aluminum, copper, titanium, and precious metals are increasingly used in binder jetting applications. These materials offer advantages such as lightweight properties, corrosion resistance, and electrical conductivity. The binder jetting process for non-ferrous materials requires specific binding agents compatible with these metals to ensure proper adhesion and structural integrity. Post-processing techniques such as infiltration and sintering are often tailored to the unique properties of each non-ferrous material to optimize the final part characteristics.

- Ceramic Material Families for Binder Jetting: Ceramic materials such as alumina, zirconia, and silicon carbide are widely utilized in binder jetting processes for their exceptional thermal resistance, hardness, and chemical stability. The binder jetting of ceramics typically involves specialized binders that can withstand the high temperatures required during sintering. These materials are particularly valuable for applications requiring high temperature resistance, biocompatibility, or electrical insulation properties. The process allows for the creation of complex ceramic components with intricate internal structures that would be difficult to produce using traditional manufacturing methods.

- Composite and Multi-material Binder Jetting: Binder jetting technology has evolved to accommodate composite and multi-material printing, combining different material families such as metal-ceramic composites or gradient materials. This approach allows for the creation of parts with region-specific properties, such as wear resistance in one area and thermal conductivity in another. The process typically involves specialized binding agents that can work with multiple material types or sequential printing of different materials. These composite approaches enable the production of functionally graded components with tailored properties for specific applications in aerospace, medical, and energy sectors.

- Binder Formulations and Material Compatibility: The development of specialized binders is crucial for successful binder jetting across different material families. These binders must be compatible with the specific material properties of ferrous, non-ferrous, and ceramic powders. Factors such as viscosity, surface tension, and curing mechanisms significantly impact the printing process and final part quality. Advanced binder formulations may include additives to enhance flowability, green strength, or sintering behavior. Research in this area focuses on developing environmentally friendly binders with improved performance characteristics and compatibility with a wider range of materials to expand the applications of binder jetting technology.

02 Non-Ferrous Material Families for Binder Jetting

Non-ferrous materials including aluminum, copper, titanium, and precious metals are increasingly used in binder jetting applications. These materials offer advantages such as lighter weight, corrosion resistance, and electrical conductivity. The binder jetting process for non-ferrous materials requires specific binding agents compatible with these metals to ensure proper adhesion and structural integrity. Post-processing techniques such as infiltration and sintering are often tailored to the unique properties of each non-ferrous material. These materials enable the production of lightweight components for electronics, consumer products, and medical devices.Expand Specific Solutions03 Ceramic Material Families for Binder Jetting

Ceramic materials including alumina, zirconia, and silicon carbide are well-suited for binder jetting processes. These materials offer exceptional heat resistance, hardness, and chemical stability. The binder jetting of ceramics typically involves specialized binders that can withstand the high temperatures required during sintering. The process allows for the creation of complex ceramic components with intricate internal structures that would be difficult to produce using traditional manufacturing methods. Ceramic binder jetting is particularly valuable for applications in medical implants, electronics, and high-temperature industrial components.Expand Specific Solutions04 Composite and Multi-material Binder Jetting

Binder jetting technology has evolved to accommodate composite and multi-material printing, combining different material families such as metal-ceramic composites or graded material structures. This approach allows for the creation of parts with tailored properties in different regions. The process typically involves specialized binder formulations that can work with multiple material types and careful control of the printing parameters to ensure proper bonding between different materials. These composite approaches enable the production of components with optimized mechanical, thermal, or electrical properties for specific applications in aerospace, energy, and advanced manufacturing sectors.Expand Specific Solutions05 Binder Formulations for Different Material Families

Specialized binder formulations are critical for successful binder jetting across different material families. These binders are designed to provide adequate green strength to printed parts while being compatible with the specific material chemistry. For ferrous materials, binders often contain polymeric components that burn out cleanly during sintering. Ceramic binders typically include dispersants and rheology modifiers to ensure proper powder wetting and binding. Non-ferrous materials may require binders with specific additives to prevent oxidation or promote sintering. The development of advanced binders has expanded the range of materials that can be processed using binder jetting technology.Expand Specific Solutions

Leading Companies in Binder Jetting Material Development

The Binder Jetting material families market is currently in a growth phase, with increasing adoption across ferrous, non-ferrous, and ceramic applications. The global market is expanding rapidly, projected to reach approximately $1.2 billion by 2028, driven by industrial manufacturing demands for complex geometries and customized parts. Technologically, the field shows varying maturity levels across material families, with ceramics being more established while metal applications are advancing quickly. Desktop Metal leads commercial innovation in metal binder jetting, while academic institutions like Guangdong University of Technology and Virginia Tech contribute significant research. Traditional materials companies including Oerlikon Metco, Sandvik, and IBIDEN are expanding their portfolios to include specialized binder jetting materials, indicating industry-wide recognition of the technology's strategic importance.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has pioneered advanced binder jetting technology through their Production System™ and Shop System™ platforms, specifically designed for high-volume manufacturing of metal parts. Their Single Pass Jetting™ technology enables printing speeds up to 12,000 cm³/hour with their proprietary binders optimized for various metal powders. For ferrous materials, they've developed specialized binder formulations compatible with low-alloy steels, tool steels, and stainless steels, achieving densities exceeding 98% after sintering. Their non-ferrous portfolio includes aluminum alloys, copper, and precious metals with tailored sintering profiles. Desktop Metal has also commercialized their ETEC brand for ceramic binder jetting, utilizing their Flexcera™ resins for dental applications and technical ceramics like silicon carbide and alumina for industrial components, with precision tolerances of ±0.2%.

Strengths: Industry-leading print speeds and throughput; comprehensive material portfolio across all three families; proprietary binder chemistry optimized for different material classes; established post-processing workflows. Weaknesses: Higher system acquisition costs compared to competitors; material-specific process parameters require optimization; sintering shrinkage management remains challenging for complex geometries.

Oerlikon Metco (US), Inc.

Technical Solution: Oerlikon Metco has developed specialized metal powders and process parameters specifically engineered for binder jetting applications. Their MetcoAdd™ powder portfolio includes optimized ferrous materials like 316L and 17-4PH stainless steels with spherical morphology and tailored particle size distributions (15-45μm) that achieve powder bed packing densities over 60%. For non-ferrous applications, they've formulated copper, nickel-based superalloys, and titanium powders with proprietary surface treatments that enhance flowability and binder interaction. Their ceramic offerings include alumina, zirconia, and silicon nitride powders with controlled agglomeration characteristics. Oerlikon's integrated approach combines material development with process parameter optimization, resulting in sintered parts with mechanical properties comparable to conventionally manufactured components (>95% theoretical density) while maintaining dimensional tolerances within ±0.3%.

Strengths: Extensive metallurgical expertise; vertically integrated powder production capabilities; customized powder formulations for specific applications; comprehensive material characterization services. Weaknesses: Primary focus on materials rather than complete binder jetting systems; requires partnerships with machine manufacturers; limited direct control over printing hardware parameters.

Key Patents and Research in Binder Jetting Materials

Particle agglomeration for additive metal manufacturing

PatentWO2019045733A1

Innovation

- The use of granules with agglomerated metallic particles and a binder system that can reflow to bind the particles together, allowing for the formation of dense parts with unique microstructures, overcoming the limitations of particle size and safety risks associated with ultrafine particles.

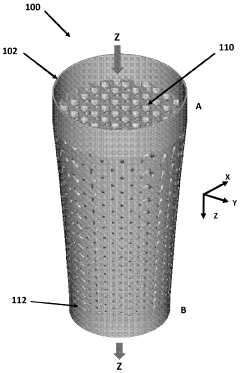

Ceramic membrane produced by binder jetting

PatentWO2023166316A1

Innovation

- A ceramic membrane produced using binder jetting additive manufacturing, where a ceramic powder is bonded with a retained binder to create a 3D printed green body, which is then post-processed to achieve desired mechanical properties and porosity, allowing for tailored pore size distribution and high water flux.

Sustainability Aspects of Binder Jetting Materials

Binder jetting technology presents significant sustainability advantages compared to traditional manufacturing methods, particularly in terms of material efficiency and environmental impact. The process inherently reduces waste through its additive nature, utilizing only the necessary amount of material for each component. This characteristic is especially valuable when working with high-value ferrous materials like stainless steel and tool steel, where material conservation directly translates to cost savings and reduced environmental footprint.

For non-ferrous materials such as aluminum, copper, and titanium alloys, binder jetting offers additional sustainability benefits through energy efficiency. Conventional manufacturing of these materials often requires energy-intensive processes for forming and machining. In contrast, binder jetting significantly reduces energy consumption by eliminating many of these steps, with studies indicating potential energy savings of 40-60% compared to traditional manufacturing methods.

Ceramic binder jetting applications demonstrate perhaps the most compelling sustainability case. The process enables complex geometries that can optimize material properties while minimizing mass, resulting in lighter components with equivalent or superior performance characteristics. This weight reduction becomes particularly important in transportation applications, where lighter ceramic components contribute to overall vehicle efficiency and reduced lifetime emissions.

The recyclability of unused powder in binder jetting operations represents another key sustainability advantage across all material families. Unlike subtractive manufacturing where material recovery is challenging, binder jetting allows for collection and reuse of up to 98% of unused powder material, creating a near-closed-loop production system. This aspect is particularly valuable for rare or strategic materials where supply chain resilience is a concern.

Water consumption in binder jetting processes presents both challenges and opportunities from a sustainability perspective. While the process requires water for binder solutions, innovations in water-based binder systems are reducing the need for harmful solvents. Recent developments in biodegradable binders for ceramic applications show particular promise, with early studies demonstrating comparable mechanical properties while eliminating toxic components.

Lifecycle assessment studies comparing binder jetting to conventional manufacturing across various material families consistently show reduced carbon footprints, with reductions ranging from 25-70% depending on the specific application and material. These environmental benefits are further amplified when considering the technology's ability to enable on-demand, localized production, which reduces transportation emissions and inventory waste throughout the supply chain.

For non-ferrous materials such as aluminum, copper, and titanium alloys, binder jetting offers additional sustainability benefits through energy efficiency. Conventional manufacturing of these materials often requires energy-intensive processes for forming and machining. In contrast, binder jetting significantly reduces energy consumption by eliminating many of these steps, with studies indicating potential energy savings of 40-60% compared to traditional manufacturing methods.

Ceramic binder jetting applications demonstrate perhaps the most compelling sustainability case. The process enables complex geometries that can optimize material properties while minimizing mass, resulting in lighter components with equivalent or superior performance characteristics. This weight reduction becomes particularly important in transportation applications, where lighter ceramic components contribute to overall vehicle efficiency and reduced lifetime emissions.

The recyclability of unused powder in binder jetting operations represents another key sustainability advantage across all material families. Unlike subtractive manufacturing where material recovery is challenging, binder jetting allows for collection and reuse of up to 98% of unused powder material, creating a near-closed-loop production system. This aspect is particularly valuable for rare or strategic materials where supply chain resilience is a concern.

Water consumption in binder jetting processes presents both challenges and opportunities from a sustainability perspective. While the process requires water for binder solutions, innovations in water-based binder systems are reducing the need for harmful solvents. Recent developments in biodegradable binders for ceramic applications show particular promise, with early studies demonstrating comparable mechanical properties while eliminating toxic components.

Lifecycle assessment studies comparing binder jetting to conventional manufacturing across various material families consistently show reduced carbon footprints, with reductions ranging from 25-70% depending on the specific application and material. These environmental benefits are further amplified when considering the technology's ability to enable on-demand, localized production, which reduces transportation emissions and inventory waste throughout the supply chain.

Cross-Industry Applications and Case Studies

Binder jetting technology has demonstrated remarkable versatility across multiple industries, revolutionizing manufacturing processes and enabling new design possibilities. In the automotive sector, ferrous materials like stainless steel and tool steel are increasingly utilized for producing complex engine components, heat exchangers, and structural parts with intricate internal channels that would be impossible to create using traditional manufacturing methods. Major automotive manufacturers have reported 30-40% weight reduction in certain components while maintaining or improving mechanical properties.

The aerospace industry has embraced binder jetting for both ferrous and non-ferrous applications, particularly with titanium alloys and aluminum composites for lightweight structural components. GE Aviation has successfully implemented binder jetting to produce fuel nozzles with 25% weight reduction and five times longer product lifespan compared to conventionally manufactured counterparts. The technology has enabled the consolidation of multiple parts into single components, significantly reducing assembly requirements and enhancing reliability.

In the medical field, binder jetting of titanium and ceramic materials has transformed the production of patient-specific implants and prosthetics. Hospitals and medical device manufacturers report improved patient outcomes due to the perfect anatomical fit of customized implants. Ceramic binder jetting has proven particularly valuable for dental applications, with over 100,000 ceramic dental restorations produced annually using this technology, offering superior biocompatibility and aesthetic qualities.

The energy sector utilizes binder jetting for manufacturing heat exchangers, turbine components, and specialized tools for harsh environments. Ceramic materials processed through binder jetting have shown exceptional performance in high-temperature applications, with some components withstanding temperatures up to 1600°C while maintaining structural integrity. This has enabled more efficient energy generation systems and extended component lifespans in extreme operating conditions.

Consumer goods manufacturers have adopted binder jetting for both functional and aesthetic applications. Stainless steel and bronze materials are commonly used for jewelry, decorative items, and consumer electronics housings. The technology allows for mass customization at scales previously unattainable, with some manufacturers reporting production runs of customized components exceeding 10,000 units while maintaining economic viability.

Industrial tooling represents another significant application area, with hardened steels and tungsten carbide materials being processed via binder jetting to create complex cutting tools, molds, and dies. Tool manufacturers have documented 40-60% reduction in lead times for specialized tooling, enabling more responsive production systems and faster time-to-market for new products across multiple industries.

The aerospace industry has embraced binder jetting for both ferrous and non-ferrous applications, particularly with titanium alloys and aluminum composites for lightweight structural components. GE Aviation has successfully implemented binder jetting to produce fuel nozzles with 25% weight reduction and five times longer product lifespan compared to conventionally manufactured counterparts. The technology has enabled the consolidation of multiple parts into single components, significantly reducing assembly requirements and enhancing reliability.

In the medical field, binder jetting of titanium and ceramic materials has transformed the production of patient-specific implants and prosthetics. Hospitals and medical device manufacturers report improved patient outcomes due to the perfect anatomical fit of customized implants. Ceramic binder jetting has proven particularly valuable for dental applications, with over 100,000 ceramic dental restorations produced annually using this technology, offering superior biocompatibility and aesthetic qualities.

The energy sector utilizes binder jetting for manufacturing heat exchangers, turbine components, and specialized tools for harsh environments. Ceramic materials processed through binder jetting have shown exceptional performance in high-temperature applications, with some components withstanding temperatures up to 1600°C while maintaining structural integrity. This has enabled more efficient energy generation systems and extended component lifespans in extreme operating conditions.

Consumer goods manufacturers have adopted binder jetting for both functional and aesthetic applications. Stainless steel and bronze materials are commonly used for jewelry, decorative items, and consumer electronics housings. The technology allows for mass customization at scales previously unattainable, with some manufacturers reporting production runs of customized components exceeding 10,000 units while maintaining economic viability.

Industrial tooling represents another significant application area, with hardened steels and tungsten carbide materials being processed via binder jetting to create complex cutting tools, molds, and dies. Tool manufacturers have documented 40-60% reduction in lead times for specialized tooling, enabling more responsive production systems and faster time-to-market for new products across multiple industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!