Binder Jetting Risk Factors: Binder Aging, Powder Oxidation And Unplanned Downtime

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting technology emerged in the early 1990s at Massachusetts Institute of Technology, representing a significant advancement in additive manufacturing. This powder-bed based 3D printing process selectively deposits liquid binding agents onto thin layers of powder materials, creating complex geometries without the need for support structures. The technology has evolved considerably over three decades, transitioning from prototype development to industrial production applications.

The evolution of Binder Jetting can be traced through several distinct phases. The initial development phase (1990s-2000s) focused on establishing fundamental process parameters and basic material compatibility. During this period, the technology was primarily used for creating concept models and prototypes with limited functional properties.

The second phase (2000s-2010s) saw significant improvements in binder formulations, powder characteristics, and machine reliability. This period marked the transition from purely visual prototypes to functional parts with improved mechanical properties, though still facing challenges in consistency and material options.

The current phase (2010s-present) has witnessed rapid advancement in industrial applications, with major developments in high-performance binders, expanded material portfolios, and enhanced process control systems. The integration of advanced sensors, real-time monitoring, and machine learning algorithms has substantially improved part quality and repeatability.

Despite these advancements, several critical risk factors continue to challenge the technology's broader adoption. Binder aging, characterized by chemical degradation and viscosity changes over time, significantly impacts print quality and consistency. Powder oxidation, particularly with metal powders, affects material properties and can lead to defects in final parts. Unplanned downtime due to maintenance issues, clogged printheads, or software failures remains a persistent challenge for production environments.

The primary objectives for future Binder Jetting development include enhancing binder stability through advanced formulations resistant to aging effects, developing improved powder handling systems with controlled atmospheres to prevent oxidation, and implementing predictive maintenance protocols powered by AI to minimize unplanned downtime.

Additionally, the technology aims to expand material compatibility, increase build speeds without sacrificing quality, and improve post-processing efficiency. These objectives align with the broader industry goal of positioning Binder Jetting as a viable solution for mass production of complex parts across automotive, aerospace, medical, and consumer goods sectors.

The evolution of Binder Jetting can be traced through several distinct phases. The initial development phase (1990s-2000s) focused on establishing fundamental process parameters and basic material compatibility. During this period, the technology was primarily used for creating concept models and prototypes with limited functional properties.

The second phase (2000s-2010s) saw significant improvements in binder formulations, powder characteristics, and machine reliability. This period marked the transition from purely visual prototypes to functional parts with improved mechanical properties, though still facing challenges in consistency and material options.

The current phase (2010s-present) has witnessed rapid advancement in industrial applications, with major developments in high-performance binders, expanded material portfolios, and enhanced process control systems. The integration of advanced sensors, real-time monitoring, and machine learning algorithms has substantially improved part quality and repeatability.

Despite these advancements, several critical risk factors continue to challenge the technology's broader adoption. Binder aging, characterized by chemical degradation and viscosity changes over time, significantly impacts print quality and consistency. Powder oxidation, particularly with metal powders, affects material properties and can lead to defects in final parts. Unplanned downtime due to maintenance issues, clogged printheads, or software failures remains a persistent challenge for production environments.

The primary objectives for future Binder Jetting development include enhancing binder stability through advanced formulations resistant to aging effects, developing improved powder handling systems with controlled atmospheres to prevent oxidation, and implementing predictive maintenance protocols powered by AI to minimize unplanned downtime.

Additionally, the technology aims to expand material compatibility, increase build speeds without sacrificing quality, and improve post-processing efficiency. These objectives align with the broader industry goal of positioning Binder Jetting as a viable solution for mass production of complex parts across automotive, aerospace, medical, and consumer goods sectors.

Market Analysis for Binder Jetting Additive Manufacturing

The global binder jetting additive manufacturing market is experiencing significant growth, with a current market valuation estimated at $300 million and projected to reach $1.3 billion by 2028. This represents a compound annual growth rate of approximately 35%, positioning binder jetting as one of the fastest-growing segments within the additive manufacturing industry.

Industrial manufacturing sectors constitute the largest market share, accounting for nearly 45% of the total binder jetting market. The automotive industry follows closely, representing approximately 30% of market demand, driven by the technology's ability to produce complex metal components at scale. Aerospace and healthcare sectors collectively contribute about 20% of market demand, with the remaining 5% distributed across various industries including consumer goods and architecture.

Market demand is primarily fueled by binder jetting's unique value propositions: cost-effectiveness for medium to high-volume production, ability to process a wide range of materials, and relatively high build speeds compared to other additive manufacturing technologies. The technology's capacity to produce parts without support structures represents a significant cost advantage, reducing post-processing requirements and material waste.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization in China and significant investments in advanced manufacturing technologies across the region.

The market faces several challenges related to the risk factors identified. Binder aging issues affect approximately 30% of users, resulting in inconsistent part quality and increased material costs. Powder oxidation problems impact nearly 25% of operations, particularly those working with reactive metal powders. Unplanned downtime, affecting an estimated 40% of industrial users, represents perhaps the most significant market constraint, reducing overall equipment effectiveness and increasing operational costs.

Customer surveys indicate that reliability improvements could expand market adoption by up to 50% among potential industrial users who currently view the technology as insufficiently mature for production environments. This represents a substantial growth opportunity for manufacturers who can effectively address these risk factors.

Market forecasts suggest that solutions addressing binder aging, powder oxidation, and unplanned downtime could unlock an additional $500 million in market value by 2026, highlighting the significant commercial potential for technological innovations in these areas.

Industrial manufacturing sectors constitute the largest market share, accounting for nearly 45% of the total binder jetting market. The automotive industry follows closely, representing approximately 30% of market demand, driven by the technology's ability to produce complex metal components at scale. Aerospace and healthcare sectors collectively contribute about 20% of market demand, with the remaining 5% distributed across various industries including consumer goods and architecture.

Market demand is primarily fueled by binder jetting's unique value propositions: cost-effectiveness for medium to high-volume production, ability to process a wide range of materials, and relatively high build speeds compared to other additive manufacturing technologies. The technology's capacity to produce parts without support structures represents a significant cost advantage, reducing post-processing requirements and material waste.

Regional analysis reveals North America currently leads the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years, driven by rapid industrialization in China and significant investments in advanced manufacturing technologies across the region.

The market faces several challenges related to the risk factors identified. Binder aging issues affect approximately 30% of users, resulting in inconsistent part quality and increased material costs. Powder oxidation problems impact nearly 25% of operations, particularly those working with reactive metal powders. Unplanned downtime, affecting an estimated 40% of industrial users, represents perhaps the most significant market constraint, reducing overall equipment effectiveness and increasing operational costs.

Customer surveys indicate that reliability improvements could expand market adoption by up to 50% among potential industrial users who currently view the technology as insufficiently mature for production environments. This represents a substantial growth opportunity for manufacturers who can effectively address these risk factors.

Market forecasts suggest that solutions addressing binder aging, powder oxidation, and unplanned downtime could unlock an additional $500 million in market value by 2026, highlighting the significant commercial potential for technological innovations in these areas.

Current Challenges in Binder Jetting Processes

Binder jetting technology has emerged as a promising additive manufacturing method, offering advantages in production speed, material versatility, and cost-effectiveness. However, the process faces several significant challenges that impact reliability, consistency, and overall production efficiency. These challenges primarily stem from three interconnected risk factors: binder aging, powder oxidation, and unplanned downtime.

Binder aging represents a critical concern in the binder jetting process. The liquid binders used to selectively bind powder particles undergo chemical degradation over time, resulting in viscosity changes, reduced binding strength, and inconsistent droplet formation. This degradation accelerates when binders are exposed to environmental factors such as heat, light, and oxygen, leading to significant variations in part quality and dimensional accuracy.

Powder oxidation constitutes another major challenge, particularly for metal powders used in binder jetting. When exposed to atmospheric oxygen, metal powders form oxide layers that alter surface chemistry and particle morphology. This oxidation process affects powder flowability, packing density, and sintering behavior, ultimately compromising the mechanical properties and surface finish of printed parts. The challenge is exacerbated by the fact that powder recycling—a key economic factor in additive manufacturing—becomes increasingly problematic as oxidation levels rise.

Unplanned downtime presents a substantial operational challenge for binder jetting systems. These interruptions can result from printhead clogging (often related to binder aging), powder spreading inconsistencies, environmental control failures, or software/hardware malfunctions. Each downtime event not only reduces production throughput but can also lead to material waste and quality issues in parts being produced during the interruption.

The interrelationship between these challenges compounds their impact. For instance, binder aging accelerates printhead clogging, which increases downtime frequency. Similarly, extended downtime periods expose powders to oxidation risk for longer durations. This creates a negative feedback loop that can significantly undermine process stability and production economics.

Current industrial solutions attempt to address these challenges through environmental controls (temperature, humidity, and oxygen monitoring), material handling protocols, and preventive maintenance schedules. However, these approaches often treat symptoms rather than root causes, and their effectiveness varies considerably across different production environments and material systems.

The lack of standardized testing methodologies for binder stability and powder oxidation further complicates the situation, making it difficult for manufacturers to predict and prevent these issues proactively. This gap in standardization represents a significant barrier to wider industrial adoption of binder jetting technology, particularly in sectors with stringent quality requirements such as aerospace and medical device manufacturing.

Binder aging represents a critical concern in the binder jetting process. The liquid binders used to selectively bind powder particles undergo chemical degradation over time, resulting in viscosity changes, reduced binding strength, and inconsistent droplet formation. This degradation accelerates when binders are exposed to environmental factors such as heat, light, and oxygen, leading to significant variations in part quality and dimensional accuracy.

Powder oxidation constitutes another major challenge, particularly for metal powders used in binder jetting. When exposed to atmospheric oxygen, metal powders form oxide layers that alter surface chemistry and particle morphology. This oxidation process affects powder flowability, packing density, and sintering behavior, ultimately compromising the mechanical properties and surface finish of printed parts. The challenge is exacerbated by the fact that powder recycling—a key economic factor in additive manufacturing—becomes increasingly problematic as oxidation levels rise.

Unplanned downtime presents a substantial operational challenge for binder jetting systems. These interruptions can result from printhead clogging (often related to binder aging), powder spreading inconsistencies, environmental control failures, or software/hardware malfunctions. Each downtime event not only reduces production throughput but can also lead to material waste and quality issues in parts being produced during the interruption.

The interrelationship between these challenges compounds their impact. For instance, binder aging accelerates printhead clogging, which increases downtime frequency. Similarly, extended downtime periods expose powders to oxidation risk for longer durations. This creates a negative feedback loop that can significantly undermine process stability and production economics.

Current industrial solutions attempt to address these challenges through environmental controls (temperature, humidity, and oxygen monitoring), material handling protocols, and preventive maintenance schedules. However, these approaches often treat symptoms rather than root causes, and their effectiveness varies considerably across different production environments and material systems.

The lack of standardized testing methodologies for binder stability and powder oxidation further complicates the situation, making it difficult for manufacturers to predict and prevent these issues proactively. This gap in standardization represents a significant barrier to wider industrial adoption of binder jetting technology, particularly in sectors with stringent quality requirements such as aerospace and medical device manufacturing.

Existing Risk Mitigation Strategies for Binder Jetting

01 Binder aging and degradation issues

Binder aging is a significant risk factor in binder jetting processes, where the chemical stability of the binder deteriorates over time. This degradation can lead to inconsistent binding strength, reduced part quality, and increased failure rates. Factors affecting binder aging include exposure to light, temperature fluctuations, and chemical reactions with atmospheric components. Implementing proper storage conditions, regular quality checks, and using stabilizing additives can help mitigate these risks and extend binder shelf life.- Binder aging and degradation mechanisms: Binder aging in additive manufacturing processes can lead to significant quality issues in printed parts. The degradation of binders over time can be caused by exposure to light, heat, humidity, and chemical reactions. These factors can alter the viscosity, surface tension, and binding properties of the liquid, resulting in inconsistent droplet formation and poor layer adhesion. Implementing proper storage conditions, regular quality checks, and establishing a binder replacement schedule can help mitigate these risks and maintain consistent print quality.

- Powder oxidation prevention strategies: Metal and polymer powders used in binder jetting are susceptible to oxidation when exposed to air and moisture, which can significantly impact the final part properties. Oxidized powders may exhibit reduced flowability, altered particle size distribution, and compromised mechanical properties in finished parts. Effective prevention strategies include controlled atmosphere storage systems, inert gas environments during processing, moisture control measures, and implementing powder recycling protocols that include testing for oxidation levels before reuse. These measures help maintain powder quality and ensure consistent part production.

- Unplanned downtime reduction through predictive maintenance: Unplanned downtime in binder jetting operations can significantly impact production schedules and increase operational costs. Implementing predictive maintenance systems that utilize machine learning algorithms and sensor data can help identify potential equipment failures before they occur. These systems monitor critical parameters such as printhead performance, powder spreading uniformity, and environmental conditions to detect anomalies. By transitioning from reactive to predictive maintenance approaches, manufacturers can schedule interventions during planned downtime periods, optimize spare parts inventory, and establish standardized troubleshooting procedures to minimize production disruptions.

- Environmental control for process stability: Environmental factors such as temperature, humidity, and air quality significantly impact binder jetting processes. Fluctuations in these conditions can affect binder viscosity, powder flowability, and curing behavior, leading to inconsistent part quality. Advanced environmental control systems that maintain stable conditions throughout the printing process are essential for reliable production. These systems may include HVAC controls with tight tolerances, humidity regulation equipment, air filtration to remove contaminants, and environmental monitoring systems that provide real-time data and alerts when parameters drift outside acceptable ranges.

- Quality assurance and process monitoring systems: Comprehensive quality assurance protocols are critical for identifying and mitigating risks in binder jetting processes. Advanced monitoring systems that incorporate in-situ sensors, machine vision, and real-time data analytics can detect process anomalies related to binder deposition, powder spreading, and part formation. These systems enable operators to identify issues such as binder aging effects, powder oxidation, or equipment malfunctions before they result in failed builds. Implementing closed-loop feedback systems that automatically adjust process parameters based on monitoring data can further enhance process reliability and reduce the impact of material and equipment variations.

02 Powder oxidation and material degradation

Powder oxidation presents a critical challenge in binder jetting operations, particularly with metal and reactive powders. When exposed to oxygen and moisture, powders can form oxide layers that compromise material properties, reduce flowability, and affect final part quality. This oxidation can alter the powder's chemical composition, particle size distribution, and surface characteristics. Preventive measures include controlled atmosphere storage, inert gas environments during processing, moisture control systems, and implementing proper powder handling protocols to minimize exposure to oxidizing conditions.Expand Specific Solutions03 Equipment maintenance and unplanned downtime

Unplanned downtime in binder jetting operations significantly impacts production efficiency and part quality. Common causes include printhead clogging, mechanical failures, software issues, and sensor malfunctions. Implementing predictive maintenance strategies using real-time monitoring systems can help identify potential failures before they occur. Regular calibration, cleaning protocols, and establishing preventive maintenance schedules are essential for minimizing unexpected equipment failures and maintaining consistent production quality.Expand Specific Solutions04 Process parameter optimization and quality control

Optimizing process parameters is crucial for mitigating risks in binder jetting. Factors such as binder saturation levels, drying times, curing temperatures, and layer thickness significantly impact part quality and process reliability. Inadequate parameter control can lead to dimensional inaccuracies, internal defects, and structural weaknesses. Implementing robust quality control systems with in-process monitoring capabilities allows for real-time adjustments and helps maintain consistent part quality while reducing material waste and production failures.Expand Specific Solutions05 Environmental control and storage solutions

Environmental factors significantly impact binder jetting processes, with humidity and temperature fluctuations affecting both powder and binder properties. Controlled storage environments with humidity regulation, temperature stability, and protection from light exposure are essential for maintaining material integrity. Advanced storage solutions incorporating inert gas systems, automated material handling, and environmental monitoring help preserve powder reactivity and binder stability. Implementing proper material rotation protocols and shelf-life tracking systems further reduces risks associated with material degradation.Expand Specific Solutions

Industry Leaders in Binder Jetting Equipment and Materials

The binder jetting additive manufacturing market is currently in a growth phase, with increasing adoption across industrial applications despite technical challenges like binder aging, powder oxidation, and unplanned downtime. The global market is projected to expand significantly, driven by demand for cost-effective metal and ceramic part production. Leading players include Desktop Metal, which has pioneered accessible binder jetting systems, HP Development focusing on high-volume production capabilities, and established materials specialists like Evonik and 3M developing specialized binders and powders. Traditional manufacturing companies including FANUC, GE, and Xerox are also entering this space, while research institutions such as Virginia Tech and University of Surrey are addressing technical limitations through collaborative R&D efforts to improve process reliability and material performance.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed advanced binder jetting systems with proprietary anti-aging binder formulations that incorporate stabilizers and preservatives to extend shelf life. Their Single Pass Jetting (SPJ) technology utilizes a closed-loop feedback system that continuously monitors binder viscosity and surface tension, automatically adjusting dispensing parameters to compensate for aging effects. The company has implemented a nitrogen-purged powder handling system that minimizes oxidation during storage and printing processes. Their Production System P-50 incorporates real-time monitoring with predictive maintenance algorithms that analyze machine performance data to forecast potential failures before they occur, reducing unplanned downtime by up to 60%. Desktop Metal's binder systems also feature automated quality control measures that detect and compensate for variations in binder properties during the printing process.

Strengths: Industry-leading predictive maintenance systems and closed-loop quality control significantly reduce downtime. Their nitrogen-purged powder handling system effectively minimizes oxidation issues. Weaknesses: Their proprietary binder systems may require more frequent replacement compared to competitors, and the advanced monitoring systems add complexity and cost to the overall system.

Evonik Operations GmbH

Technical Solution: Evonik has developed specialized polymer-based binders with enhanced stability profiles specifically designed for binder jetting applications. Their VESTOSINT® powder materials feature proprietary surface treatments that resist oxidation even under challenging environmental conditions. Evonik's binder formulations incorporate antioxidant packages that significantly extend shelf life while maintaining consistent viscosity and surface tension properties critical for reliable jetting performance. Their materials science approach includes developing powder-binder combinations that are optimized to work together, with chemical compatibility that reduces aging effects. Evonik has created a comprehensive material handling protocol that includes moisture-controlled storage systems and inert gas packaging to prevent premature degradation. Their quality control system includes regular testing of stored materials with standardized procedures to detect early signs of aging or oxidation, allowing for proactive material management before print quality is affected.

Strengths: Superior material science expertise resulting in highly stable binder formulations and excellent powder-binder compatibility that minimizes aging effects. Weaknesses: Their solutions focus primarily on the materials side rather than machine systems, requiring integration with third-party hardware that may not be optimized for their specific materials.

Critical Patents and Research on Binder Stability

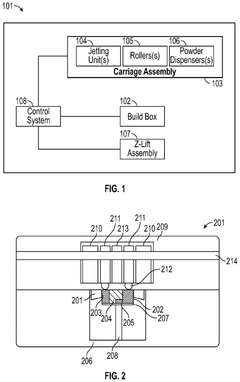

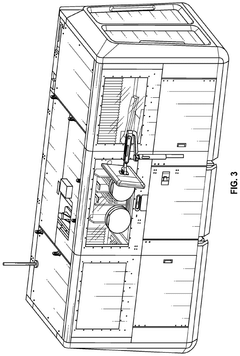

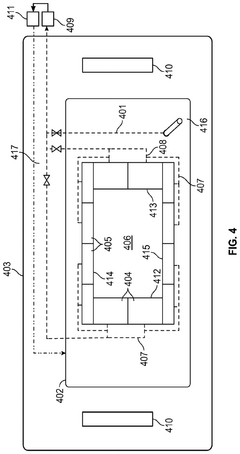

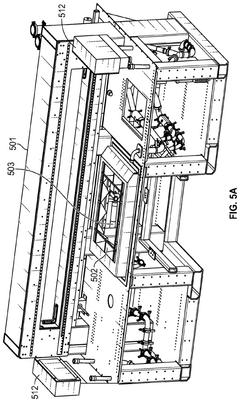

Downdraft system for binder jetting additive manufacturing

PatentPendingUS20250235930A1

Innovation

- A downdraft system with powder collection chutes and a pneumatic conveyance system is implemented to capture and convey excess build material powder using a controlled gas flow, separating it from the process gas and collecting it in a powder collection unit, maintaining a controlled gaseous atmosphere to prevent hazardous reactions.

Maintenance Protocols and Predictive Analytics

Effective maintenance protocols and predictive analytics systems are crucial for mitigating the primary risk factors in binder jetting processes. Regular maintenance schedules must be established based on machine usage patterns rather than arbitrary time intervals, with particular attention to components that interact with binders and powders. These schedules should include comprehensive cleaning of print heads, powder beds, and recoating mechanisms to prevent binder residue accumulation and powder contamination.

Preventive maintenance protocols should specifically target binder delivery systems, incorporating regular inspection of tubing, nozzles, and reservoirs for signs of degradation or clogging. Implementation of filtration systems within the binder circulation path can significantly reduce particulate contamination that accelerates binder aging. Additionally, environmental control systems require regular calibration to maintain optimal temperature and humidity levels that prevent premature binder degradation.

For powder management, maintenance protocols must include regular inspection and cleaning of storage containers, transfer mechanisms, and recycling systems. Implementing nitrogen purging systems for powder storage can dramatically reduce oxidation risks during extended storage periods. Standardized procedures for powder handling, including exposure time limitations during machine operation, help minimize oxidation potential.

Advanced predictive analytics offers transformative potential for binder jetting reliability. By integrating IoT sensors throughout critical system components, manufacturers can continuously monitor parameters such as binder viscosity changes, print head pressure fluctuations, and powder moisture content. Machine learning algorithms can then analyze these data streams to identify patterns preceding component failures or quality degradation.

Real-time monitoring systems can detect subtle changes in binder jetting performance that indicate potential issues before they cause system failures. For example, variations in droplet formation patterns may signal early binder degradation, while changes in powder bed density might indicate oxidation issues. These early warning indicators enable proactive intervention before quality is compromised.

Digital twin technology represents the cutting edge of predictive maintenance for binder jetting systems. By creating virtual replicas of physical machines that update in real-time, operators can simulate various operating conditions and predict maintenance needs with unprecedented accuracy. This approach enables optimization of maintenance scheduling to minimize downtime while maximizing component lifespan and print quality consistency.

Preventive maintenance protocols should specifically target binder delivery systems, incorporating regular inspection of tubing, nozzles, and reservoirs for signs of degradation or clogging. Implementation of filtration systems within the binder circulation path can significantly reduce particulate contamination that accelerates binder aging. Additionally, environmental control systems require regular calibration to maintain optimal temperature and humidity levels that prevent premature binder degradation.

For powder management, maintenance protocols must include regular inspection and cleaning of storage containers, transfer mechanisms, and recycling systems. Implementing nitrogen purging systems for powder storage can dramatically reduce oxidation risks during extended storage periods. Standardized procedures for powder handling, including exposure time limitations during machine operation, help minimize oxidation potential.

Advanced predictive analytics offers transformative potential for binder jetting reliability. By integrating IoT sensors throughout critical system components, manufacturers can continuously monitor parameters such as binder viscosity changes, print head pressure fluctuations, and powder moisture content. Machine learning algorithms can then analyze these data streams to identify patterns preceding component failures or quality degradation.

Real-time monitoring systems can detect subtle changes in binder jetting performance that indicate potential issues before they cause system failures. For example, variations in droplet formation patterns may signal early binder degradation, while changes in powder bed density might indicate oxidation issues. These early warning indicators enable proactive intervention before quality is compromised.

Digital twin technology represents the cutting edge of predictive maintenance for binder jetting systems. By creating virtual replicas of physical machines that update in real-time, operators can simulate various operating conditions and predict maintenance needs with unprecedented accuracy. This approach enables optimization of maintenance scheduling to minimize downtime while maximizing component lifespan and print quality consistency.

Environmental Factors Affecting Binder Jetting Reliability

Environmental factors play a critical role in the reliability and performance of binder jetting processes. Temperature fluctuations within the manufacturing environment can significantly impact binder viscosity, affecting droplet formation and spreading behavior. Optimal operating conditions typically require temperature stability within ±2°C, as variations beyond this range can lead to inconsistent binder deposition and compromised part quality.

Humidity represents another crucial environmental parameter that directly influences binder jetting reliability. High humidity levels (above 60% RH) can cause premature binder curing or absorption of atmospheric moisture, altering rheological properties. Conversely, excessively low humidity (below 30% RH) may accelerate solvent evaporation rates, potentially leading to nozzle clogging and print head failures.

Airborne particulates and contaminants present significant challenges to binder jetting operations. Even microscopic dust particles (5-10μm) can interfere with powder spreading mechanisms or contaminate the binder fluid system. Manufacturing facilities implementing binder jetting technology should maintain ISO Class 8 (or better) cleanroom conditions to mitigate these risks, particularly for high-precision applications.

Vibration and mechanical disturbances transmitted through building structures can compromise print accuracy and surface finish quality. Studies have shown that vibrations exceeding 0.5g can induce visible defects in printed components, especially during fine feature creation. Strategic placement of equipment on vibration-dampening foundations and isolation from heavy machinery operations becomes essential for consistent production quality.

Atmospheric pressure variations, though often overlooked, can affect the behavior of binder droplet formation and powder bed characteristics. Facilities at high altitudes may require specific calibration adjustments to compensate for reduced atmospheric pressure, which can alter fluid dynamics within the print head system.

Electromagnetic interference (EMI) from nearby equipment can disrupt the precise electronic controls governing binder jetting systems. This is particularly relevant for facilities where multiple manufacturing technologies operate in proximity. Proper shielding and grounding protocols should be implemented to protect sensitive electronic components from EMI-related failures.

Light exposure, particularly UV radiation, can accelerate binder aging processes through photodegradation mechanisms. This becomes especially problematic for systems utilizing photosensitive binder formulations or when materials are stored in areas with significant natural light exposure. Implementing appropriate light-blocking storage solutions and minimizing UV exposure during processing can extend binder shelf life and maintain consistent performance characteristics.

Humidity represents another crucial environmental parameter that directly influences binder jetting reliability. High humidity levels (above 60% RH) can cause premature binder curing or absorption of atmospheric moisture, altering rheological properties. Conversely, excessively low humidity (below 30% RH) may accelerate solvent evaporation rates, potentially leading to nozzle clogging and print head failures.

Airborne particulates and contaminants present significant challenges to binder jetting operations. Even microscopic dust particles (5-10μm) can interfere with powder spreading mechanisms or contaminate the binder fluid system. Manufacturing facilities implementing binder jetting technology should maintain ISO Class 8 (or better) cleanroom conditions to mitigate these risks, particularly for high-precision applications.

Vibration and mechanical disturbances transmitted through building structures can compromise print accuracy and surface finish quality. Studies have shown that vibrations exceeding 0.5g can induce visible defects in printed components, especially during fine feature creation. Strategic placement of equipment on vibration-dampening foundations and isolation from heavy machinery operations becomes essential for consistent production quality.

Atmospheric pressure variations, though often overlooked, can affect the behavior of binder droplet formation and powder bed characteristics. Facilities at high altitudes may require specific calibration adjustments to compensate for reduced atmospheric pressure, which can alter fluid dynamics within the print head system.

Electromagnetic interference (EMI) from nearby equipment can disrupt the precise electronic controls governing binder jetting systems. This is particularly relevant for facilities where multiple manufacturing technologies operate in proximity. Proper shielding and grounding protocols should be implemented to protect sensitive electronic components from EMI-related failures.

Light exposure, particularly UV radiation, can accelerate binder aging processes through photodegradation mechanisms. This becomes especially problematic for systems utilizing photosensitive binder formulations or when materials are stored in areas with significant natural light exposure. Implementing appropriate light-blocking storage solutions and minimizing UV exposure during processing can extend binder shelf life and maintain consistent performance characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!