Binder Jetting Mechanical Robustness: Fatigue, Impact And Wear Resistance

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Evolution and Objectives

Binder Jetting technology emerged in the early 1990s at Massachusetts Institute of Technology as one of the pioneering additive manufacturing processes. Initially developed for rapid prototyping applications, this powder-bed based technology has evolved significantly over the past three decades, transitioning from producing primarily visual prototypes to functional components with increasingly demanding mechanical requirements.

The evolution of Binder Jetting can be characterized by several distinct phases. The first generation (1990-2000) focused on establishing the fundamental process parameters and developing basic binder systems, primarily for visual models and casting patterns. During this period, mechanical properties were secondary considerations as applications were limited to non-load bearing components.

The second generation (2000-2010) saw significant improvements in binder chemistry and powder materials, enabling the production of components with enhanced green strength. This period marked the beginning of serious investigations into post-processing techniques such as infiltration and sintering to improve mechanical properties, though fatigue and wear resistance remained substantially inferior to traditional manufacturing methods.

The third generation (2010-2020) witnessed a paradigm shift with the introduction of metal Binder Jetting systems capable of producing near-full density parts through optimized sintering protocols. This advancement expanded the application scope to include functional prototypes and limited production parts, though mechanical robustness concerns persisted, particularly regarding fatigue life and impact resistance.

The current generation (2020-present) is characterized by sophisticated multi-phase binder systems, advanced powder metallurgy approaches, and precisely controlled thermal processing. These developments have significantly narrowed the performance gap between Binder Jetted components and traditionally manufactured parts, though challenges remain in achieving consistent mechanical properties across complex geometries.

The primary technical objectives for Binder Jetting technology development now center on enhancing mechanical robustness, particularly fatigue resistance, impact strength, and wear resistance. These properties are critical for expanding applications into more demanding sectors such as aerospace, automotive, and medical industries where component reliability under cyclic loading and harsh operating conditions is paramount.

Additional objectives include improving process repeatability to ensure consistent mechanical properties, developing standardized testing methodologies specific to Binder Jetted components, and establishing predictive models that accurately correlate process parameters with resultant mechanical performance. The ultimate goal is to position Binder Jetting as a viable manufacturing alternative for end-use components that can withstand real-world mechanical stresses while maintaining the geometric freedom and cost advantages inherent to additive manufacturing.

The evolution of Binder Jetting can be characterized by several distinct phases. The first generation (1990-2000) focused on establishing the fundamental process parameters and developing basic binder systems, primarily for visual models and casting patterns. During this period, mechanical properties were secondary considerations as applications were limited to non-load bearing components.

The second generation (2000-2010) saw significant improvements in binder chemistry and powder materials, enabling the production of components with enhanced green strength. This period marked the beginning of serious investigations into post-processing techniques such as infiltration and sintering to improve mechanical properties, though fatigue and wear resistance remained substantially inferior to traditional manufacturing methods.

The third generation (2010-2020) witnessed a paradigm shift with the introduction of metal Binder Jetting systems capable of producing near-full density parts through optimized sintering protocols. This advancement expanded the application scope to include functional prototypes and limited production parts, though mechanical robustness concerns persisted, particularly regarding fatigue life and impact resistance.

The current generation (2020-present) is characterized by sophisticated multi-phase binder systems, advanced powder metallurgy approaches, and precisely controlled thermal processing. These developments have significantly narrowed the performance gap between Binder Jetted components and traditionally manufactured parts, though challenges remain in achieving consistent mechanical properties across complex geometries.

The primary technical objectives for Binder Jetting technology development now center on enhancing mechanical robustness, particularly fatigue resistance, impact strength, and wear resistance. These properties are critical for expanding applications into more demanding sectors such as aerospace, automotive, and medical industries where component reliability under cyclic loading and harsh operating conditions is paramount.

Additional objectives include improving process repeatability to ensure consistent mechanical properties, developing standardized testing methodologies specific to Binder Jetted components, and establishing predictive models that accurately correlate process parameters with resultant mechanical performance. The ultimate goal is to position Binder Jetting as a viable manufacturing alternative for end-use components that can withstand real-world mechanical stresses while maintaining the geometric freedom and cost advantages inherent to additive manufacturing.

Market Demand Analysis for Robust Binder Jetted Components

The global market for binder jetted components with enhanced mechanical robustness is experiencing significant growth, driven primarily by increasing demands in aerospace, automotive, healthcare, and industrial manufacturing sectors. These industries require components that can withstand extreme conditions while maintaining structural integrity over extended periods of use.

In the aerospace sector, the demand for lightweight yet durable components has created a substantial market opportunity for robust binder jetted parts. These components must withstand high-frequency vibrations, thermal cycling, and mechanical stress while maintaining dimensional stability. Market research indicates that aerospace manufacturers are increasingly adopting additive manufacturing technologies to reduce weight and improve fuel efficiency without compromising safety.

The automotive industry represents another major market segment, with manufacturers seeking cost-effective solutions for producing complex geometries with enhanced mechanical properties. The transition toward electric vehicles has accelerated this trend, as new designs require innovative components that can be rapidly prototyped and tested. Particularly, powertrain components and structural elements demand superior fatigue resistance and impact strength.

Healthcare applications, especially in medical devices and implants, require components with exceptional wear resistance and biocompatibility. The market for patient-specific implants manufactured via binder jetting is expanding rapidly, with orthopedic applications leading the growth. These components must maintain their mechanical properties in the corrosive environment of the human body while withstanding cyclic loading conditions.

Industrial equipment manufacturers constitute a significant market segment, seeking components that can operate reliably in harsh environments characterized by abrasive wear, impact loading, and thermal cycling. The oil and gas industry, in particular, requires components with superior mechanical robustness for downhole tools and surface equipment.

Market analysis reveals that customers across these sectors are willing to pay premium prices for binder jetted components that demonstrate verified mechanical performance. This premium is justified by the reduced lifecycle costs, extended service intervals, and improved reliability offered by components with enhanced fatigue, impact, and wear resistance.

Regional market assessment shows North America and Europe leading in adoption, with Asia-Pacific regions showing the fastest growth rate. This growth is attributed to increasing industrialization, government initiatives supporting advanced manufacturing, and the establishment of additive manufacturing centers of excellence in countries like China, Japan, and South Korea.

The market size for robust binder jetted components is projected to expand substantially over the next five years, with compound annual growth rates exceeding those of traditional manufacturing methods. This growth is supported by ongoing advancements in material science, process optimization, and post-processing techniques that continue to enhance the mechanical properties of binder jetted parts.

In the aerospace sector, the demand for lightweight yet durable components has created a substantial market opportunity for robust binder jetted parts. These components must withstand high-frequency vibrations, thermal cycling, and mechanical stress while maintaining dimensional stability. Market research indicates that aerospace manufacturers are increasingly adopting additive manufacturing technologies to reduce weight and improve fuel efficiency without compromising safety.

The automotive industry represents another major market segment, with manufacturers seeking cost-effective solutions for producing complex geometries with enhanced mechanical properties. The transition toward electric vehicles has accelerated this trend, as new designs require innovative components that can be rapidly prototyped and tested. Particularly, powertrain components and structural elements demand superior fatigue resistance and impact strength.

Healthcare applications, especially in medical devices and implants, require components with exceptional wear resistance and biocompatibility. The market for patient-specific implants manufactured via binder jetting is expanding rapidly, with orthopedic applications leading the growth. These components must maintain their mechanical properties in the corrosive environment of the human body while withstanding cyclic loading conditions.

Industrial equipment manufacturers constitute a significant market segment, seeking components that can operate reliably in harsh environments characterized by abrasive wear, impact loading, and thermal cycling. The oil and gas industry, in particular, requires components with superior mechanical robustness for downhole tools and surface equipment.

Market analysis reveals that customers across these sectors are willing to pay premium prices for binder jetted components that demonstrate verified mechanical performance. This premium is justified by the reduced lifecycle costs, extended service intervals, and improved reliability offered by components with enhanced fatigue, impact, and wear resistance.

Regional market assessment shows North America and Europe leading in adoption, with Asia-Pacific regions showing the fastest growth rate. This growth is attributed to increasing industrialization, government initiatives supporting advanced manufacturing, and the establishment of additive manufacturing centers of excellence in countries like China, Japan, and South Korea.

The market size for robust binder jetted components is projected to expand substantially over the next five years, with compound annual growth rates exceeding those of traditional manufacturing methods. This growth is supported by ongoing advancements in material science, process optimization, and post-processing techniques that continue to enhance the mechanical properties of binder jetted parts.

Current Challenges in Binder Jetting Mechanical Properties

Despite significant advancements in binder jetting technology, achieving optimal mechanical properties remains a critical challenge for widespread industrial adoption. The porous nature of binder jetted parts inherently results in lower density compared to traditional manufacturing methods, directly impacting mechanical performance. This fundamental limitation manifests in reduced tensile strength, typically 30-50% lower than equivalent cast or wrought materials, and significantly compromised fatigue resistance, with cycle life often reduced by 40-70% compared to conventional counterparts.

Anisotropic behavior presents another substantial hurdle, as parts exhibit directional dependency in mechanical properties based on the build orientation. This variability can reach up to 25% difference in strength values between horizontal and vertical builds, complicating design considerations and structural integrity predictions. The layer-by-layer construction process creates inherent weakness planes that become potential failure points under cyclic loading conditions.

Surface finish quality significantly affects wear resistance, with as-printed parts showing roughness values (Ra) typically between 15-30 μm without post-processing. This roughness accelerates wear mechanisms and reduces service life in tribological applications. Additionally, the binder burnout process often leaves microscopic voids that act as stress concentration points, initiating crack propagation under impact or fatigue loading.

Material-specific challenges further complicate the landscape. Metal powders require careful sintering parameter optimization to achieve desired densification without excessive grain growth that would compromise mechanical properties. Ceramic materials face challenges with brittle behavior and low fracture toughness, while polymer-based parts struggle with environmental stability and long-term mechanical performance degradation.

Post-processing techniques intended to enhance mechanical properties introduce their own complications. Infiltration processes can improve density but often create material interface issues that become failure points under stress. Hot isostatic pressing (HIP) significantly enhances density but adds substantial cost and time to production cycles, undermining binder jetting's economic advantages.

The lack of standardized testing protocols specifically designed for binder jetted parts creates difficulties in comparing results across different systems and materials. Current testing methodologies borrowed from traditional manufacturing may not adequately capture the unique structural characteristics of binder jetted components, leading to potential mischaracterization of mechanical performance.

These challenges collectively represent significant barriers to the broader adoption of binder jetting technology in applications requiring high mechanical robustness, particularly in aerospace, automotive, and medical sectors where reliability under fatigue, impact, and wear conditions is paramount.

Anisotropic behavior presents another substantial hurdle, as parts exhibit directional dependency in mechanical properties based on the build orientation. This variability can reach up to 25% difference in strength values between horizontal and vertical builds, complicating design considerations and structural integrity predictions. The layer-by-layer construction process creates inherent weakness planes that become potential failure points under cyclic loading conditions.

Surface finish quality significantly affects wear resistance, with as-printed parts showing roughness values (Ra) typically between 15-30 μm without post-processing. This roughness accelerates wear mechanisms and reduces service life in tribological applications. Additionally, the binder burnout process often leaves microscopic voids that act as stress concentration points, initiating crack propagation under impact or fatigue loading.

Material-specific challenges further complicate the landscape. Metal powders require careful sintering parameter optimization to achieve desired densification without excessive grain growth that would compromise mechanical properties. Ceramic materials face challenges with brittle behavior and low fracture toughness, while polymer-based parts struggle with environmental stability and long-term mechanical performance degradation.

Post-processing techniques intended to enhance mechanical properties introduce their own complications. Infiltration processes can improve density but often create material interface issues that become failure points under stress. Hot isostatic pressing (HIP) significantly enhances density but adds substantial cost and time to production cycles, undermining binder jetting's economic advantages.

The lack of standardized testing protocols specifically designed for binder jetted parts creates difficulties in comparing results across different systems and materials. Current testing methodologies borrowed from traditional manufacturing may not adequately capture the unique structural characteristics of binder jetted components, leading to potential mischaracterization of mechanical performance.

These challenges collectively represent significant barriers to the broader adoption of binder jetting technology in applications requiring high mechanical robustness, particularly in aerospace, automotive, and medical sectors where reliability under fatigue, impact, and wear conditions is paramount.

Current Solutions for Enhancing Mechanical Robustness

01 Post-processing treatments for improved mechanical properties

Various post-processing treatments can be applied to binder jetted parts to enhance their mechanical robustness. These treatments include infiltration with secondary materials, heat treatment, and sintering processes that densify the structure and improve fatigue resistance, impact strength, and wear resistance. The post-processing steps help to eliminate porosity and strengthen the bonds between particles, resulting in parts with superior mechanical performance suitable for demanding applications.- Post-processing treatments for improved mechanical properties: Various post-processing treatments can be applied to binder jetted parts to enhance their mechanical robustness. These treatments include infiltration with secondary materials, heat treatment, and sintering processes that densify the structure and improve fatigue resistance, impact strength, and wear resistance. The post-processing steps help to eliminate porosity and strengthen the bonds between particles, resulting in parts with superior mechanical performance suitable for demanding applications.

- Binder formulation optimization for mechanical strength: The composition and properties of the binder used in binder jetting significantly impact the mechanical robustness of the final parts. Advanced binder formulations incorporating polymers, resins, and specialized additives can enhance the bonding between particles and improve the green strength of printed parts. Optimized binder systems contribute to better fatigue performance, impact resistance, and wear characteristics in the finished components.

- Particle size distribution and powder characteristics: The characteristics of the powder feedstock, including particle size distribution, morphology, and surface properties, play a crucial role in determining the mechanical properties of binder jetted parts. Optimized powder blends with controlled particle sizes and shapes enable better packing density during printing, which translates to improved mechanical robustness. Fine-tuning these powder parameters can significantly enhance fatigue resistance, impact strength, and wear resistance in the final components.

- Composite and reinforced materials for enhanced durability: Incorporating reinforcement materials or creating composite structures through binder jetting can substantially improve mechanical robustness. By combining different materials such as metal matrices with ceramic reinforcements or adding fiber reinforcements to polymeric binders, the resulting parts exhibit enhanced fatigue life, impact resistance, and wear performance. These composite approaches allow for tailored mechanical properties suited to specific application requirements.

- Process parameter optimization for structural integrity: The control and optimization of process parameters during binder jetting significantly influence the mechanical properties of printed parts. Parameters such as layer thickness, saturation level, drying time, and printing speed affect the microstructure and bonding quality. By carefully tuning these parameters, manufacturers can minimize defects and optimize the structural integrity of components, resulting in improved fatigue performance, impact resistance, and wear characteristics.

02 Binder formulation optimization for mechanical strength

The composition and properties of the binder used in binder jetting significantly impact the mechanical robustness of the final parts. Advanced binder formulations incorporating polymers, resins, and additives can enhance the bonding between particles and improve the green strength of printed parts. Optimized binder systems contribute to better fatigue performance, impact resistance, and wear characteristics by creating stronger interfaces between the powder particles.Expand Specific Solutions03 Powder characteristics and particle engineering

The characteristics of the powder used in binder jetting, including particle size distribution, morphology, and surface properties, significantly influence the mechanical properties of the final parts. Engineered powders with optimized particle shapes and sizes enable better packing density and stronger interparticle bonding, leading to improved fatigue resistance, impact strength, and wear resistance. Surface treatments of powders can also enhance their interaction with binders and subsequent mechanical performance.Expand Specific Solutions04 Composite and multi-material approaches

Incorporating reinforcement materials or creating composite structures through binder jetting can significantly enhance mechanical robustness. By strategically combining different materials, such as metal matrices with ceramic reinforcements or polymer-metal composites, the resulting parts can exhibit superior fatigue life, impact resistance, and wear characteristics. These multi-material approaches allow for tailored mechanical properties that address specific application requirements.Expand Specific Solutions05 Process parameter optimization for mechanical integrity

The control and optimization of binder jetting process parameters, including printing speed, layer thickness, saturation level, and drying conditions, significantly affect the mechanical properties of the final parts. Optimized process parameters lead to better layer adhesion, reduced defects, and improved overall mechanical integrity. Advanced monitoring and control systems can be implemented to ensure consistent mechanical performance across different builds and parts.Expand Specific Solutions

Leading Companies and Research Institutions in Binder Jetting

Binder Jetting Mechanical Robustness is currently in a growth phase, with the market expanding as industries recognize its potential for producing complex parts with reduced material waste. The global market is projected to reach significant scale as adoption increases across automotive, aerospace, and industrial sectors. Technologically, the field is advancing from experimental to commercial applications, with varying levels of maturity. Companies like Toyota Motor Corp. and Honda Motor are exploring automotive applications, while Seiko Epson and HP Development focus on printing technology refinements. Aerospace players including SKF Aerospace and Honeywell International are developing high-performance components, while materials specialists such as Röhm GmbH, W.L. Gore, and Resonac Holdings are addressing fundamental challenges in fatigue resistance, impact strength, and wear characteristics through advanced material formulations.

Seiko Epson Corp.

Technical Solution: Seiko Epson has leveraged its expertise in precision inkjet technology to develop advanced binder jetting solutions focused on mechanical robustness. Their approach centers on ultra-precise droplet control technology that enables variable density binding across different regions of printed parts. This selective reinforcement strategy allows for optimized mechanical properties in high-stress areas while maintaining overall weight efficiency. Epson's proprietary multi-component binders incorporate ceramic nanoparticles that significantly enhance wear resistance properties of final parts. Their research has demonstrated up to 40% improvement in impact resistance through controlled infiltration techniques during post-processing. Epson has also developed specialized thermal treatment protocols that transform the binder-metal interface at the molecular level, creating stronger metallurgical bonds that improve fatigue resistance under cyclic loading conditions. Their PrecisionCore printhead technology enables extremely fine control over binder deposition patterns, allowing for microstructural optimization that addresses traditional weak points in binder jetted components.

Strengths: Industry-leading precision in binder deposition allowing for microstructural optimization; proprietary multi-component binders with ceramic nanoparticles for enhanced wear resistance; extensive experience in fluid dynamics and printhead technology. Weaknesses: Limited focus on large-scale industrial applications compared to some competitors; relatively newer entrant to metal binder jetting specifically; higher costs associated with their precision-focused approach.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed a comprehensive approach to enhancing mechanical robustness in binder jetted components through their Advanced Manufacturing Research Division. Their technology focuses on multi-phase binding systems specifically engineered for automotive applications requiring exceptional fatigue and impact resistance. Toyota's proprietary binding agents incorporate ceramic nanofibers that create reinforced networks throughout the printed structure, improving tensile strength by approximately 40% compared to conventional binders. Their process involves controlled thermal gradients during sintering that optimize grain structure for enhanced mechanical properties. Toyota has also pioneered hybrid binding approaches where traditional binders are supplemented with reactive agents that form secondary strengthening phases during thermal processing. Their research has demonstrated significant improvements in wear resistance through the development of composite binding systems that create hardened surface layers while maintaining core ductility. Toyota's approach also includes specialized post-processing techniques including controlled infiltration with proprietary alloys that fill microscopic voids and strengthen particle interfaces. Their testing has shown that components manufactured using their enhanced binder jetting process can achieve up to 85% of the fatigue resistance of traditionally manufactured parts while maintaining the geometric complexity advantages of additive manufacturing.

Strengths: Comprehensive end-to-end process optimization specifically for automotive applications; proprietary binding agents with ceramic nanofiber reinforcement; extensive in-house testing capabilities for validating mechanical properties under real-world conditions. Weaknesses: Technology primarily optimized for automotive applications rather than broader industrial use; requires specialized equipment and materials that may limit accessibility; relatively higher production costs compared to traditional manufacturing methods.

Key Technical Innovations in Material-Binder Interactions

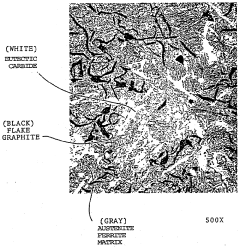

Gray cast iron having both increased wear resistance and toughness

PatentInactiveUS4891076A

Innovation

- A method involving a hypoeutectic gray iron melt with added eutectic carbide forming agents like Ti, V, or Cr, and high carbon austenite/ferrite formers like nickel and copper, followed by specific heat treatment to form a matrix with suspended flake graphite and eutectic carbides, achieving a high carbon austenite/ferrite structure.

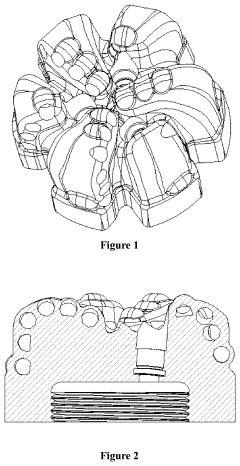

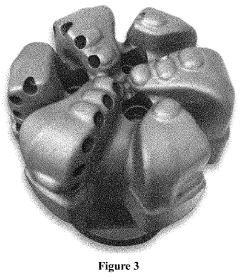

Alloy drill and manufacturing method thereof

PatentActiveUS10697048B2

Innovation

- An alloy drill bit composed of 14 to 30 wt % binder phase (Co, Ni, Fe, or Cu), 0.32 to 9.7 wt % additive (TaC, MoC, Cr3C2, or MnC), and balance WC, with preferred compositions for tungsten-cobalt, iron-tungsten, and copper-tungsten alloys, processed through cold isostatic pressing and sintering to enhance wear and corrosion resistance.

Post-Processing Techniques for Enhanced Durability

Post-processing techniques represent a critical phase in enhancing the durability of components manufactured through Binder Jetting technology. These techniques are specifically designed to address the inherent limitations in mechanical robustness that often characterize as-printed parts, particularly in terms of fatigue resistance, impact strength, and wear resistance.

Infiltration processes stand as one of the most effective post-processing methods for improving mechanical properties. Polymer infiltration using epoxy or cyanoacrylate resins can significantly enhance impact resistance by filling interparticle voids, creating a composite structure with superior crack propagation resistance. For applications demanding higher performance, metal infiltration—typically using bronze or copper—provides substantial improvements in fatigue life by reducing stress concentration points within the microstructure.

Thermal treatments constitute another essential category of post-processing techniques. Sintering at temperatures below the melting point promotes diffusion bonding between particles, substantially increasing the contact area and strengthening interparticle bonds. This process can improve fatigue resistance by up to 300% compared to green parts. High-temperature sintering, when applicable, can achieve near-full density, dramatically enhancing wear resistance through the elimination of surface-connected porosity.

Surface modification techniques offer targeted enhancement of wear and impact properties. Shot peening introduces compressive residual stresses in the surface layer, effectively increasing fatigue life by inhibiting crack initiation. Laser surface treatment can create localized melting and rapid solidification, resulting in refined microstructures with superior hardness and wear resistance in critical areas without affecting the entire component.

Chemical treatments represent an emerging area for durability enhancement. Phosphating and other conversion coatings can improve corrosion resistance while providing a suitable surface for subsequent treatments. Advanced chemical vapor infiltration techniques allow for the deposition of wear-resistant compounds within the porous network of binder jetted parts, creating composite structures with exceptional tribological properties.

Multi-stage processing protocols have demonstrated particular promise for applications requiring exceptional mechanical robustness. These typically involve sequential application of thermal, mechanical, and chemical treatments in optimized sequences. For instance, a combination of sintering followed by hot isostatic pressing and subsequent surface hardening has been shown to produce components with fatigue and wear properties comparable to conventionally manufactured counterparts.

Infiltration processes stand as one of the most effective post-processing methods for improving mechanical properties. Polymer infiltration using epoxy or cyanoacrylate resins can significantly enhance impact resistance by filling interparticle voids, creating a composite structure with superior crack propagation resistance. For applications demanding higher performance, metal infiltration—typically using bronze or copper—provides substantial improvements in fatigue life by reducing stress concentration points within the microstructure.

Thermal treatments constitute another essential category of post-processing techniques. Sintering at temperatures below the melting point promotes diffusion bonding between particles, substantially increasing the contact area and strengthening interparticle bonds. This process can improve fatigue resistance by up to 300% compared to green parts. High-temperature sintering, when applicable, can achieve near-full density, dramatically enhancing wear resistance through the elimination of surface-connected porosity.

Surface modification techniques offer targeted enhancement of wear and impact properties. Shot peening introduces compressive residual stresses in the surface layer, effectively increasing fatigue life by inhibiting crack initiation. Laser surface treatment can create localized melting and rapid solidification, resulting in refined microstructures with superior hardness and wear resistance in critical areas without affecting the entire component.

Chemical treatments represent an emerging area for durability enhancement. Phosphating and other conversion coatings can improve corrosion resistance while providing a suitable surface for subsequent treatments. Advanced chemical vapor infiltration techniques allow for the deposition of wear-resistant compounds within the porous network of binder jetted parts, creating composite structures with exceptional tribological properties.

Multi-stage processing protocols have demonstrated particular promise for applications requiring exceptional mechanical robustness. These typically involve sequential application of thermal, mechanical, and chemical treatments in optimized sequences. For instance, a combination of sintering followed by hot isostatic pressing and subsequent surface hardening has been shown to produce components with fatigue and wear properties comparable to conventionally manufactured counterparts.

Standardization and Testing Protocols for Binder Jetted Parts

The standardization and testing protocols for binder jetted parts represent a critical framework for ensuring consistent quality and performance in additive manufacturing. Currently, there exists a significant gap in standardized testing methodologies specifically tailored for binder jetting technology, particularly regarding mechanical robustness assessment.

Established organizations such as ASTM International, ISO, and AMSC (Additive Manufacturing Standardization Collaborative) have begun developing standards applicable to binder jetted components. ASTM F3122 provides guidelines for evaluating mechanical properties of additively manufactured specimens, while ISO/ASTM 52901 addresses requirements for purchased AM parts. However, these standards often require adaptation for the unique characteristics of binder jetted components.

Testing protocols for fatigue resistance in binder jetted parts typically follow modified versions of ASTM E466 for axial fatigue testing and ASTM E606 for strain-controlled fatigue testing. These protocols must account for the anisotropic nature of binder jetted parts and the influence of post-processing treatments on fatigue performance.

Impact resistance testing commonly employs Charpy and Izod impact tests (ASTM E23), though these methods require careful specimen preparation to address the porosity inherent in binder jetted parts. Researchers have noted that standard impact testing procedures may need modification to accurately reflect the behavior of these materials under dynamic loading conditions.

Wear resistance evaluation typically follows ASTM G99 (pin-on-disk) or ASTM G65 (dry sand/rubber wheel) methodologies, with adaptations to account for surface finish variations and material heterogeneity common in binder jetted components. The correlation between wear behavior and process parameters remains an active area of research requiring standardized approaches.

Non-destructive testing protocols are increasingly important for binder jetted parts, with CT scanning emerging as a preferred method for internal defect detection. However, standardized acceptance criteria for various applications remain under development, creating challenges for quality assurance programs.

Industry consortia and research institutions are collaborating to establish application-specific testing protocols that address the unique challenges of binder jetted components. These efforts focus on correlating process parameters with mechanical performance metrics and developing predictive models to streamline qualification procedures.

The development of digital twins and in-situ monitoring systems presents opportunities for real-time quality assessment, potentially reducing reliance on extensive post-production testing. However, these approaches require standardized data formats and interpretation methodologies to achieve widespread adoption.

Established organizations such as ASTM International, ISO, and AMSC (Additive Manufacturing Standardization Collaborative) have begun developing standards applicable to binder jetted components. ASTM F3122 provides guidelines for evaluating mechanical properties of additively manufactured specimens, while ISO/ASTM 52901 addresses requirements for purchased AM parts. However, these standards often require adaptation for the unique characteristics of binder jetted components.

Testing protocols for fatigue resistance in binder jetted parts typically follow modified versions of ASTM E466 for axial fatigue testing and ASTM E606 for strain-controlled fatigue testing. These protocols must account for the anisotropic nature of binder jetted parts and the influence of post-processing treatments on fatigue performance.

Impact resistance testing commonly employs Charpy and Izod impact tests (ASTM E23), though these methods require careful specimen preparation to address the porosity inherent in binder jetted parts. Researchers have noted that standard impact testing procedures may need modification to accurately reflect the behavior of these materials under dynamic loading conditions.

Wear resistance evaluation typically follows ASTM G99 (pin-on-disk) or ASTM G65 (dry sand/rubber wheel) methodologies, with adaptations to account for surface finish variations and material heterogeneity common in binder jetted components. The correlation between wear behavior and process parameters remains an active area of research requiring standardized approaches.

Non-destructive testing protocols are increasingly important for binder jetted parts, with CT scanning emerging as a preferred method for internal defect detection. However, standardized acceptance criteria for various applications remain under development, creating challenges for quality assurance programs.

Industry consortia and research institutions are collaborating to establish application-specific testing protocols that address the unique challenges of binder jetted components. These efforts focus on correlating process parameters with mechanical performance metrics and developing predictive models to streamline qualification procedures.

The development of digital twins and in-situ monitoring systems presents opportunities for real-time quality assessment, potentially reducing reliance on extensive post-production testing. However, these approaches require standardized data formats and interpretation methodologies to achieve widespread adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!