How Binder Jetting Prevents Cracking During Debinding And Sintering?

SEP 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Binder Jetting Technology Background and Objectives

Binder Jetting (BJ) technology has emerged as a significant advancement in the field of additive manufacturing since its inception in the early 1990s at MIT. This powder-bed-based 3D printing technique selectively deposits a liquid binding agent onto powder particles, creating complex geometries layer by layer without the need for support structures. The evolution of BJ technology has been marked by continuous improvements in binder formulations, printing precision, and post-processing techniques.

The technology has gained substantial traction in recent years due to its ability to process a wide range of materials including metals, ceramics, and composites at relatively high production rates compared to other additive manufacturing methods. Unlike laser-based processes, BJ operates at room temperature during the printing phase, which eliminates thermal stresses during part building and enables the production of larger components with reduced residual stresses.

However, the post-processing stages—particularly debinding and sintering—present significant challenges that have historically limited BJ's widespread industrial adoption. During these critical phases, parts are susceptible to cracking, warping, and dimensional instability due to non-uniform shrinkage and trapped gases from binder removal. These issues become particularly pronounced when processing materials with high sintering temperatures or complex geometries.

The primary objective of current BJ technology development is to establish robust methodologies that prevent cracking during the debinding and sintering stages while maintaining dimensional accuracy and mechanical properties. This involves optimizing several interconnected parameters: binder chemistry and distribution, powder characteristics, debinding protocols, sintering profiles, and part design considerations.

Recent technological advancements have focused on developing specialized binders that decompose predictably and uniformly, creating controlled microporous networks that facilitate gas escape during debinding. Simultaneously, research has progressed toward optimizing sintering schedules that accommodate the unique requirements of binder-jetted parts, particularly the need for slower heating rates and extended holding times at critical temperature thresholds.

The trajectory of BJ technology is moving toward closed-loop systems that integrate in-situ monitoring and real-time adjustments during post-processing. These systems aim to detect and mitigate potential defect formation before cracks develop, representing a paradigm shift from reactive to preventive approaches in additive manufacturing quality control.

As industries increasingly demand metal and ceramic components with complex geometries and customized properties, solving the cracking challenges in BJ technology has become a strategic priority for research institutions and manufacturing companies alike. Success in this area would position BJ as a viable alternative to traditional manufacturing methods for high-value applications in aerospace, medical, automotive, and energy sectors.

The technology has gained substantial traction in recent years due to its ability to process a wide range of materials including metals, ceramics, and composites at relatively high production rates compared to other additive manufacturing methods. Unlike laser-based processes, BJ operates at room temperature during the printing phase, which eliminates thermal stresses during part building and enables the production of larger components with reduced residual stresses.

However, the post-processing stages—particularly debinding and sintering—present significant challenges that have historically limited BJ's widespread industrial adoption. During these critical phases, parts are susceptible to cracking, warping, and dimensional instability due to non-uniform shrinkage and trapped gases from binder removal. These issues become particularly pronounced when processing materials with high sintering temperatures or complex geometries.

The primary objective of current BJ technology development is to establish robust methodologies that prevent cracking during the debinding and sintering stages while maintaining dimensional accuracy and mechanical properties. This involves optimizing several interconnected parameters: binder chemistry and distribution, powder characteristics, debinding protocols, sintering profiles, and part design considerations.

Recent technological advancements have focused on developing specialized binders that decompose predictably and uniformly, creating controlled microporous networks that facilitate gas escape during debinding. Simultaneously, research has progressed toward optimizing sintering schedules that accommodate the unique requirements of binder-jetted parts, particularly the need for slower heating rates and extended holding times at critical temperature thresholds.

The trajectory of BJ technology is moving toward closed-loop systems that integrate in-situ monitoring and real-time adjustments during post-processing. These systems aim to detect and mitigate potential defect formation before cracks develop, representing a paradigm shift from reactive to preventive approaches in additive manufacturing quality control.

As industries increasingly demand metal and ceramic components with complex geometries and customized properties, solving the cracking challenges in BJ technology has become a strategic priority for research institutions and manufacturing companies alike. Success in this area would position BJ as a viable alternative to traditional manufacturing methods for high-value applications in aerospace, medical, automotive, and energy sectors.

Market Analysis for Crack-Free Additive Manufacturing

The global market for crack-free additive manufacturing technologies, particularly binder jetting, has witnessed substantial growth in recent years. The market size for metal additive manufacturing reached approximately $2.7 billion in 2022 and is projected to grow at a CAGR of 21.5% through 2030. Within this broader market, binder jetting technology represents a rapidly expanding segment due to its ability to address critical challenges in metal part production, especially crack prevention during debinding and sintering processes.

Demand for crack-free manufacturing solutions is primarily driven by high-value industries including aerospace, automotive, medical devices, and industrial equipment manufacturing. These sectors require components with exceptional structural integrity and mechanical properties. The aerospace industry alone accounts for nearly 25% of the metal additive manufacturing market, with particular emphasis on crack-free production methods for critical components subject to extreme operational conditions.

Market research indicates that manufacturers are increasingly prioritizing technologies that can deliver consistent quality while reducing material waste and production costs. Binder jetting's ability to prevent cracking during thermal processing stages represents a significant value proposition, potentially reducing rejection rates by 15-20% compared to conventional manufacturing methods.

Regional analysis shows North America currently leads the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China, Japan, and South Korea, where significant investments are being made in advanced manufacturing technologies.

Customer segmentation reveals that large enterprises currently dominate adoption of advanced binder jetting technologies, accounting for approximately 70% of the market. However, the small and medium enterprise segment is expected to grow at a faster rate as technology costs decrease and accessibility improves through service bureau models.

Key market drivers include increasing demand for complex geometries that are difficult to produce using traditional manufacturing methods, growing emphasis on lightweight components for improved fuel efficiency, and the push toward more sustainable manufacturing processes with reduced material waste. Additionally, regulatory pressures in aerospace and medical industries for higher quality standards are accelerating adoption of technologies that can consistently produce crack-free components.

Market challenges include the high initial investment costs for binder jetting equipment, technical expertise requirements, and competition from other additive manufacturing technologies such as selective laser melting. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address existing limitations.

Demand for crack-free manufacturing solutions is primarily driven by high-value industries including aerospace, automotive, medical devices, and industrial equipment manufacturing. These sectors require components with exceptional structural integrity and mechanical properties. The aerospace industry alone accounts for nearly 25% of the metal additive manufacturing market, with particular emphasis on crack-free production methods for critical components subject to extreme operational conditions.

Market research indicates that manufacturers are increasingly prioritizing technologies that can deliver consistent quality while reducing material waste and production costs. Binder jetting's ability to prevent cracking during thermal processing stages represents a significant value proposition, potentially reducing rejection rates by 15-20% compared to conventional manufacturing methods.

Regional analysis shows North America currently leads the market with approximately 40% share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China, Japan, and South Korea, where significant investments are being made in advanced manufacturing technologies.

Customer segmentation reveals that large enterprises currently dominate adoption of advanced binder jetting technologies, accounting for approximately 70% of the market. However, the small and medium enterprise segment is expected to grow at a faster rate as technology costs decrease and accessibility improves through service bureau models.

Key market drivers include increasing demand for complex geometries that are difficult to produce using traditional manufacturing methods, growing emphasis on lightweight components for improved fuel efficiency, and the push toward more sustainable manufacturing processes with reduced material waste. Additionally, regulatory pressures in aerospace and medical industries for higher quality standards are accelerating adoption of technologies that can consistently produce crack-free components.

Market challenges include the high initial investment costs for binder jetting equipment, technical expertise requirements, and competition from other additive manufacturing technologies such as selective laser melting. Despite these challenges, the market outlook remains highly positive as technological advancements continue to address existing limitations.

Current Challenges in Debinding and Sintering Processes

Despite significant advancements in binder jetting technology, the debinding and sintering processes remain critical challenges that can significantly impact the quality and integrity of final parts. One of the primary challenges is the management of internal stresses that develop during these processes, which can lead to warping, cracking, or complete part failure. These stresses arise from non-uniform shrinkage rates across different sections of the printed component, particularly in complex geometries with varying wall thicknesses.

Thermal management presents another significant hurdle. The debinding phase requires precise temperature control to ensure the binder is removed gradually without causing rapid gas formation that could create internal pressure and subsequent cracking. Similarly, during sintering, temperature gradients within the part can lead to differential densification rates, exacerbating stress development and potential defect formation.

Material compatibility issues further complicate these processes. Different powder materials exhibit varying shrinkage behaviors, thermal expansion coefficients, and sintering kinetics. This variability makes it difficult to establish universal processing parameters, necessitating extensive experimentation and optimization for each new material system introduced to the binder jetting process.

The binder removal rate represents a delicate balance that must be carefully controlled. If binder removal occurs too rapidly, it can create voids or channels within the part that compromise structural integrity. Conversely, if removal is too slow, residual binder may remain trapped within the part, leading to defects during the subsequent sintering stage or contamination in the final product.

Support structures, or rather their absence in many binder jetting applications, present additional challenges. Unlike some other additive manufacturing techniques, binder jetting typically relies on the surrounding unbound powder to provide support during printing. However, this support is lost during debinding and sintering, potentially leading to gravitational deformation in parts with overhangs or complex geometries.

Atmosphere control during both processes is critical yet challenging to maintain consistently. Oxygen content, humidity levels, and other environmental factors can significantly impact both debinding and sintering outcomes. Inadequate atmosphere control can lead to oxidation, uneven binder removal, or incomplete sintering, all of which compromise part quality.

Scale-up challenges persist as manufacturers attempt to move from prototype to production volumes. Maintaining consistent debinding and sintering conditions across larger batch sizes or larger individual parts introduces new variables that can affect process reliability and repeatability. These challenges are particularly pronounced when dealing with parts that have significant variations in cross-sectional thickness.

Thermal management presents another significant hurdle. The debinding phase requires precise temperature control to ensure the binder is removed gradually without causing rapid gas formation that could create internal pressure and subsequent cracking. Similarly, during sintering, temperature gradients within the part can lead to differential densification rates, exacerbating stress development and potential defect formation.

Material compatibility issues further complicate these processes. Different powder materials exhibit varying shrinkage behaviors, thermal expansion coefficients, and sintering kinetics. This variability makes it difficult to establish universal processing parameters, necessitating extensive experimentation and optimization for each new material system introduced to the binder jetting process.

The binder removal rate represents a delicate balance that must be carefully controlled. If binder removal occurs too rapidly, it can create voids or channels within the part that compromise structural integrity. Conversely, if removal is too slow, residual binder may remain trapped within the part, leading to defects during the subsequent sintering stage or contamination in the final product.

Support structures, or rather their absence in many binder jetting applications, present additional challenges. Unlike some other additive manufacturing techniques, binder jetting typically relies on the surrounding unbound powder to provide support during printing. However, this support is lost during debinding and sintering, potentially leading to gravitational deformation in parts with overhangs or complex geometries.

Atmosphere control during both processes is critical yet challenging to maintain consistently. Oxygen content, humidity levels, and other environmental factors can significantly impact both debinding and sintering outcomes. Inadequate atmosphere control can lead to oxidation, uneven binder removal, or incomplete sintering, all of which compromise part quality.

Scale-up challenges persist as manufacturers attempt to move from prototype to production volumes. Maintaining consistent debinding and sintering conditions across larger batch sizes or larger individual parts introduces new variables that can affect process reliability and repeatability. These challenges are particularly pronounced when dealing with parts that have significant variations in cross-sectional thickness.

Current Anti-Cracking Solutions in Binder Jetting

01 Binder composition optimization

Optimizing the binder composition is crucial for preventing cracking in binder jetting processes. This includes using specialized polymers, adjusting viscosity, and incorporating additives that enhance binding strength while maintaining flexibility during curing. Properly formulated binders can accommodate shrinkage stresses during drying and sintering, significantly reducing crack formation in the final parts.- Optimized binder composition and properties: Developing specialized binder formulations with optimized rheological properties can significantly reduce cracking in binder jetting processes. These formulations often include additives that improve flexibility, adhesion, and uniform distribution throughout the powder bed. Adjusting viscosity, surface tension, and drying characteristics of the binder helps prevent stress concentration during curing and sintering phases, which are common causes of cracking in printed parts.

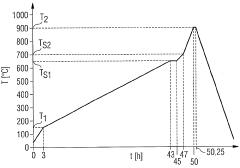

- Controlled thermal processing parameters: Implementing precise thermal management strategies during post-processing stages is crucial for preventing cracks in binder jetted parts. This includes optimized heating and cooling rates, carefully controlled temperature gradients, and specialized debinding and sintering profiles. Gradual temperature transitions help minimize thermal stresses that can lead to cracking, while controlled atmosphere conditions during sintering can further enhance structural integrity of the final parts.

- Powder characteristics and preparation techniques: The physical and chemical properties of the powder material significantly impact crack formation in binder jetting. Optimizing particle size distribution, shape, and surface characteristics can improve packing density and reduce void formation that leads to cracking. Pre-treatment methods such as powder coating, surface modification, or blending with secondary materials can enhance powder-binder interactions and create more homogeneous structures with reduced cracking tendency.

- Process parameter optimization and control: Fine-tuning process parameters such as layer thickness, printing speed, saturation level, and drying conditions can significantly reduce cracking in binder jetted parts. Advanced process monitoring and control systems enable real-time adjustments to maintain optimal conditions throughout the build process. Implementing specialized printing strategies, such as variable saturation patterns or adaptive layer deposition, can help distribute stresses more evenly and prevent crack initiation.

- Post-processing and infiltration techniques: Specialized post-processing methods can effectively prevent or repair cracks in binder jetted components. These include infiltration with secondary materials to fill voids and strengthen the structure, isostatic pressing to increase density, and surface treatments to seal micro-cracks. Advanced curing techniques that incorporate pressure control, humidity management, or chemical catalysts can promote more uniform consolidation and minimize internal stresses that lead to cracking.

02 Process parameter control

Controlling process parameters such as printing speed, layer thickness, drying time, and sintering temperature profiles is essential for crack prevention in binder jetting. Optimized printing parameters ensure uniform binder distribution, while carefully managed thermal cycles prevent thermal shock and excessive stress buildup during phase transitions. Gradual heating and cooling rates are particularly important for maintaining structural integrity.Expand Specific Solutions03 Material selection and preparation

The selection and preparation of powder materials significantly impact crack formation in binder jetted parts. Using powders with optimized particle size distribution, shape, and surface characteristics improves packing density and reduces void formation. Pre-treatment of powders, such as surface modification or coating, can enhance binder-powder interaction and result in more homogeneous green parts with reduced cracking tendency during post-processing.Expand Specific Solutions04 Post-processing techniques

Specialized post-processing techniques can effectively prevent or repair cracks in binder jetted components. These include controlled drying environments, infiltration with secondary materials to fill micro-cracks, isostatic pressing to increase density, and specialized sintering protocols. Some approaches incorporate intermediate strengthening steps before final sintering to provide structural support during the most critical phase transformations.Expand Specific Solutions05 Reinforcement additives and structures

Incorporating reinforcement additives or designing specific internal structures can significantly reduce cracking in binder jetted parts. Fiber reinforcements, nanoparticle additions, or engineered lattice structures distribute stresses more evenly throughout the part. These reinforcements provide crack-arresting mechanisms and improve the overall mechanical properties of the printed components, particularly during the critical green-to-sintered transition phase.Expand Specific Solutions

Leading Companies in Binder Jetting Technology

Binder Jetting technology is currently in a growth phase within the additive manufacturing industry, with the global market expected to expand significantly as industries adopt this technology for complex metal part production. The technical maturity varies across players, with established companies like General Electric and Desktop Metal leading innovation in preventing cracking during debinding and sintering processes. These companies have developed proprietary techniques including controlled thermal cycles and specialized binder formulations. Academic institutions such as Rice University and Technical University of Berlin are advancing fundamental research, while materials specialists like BASF and Sandvik are developing optimized powders and binders specifically designed to minimize thermal stresses during processing. The collaborative ecosystem between equipment manufacturers, material suppliers, and research institutions is accelerating solutions to this critical technical challenge.

General Electric Company

Technical Solution: GE has developed advanced binder jetting solutions through its GE Additive division that focus on preventing cracking during the critical debinding and sintering phases. Their approach centers on a multi-component binder system with primary and secondary binders that decompose at different temperature ranges. This staged decomposition allows for controlled porosity development during debinding, creating escape channels for remaining binder components and reducing internal pressure that leads to cracking. GE's process incorporates precise thermal profiling with extremely slow heating rates (0.1-0.3°C/min) during critical phase transitions identified through extensive thermal analysis. The company utilizes specialized sintering equipment with multi-zone temperature control and programmable atmosphere composition that can transition between reducing and neutral environments at specific process stages. GE has also developed specialized powder treatments that optimize particle size distribution and surface characteristics to enhance green part strength and reduce debinding-related defects. Their systems incorporate in-situ monitoring with feedback control to make real-time adjustments to sintering parameters.

Strengths: Extensive metallurgical expertise and material science capabilities; proprietary sintering furnaces with precise atmosphere control; significant R&D resources for continuous process improvement. Weaknesses: Solutions primarily optimized for aerospace and industrial applications rather than broader markets; higher implementation costs; longer development cycles for new materials.

Desktop Metal, Inc.

Technical Solution: Desktop Metal has developed a proprietary binder jetting technology called Single Pass Jetting (SPJ) that specifically addresses cracking issues during debinding and sintering. Their approach utilizes specialized binder formulations with controlled rheological properties that enable uniform distribution throughout the powder bed. The company's process incorporates a multi-stage thermal debinding protocol that gradually removes binder components at precisely controlled temperature ramps (typically 0.5-2°C/min) to prevent rapid gas evolution that could cause cracking. Desktop Metal's sintering technology employs proprietary sintering setups with controlled atmosphere compositions and precise temperature profiles that maintain uniform shrinkage rates across parts. Their Live Sinter software simulates and predicts deformation during sintering, allowing for pre-compensation in the printed geometry to achieve final parts with minimal cracking and distortion. The company has also developed specialized support structures and sintering setters that accommodate differential shrinkage rates in complex geometries.

Strengths: Industry-leading simulation software for predicting and compensating for sintering distortion; integrated end-to-end solution from printing through sintering; high throughput production capabilities. Weaknesses: Higher system costs compared to some competitors; proprietary material systems may limit material flexibility; requires significant technical expertise to optimize process parameters.

Key Patents and Research on Crack Prevention Mechanisms

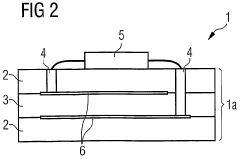

Process for the production of an inorganic sintered body

PatentInactiveEP0413231A3

Innovation

- The use of polyoxymethylene as a binder in combination with a gaseous acidic atmosphere or boron trifluoride for debinding at lower temperatures, allowing for rapid and crack-free removal of the binder without deforming the green body, followed by sintering.

Method for producing a ceramic substrate

PatentWO2004014647A1

Innovation

- A method where debinding and sintering are performed in the same furnace, maintaining a minimum temperature to prevent cooling, and controlling the temperature and atmosphere to manage oxidation, ensuring the ceramic body remains above the debinding temperature until sintering is complete, followed by cooling only after sufficient strength is achieved.

Material Science Considerations for Crack Resistance

The material science aspects of binder jetting technology play a crucial role in preventing crack formation during the debinding and sintering processes. At the microstructural level, particle size distribution significantly impacts crack resistance. Optimally designed powder systems with multi-modal distributions allow for higher packing densities, reducing the volumetric shrinkage during sintering and minimizing internal stresses that lead to cracking. Fine particles fill interstitial spaces between larger particles, creating a more homogeneous structure that distributes stress more evenly throughout the part.

Powder morphology also contributes substantially to crack prevention. Spherical particles facilitate better flowability and packing compared to irregular shapes, resulting in more uniform green parts with fewer defects that could serve as crack initiation sites. The surface chemistry of particles influences their interaction with binders and affects the strength of the green part before sintering, with properly functionalized surfaces enabling stronger particle-binder interfaces.

The thermal expansion coefficient of the material represents another critical factor. Materials with lower coefficients experience less dimensional change during heating and cooling cycles, reducing internal stresses. For multi-material systems, matching thermal expansion coefficients between components helps prevent differential expansion that could lead to delamination or cracking at interfaces.

Grain boundary engineering has emerged as an advanced approach to enhance crack resistance. By controlling the formation and characteristics of grain boundaries during sintering, manufacturers can create microstructures with improved mechanical properties. Special grain boundaries with specific crystallographic orientations can impede crack propagation by forcing cracks to follow more tortuous paths, effectively increasing the energy required for crack growth.

Phase transformation behavior during thermal processing must be carefully managed as well. Some materials undergo volume changes during phase transformations that can induce significant internal stresses. Understanding these transformations and designing appropriate thermal profiles can mitigate associated risks. In some cases, controlled phase transformations can be leveraged to induce compressive stresses that actually enhance crack resistance.

Dopants and sintering aids represent another material science strategy for crack prevention. Small additions of specific elements can modify grain boundary mobility, inhibit grain growth, and enhance densification kinetics. These additives can lower sintering temperatures, reduce thermal gradients, and promote more uniform shrinkage throughout the part, all contributing to reduced cracking tendency during the critical thermal processing stages.

Powder morphology also contributes substantially to crack prevention. Spherical particles facilitate better flowability and packing compared to irregular shapes, resulting in more uniform green parts with fewer defects that could serve as crack initiation sites. The surface chemistry of particles influences their interaction with binders and affects the strength of the green part before sintering, with properly functionalized surfaces enabling stronger particle-binder interfaces.

The thermal expansion coefficient of the material represents another critical factor. Materials with lower coefficients experience less dimensional change during heating and cooling cycles, reducing internal stresses. For multi-material systems, matching thermal expansion coefficients between components helps prevent differential expansion that could lead to delamination or cracking at interfaces.

Grain boundary engineering has emerged as an advanced approach to enhance crack resistance. By controlling the formation and characteristics of grain boundaries during sintering, manufacturers can create microstructures with improved mechanical properties. Special grain boundaries with specific crystallographic orientations can impede crack propagation by forcing cracks to follow more tortuous paths, effectively increasing the energy required for crack growth.

Phase transformation behavior during thermal processing must be carefully managed as well. Some materials undergo volume changes during phase transformations that can induce significant internal stresses. Understanding these transformations and designing appropriate thermal profiles can mitigate associated risks. In some cases, controlled phase transformations can be leveraged to induce compressive stresses that actually enhance crack resistance.

Dopants and sintering aids represent another material science strategy for crack prevention. Small additions of specific elements can modify grain boundary mobility, inhibit grain growth, and enhance densification kinetics. These additives can lower sintering temperatures, reduce thermal gradients, and promote more uniform shrinkage throughout the part, all contributing to reduced cracking tendency during the critical thermal processing stages.

Environmental Impact of Binder Jetting Manufacturing Processes

Binder jetting technology, while offering numerous advantages in additive manufacturing, presents several environmental considerations that warrant thorough examination. The environmental footprint of binder jetting processes extends across multiple dimensions, from resource consumption to waste generation and energy usage.

The primary environmental concern relates to the binders themselves, which often contain volatile organic compounds (VOCs) and other potentially hazardous chemicals. During the debinding phase, these compounds are released into the atmosphere unless properly captured and treated. Advanced systems now incorporate filtration mechanisms and closed-loop processing environments to minimize these emissions, significantly reducing the environmental impact compared to earlier generations of the technology.

Water consumption represents another critical environmental factor in binder jetting operations. The process typically requires substantial amounts of water for powder preparation, cleaning, and post-processing. Recent innovations have focused on water recycling systems and more efficient cleaning processes that reduce overall consumption by up to 40% compared to conventional methods, addressing water scarcity concerns in manufacturing contexts.

Energy efficiency considerations are particularly relevant when examining the sintering phase of binder jetting. Traditional sintering requires sustained high temperatures, resulting in considerable energy consumption. However, modern binder formulations that facilitate lower sintering temperatures and shorter cycle times have emerged, reducing the carbon footprint of this energy-intensive stage. Some manufacturers report energy savings of 25-30% with these advanced binder systems.

Waste management presents both challenges and opportunities in binder jetting processes. While the technology generates less material waste than subtractive manufacturing methods, the handling of unused powders and cleaning residues requires careful management. Closed-loop powder recycling systems now achieve recovery rates exceeding 95% for many materials, substantially improving resource efficiency and reducing waste disposal requirements.

Life cycle assessments of binder jetting processes indicate that the environmental impact varies significantly based on material selection, equipment efficiency, and operational practices. Ceramic and metal powders typically have different environmental profiles, with some requiring more energy-intensive production methods than others. The development of bio-based binders represents a promising direction for reducing the environmental footprint, with several research groups reporting successful implementation of plant-derived binding agents that maintain performance while reducing toxicity and improving biodegradability.

Regulatory frameworks increasingly influence the environmental aspects of binder jetting operations, with stricter emissions standards and waste management requirements driving technological innovation in this space. Manufacturers adopting proactive environmental strategies often gain competitive advantages through improved regulatory compliance and enhanced sustainability credentials.

The primary environmental concern relates to the binders themselves, which often contain volatile organic compounds (VOCs) and other potentially hazardous chemicals. During the debinding phase, these compounds are released into the atmosphere unless properly captured and treated. Advanced systems now incorporate filtration mechanisms and closed-loop processing environments to minimize these emissions, significantly reducing the environmental impact compared to earlier generations of the technology.

Water consumption represents another critical environmental factor in binder jetting operations. The process typically requires substantial amounts of water for powder preparation, cleaning, and post-processing. Recent innovations have focused on water recycling systems and more efficient cleaning processes that reduce overall consumption by up to 40% compared to conventional methods, addressing water scarcity concerns in manufacturing contexts.

Energy efficiency considerations are particularly relevant when examining the sintering phase of binder jetting. Traditional sintering requires sustained high temperatures, resulting in considerable energy consumption. However, modern binder formulations that facilitate lower sintering temperatures and shorter cycle times have emerged, reducing the carbon footprint of this energy-intensive stage. Some manufacturers report energy savings of 25-30% with these advanced binder systems.

Waste management presents both challenges and opportunities in binder jetting processes. While the technology generates less material waste than subtractive manufacturing methods, the handling of unused powders and cleaning residues requires careful management. Closed-loop powder recycling systems now achieve recovery rates exceeding 95% for many materials, substantially improving resource efficiency and reducing waste disposal requirements.

Life cycle assessments of binder jetting processes indicate that the environmental impact varies significantly based on material selection, equipment efficiency, and operational practices. Ceramic and metal powders typically have different environmental profiles, with some requiring more energy-intensive production methods than others. The development of bio-based binders represents a promising direction for reducing the environmental footprint, with several research groups reporting successful implementation of plant-derived binding agents that maintain performance while reducing toxicity and improving biodegradability.

Regulatory frameworks increasingly influence the environmental aspects of binder jetting operations, with stricter emissions standards and waste management requirements driving technological innovation in this space. Manufacturers adopting proactive environmental strategies often gain competitive advantages through improved regulatory compliance and enhanced sustainability credentials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!